Passing an inspection by the Authority Having Jurisdiction (AHJ) is the final gatekeeper for energizing a solar photovoltaic (PV) or energy storage system (ESS). Navigating the National Electrical Code (NEC), specifically Articles 690 for PV systems and 706 for energy storage, can be complex. An inspector's primary goal is to verify safety and code compliance. Understanding their perspective and key focus areas can prevent costly delays and ensure your system is safe and reliable.

Foundational Expectations: Documentation and General Safety

Before an inspector even looks at the physical hardware, they review the submitted plans. A successful inspection starts with thorough and professional documentation that demonstrates a clear understanding of the project and relevant codes.

The Importance of a Complete Plan Set

Inspectors expect a comprehensive plan set that leaves no room for ambiguity. This includes a detailed single-line electrical diagram, specification sheets for all major components (modules, inverters, batteries), and a site plan showing the location of all equipment. A clear plan shows the AHJ that the installation was thoughtfully designed to meet all structural and electrical requirements from the start. The inspector will compare the final installation directly against these approved plans.

Proper Product Listing and Certification

Every major component in your system must be tested and certified by a Nationally Recognized Testing Laboratory (NRTL), such as UL. Inspectors will verify that modules, inverters, and especially energy storage systems carry the appropriate listings. For ESS, a UL 9540 certification is the gold standard, indicating the entire system has been tested for safety. Using unlisted equipment is a significant red flag for inspectors and a common reason for failed inspections. The NEC applies to all major components, and these certifications provide the necessary safety verification.

Key Focus Areas in NEC 690 for PV Systems

Article 690 covers the specific requirements for solar PV installations. While every section is important, inspectors often pay special attention to a few critical safety functions.

