A solar panel system is a significant investment in energy independence. Its longevity and performance, however, depend entirely on the quality of its foundation: the mounting system. For tile and metal roofs, which present unique challenges, designing a mounting system that can withstand powerful environmental forces like wind uplift and snow load is not just important—it's critical for safety and durability.

Understanding the Forces: Wind Uplift and Snow Load

Before selecting hardware, you must understand the forces your solar array will face. Wind and snow exert powerful, complex pressures that can compromise a poorly designed system. Proper engineering accounts for these location-specific environmental loads.

The Dynamics of Wind Uplift on Solar Arrays

Wind flowing over a roof creates a pressure differential, much like on an airplane's wing. This can result in a significant lifting force, known as wind uplift. The intensity of this force depends on wind speed, building height, roof shape, and the tilt of the panels. According to research highlighted by the U.S. Department of Energy, understanding these aerodynamic effects through methods like wind tunnel testing is crucial for developing resilient and cost-effective mounting solutions. Industry standards, such as the American Society of Civil Engineers (ASCE) 7 guidelines, provide detailed methodologies for calculating these design wind loads to ensure structural safety.

Calculating and Mitigating Snow Load

Snow accumulation adds a substantial downward force, or static load, to a roof and solar array. The total weight depends on regional snowfall data, roof pitch, and even the panel's surface texture. A key consideration is an unbalanced snow load, where wind causes snow to drift and accumulate unevenly, creating concentrated points of pressure. Engineers use snow load calculations based on local building codes and standards like ASCE 7 to determine the maximum anticipated weight the mounting system must support. Proper design ensures the racking and attachments can handle these heavy loads without failing.

Design Considerations for Tile Roofs

Tile roofs are durable and aesthetically pleasing, but their brittle nature requires specialized mounting techniques. The primary goal is to transfer the load from the solar array directly to the roof's structural rafters without damaging the tiles or compromising the roof's water barrier.

Selecting the Right Tile Mounts

Several types of mounts are designed specifically for tile roofs, each with a distinct approach:

