Marine solar systems promise quiet power and fewer engine hours. The truth is more nuanced. Solar can run a surprising set of boat electronics, yet it also hits hard limits. This page shows what works, what fails, and how to size gear so you are not stuck at anchor with a flat battery.

Key takeaways backed by data

- Solar power for boats can reliably cover low-to-medium DC loads (instruments, nav, lighting, fridge) with adequate panel area and storage.

- High-draw AC loads (air-con, electric cooking, water heaters, large thrusters) exceed practical solar harvest on typical hulls.

- Energy yield depends on sun hours, temperature, tilt, shading, and electronics. As noted by the IEA, PV output follows daily and seasonal patterns with cloud-driven variability.

- Demonstrations show what’s possible: a PV-only boat circumnavigated the globe, and a PV plane flew 26 hours, as reported in the IEA Solar Energy Perspectives. Those feats relied on huge area, meticulous design, and low loads.

What works on solar alone

Low-to-medium DC loads

On most boats, these loads are practical on solar if you size the array and battery bank well:

- LED cabin and nav lights

- Chartplotter, depth, AIS, instruments

- VHF standby and intermittent transmit

- Fridge with efficient compressor and good insulation

- USB device charging

Energy yield rather than nameplate efficiency drives success. As summarized by the IEA, operating conditions change real output beyond lab efficiency. On a moving hull, tilt and shading make that even more true.

Autopilot and radar (case-by-case)

Autopilots can draw 2–6 A at 12 V while working, with higher peaks in swell. Over a 6-hour motor-sail, that can add 150–400 Wh. Radar in intermittent watch mode can be manageable, but continuous transmit adds up. A robust array and storage help cover these duty cycles.

What typically fails on solar alone

Some loads are rarely viable with boat electronics solar power, unless you have an unusually large catamaran roof packed with modules:

- Air conditioning and resistive heating

- Electric cooktops, kettles, water heaters

- High-power dive compressors

- Long thruster or windlass duty (short bursts may come from the battery; recharge then becomes the issue)

As noted in the IEA Solar Energy Perspectives, electric mobility lacks the abundant waste heat of fuel engines. Generating heat with electricity is energy-intensive. The same physics limit space heating and hot water from marine PV.

Sizing the system: realistic numbers

Daily energy budget

Build a daily budget in watt-hours (Wh). Multiply each load’s power by its run-time. Keep a 15–30% margin for cloudy hours and shading.

| Load | Typical power | Duty/Day | Daily energy (Wh) |

|---|---|---|---|

| LED cabin + nav lights | 10–20 W | 4 h | 40–80 |

| Chartplotter + instruments | 15–25 W | 6 h | 90–150 |

| VHF (standby mostly) | 5 W avg | 8 h | 40 |

| Fridge (efficient) | 40–60 W | 30–40% duty | 300–500 |

| Autopilot (cruising day) | 25–60 W avg | 6 h | 150–360 |

| Phones/tablets | 10–20 W | 2 h | 20–40 |

| Total (typical day) | 640–1,170 |

Use this as a template and adjust to your boat.

