A deep cycle lithium battery is the heart of a modern energy storage solution. It holds the power that grants you energy independence. But simply owning a high-quality lithium iron phosphate battery is not enough to guarantee its best output. True peak performance is achieved when the battery, its internal management system, and the hybrid controller inverter work together as a single, intelligent unit. This guide details how to create that synergy and get the most from your investment.

The Core Components: An Integrated Power Trio

Optimizing your system begins with understanding the distinct but interconnected roles of its three main components. They are not separate parts but a team working toward a common goal: reliable, efficient power.

Your Deep Cycle Lithium Battery

At the center is the deep cycle lithium battery, typically a Lithium Iron Phosphate (LiFePO4) model. These batteries are designed for repeated, deep discharges, making them ideal for solar energy storage. Their high energy density, long cycle life, and inherent safety features provide a robust foundation for any off-grid or home battery storage system.

The Unseen Guardian: The Battery Management System (BMS)

Inside every quality lithium battery pack is a Battery Management System, or BMS. This is the battery's onboard brain. Its primary job is protection. The BMS prevents damage from over-charging, over-discharging, high temperatures, and short circuits. It also performs cell balancing, ensuring all the individual cells within the battery maintain an equal state of charge. This balancing act is crucial for maximizing the battery's capacity and extending its lifespan.

