Many owners want lower bills and fewer outages at the same time. A lithium battery paired with solar helps on both fronts when design, controls, and tariffs align with real operations. Think about the loads that must stay on, the price windows that hurt the most, and the space you have for panels and equipment. With those basics in view, you can choose a path that fits today and still scales tomorrow.

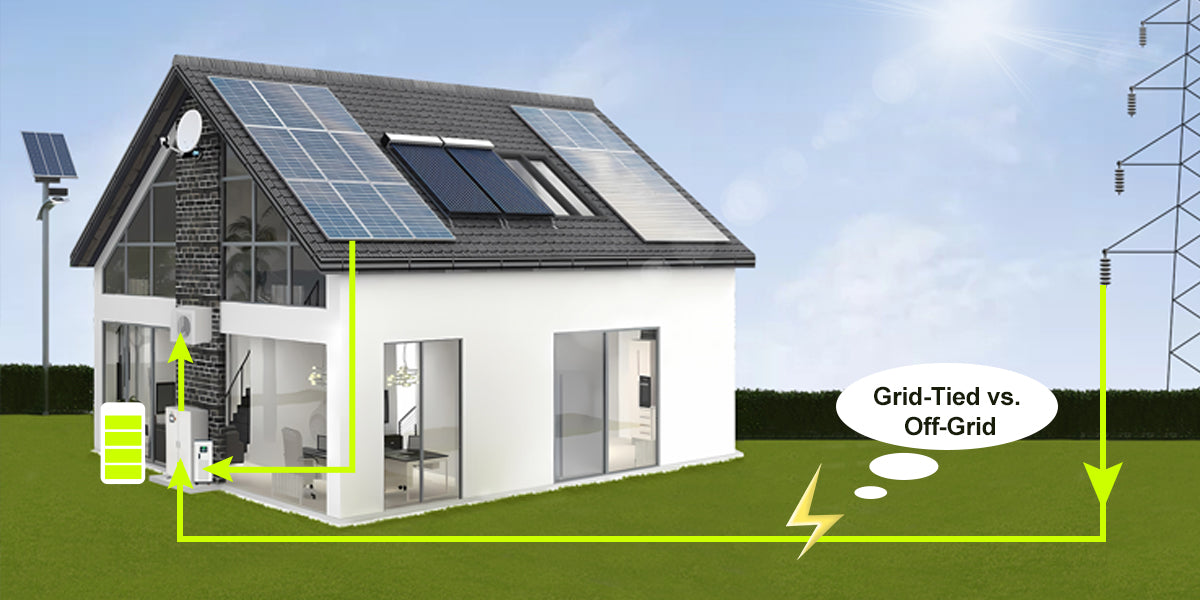

What’s the Real Difference Between Grid-Tied vs Off-Grid Solar for a Business?

Your decision rests on how much you rely on the utility during normal days and during outages. Daily power quality, tariff structure, and outage patterns all influence the architecture. Risk tolerance matters as well because backup scope and recovery speed shape both hardware and procedures.

Grid-tied keeps your site connected to the utility. Solar offsets daytime use. A hybrid inverter charges the lithium battery and supports selected loads. The grid fills shortfalls and may accept exports if policy allows. During a blackout, islanding and transfer gear keep critical circuits alive.

Off-grid removes utility reliance. Solar and storage cover all energy needs. Many sites add a generator to manage long storms and seasonal lows. Sizing focuses on autonomy, charge rates, and redundancy so operations continue without grid support.

Key Implications

- Energy source: grid-tied blends self-generation with utility supply. Off-grid relies on on-site assets.

- Risk posture: grid-tied cuts bills and supports selective backup. Off-grid targets full continuity.

- Complexity: grid-tied centers on interconnection and tariffs. Off-grid centers on sizing and resilience.

Cost & ROI: Grid-Tied with LiFePO4 Storage vs Fully Off-Grid

A lithium battery stores daytime solar, trims peaks, and supports better use of time-of-use windows. Clear cost drivers help you pick a path with fewer surprises.

Cost Drivers Table

| Driver | Grid-Tied With Storage | Fully Off-Grid |

| CapEx Focus | Hybrid inverter, moderate LiFePO4 battery, interconnection | Larger battery bank, inverter stack, often generator |

| Operating Levers | Peak shaving, TOU shifting, demand charge control | Fuel and service if a generator is used, management of deeper cycling |

| Policy & Admin | Interconnection process, export rules if any | Permitting for stand-alone power systems |

| Resilience Target | Selective backup hours for key circuits | Full autonomy by design |

| Expansion Path | Scale battery or PV as needs grow | Scale all subsystems to maintain autonomy |

A lithium battery raises round-trip efficiency and supports routine, deeper cycles compared to many legacy chemistries, which improves useful energy over time. In grid-tied designs, TOU rates and demand charges drive most savings. In off-grid designs, reserve capacity for low-sun periods raises CapEx but protects uptime and contracts.