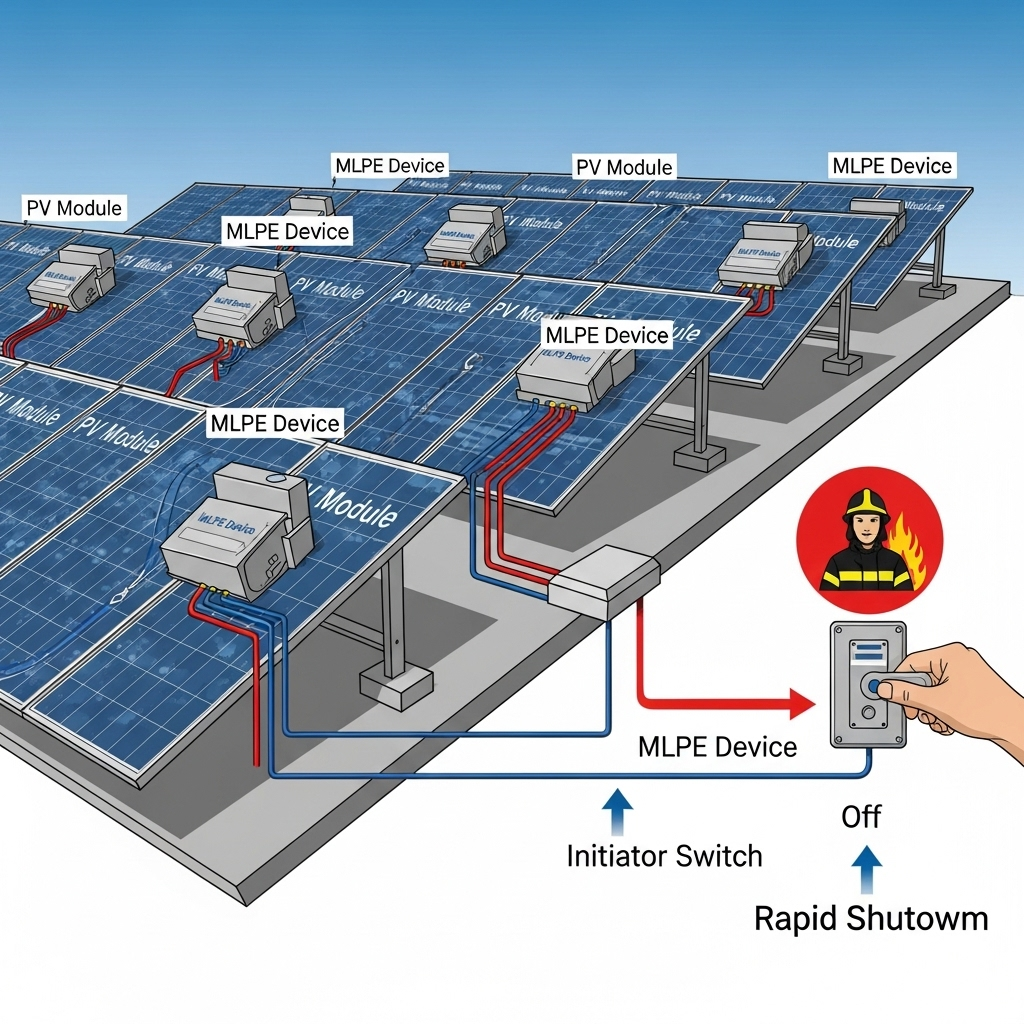

Rapid Shutdown (NEC 690.12): The Top Priority

Rapid shutdown capability is a non-negotiable safety requirement designed to protect first responders from shock hazards. Inspectors will verify that the system can be de-energized quickly and effectively. They check for the correct placement of the rapid shutdown initiator, test its function, and ensure clear, durable labeling is present. The system must reduce conductor voltage to specific levels within a set timeframe, both inside and outside the array boundary, as outlined in NEC 690.12.

Disconnecting Means and Overcurrent Protection

Proper disconnects and overcurrent protection devices (OCPDs), like circuit breakers and fuses, are fundamental to electrical safety. Inspectors verify that PV system disconnects are readily accessible and correctly rated for the system's voltage and current. They also confirm that OCPDs are properly sized—typically at 125% of the maximum calculated current—to protect conductors from overheating and potential fire hazards.