The System Conductor: The Hybrid Controller Inverter

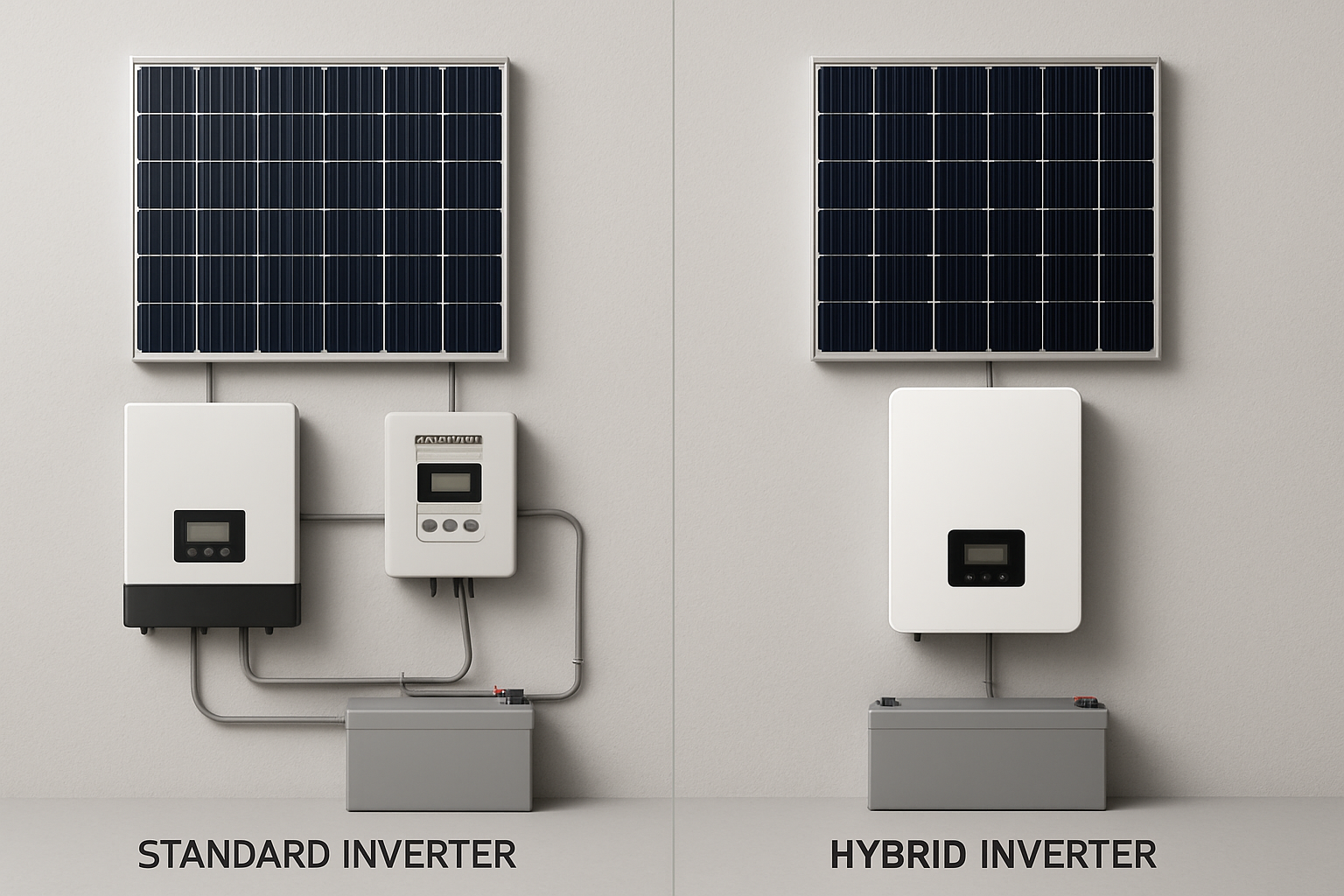

The hybrid controller inverter is the operational commander of your entire system. It intelligently manages the flow of energy between your solar panels, your lithium battery storage, your home's appliances, and the electrical grid. Unlike standard inverters, a hybrid model contains both a solar charge controller and an inverter in one unit, streamlining the system and enabling more sophisticated control over your power resources.

Achieving Synergy Through Inverter Controller Integration

Peak performance is born from seamless communication and precise configuration between the BMS and the hybrid controller inverter. When these two components are correctly integrated, they operate as a unified system, making real-time adjustments for optimal efficiency and safety.

Why Communication is a Game Changer

Advanced hybrid controller inverters can communicate directly with the battery's BMS using protocols like CAN or RS485. This digital handshake allows the inverter to receive critical data, including:

- State of Charge (SoC): The exact percentage of remaining battery capacity.

- Voltage and Current: Real-time electrical measurements.

- Temperature: Internal battery temperature readings.

- BMS Status: Any alerts or warnings from the BMS.

Armed with this information, the inverter can make smarter decisions, such as adjusting the charging current based on temperature or stopping the discharge precisely when the battery reaches its lower limit. This prevents guesswork and ensures the battery always operates within its ideal parameters.

Configuring Your System for LiFePO4 Batteries

Improper inverter settings are a common cause of poor performance and can even damage a lithium battery. Unlike traditional lead-acid batteries, LiFePO4 batteries have very different charging requirements. Setting the correct parameters in your hybrid controller inverter is non-negotiable.

Here is a table comparing typical settings, but always consult your battery manufacturer's datasheet for specific values:

| Parameter | LiFePO4 (Typical) | Sealed Lead-Acid (Typical) | Why it Matters for Lithium |

|---|---|---|---|

| Bulk/Absorption Voltage | 14.2V - 14.6V | 14.4V - 14.8V | Precise voltage control prevents overcharging and cell damage. |

| Float Voltage | 13.5V - 13.8V (or disabled) | 13.5V - 13.8V | Many LiFePO4 batteries do not require a float charge. Holding them at a high voltage can reduce lifespan. |

| Equalization | Disabled | 15.2V - 15.6V | Equalization is harmful to lithium batteries and must be turned off. The BMS handles cell balancing. |

| Low Voltage Cut-off | 11.6V - 12.0V | 10.5V - 11.0V | Protects the battery from over-discharge, which can cause irreversible damage. |

Advanced Strategies for Maximizing Performance

With a properly integrated system, you can employ advanced strategies to further enhance efficiency and longevity.