When Does Business Energy Independence Make Off-Grid the Right Choice?

Go off-grid when outages or remoteness threaten core work. Reliability targets, fuel logistics, and seasonal variability should be clear before you buy hardware. Once those factors are quantified, the design path becomes much simpler.

Signals You Are Ready For Off-Grid

- Remote or costly grid extensions

- Processes that cannot pause without losses or safety issues

- Sites with chronic sags, flicker, or slow utility repairs

- Predictable loads and ample space for arrays and a battery room

Reliability Planning

Set autonomy in days for critical circuits. Match the lithium battery to night use and weather buffers. Consider a generator if continuity must hold through the worst month. Test transfer paths and write simple runbooks for staff.

The Benefits of a Grid-Tied Solar System for a Business

Many teams start with the grid because it lowers risk and speeds payback. The benefits of a grid-tied solar system for a business concentrate on steady savings, practical backup, and smooth expansion.

Why Grid-Tied Often Wins First

- Lower purchases during sun hours

- Peak shaving with a charged lithium battery during high-price windows

- Smaller initial storage since the grid provides make-up energy

- Easier scaling as loads grow or shift

Backup Behavior

A good hybrid design islands critical circuits during an outage. Confirm continuous and surge power ratings for large motors. Validate charge power so the pack can refill between events. Keep transfer tests on a calendar and log outcomes.

How to Size a LiFePO4 Battery for Business

Right-sizing turns potential into reliability. A LiFePO4 battery for business delivers stable voltage and deep, repeatable cycles, yet real performance depends on a clear method. Think in four parts. Build a small but trustworthy dataset, define what success means, convert goals into power and energy, then test the design against rough weeks. With that sequence, the system supports daily work instead of forcing work to fit the system.

Profile Loads

A clear picture of demand is the foundation. Interval data at 15-minute or hourly resolution gives the best view; when that is unavailable, temporary metering for a week helps. Critical circuits belong in one bucket, discretionary circuits in another. Peak kW and typical night kWh reveal both the muscle and the stamina your site needs. With those numbers in hand, later choices about size and cost stay grounded.

Set Objectives

Success needs a definition everyone shares. Backup hours for critical circuits establish the resilience target. Tariff windows and demand thresholds become the map for peak shaving. A self-consumption goal should reflect roof area, shift patterns, and staffing reality. Clear aims align budgets, timelines, and expectations before equipment is named.

Translate Into Capacity

Objectives turn into power and energy requirements. Usable kWh depends on planned depth of discharge and round-trip efficiency, not nameplate alone. Continuous inverter power should cover routine production; surge headroom protects compressors and pumps. Charge rate determines how quickly the pack returns to ready before the next price window or after an outage. A simple check keeps the math honest: energy for the night, power for the spikes, recovery before the next event.

Stress-Test the Plan

Paper tests catch weak spots at low cost. Cloudy stretches and seasonal lows should be modeled so reserves do not vanish at the wrong time. Include at least one outage longer than the usual event and confirm critical loads remain online. Physical space and electrical allowance for future modules reduce rework later. A plan that survives rough-week scenarios tends to run smoothly day to day.

What Operational Considerations Matter: Inverters, Monitoring, and Compliance?

Smooth operation keeps savings high and downtime low. Hardware choices, data practices, and paperwork carry equal weight in daily use. Think of the inverter as the heart, monitoring as the nervous system, and compliance as the rules that keep people and assets safe.

Inverters

Hybrid capability matters. An inverter should handle charging, discharging, and clean islanding under load. Continuous power needs to match routine production, while surge headroom protects motors and compressors. Most teams verify transfer timing and waveform quality during failover tests because sensitive equipment can react to small distortions. Charge rates also matter, so the pack can recover before the next peak window. Plan for growth early and capture parallel limits in writing to keep future upgrades predictable.

Monitoring

A single platform helps operators see solar, battery, and load data on the same screen. Teams track state of charge, cycle counts, temperature, and alarms with clear thresholds that everyone understands. Alerts route to the right people quickly, and short runbooks cover common events such as a low state of charge or an inverter warning. Weekly reviews compare trends to the site schedule, then settings adjust to keep the system efficient and stable.

Compliance

Interconnection rules and export limits should be clear before equipment orders. Electrical and fire codes define clearances, ventilation, labeling, and emergency access, so designs reflect those requirements from the start. Commissioning results, transfer tests, and maintenance logs belong in a shared folder for easy audits. A yearly review checks permits and safety items. Strong compliance protects staff, speeds inspections, and prevents costly rework.

