The foundation of any reliable rooftop solar system is its racking. For years, the standard approach involved long, heavy rails that formed a rigid grid for attaching panels. But the solar industry is constantly innovating to become more efficient. For 2025, two significant trends are reshaping rooftop installations: the move toward rail-less mounting systems and the widespread adoption of universal clamps. These advancements are making solar installations faster, more cost-effective, and aesthetically cleaner across shingle, tile, and metal roofs.

The Rise of Rail-Less Solar Mounting Systems

Rail-less, or direct-attach, mounting is a streamlined approach that eliminates the need for long horizontal rails. Instead, solar panels are attached directly to specialized roof mounts that are secured to the rafters. This simple change has profound effects on the entire installation process.

Key Advantages Driving Adoption

The primary drivers behind the shift to rail-less systems are significant reductions in cost, labor, and logistical complexity. By removing a major component, these systems require less material, which translates to lower upfront costs. This innovation directly addresses the balance-of-system (BoS) costs, which represent a large portion of a project's total expense. According to research from the Lawrence Berkeley National Laboratory, BoS costs are a critical area for cost reduction in solar projects. Rail-less systems contribute directly to this goal.

Installers benefit from faster setup times. They no longer need to spend time measuring, cutting, and leveling long rails. This can reduce installation time by a noticeable margin, allowing teams to complete more projects. Furthermore, the hardware is lighter and less cumbersome to transport onto a roof, improving safety and efficiency.

| Feature | Traditional Railed System | Rail-Less System |

|---|---|---|

| Primary Components | Rails, Splices, Mounts, Mid-Clamps, End-Clamps | Mounts, Integrated Clamping Hardware |

| Installation Steps | Locate Rafters, Install Mounts, Attach Rails, Mount Panels | Locate Rafters, Install Mounts, Mount Panels |

| Roof Weight | Higher | Lower |

| Aesthetics | Higher Profile | Lower Profile, Sleeker Appearance |

Considerations for Different Roof Types

Rail-less systems offer flexibility for various roof materials. On asphalt shingle roofs, the mounts are installed with flashing to ensure a watertight seal. For metal roofs, particularly standing-seam types, rail-less systems can be paired with non-penetrating seam clamps, preserving the roof's integrity entirely. Even on tile roofs, specialized tile hooks can serve as the anchor points, eliminating the need for rails while accommodating the unique shape of the tiles.

