Choosing a lithium battery for your energy storage system is a significant step toward energy independence. But with a growing number of lithium battery manufacturers, not all products offer the same level of safety and reliability. A thorough vetting process is essential to protect your investment and ensure safety. Asking the right questions helps you distinguish a high-quality manufacturer from one that might cut corners. This framework provides the key questions you should ask any potential supplier.

Foundational Questions: Certifications and Compliance

Third-party certifications are the bedrock of battery safety. They provide independent verification that a product meets rigorous safety and performance standards. A manufacturer's commitment to certification reflects their commitment to quality.

What Key Safety Certifications Should You Look For?

Specific certifications cover different aspects of battery safety, from the individual cell to the complete system. Ask for documentation proving compliance with these critical standards:

- UL 1642: This standard tests the safety of lithium-ion cells, evaluating them for risks like fire and explosion.

- UL 1973: This applies to batteries used in stationary applications like home energy storage. It's a comprehensive standard that assesses the battery's ability to withstand overcharging, short circuits, and other fault conditions.

- UL 9540: This certification is for the entire Energy Storage System (ESS), including the battery, inverter, and controls. It ensures all components work together safely.

- UN 38.3: This is a mandatory global standard for the safe transportation of lithium batteries, which subjects them to rigorous environmental and physical stress tests.

- IEC 62619: An international standard that specifies safety requirements for secondary lithium cells and batteries in industrial applications.

How Do They Ensure Ongoing Compliance?

Standards evolve. A reputable manufacturer should have a clear process for monitoring changes in safety regulations and updating their products accordingly. Ask if they conduct regular internal audits and how they manage compliance over the product's entire lifecycle. This demonstrates a proactive approach to safety rather than a purely reactive one.

Digging Deeper: Manufacturing Processes and Quality Control

Certifications are a great start, but what happens on the factory floor is just as important. A manufacturer's internal processes for quality control determine the consistency and reliability of their products.

Can You Describe Your Cell Sourcing and Grading Process?

The individual cells are the heart of the battery. They are typically categorized into grades:

- Grade A: Brand new, top-quality cells that meet stringent performance and capacity standards.

- Grade B: Cells that did not meet the manufacturer's top standards but are still functional, often with lower capacity or shorter lifespans.

- Grade C: Often recycled or used cells with significant degradation.

For any serious energy storage application, only Grade A cells are acceptable. Ask potential suppliers how they source their cells and what procedures they use to verify their grade and authenticity. A transparent manufacturer will be able to provide clear answers.

What Quality Control Checks Are in Place During Assembly?

A battery pack is more than just a collection of cells. Ask about the quality control checkpoints during the assembly process. Key areas include the quality of the laser welding connecting the cells, the proper installation and testing of the Battery Management System (BMS), insulation checks between components, and end-of-line testing. Each finished battery should be tested for capacity, voltage, internal resistance, and BMS functionality before it leaves the factory.

How Do You Manage Traceability?

Traceability means that every battery and its critical components (like the cell and BMS) can be tracked with a unique serial number. This is vital for quality control. If a defect is found in a specific batch of cells, traceability allows the manufacturer to quickly identify all affected batteries. Ask a potential supplier about their system for tracking components from origin to final assembly.

Performance and Safety Under Real-World Conditions

A well-made battery should perform reliably and safely for years. A manufacturer's confidence in their product should be backed by extensive testing data and a solid warranty.

What Testing Data Can You Provide on Thermal Stability?