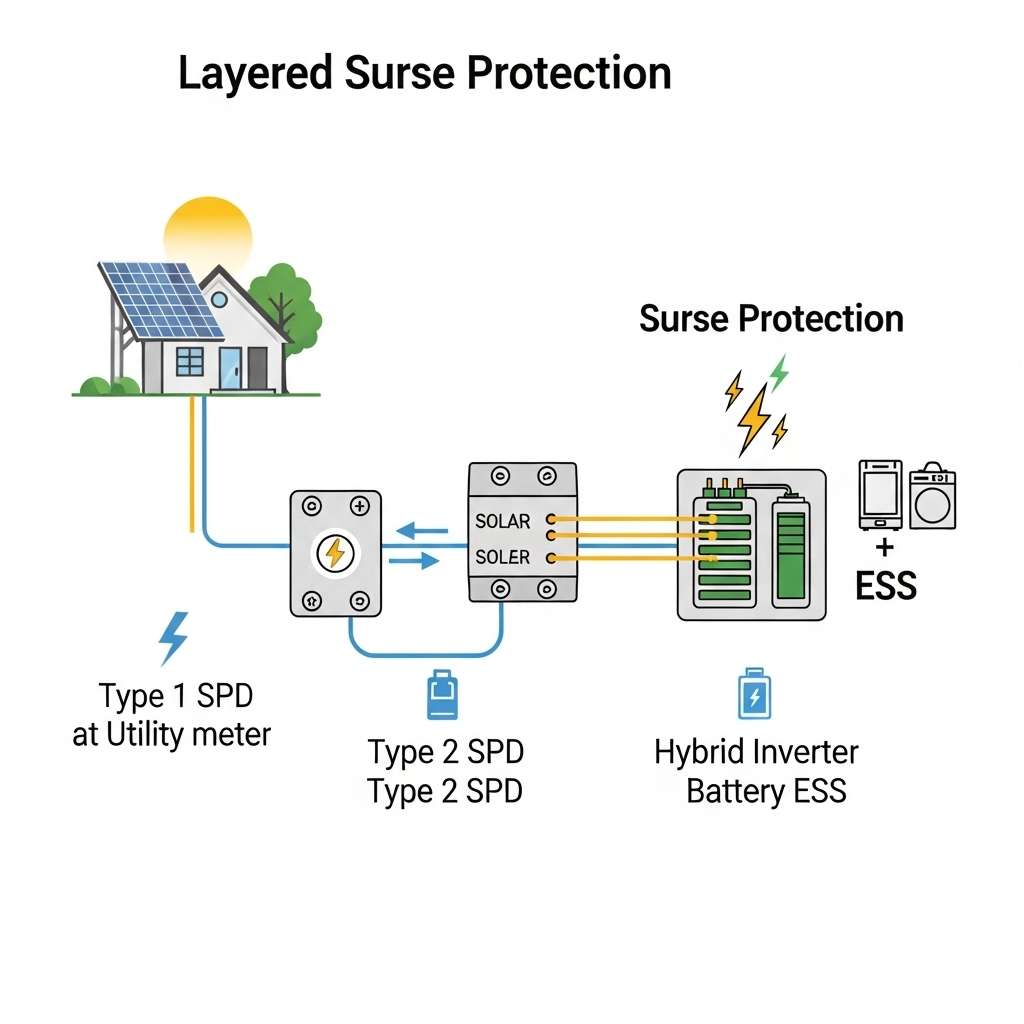

Conductor Management and Grounding

Neat and secure wire management is a sign of a professional installation. Inspectors look for conductors that are properly supported and protected from physical damage. Furthermore, they will meticulously check the system's grounding. This includes verifying that all metallic components, such as module frames and racking, are bonded together and connected to the equipment grounding conductor to create a safe path for fault current.

