The constant hum of a diesel generator is a familiar sound on most construction sites. For decades, it has been the default power source. But this reliance comes with significant costs: volatile fuel prices, frequent maintenance, disruptive noise, and harmful emissions. Today, advanced portable power solutions offer a cleaner, quieter, and more cost-effective alternative. This case study examines the real-world application of a solar-battery trailer on a construction site, demonstrating its direct impact on diesel reduction and operational efficiency.

The Challenge: Over-Reliance on Diesel Power in Construction

Diesel generators present several persistent challenges that impact a project's budget, timeline, and community relations. Understanding these drawbacks is the first step toward adopting more efficient technologies.

The High Cost of Fuel and Maintenance

The primary operating expense of a diesel generator is fuel. Prices are unpredictable and subject to market fluctuations, making budget forecasting difficult. Beyond the cost of diesel itself, you must account for transportation to the site and the labor required for refueling. Regular maintenance, including oil changes and filter replacements, adds to the total cost of ownership and introduces periods of downtime.

Environmental and Community Impact

Construction sites are under increasing pressure to reduce their environmental footprint. Diesel generators are a major source of carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. These emissions contribute to air pollution and can violate local environmental regulations. Furthermore, the constant noise can exceed municipal curfews, leading to fines and strained relationships with the surrounding community. This noise also creates a more hazardous work environment by impeding clear communication among crew members.

Operational Inefficiencies

Generators are often sized for peak loads, meaning they run inefficiently most of the time when powering lighter, baseline loads like site offices or security systems. This condition, known as wet stacking, leads to wasted fuel and can cause long-term damage to the engine. Relying on a single fuel source also introduces a supply chain vulnerability that can halt progress if deliveries are delayed.

The Solution: A Real-World Deployment of a Solar-Battery Trailer

To address these challenges, a mid-sized commercial construction project deployed a solar-battery trailer to power its site operations. The goal was to minimize diesel generator runtime, cut fuel costs, and create a safer, more productive work environment.

System Configuration and Specifications

The portable power solution was designed for autonomy and high performance, capable of handling the varied loads of a dynamic job site. The core components included:

- Solar Array: A 5 kW array of high-efficiency solar panels to capture maximum energy throughout the day.

- Battery Storage: A 30 kWh LiFePO4 (Lithium Iron Phosphate) battery bank. This chemistry was chosen for its long cycle life, safety, and thermal stability.

