Weekender boats carry small but steady electrical loads—lights, instruments, a VHF, a fridge. You can keep batteries up with the engine alternator or with solar power. This piece runs the numbers, shows practical trade-offs, and gives a clear path to a hybrid setup that fits most boat power systems.

What loads are we actually powering?

Start with an energy budget. Use average watts and hours per day. Keep it conservative, then add a 15–20% buffer.

- LED cabin lights: 10 W × 5 lights × 4 hours = 200 Wh/day

- Instruments + GPS/plotter: 15–25 W × 5 hours = ~100 Wh/day

- VHF (standby mostly): ~5 W × 12 hours = ~60 Wh/day

- Fridge (12 V compressor): ~35–50 W average × 24 hours = ~960–1,200 Wh/day

- Phone/tablet charging, pumps, odds and ends: ~100–200 Wh/day

Typical total: 1.2–1.7 kWh per day. For a single overnight, plan on ~1.3 kWh. For a two-night weekend, plan on 2.6–3.4 kWh.

Alternator charging: fast, familiar, but fuel-driven

The cost equation

Alternators can replace charge quickly while you motor. The cost is fuel plus engine hours. A simple way to estimate cost per kWh of electricity from an engine-driven alternator:

- Energy content: gasoline ≈ 33.7 kWh/gal; diesel ≈ 38.6 kWh/gal

- Chain efficiency at light load (engine + belt + alternator): often ~10–20%

Approximate electricity per gallon: gasoline 3.4–6.7 kWh/gal; diesel 3.9–7.7 kWh/gal. If fuel is $4.50–$6.00/gal, cost lands near $0.70–$1.70 per kWh. Use your local prices; the EIA tracks fuel data you can reference.

Hidden costs and technical caveats

- Engine hours and maintenance: extra runtime adds wear, oil use, and belt wear.

- Noise and heat: not ideal at anchor.

- Charge profile: flooded/AGM taper quickly. LiFePO4 holds high current longer, which can overheat stock alternators. Many skippers add a smart regulator or DC–DC charger to limit alternator load.

- Output at idle: a “100 A” alternator rarely makes 100 A at low RPM or high heat.

For planning, figure that generating 1.3 kWh might take 1–2 engine hours with a 60–100 A alternator, depending on voltage, acceptance, and taper.

Solar power: quiet, predictable, and low running cost

How much energy can small arrays make on a boat?

On a weekender, deck space limits you to ~100–400 W. Daily output depends on location, season, shading, and tilt. A practical planning rule for flat-mounted panels on a boat:

- Equivalent sun hours across seasons: 3.5–5.5

- Derate for heat, wiring, controller, and partial shade: ~0.65–0.75

Examples (using 4 sun hours and 0.7 derate):

- 100 W: 100 × 4 × 0.7 ≈ 280 Wh/day

- 200 W: ≈ 560 Wh/day

- 400 W: ≈ 1.12 kWh/day

Panels last. Field data show a median performance loss of about 0.75% per year across many systems, so output declines slowly. See A Clearer Picture of U.S. Solar Power Performance from the U.S. Department of Energy for details.

Cost context and reliability

Recent analyses highlight how solar’s levelized costs shifted with supply chain dynamics, while policy support improved economics in some regions. The IEA report on energy investment (2023) notes cost movements between early 2021 and late 2022 and cites a production tax credit effect of about $26/MWh in the U.S. context. Although that report covers grid-scale assets, it signals mature supply chains and broadly improving productivity for PV hardware that also benefits marine buyers.

For broader benchmarks on renewables’ cost trends and system value, see IRENA and the IEA’s Next-Generation Wind and Solar Power.

Worked example: 2-day weekend, 2.6 kWh required

Assumptions:

- Loads: ~1.3 kWh/day, so 2.6 kWh for two nights

- Alternator: effective electricity cost $1.00/kWh (mid-range)

- Solar: 200 W or 400 W, MPPT controller, tidy wiring

| Scenario | Upfront cost (USD) | Daily energy (kWh/day) | Cost per kWh over 5 years | Weekend fuel/electric cost for 2.6 kWh |

|---|---|---|---|---|

| Alternator charging | 0 (existing) | On demand | $0.70–$1.70 (fuel-dependent) | $1.80–$4.40 |

| 200 W solar + MPPT | ~$600 | ~0.56 | $0.59–$1.07* | $0 (sunny), shortfall ~1.5 kWh via alternator ≈ $1.50 |

| 400 W solar + MPPT | ~$1,200 | ~1.12 | $0.59–$1.07* | ~2.24 kWh from solar, ~0.36 kWh via alternator ≈ $0.36 |

*Lower bound assumes 365 charge days per year (boat on a mooring or slip harvesting year-round). Upper bound assumes ~200 productive days per year. Both ignore a small 0.75%/year PV degradation, which changes results slightly; see the DOE’s PV Fleet analysis: A Clearer Picture of U.S. Solar Power Performance.