Solar harvest at sea

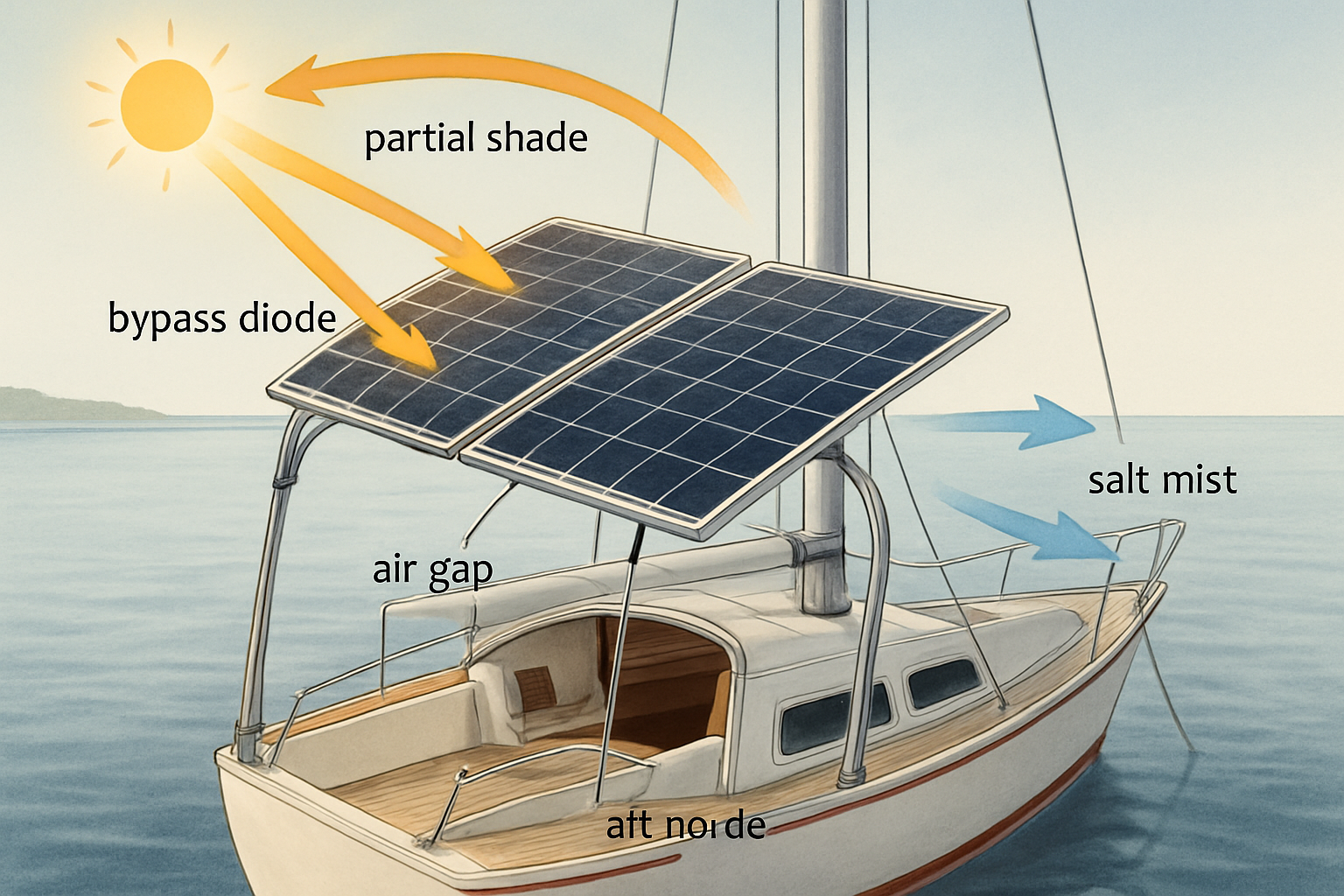

Solar panel efficiency in marine environments is influenced by temperature, angle, and partial shading. Salt film also hurts output. A practical derate of 0.6–0.75 from nameplate harvest is common on boats. Peak sun hours vary by latitude and season; output follows the sun’s daily “bell” shape with cloud-driven ramps, consistent with IEA analysis.

| Array size | Assumed PSH | Derate | Daily harvest (Wh) |

|---|---|---|---|

| 100 W | 5 | 0.65 | 325 |

| 200 W | 5 | 0.65 | 650 |

| 400 W | 5 | 0.65 | 1,300 |

| 600 W | 5 | 0.65 | 1,950 |

Compare these with your budget. A 400–600 W array commonly covers a fridge, instruments, lights, and moderate autopilot use in good sun.

Hardware choices that move the needle

Panels: rigid vs flexible

- Rigid glass panels offer better longevity and heat dissipation. Lower temperature improves operating efficiency; the U.S. DOE notes that higher cell temperatures reduce PV output.

- Flexible panels are lighter and easier on curved surfaces but tend to run hotter and may degrade faster in harsh marine UV and salt.