Which LiFePO4-Powered Path Fits Your Commercial Solar Solutions?

A short pathway keeps choices clear for busy teams. Match your site to one of the options below and review once a quarter as operations evolve.

Choose Grid-Tied With Storage When

- The grid is stable, and tariffs reward peak shaving

- Year-one capital efficiency matters

- You want fast savings with room to scale later

Choose Off-Grid When

- The grid is unreliable or absent

- Outages create lost inventory, safety risks, or missed contracts

- You can host ample solar and manage disciplined operations

Go Phased If

- Budgets move in stages

- Production patterns will change over the next few years

- A modular lithium battery platform can expand without rework

Choosing the Right Commercial Solar Solution with LiFePO4

Set clear goals, then size and operate to match those goals. Grid-tied designs cut bills and deliver selective backup with modest storage. Off-grid brings full control at the cost of larger capacity and tighter planning. A lithium battery strengthens both paths by shaping peaks, supporting night use, and improving resilience. Document settings, schedule failover tests, and review data each quarter. Small improvements compound into strong, measurable outcomes.

FAQs

Q1. Do we need special fire safety measures for LiFePO4 at our facility?

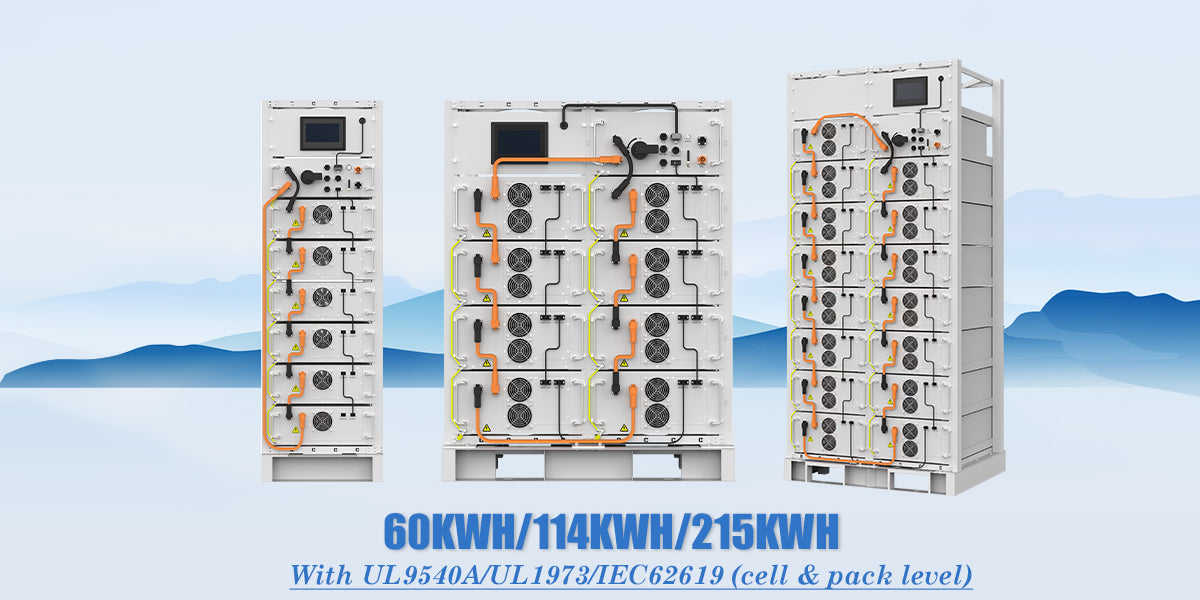

Yes. Confirm NFPA 855 requirements with your AHJ. Choose UL 9540/9540A-tested systems, plan ventilation and clearances, add detection and emergency shutoff, and pre-coordinate training with the local fire marshal.

Q2. Which battery warranty terms matter most for a business?

Look for cycle or throughput limits, calendar years, capacity retention, and temperature windows. Require API-accessible logs to prove operating history. Clarify parts, labor, shipping, response times, and onsite service coverage.

Q3. Can a LiFePO4 battery join demand response or a virtual power plant?

In many regions, yes. You need telemetry, secure remote dispatch, and utility-approved metering. Check tariff eligibility. Aggregators can enroll multi-site fleets and share revenue under a program contract.

Q4. How should we plan space and structural support for the battery system?

Treat it like equipment, not furniture. Get a structural engineer to confirm floor loading and anchoring. Plan aisles, door widths, forklift access, ventilation paths, and clear emergency egress routes.

Q5. How do we secure monitoring and control networks for commercial solar solutions?

Use a separate OT network or VLAN, VPN access, and MFA. Remove default passwords, apply vendor updates, back up configs, and define roles. Document an incident response plan with contacts.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.