Payback snapshots

- 400 W array: ~1.12 kWh/day. Valued at $1.00/kWh, that’s ~$409/year if harvesting year-round, or ~$224/year at ~200 days. Payback ≈ 3.0–5.4 years.

- 200 W array: half the energy, so payback roughly doubles.

These are directional figures. Your true payback improves if fuel prices rise or if you value quieter anchor time and lower engine wear.

Technical notes that impact the math

Battery chemistry and charge control

- LiFePO4 pairs well with solar. It accepts higher charge rates and cycles deeply. Use a marine MPPT with lithium profiles.

- Alternator protection: add a smart regulator or DC–DC charger to limit alternator load into LiFePO4. Stock alternators can overheat under continuous high-current charging.

- AGM/flooded: check absorption/float voltages and temperature compensation. Program the controller properly.

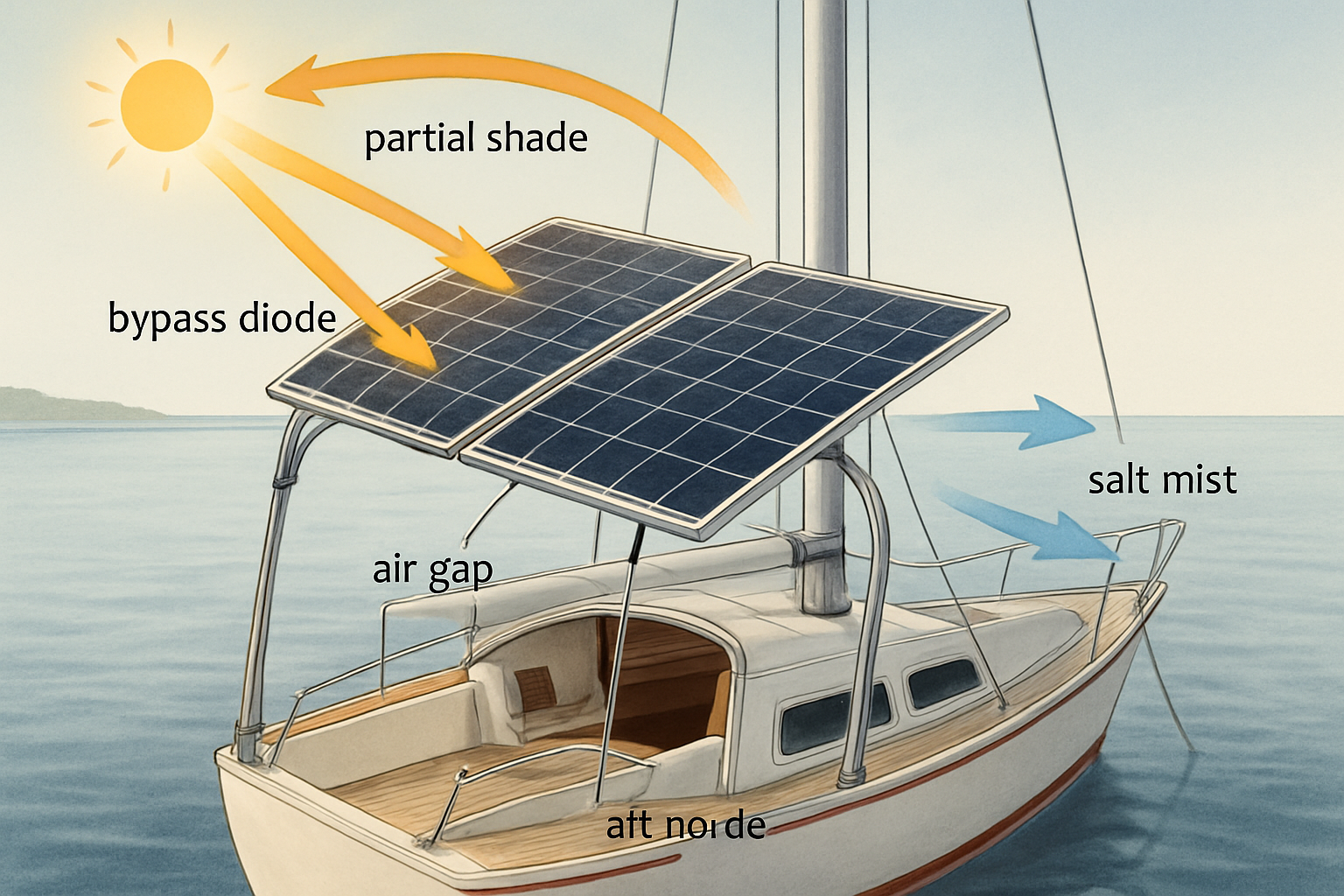

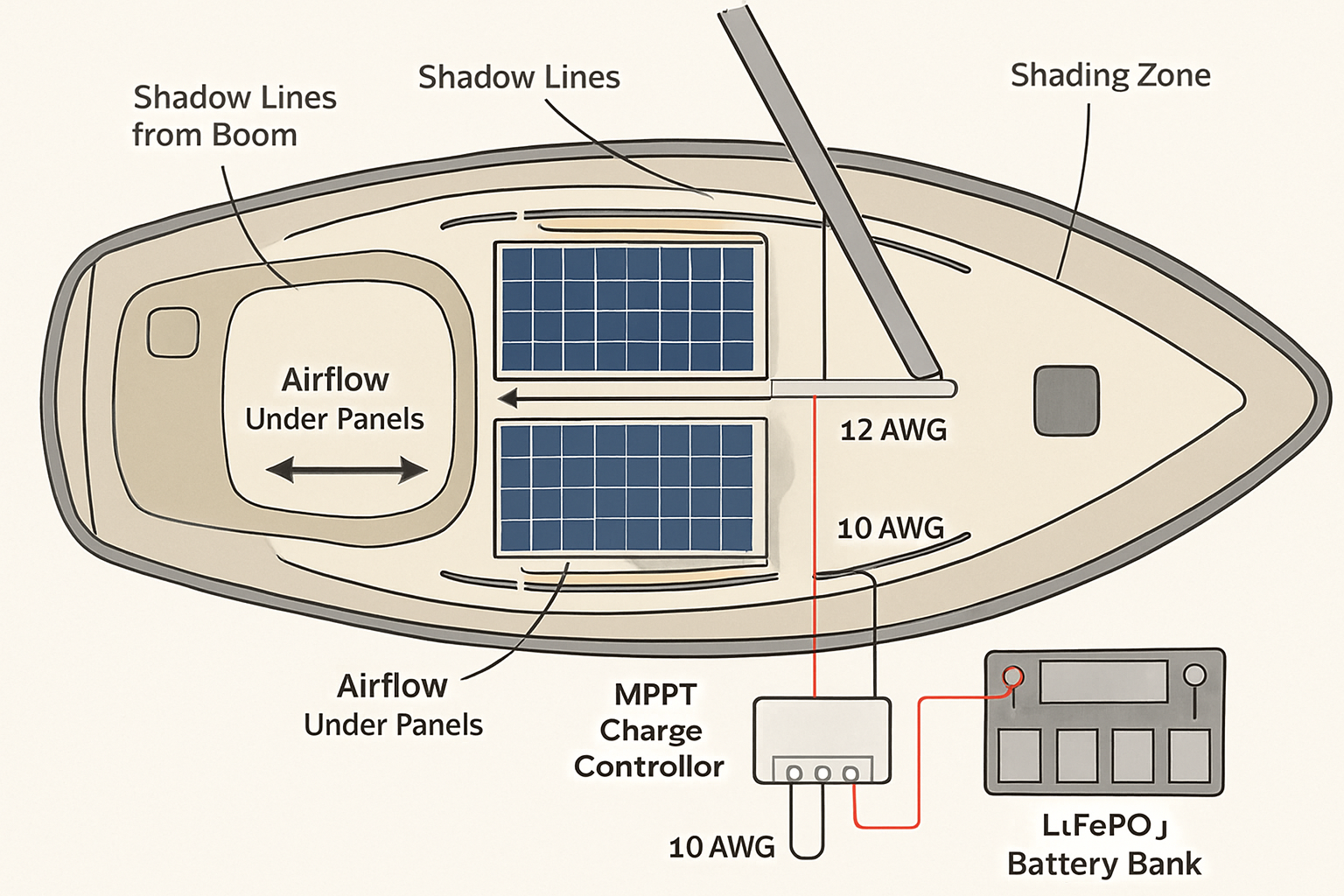

Wiring and shading

- Use marine tinned copper, sized for ≤3% voltage drop on the PV run. Short, direct routes help.