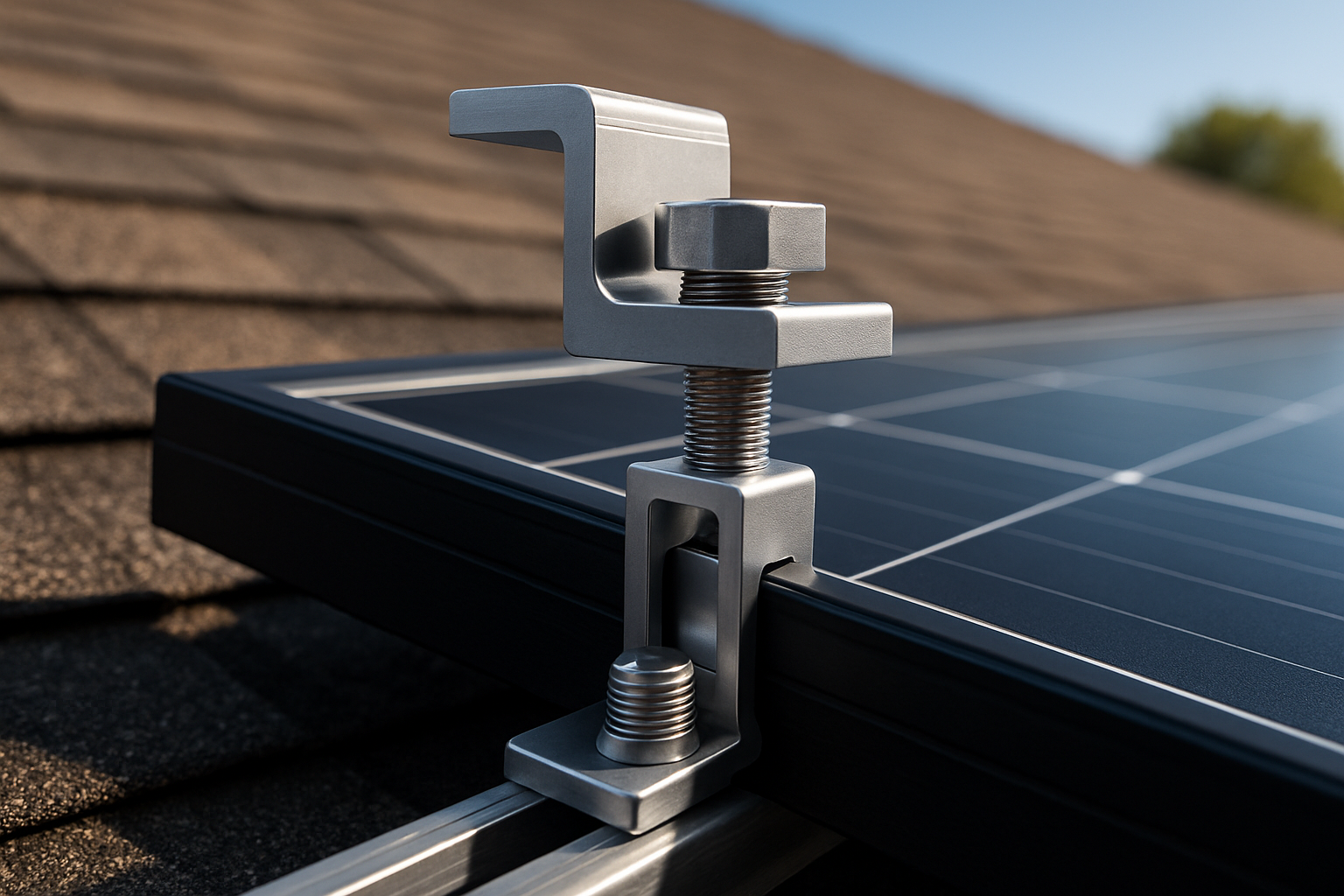

- Tile Hooks: These are the most common solution. The hook slides under a tile and is bolted directly into a roof rafter. The arm of the hook then extends out from underneath the tile, providing an attachment point for the racking system above the tile surface.

- Replacement Mounts: This method involves removing a tile and replacing it with a mount shaped like a tile but with an integrated flashing and attachment point. This creates a seamless look and a robust, waterproof seal.

- Inset or 'Comp-Out' Installation: For some tile types, installers may remove a section of tiles, install a standard composite shingle underlayment, and then use traditional flashing and mounts before replacing the tiles around the array.

Attachment and Waterproofing Techniques

Proper waterproofing is non-negotiable. Every penetration point must be sealed with high-quality flashing that integrates with the roof's underlayment. The process involves carefully lifting the tile, drilling a pilot hole into the center of a rafter, applying a durable sealant, securing the mount, and then placing the flashing to direct water away from the penetration. This meticulous process prevents leaks and protects the roof's structural integrity.

Engineering Mounts for Metal Roofs

Metal roofs are an excellent platform for solar panels, offering durability and longevity. The mounting strategy varies significantly depending on the type of metal roof.

Standing Seam vs. Corrugated Metal Roofs

For standing seam metal roofs, non-penetrating clamps are the preferred method. These clamps attach directly to the raised seams using set screws, securing the racking system without creating any holes in the roof surface. This preserves the roof's warranty and eliminates potential leak points. For corrugated or R-panel roofs, hanger bolts or specialized brackets are used. These penetrate the roof but are installed on the high point of the corrugation and sealed with high-grade EPDM rubber washers to ensure a watertight connection.

Thermal Expansion and Material Compatibility

Metal roofs expand and contract with temperature changes. The mounting system must be designed to accommodate this movement to prevent stress on the fasteners, the roof panels, and the solar modules themselves. Furthermore, using materials that are metallurgically compatible—such as aluminum clamps on an aluminum roof—is crucial to prevent galvanic corrosion, which can degrade both the roof and the mounting hardware over time.

Integrating System Performance with Structural Integrity

A secure mounting system does more than just hold panels in place; it ensures the long-term energy production and financial viability of your solar investment. Panels that shift or become damaged due to inadequate mounting will not perform optimally.

The Role of Racking in Load Management

The racking, or rails, that the panels sit on are the backbone of the array. The strength of these rails and the distance they can span between attachment points are engineered based on the calculated wind and snow loads for the specific location. In areas with high winds or heavy snowfall, stronger rails with shorter spans are necessary to prevent bending or failure. A robust mounting system is the foundation for long-term energy production. Once secured against environmental forces, the focus can shift to optimizing output. The overall efficiency of your system depends on many factors, and a comprehensive understanding of solar storage performance is key to maximizing your return on investment.

A Foundation for Resilient Energy

Ultimately, designing mounts for tile and metal roofs is a task of precision engineering. It requires a thorough analysis of local wind and snow conditions, careful selection of roof-appropriate hardware, and meticulous installation techniques. By prioritizing a robust and resilient mounting system, you protect your home, your roof, and your ability to generate clean, reliable energy for decades. As organizations like the International Renewable Energy Agency (IRENA) emphasize, building resilient renewable energy infrastructure is fundamental to a successful energy transition.

Disclaimer: This article is for informational purposes only and does not constitute professional engineering or installation advice. Always consult with a qualified structural engineer and a certified solar installer to design a system that complies with local building codes and regulations.

Frequently Asked Questions

Do solar panels increase the risk of wind damage to my roof?

Not if installed correctly. A properly engineered system is designed to withstand local wind speeds and is securely anchored to the roof's structural members. The ASCE 7-16 standard provides specific guidance for determining wind loads on rooftop solar panels to ensure they are safe and secure.

How much weight do solar panels and their mounts add to a roof?

A typical solar panel system adds about 2-4 pounds per square foot. Most modern roofs can easily handle this additional static load. However, a structural assessment by a qualified professional is always recommended, especially for older homes or in regions with very high snow loads.

Can you install solar panels on any type of tile or metal roof?

Most tile (clay, concrete) and metal (standing seam, corrugated) roofs are suitable for solar installations. However, the specific mounting hardware and technique will vary significantly. Fragile tiles, such as Spanish or S-tiles, require specialized hooks and extra care to prevent breakage during installation.

What is the difference between penetrating and non-penetrating mounts?

Penetrating mounts, used on tile and corrugated metal roofs, involve drilling through the roof surface to attach to the underlying rafters. These require robust waterproofing with flashing and sealants. Non-penetrating mounts, typically used on standing seam metal roofs, clamp onto the seams without making holes, preserving the roof's integrity and warranty.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.