Universal Clamps: Simplifying Module Compatibility

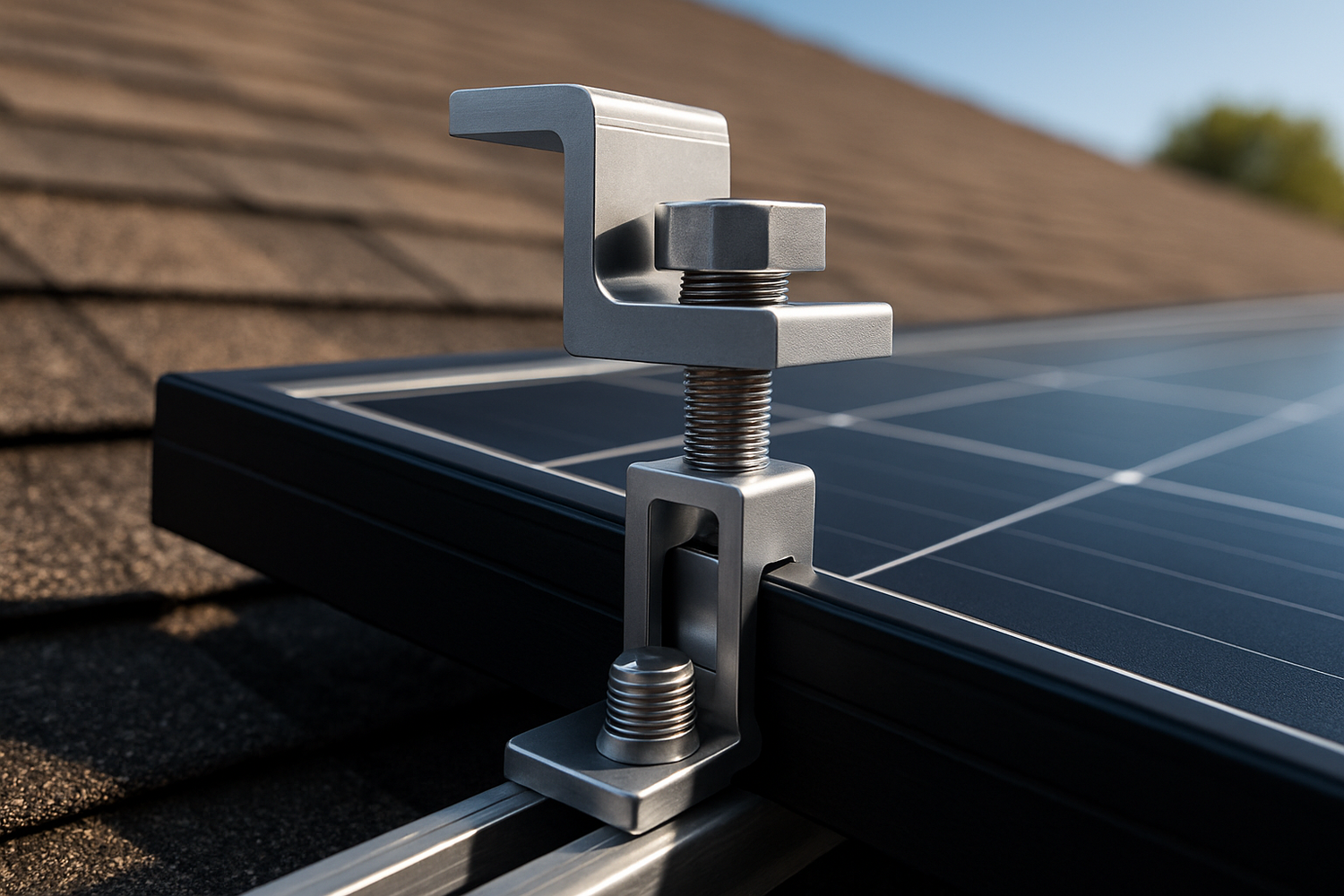

Alongside the structural evolution of racking, the hardware used to secure the panels is also getting smarter. Universal clamps are quickly replacing module-specific clamps, solving a long-standing logistical challenge for installers.

Moving Beyond Module-Specific Hardware

In the past, installers needed to stock different mid-clamps and end-clamps to match the frame thickness of the specific solar panels used in a project (e.g., 32mm, 35mm, 40mm). This created inventory headaches and increased the risk of installation errors. Universal clamps feature an adjustable design that allows them to securely fit a wide range of module frame heights, typically from 30mm to 50mm. This single piece of hardware can replace a half-dozen different clamp sizes.

How Universal Clamps Streamline Operations

The most immediate benefit is simplified inventory management. Installers can stock one type of clamp, reducing carrying costs and ensuring they always have the right hardware on hand. This flexibility is invaluable when module specifications change or when working with multiple panel brands. Using a single, adjustable clamp type also minimizes the chance of using incorrect hardware, which could lead to improper torque, panel damage, or even voiding a manufacturer's warranty. The result is a more standardized and error-proof installation process.

The Impact of These Trends on Solar System Performance and Cost

These hardware innovations are not just about convenience; they have a direct impact on the financial viability and long-term reliability of solar energy systems. By targeting BoS costs, they help make solar more accessible.

Driving Down Overall Project Costs

The cost of solar energy continues to fall, driven by improvements in every part of the supply chain. A report from the International Renewable Energy Agency, Renewable Power Generation Costs in 2024, highlights that innovations in mounting hardware are a key contributor to lower total installed costs. Rail-less systems and universal clamps reduce both material and labor expenses, accelerating this trend and making the return on investment for homeowners more attractive.

Ensuring Long-Term Reliability

A properly installed mounting system is fundamental to the 25+ year lifespan of a solar array. Rail-less systems, especially when paired with non-penetrating attachments on metal roofs, can reduce the number of potential failure points for water intrusion. Universal clamps ensure that panels are held with the correct, evenly distributed pressure, protecting them from microcracks and other stress-related damage. Optimizing the mounting system is just one part of the equation. The overall efficiency and payback period also depend on pairing it with the right components. A deep understanding of solar storage performance metrics is crucial for designing a system that delivers reliable power and maximises your investment.

A Smarter Future for Rooftop Solar

The evolution of PV racking toward rail-less designs and universal hardware marks a significant step forward for the industry. These 2025 trends are making solar installations more efficient, affordable, and adaptable than ever before. For property owners, this means a better-looking system installed faster and at a lower cost. For installers, it means simplified logistics, reduced labor, and fewer errors. As technology continues to improve, these smarter approaches to mounting will help accelerate the adoption of clean energy on rooftops everywhere.

Frequently Asked Questions

Are rail-less solar mounting systems as strong as traditional railed systems?

Yes, when properly engineered and installed. They undergo the same rigorous testing for wind uplift and snow load as conventional systems and must comply with local building codes. The strength comes from the direct connection to the roof structure, ensuring a secure foundation for the solar array.

Can universal clamps be used with any solar panel?

They are designed to fit a wide range of standard framed solar panels. You should always check the clamp's specifications for the compatible module frame thickness range (e.g., 30mm to 50mm) to ensure a secure fit. They are not suitable for frameless modules, which require a different mounting solution.

Do rail-less systems work on tile roofs?

Yes, rail-less systems are compatible with tile roofs but require specific attachments like tile hooks. These hooks slide under the tiles and attach directly to the roof rafters, providing a secure anchor point for the mounting hardware without the need for long rails. This preserves the roof's water-shedding capabilities.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.