- Fuse both ends near sources (battery and array) and add a disconnect.

- Mount to minimize shadows from backstays, radar, or boom. Parallel strings reduce partial-shade losses.

Reliability references

- PV performance loss around 0.75%/year across a broad fleet per DOE PV Fleet.

- Investment and cost signals for PV hardware summarized by the IEA report on energy investment (2023).

- System value thinking and LCOE context discussed in Next-Generation Wind and Solar Power.

- Community PV programs that lock in stable rates illustrate long-term solar price stability (see Electric Cooperatives Channel Solar Resources to Rural American Communities).

- Global market and cost research: IRENA.

Hybrid strategy for weekender boats

A small array trims most of the daily load. The alternator fills gaps during cloudy spells or heavy fridge use.

- Target 60–90% solar coverage of your daily kWh. The alternator should handle the last 10–40%.

- Example: With a 400 W array (~1.12 kWh/day) and a 1.3 kWh load, run the engine ~20–40 minutes to top up, not hours.

- Use a battery monitor to keep State of Charge between 20–90% for LiFePO4 and 50–100% for lead-acid.

DIY worksheet

- Total your daily load (Wh) and multiply by days at anchor.

- Pick a PV size: PV Wh/day ≈ Panel W × sun hours × 0.65–0.75.

- Shortfall = Load − PV. Alternator kWh ≈ shortfall.

- Cost per weekend: Alternator cost ≈ alternator kWh × $/kWh (based on your fuel price and efficiency).

- Payback: PV capex ÷ annual savings (alternator kWh displaced × $/kWh).

Keep notes on shade, fridge duty cycle, and anchoring habits. These swing the result more than small price changes.

Case study: 24-foot weekender

Setup: 100 Ah LiFePO4 (≈1.28 kWh usable at 80% DoD), 400 W solar, MPPT, stock 80 A alternator with DC–DC limiting to 40 A.

- Average day: 1.3 kWh load. Solar gives ~1.12 kWh. Alternator tops ~0.18 kWh (~15 minutes of charging at 40 A × 14 V ≈ 560 W).

- Cloudy day (50% solar): Alternator provides ~0.56 kWh (~1 hour).

- Annual alternator energy drops by hundreds of kWh versus no solar, saving fuel and engine hours.

Practical procurement notes

- Choose marine-grade MPPT controllers with clear lithium or lead-acid profiles.

- Mount rigid panels on arches or davits. Use backing plates and locknuts to beat vibration.

- Flexible panels work on curved biminis; lifespans vary. Prioritize ventilation and avoid foot traffic.

- Use a quality fuse block and a battery disconnect. Label everything.

Policy and market research from the IEA report on energy investment (2023) and IRENA show strong investment signals for low-emission power, which supports component availability. While those studies focus on utility assets, the hardware pipeline is shared by small-scale users like boaters.

Disclaimer: This content is for information only and does not constitute financial or legal advice.

FAQs

How big should a solar array be for a weekender boat?

For 1.2–1.7 kWh/day, target 300–450 W if you want solar to carry most loads on sunny days. With 200 W, plan for alternator top-ups, especially for a fridge.

Can solar fully replace alternator charging?

On small boats, space limits PV to ~400 W. Solar can cover lights, instruments, and a modest fridge much of the time. Keep the alternator or a small DC–DC from the engine as backup.

Is solar reliable over years in the marine environment?

Yes with marine-grade gear and good mounting. Panels typically lose about 0.75% output per year per DOE PV Fleet. Wash panels and keep wiring dry.

Do I need MPPT or is PWM fine?

MPPT is worth it on boats. Shade and changing panel temperatures are common. MPPT squeezes more energy and supports lithium profiles.

What fuel price should I use in the alternator cost math?

Use local marina prices and your engine type. The EIA is a solid source for average gasoline and diesel prices to sanity-check your numbers.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.