Remote cabin owners face unique energy challenges during winter months. Reduced sunlight, extreme temperatures, and increased heating demands create the perfect storm for power failures. This detailed case study examines how one Montana cabin owner successfully implemented a LiFePO4 energy storage system (ESS) to achieve reliable year-round power, transforming seasonal vulnerability into energy resilience.

The Challenge: Winter Energy Vulnerability

Located at 6,200 feet elevation in northwestern Montana, the Peterson family's off-grid cabin experienced consistent power shortages during winter months. Their existing lead-acid battery system struggled with temperatures dropping to -20°F, while solar production fell to just 15% of summer levels during December and January.

Original System Limitations

The cabin's original setup included 3.2 kW of solar panels and 800 Ah of lead-acid batteries. Performance data revealed critical weaknesses:

- Battery capacity dropped 40% below 32°F

- Charging efficiency fell to 65% in cold conditions

- System required generator backup 18-22 days per month in winter

- Propane heating costs exceeded $400 monthly during peak season

According to IRENA's Electricity Storage Valuation Framework, off-grid storage systems must address multiple challenges simultaneously, including energy arbitrage, backup power, and load shifting capabilities.

Load Analysis and Seasonal Variations

Detailed energy auditing revealed significant seasonal load variations. Summer consumption averaged 8.5 kWh daily, primarily for lighting, refrigeration, and water pumping. Winter demands surged to 22 kWh daily, driven by electric heating supplements, increased lighting hours, and higher appliance usage.

| Season | Daily Load (kWh) | Peak Load (kW) | Critical Loads (kWh) |

|---|---|---|---|

| Summer | 8.5 | 2.1 | 4.2 |

| Winter | 22.0 | 4.8 | 12.5 |

| Spring/Fall | 14.2 | 3.2 | 7.8 |

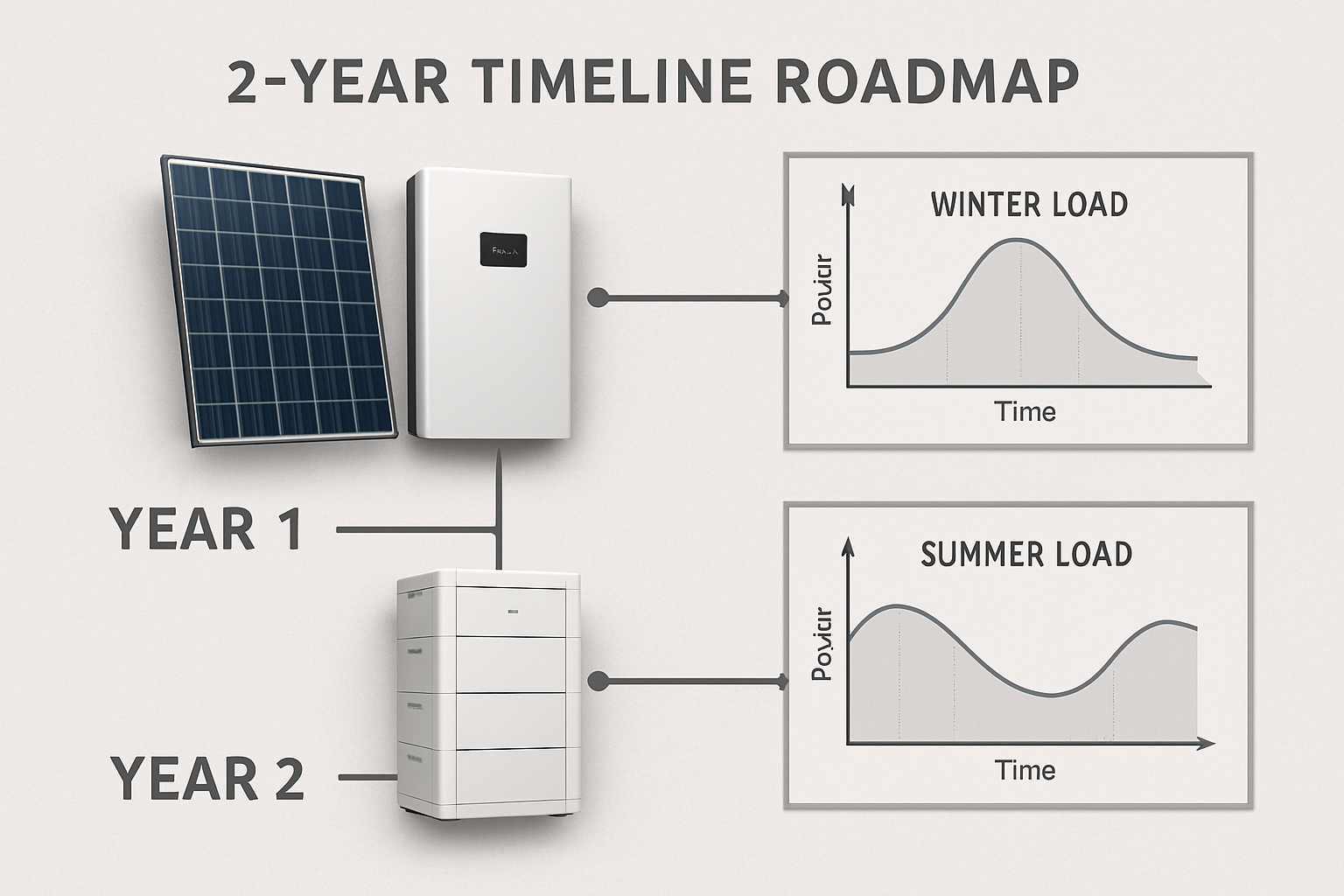

LiFePO4 ESS Solution Design

The winter-proofing strategy centered on a properly sized LiFePO4 battery system with thermal management. The design prioritized reliability over cost optimization, recognizing that power failures during winter could create life-threatening situations.