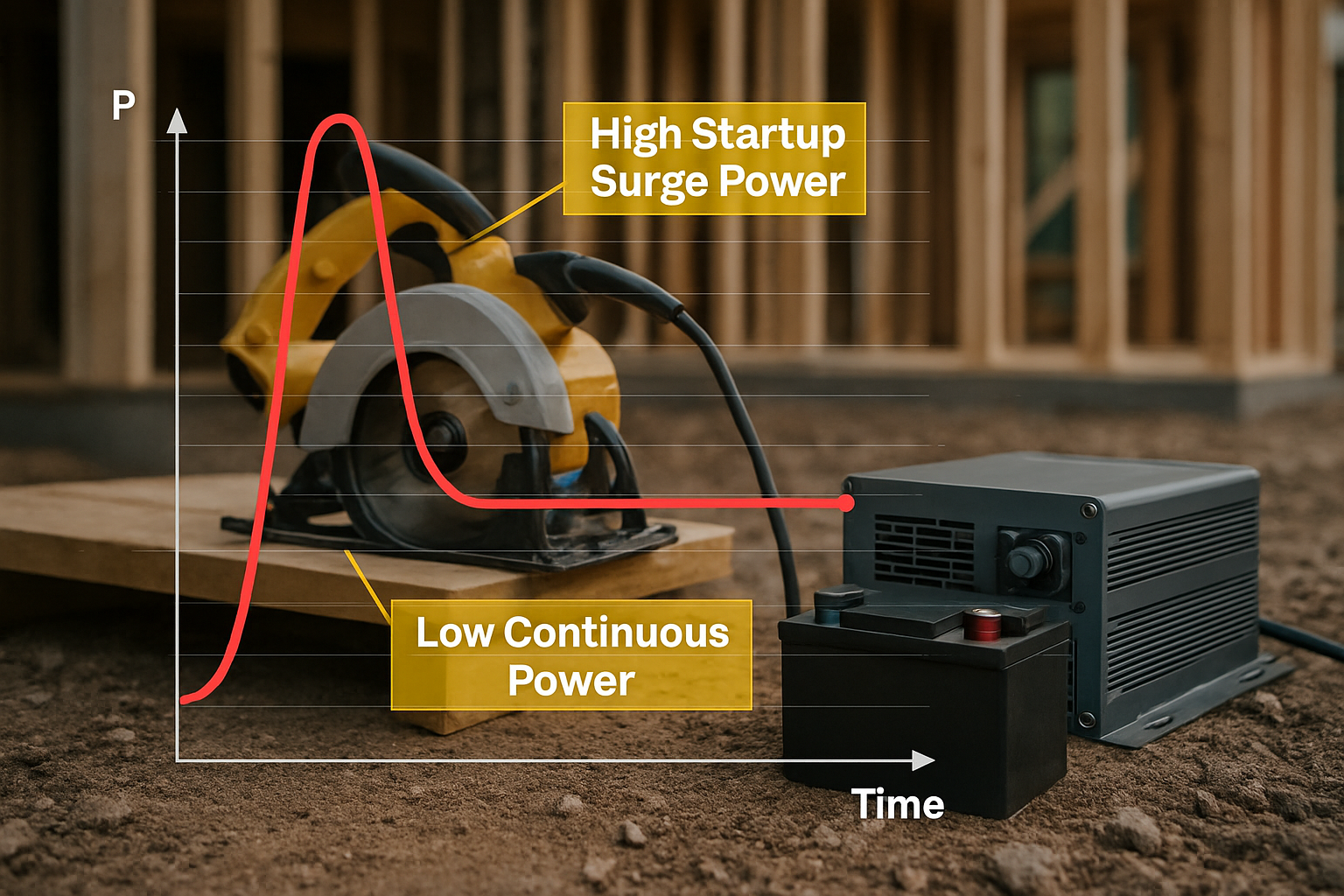

- Hybrid Inverter: A 12 kW hybrid inverter capable of delivering clean, stable AC power for sensitive electronics while also handling the high surge demands of power tools.

- Trailer Design: A rugged, road-ready trailer for easy transportation and rapid deployment on site.

Application on a Mid-Sized Commercial Site

The project involved the construction of a two-story office building. The solar-battery trailer was tasked with powering the site office, which included computers, printers, and lighting. It also powered charging stations for the crew's cordless tools and ran intermittent medium-duty equipment like chop saws and grinders. The site's existing 30 kW diesel generator was kept in reserve, intended only for the most demanding, continuous loads or as a backup during extended periods of poor weather.

Analyzing the Results: Quantifiable Diesel Reduction and Benefits

The deployment of the solar-battery trailer produced immediate and measurable improvements across several key areas. The shift away from continuous diesel generation transformed the site's energy profile.

Drastic Fuel Savings and Reduced Operating Hours

Before the solar trailer, the diesel generator ran for approximately 10 hours each day. After the trailer was deployed, the generator's runtime was reduced to an average of just one hour per day, an astonishing 90% decrease. This was primarily needed to support heavy equipment during specific, short phases of the project. The interest in such hybrid systems is growing, especially for industrial applications with limited grid access. As noted in the Electricity Storage Valuation Framework, rising operational costs for diesel systems are making PV-diesel hybrid solutions increasingly attractive. The table below illustrates the dramatic cost difference.

| Metric | Diesel Generator (Before) | Solar-Battery Trailer (After) |

|---|---|---|

| Daily Runtime | 10 hours | 1 hour (Diesel Generator) |

| Estimated Daily Fuel Cost | $120 | $12 |

| Monthly Fuel Savings | - | ~$2,160 |

| Monthly CO2 Emissions Reduction | - | ~2.5 tons |

Note: Costs and emissions are estimates based on average fuel consumption and prices.

Enhanced Site Safety and Productivity

The most immediate benefit noticed by the crew was the silence. Eliminating generator noise improved on-site communication, reducing the risk of accidents. Workers reported less fatigue at the end of the day. The clean power from the inverter protected sensitive electronics in the site office, preventing data loss or equipment damage. Furthermore, removing the daily need for refueling eliminated a potential fire hazard and freed up labor for more productive tasks.

Meeting Sustainability Goals

The significant reduction in fuel consumption directly translated to a smaller carbon footprint. By cutting generator runtime, the project eliminated tons of CO2 emissions over its duration. This provided a tangible demonstration of the company's commitment to sustainability, a valuable asset when bidding for future projects, particularly those with environmental performance requirements. The move reflects a broader trend toward electrification, where low-cost solar can increasingly compete with fossil fuels. According to an IEA report on clean energy innovation, the economics of low-cost solar are driving electrification in a growing number of applications.

Key Takeaways for Your Next Project

This case study confirms that solar-battery trailers are no longer a niche concept but a practical and financially sound solution for modern construction. They offer a clear path to reducing operational expenditures, improving site conditions, and achieving sustainability targets. By integrating these portable power solutions, you can turn energy from a recurring cost into a strategic asset. This aligns with the global energy transition, where islands and remote locations are already proving the viability of renewables. A project on the island of Ta’u, for instance, uses a 1.4 MW solar array and 6 MWh of battery storage to drastically reduce diesel use, as detailed in an IRENA publication.

Frequently Asked Questions

How much diesel can a solar-battery trailer realistically replace?

The amount of diesel replaced depends on the size of the solar and battery system, the site's total energy demand, and local weather conditions. For powering baseline loads like offices and security, along with intermittent tool use, a properly sized system can often replace 80-100% of a diesel generator's runtime.

Can these trailers power heavy-duty equipment like welders?

Yes. A trailer equipped with a powerful hybrid inverter and a sufficient battery bank can handle the high surge loads required by equipment like welders and large saws. For continuous, high-draw applications, the trailer can work in a hybrid mode, allowing the generator to run only when absolutely necessary, still resulting in massive fuel savings.

What happens during cloudy days or at night?

The integrated LiFePO4 battery bank is the core of the system's reliability. It stores excess energy generated by the solar panels during peak sunlight hours. This stored energy is then used to power the site overnight and during periods of low sunlight, ensuring a consistent and uninterrupted power supply. Systems can be designed with enough storage for several days of autonomy, providing a reliable buffer against poor weather.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.