Charge controllers

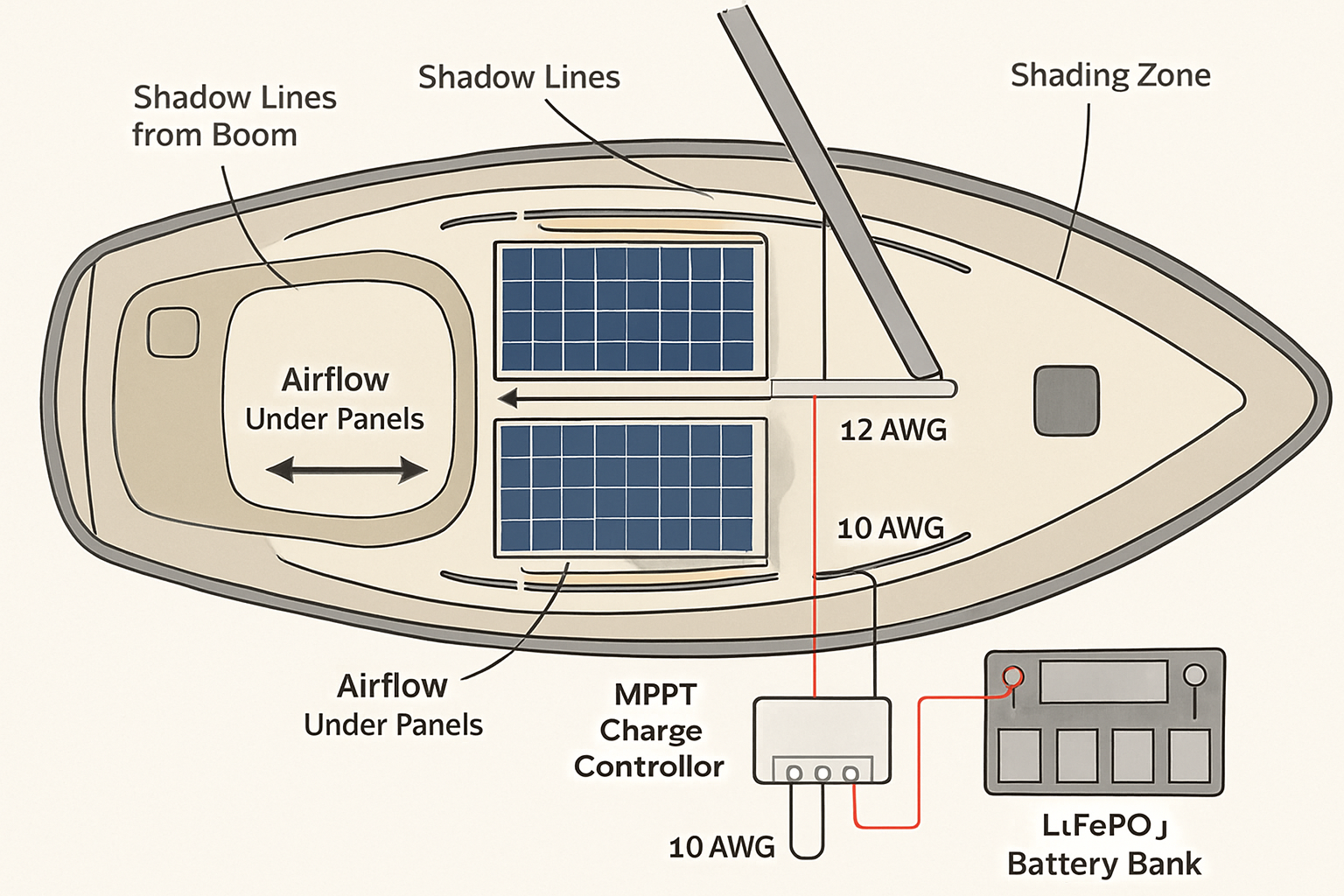

- MPPT beats PWM on boats. With shifting angles and partial shading, MPPT recovers more energy across the day.

- Consider multiple MPPTs for separate panel groups (arch vs bimini) to limit mismatch loss. Module-level electronics can reduce mismatch in rooftop PV; the same principle helps in marine layouts with intermittent shading, a concept highlighted in industry work on MLPE summarized by Energy.gov.

Battery chemistry

- LiFePO4 (lithium iron phosphate) suits marine duty: high cycle life, flat voltage curve, fast charge acceptance, and usable depth of discharge around 80–90% with a proper BMS. That makes solar storage more compact and reliable.

- Lead-acid can work, but partial state of charge and limited usable capacity cut real autonomy. Charging to 100% daily from PV is tough.

Inverters and AC loads

- Keep AC loads minimal. Every DC–AC conversion adds losses.

- Use DC versions of loads where possible (fridge, fans, water pumps, chargers).

Design realities at sea

Shading and mismatch

Masts, booms, radar domes, and crew cast persistent shadows. Even small shadows can slash output on a series string. Split arrays into parallel strings with their own MPPT inputs. Shorter strings reduce the impact of a single shaded module. This aligns with known mismatch behavior documented for PV systems and the role of power electronics to mitigate it in distributed designs, as described in industry literature and echoed in IEA work.