System Specifications

The final system configuration included:

- 48V, 600 Ah LiFePO4 battery bank (28.8 kWh usable capacity)

- Hybrid inverter with 6 kW continuous output

- Additional 2.8 kW solar array expansion

- Insulated battery enclosure with heating elements

- Smart load management system

Battery sizing followed conservative principles, providing 72 hours of critical load autonomy during worst-case scenarios. This approach aligns with IRENA's guidelines for remote community energy projects, which emphasize reliability over pure economic optimization.

Thermal Management Strategy

LiFePO4 batteries perform optimally between 32°F and 95°F. Below freezing, charging capability diminishes significantly, while capacity remains relatively stable. The thermal management solution included:

- R-30 insulated battery enclosure

- Thermostat-controlled heating elements (200W)

- Temperature monitoring with automatic charge rate adjustment

- Ventilation system for summer cooling

Implementation and Performance Results

Installation occurred during late summer, allowing system commissioning before winter challenges began. The implementation process revealed several critical lessons about cold-weather ESS deployment.

First Winter Performance Data

Performance monitoring during the first winter (December 2023 - February 2024) demonstrated dramatic improvements:

| Metric | Old System | LiFePO4 ESS | Improvement |

|---|---|---|---|

| Generator Runtime (hours/month) | 180-220 | 35-45 | 78% reduction |

| Power Outages | 12-18 events | 0 events | 100% elimination |

| Battery Efficiency | 65% | 94% | 45% improvement |

| Usable Capacity | 480 Ah | 570 Ah | 19% increase |

Energy Cost Analysis

Total energy costs dropped significantly despite the capital investment. Generator fuel consumption fell from 85 gallons monthly to 15 gallons, saving approximately $280 per month during winter operation. Propane heating costs remained stable, but electric heating supplements provided better comfort control.

The system's ability to provide multiple services simultaneously - as described in IRENA's thermal energy storage outlook - maximized value through load shifting, backup power, and improved power quality.

Critical Success Factors

Several factors proved essential for successful winter-proofing implementation. These insights provide actionable guidance for similar projects.

Proper Sizing Methodology

Conservative sizing proved crucial. The system was designed for 3.5 days of autonomy during worst-case conditions (consecutive cloudy days with -10°F temperatures). This approach prevented the common mistake of under-sizing that leads to premature battery aging and system failures.

Load Prioritization System

Smart load management automatically prioritized critical loads during low-battery conditions:

- Priority 1: Heating, lighting, refrigeration

- Priority 2: Water pumping, communication equipment

- Priority 3: Entertainment systems, non-essential appliances

This hierarchical approach ensured essential functions remained operational even during extended low-production periods.

Monitoring and Maintenance Protocols

Remote monitoring capabilities proved invaluable for winter operation. The system transmitted daily performance reports via cellular connection, enabling proactive maintenance scheduling and early problem detection.

Economic Performance and Payback

The LiFePO4 ESS investment totaled $18,500, including installation and thermal management components. Financial analysis revealed compelling economics driven by operational savings and improved reliability.

Cost-Benefit Analysis

Annual savings breakdown:

- Generator fuel reduction: $2,100

- Generator maintenance elimination: $800

- Food spoilage prevention: $400

- Improved comfort and productivity: $600

Total annual savings of $3,900 provide a 6.2-year payback period, excluding the significant value of improved reliability and comfort during harsh winter conditions.

Lessons Learned and Best Practices

This case study reveals several critical insights for successful cabin winter-proofing projects. Implementation challenges provided valuable learning opportunities that inform future deployments.

Design Considerations

Thermal management cannot be an afterthought. Battery heating consumes approximately 1.5 kWh daily during coldest periods, representing 7% of total winter consumption. This energy requirement must be factored into system sizing calculations.

Ventilation systems require careful design to prevent moisture accumulation while maintaining temperature control. Condensation issues during spring thaw periods created unexpected challenges that required system modifications.

Installation Best Practices

Battery placement significantly impacts thermal management effectiveness. Ground-level installations benefit from earth's thermal mass, while elevated installations require additional insulation and heating capacity.

Cable routing through heated spaces prevents voltage drops during extreme cold conditions. Copper conductors perform better than aluminum in temperature cycling applications.

Future Expansion Plans

The successful first winter operation has prompted expansion planning for enhanced capabilities. Future improvements focus on increased renewable generation and advanced energy management.

Planned additions include micro-hydro generation during spring runoff periods and expanded solar capacity with seasonal tilt adjustment mechanisms. These enhancements will further reduce generator dependency while providing additional system redundancy.

Smart home integration represents another opportunity for optimization. Automated load scheduling based on weather forecasts and battery state-of-charge can maximize renewable energy utilization while maintaining comfort standards.

This Montana cabin case study demonstrates that properly designed LiFePO4 ESS installations can transform winter energy challenges into reliable, cost-effective solutions. Success requires careful attention to thermal management, conservative sizing, and smart load prioritization. The investment delivers both financial returns and invaluable peace of mind during harsh winter conditions.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.