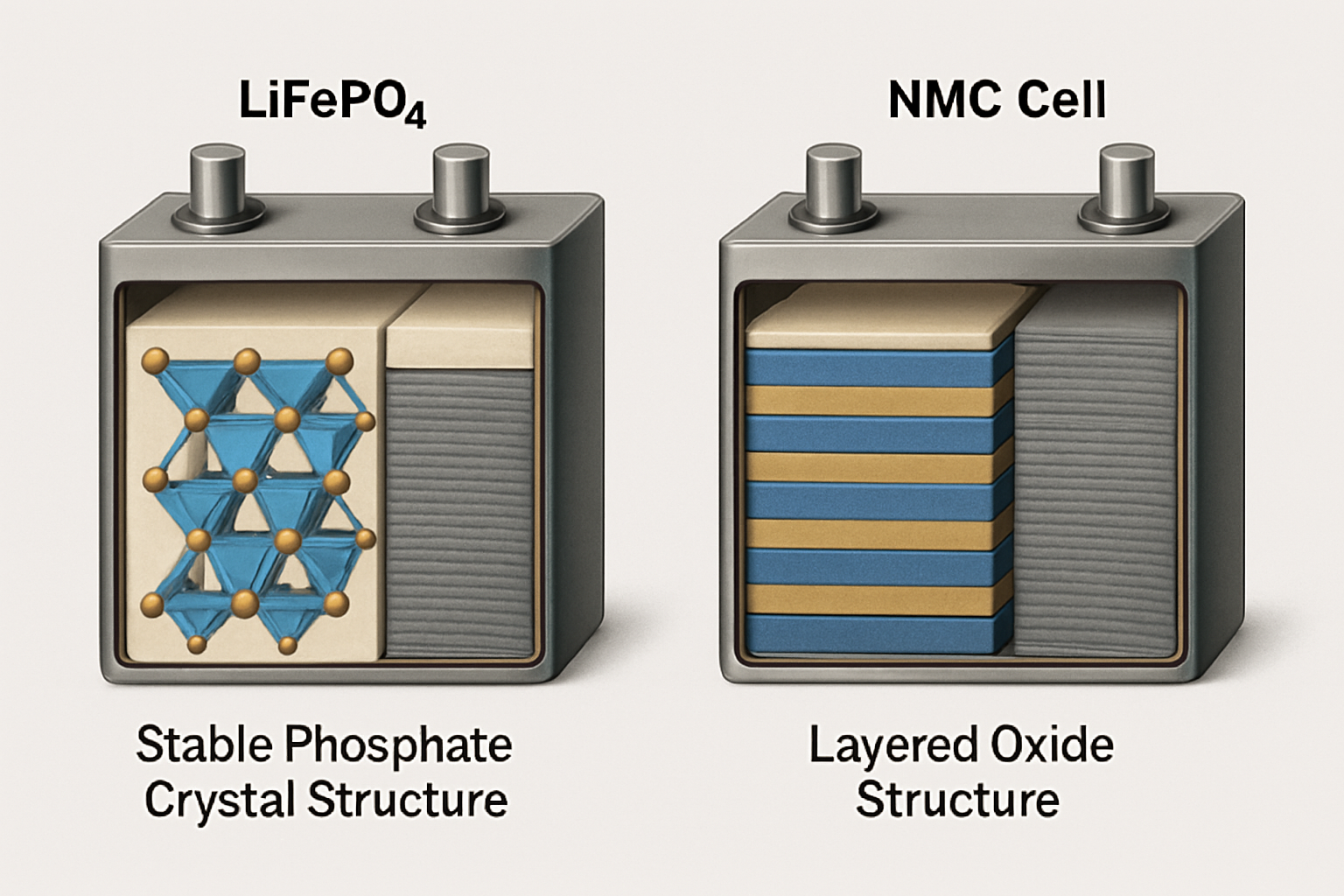

Thermal runaway is the primary safety concern with lithium batteries. Ask for data that shows the battery's thermal stability and its threshold for thermal runaway. LiFePO4 (Lithium Iron Phosphate) chemistry is known for its superior thermal stability compared to other lithium-ion chemistries, making it a safer choice for home energy storage.

How Are Your Batteries Tested for Cycle Life and Durability?

Cycle life—the number of charge and discharge cycles a battery can endure before its capacity degrades significantly—is a key indicator of quality and longevity. Ask for the manufacturer's cycle life test data and the conditions under which it was obtained. Understanding metrics like Depth of Discharge (DoD) is essential for evaluating these claims. A high-quality LiFePO4 battery should deliver thousands of cycles while retaining most of its original capacity. For a deeper look at these performance metrics, the Ultimate Reference for Solar Storage Performance provides a detailed analysis of what to look for.

What Are Your Warranty and Technical Support Policies?

A strong warranty reflects a manufacturer's confidence in their product's durability. According to a report from IRENA on Electrification with renewables: Enhancing healthcare delivery in Mozambique, lithium-ion batteries should have a lifespan of around ten years, and warranties should align with this expectation. Inquire about the warranty period, what it covers, and the process for making a claim. Equally important is the availability of responsive technical support to assist with installation or operational questions.

A Supplier's Commitment to Transparency and Partnership

Choosing a supplier is about more than just the product; it's about building a relationship with a company you can trust. Transparency is a key indicator of a reliable partner.

Can We Tour Your Facility or See a Virtual Tour?

A manufacturer who is proud of their processes and quality control will often be willing to showcase their facility, either in person or through a virtual tour. This openness is a positive sign and allows you to see their operations firsthand.

Who Are Your Primary Component Suppliers?

The quality of a battery depends on its components. Asking about their suppliers for critical parts like cells and the BMS can reveal a lot about their commitment to quality. As the IEA's Energy Technology Perspectives 2024 notes, greater standardization and compatibility in the supply chain are vital for reducing risks. A manufacturer who is transparent about their supply chain is likely more confident in the quality of their components.

Final Considerations Before You Commit

Selecting the right lithium battery manufacturer requires careful consideration beyond the spec sheet. By asking targeted questions about certifications, quality control, performance data, and transparency, you can build a clear picture of a supplier's dedication to safety and quality. The global shift toward clean energy requires massive investment in reliable technology. The World Energy Investment 2023 report underscores the capital flowing into quality manufacturing. Your due diligence ensures you partner with a manufacturer who is part of the solution, providing a safe and dependable foundation for your energy system for years to come.

Frequently Asked Questions

Why is vetting a lithium battery manufacturer so important for fire safety?

Vetting is critical because manufacturing defects, low-quality components (like Grade B cells), or poorly designed Battery Management Systems (BMS) are primary causes of battery failures, including thermal runaway and fires. A thorough vetting process verifies a manufacturer's commitment to safety standards and quality control, minimizing these risks.

What is the single most important document a manufacturer can provide?

While a single document is not enough, the UL 1973 certification for stationary battery systems is arguably one of the most critical. It covers a wide range of safety tests, including thermal runaway, ensuring the battery system is designed to be resilient against common failure modes. This should be complemented by UN 38.3 for transport safety.

Is a higher price always an indicator of a safer battery?

Not always, but an unusually low price can be a red flag. High-quality, Grade A cells, robust BMS technology, and comprehensive testing and certification processes all have associated costs. Extremely cheap batteries may cut corners in these areas. Focus on verifiable quality and certifications rather than price alone. As noted in investment trends, quality manufacturing requires significant capital. The IEA's World Energy Investment 2023 report highlights the substantial investment required in the clean energy supply chain, which includes quality battery production.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.