Intelligent Temperature Management

Lithium batteries are sensitive to temperature. Performance degrades in extreme cold, and charging below freezing can cause permanent damage. High heat also accelerates battery aging. A communicating BMS will report the battery's temperature to the hybrid inverter, which can then automatically reduce or halt charging until conditions are safe. This intelligent thermal management is a key benefit of a fully integrated energy storage system.

Load Management and Peak Shaving

A smart hybrid system allows you to control how and when you use energy. You can program it to use solar power directly for your appliances during the day, storing only the excess energy in your 100ah lithium ion battery. During peak evening hours when electricity rates are high, you can discharge the battery to power your home, a strategy known as peak shaving. This not only reduces your utility bills but also lessens the strain on the grid. As noted in research by the International Energy Agency, such flexibility can lead to substantial cost reductions in power system operation. The ability to participate in various energy markets, as described in the IEA's Status of Power System Transformation 2019, highlights the advanced capabilities of well-managed battery systems.

Optimizing Depth of Discharge (DoD) for Longevity

While a deep cycle lithium battery can be discharged to 100%, its total lifespan (measured in cycles) can be extended by operating within a narrower DoD range. For instance, regularly cycling between 20% and 90% SoC instead of 0% to 100% can significantly increase the number of cycles you get from the battery. A programmable hybrid inverter allows you to set these custom operating ranges, balancing daily energy needs with long-term battery health. Understanding the relationship between DoD and cycle life is fundamental to evaluating solar storage performance metrics and making informed decisions about your system's operation.

Monitoring for Long-Term System Health

A well-designed system includes robust monitoring tools. These tools provide the insight needed to ensure everything is running smoothly and efficiently for years to come.

The Power of Data Visualization

Most modern hybrid controller inverters come with software or a mobile app that provides a real-time view of your energy ecosystem. You can see how much power your solar panels are generating, where that power is going, and the battery's status. This data is invaluable for understanding your energy consumption patterns and identifying opportunities for further optimization.

The Importance of Regular Check-ups

While a properly installed lithium-based system requires minimal maintenance, periodic checks are good practice. This includes visually inspecting for loose connections, ensuring the inverter's ventilation is unobstructed, and checking the system's display for any fault codes. These simple steps can help you catch small issues before they become larger problems. The increasing need for controllability and active power management, as detailed in IRENA's Grid Codes for Renewable Powered Systems, underscores the importance of a well-maintained and responsive system.

A Final Perspective

Achieving peak performance from your deep cycle lithium battery is not about a single component, but about the intelligence of the entire system. The crucial link is the integration and communication between the Battery Management System and the hybrid controller inverter. By ensuring these components work in harmony, you configure your system for optimal charging, enhanced safety, and a longer lifespan. This synergy transforms a collection of parts into a powerful, reliable, and efficient energy solution that maximizes your move toward energy independence. With battery storage deployment expanding significantly, as highlighted in IRENA's analysis of renewable power generation costs, getting the most out of every component is more important than ever.

Frequently Asked Questions

Can I use any charge controller with a deep cycle lithium battery?

No. You must use a charge controller that is specifically designed for or can be programmed for lithium (LiFePO4) batteries. Lithium batteries require different voltage settings than lead-acid batteries, and using the wrong profile can lead to underperformance or permanent damage. A hybrid controller inverter is an excellent choice as it's designed for these advanced configurations.

What happens if the inverter and BMS do not communicate?

If there is no communication, the inverter operates based on voltage readings alone, which is less accurate than using the SoC data from the BMS. This can lead to less efficient charging, premature shutdowns by the BMS to protect itself, and an overall reduction in system performance. You lose the precision and safety benefits of an integrated system.

How do I find the correct settings for my lithium battery?

Always refer to the technical datasheet provided by the battery manufacturer. This document will list the precise voltage and current settings for bulk charging, float charging (if applicable), and low-voltage cut-offs. Using these manufacturer-specified values is essential for the safety and longevity of your lithium battery pack.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.