Energy yield vs lab efficiency

Real energy harvest matters more than the module spec sheet. The IEA highlights how operating efficiency and system design set annual yield. On boats, tilt shifts hourly and air temperature and wind cooling change cell temps. Expect day-to-day swings.

Proven potential with caveats

Record-setting projects show limits and potential. A PV-only boat circumnavigated using extensive deck area and light, efficient systems, while a solar plane flew 26 hours straight, both documented in the IEA Solar Energy Perspectives. Most private boats lack such area, so focus on right-sizing loads, not just panel watts.

Step-by-step sizing example

Goal: Run fridge (400 Wh), instruments (120 Wh), lights (60 Wh), VHF (40 Wh), and autopilot (250 Wh). Total 870 Wh/day. Add 20% margin → ≈1,050 Wh/day.

- Array target: 1,050 Wh / (5 PSH × 0.65) ≈ 323 W. Round up to 400 W for cloudy spells and growth.

- Battery storage: Aim for 1.5–2 days autonomy. 1,050 Wh × 1.5 ≈ 1,575 Wh. With LiFePO4 at 12.8 V and 85% usable, usable Wh per 100 Ah ≈ 1,088 Wh. Choose 150 Ah (≈1,632 Wh usable) or 200 Ah for comfort.

- Charge controller: 40 A MPPT accommodates growth and cools efficiently.

This setup should cover typical coastal cruising days with reserve for cloud cover.

Installation details that protect output

- Mount panels with airflow under them. Cooler cells produce more power; this is consistent with engineering basics highlighted by the U.S. DOE.

- Use tinned-copper marine wire, proper fusing, and drip loops. Corrosion steals watts.

- Keep modules clean of salt film. Even a light haze reduces irradiance at the cell.

- Set conservative charge limits and temperature sensors per battery spec. A robust BMS is critical for lithium safety.

Expect variability and plan for it

Solar output is variable and ramps are common. The IEA describes PV’s daily shape and frequent ramps from clouds. Beachside squalls, swinging at anchor, and boom shadows add spikes. Design for average days, but carry backup: alternator charging, shore power, or a compact generator for rare bad stretches. Policy and market studies from IRENA and data overviews from the EIA reinforce how location and season shape solar contributions.

Frequently asked questions

Can solar run air conditioning on a monohull?

Not sustainably. A small unit may draw 600–1,200 W. Even a 600 W array only yields around 1,950 Wh on a good day at sea. That is short of continuous cooling needs.

How much solar do I need for a fridge?

Efficient marine fridges often use 300–500 Wh/day. A 200–300 W array with MPPT usually covers that in sunny regions, with room for instruments and lights.

Rigid or flexible panels for a bimini?

Rigid panels last longer and run cooler. Flexible panels are lighter and easier to mount on fabric but may have shorter service life in harsh sun and salt.

Do I need lithium batteries?

Not required, but LiFePO4 provides more usable capacity, faster charging, and lower weight. That pairs well with the variable harvest of marine solar systems.

Is bifacial worth it on boats?

Bifacial modules boost yield on reflective surfaces as noted by the IEA, but on boats the back side rarely sees strong, consistent light. Gains are limited unless elevated above bright decks.

Practical checklist

- Audit loads in Wh/day

- Target 120–150% solar over expected daily use

- Plan for 1.5–2 days battery autonomy

- Use MPPT and split arrays to tame shading

- Clean panels and check connections monthly

Final thoughts

Solar power for boats can run the essentials with smart sizing and disciplined loads. Think energy yield, not just panel labels. Match array area, MPPT, and LiFePO4 storage to your real use. Accept that heat-making devices stay off the list. This approach delivers quieter days, fewer engine hours, and more independence.

Disclaimer: Technical information here is for general planning only and not design, safety, or legal advice.

References

- IEA: Solar Energy Perspectives – case studies and fundamentals of PV systems.

- IEA: Next-Generation Wind and Solar Power – variability, operating efficiency, and energy yield insights.

- U.S. Department of Energy: Solar Energy – system basics and performance factors.

- U.S. EIA – solar resource data and seasonal considerations for energy planning.

- IRENA – global PV market and performance context supporting system design choices.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.