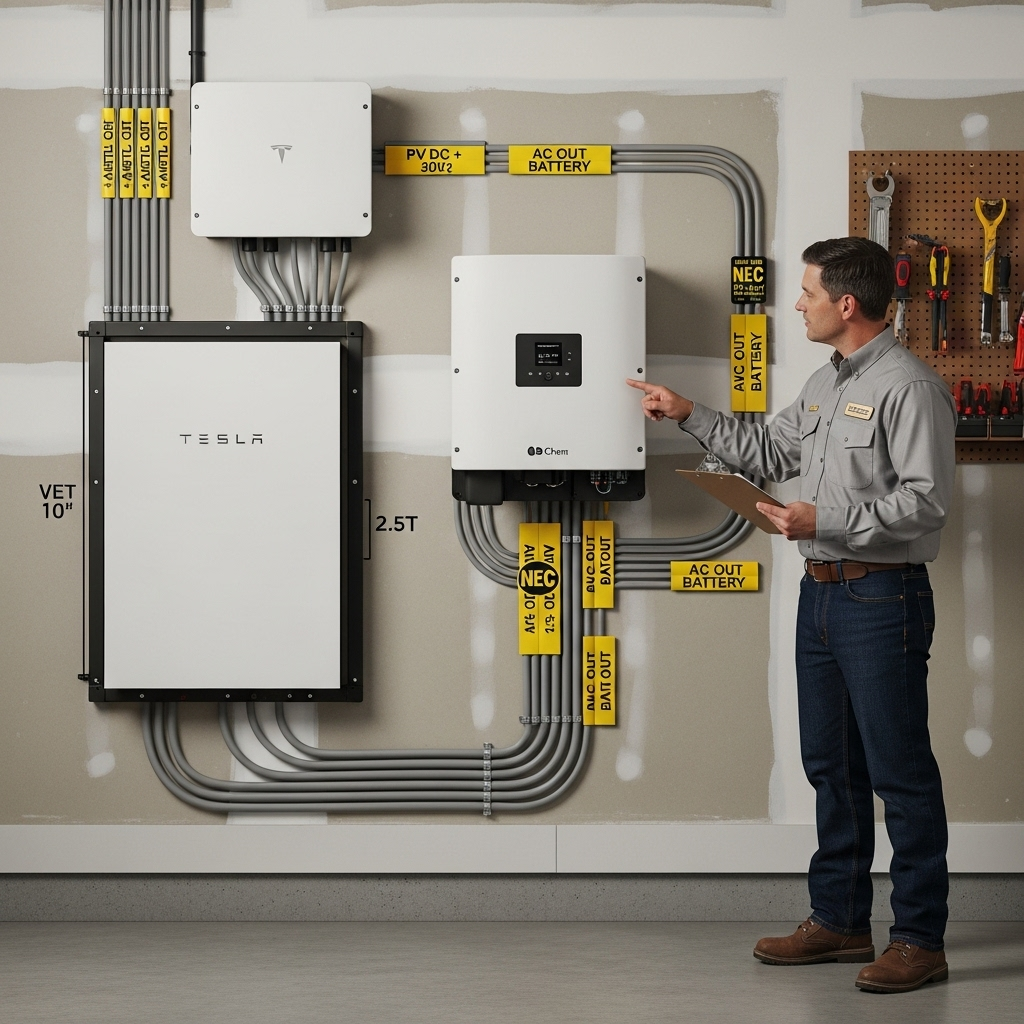

Critical Inspection Points for NEC 706 Energy Storage Systems

With the rise of energy storage, NEC Article 706 has become a key area of focus. These systems introduce unique safety considerations that AHJs scrutinize closely.

Battery Disconnecting Means (NEC 706.15)

An ESS must have a dedicated, readily accessible disconnecting means. This allows the battery to be completely isolated from all other circuits for maintenance or emergencies. An inspector will confirm the disconnect is located within sight of the battery system (or meets specific requirements for remote operation), is listed for its intended use, and is clearly labeled 'ENERGY STORAGE SYSTEM DISCONNECT'.

Ventilation and Spacing

Thermal management is critical for battery safety and longevity. Inspectors check that the ESS is installed with adequate clearance on all sides, as specified by the manufacturer's instructions. This spacing ensures proper airflow to dissipate heat. For certain battery chemistries, they will also verify that ventilation requirements are met to prevent the buildup of hazardous gases.

Commissioning and Signage

For systems in commercial settings, a commissioning process is required to verify proper operation upon installation. For all systems, signage is crucial. Inspectors will look for specific labels that identify the location of the ESS and detail emergency shutdown procedures. According to studies like the IEA's Harnessing Variable Renewables, standardized codes and procedures are essential for ensuring renewable energy systems operate safely and predictably within the larger electrical infrastructure.

The Role of Labeling Across Both Articles

Clear, durable, and accurate labeling is one of the most important—and most frequently cited—aspects of an inspection. Labels communicate critical safety information to first responders, utility personnel, and future service technicians.

A Checklist for Essential Labels

Inspectors expect to see all required labels in their proper locations. A failure to meet signage requirements is an easy way to fail an inspection. The table below summarizes some of the most critical labels.

| Label Type | NEC Reference | What it Should Indicate |

|---|---|---|

| Rapid Shutdown Switch | 690.12 | 'RAPID SHUTDOWN SWITCH FOR SOLAR PV SYSTEM' |

| PV System Disconnect | 690.13 | 'PHOTOVOLTAIC SYSTEM DISCONNECT' |

| DC Conduit/Raceways | 690.31 | 'WARNING: PHOTOVOLTAIC POWER SOURCE' |

| Energy Storage System | 706.11 | Location and shutdown procedure |

| Battery Disconnect | 706.15 | 'ENERGY STORAGE SYSTEM DISCONNECT' |

Final Thoughts for a Successful Inspection

Passing an AHJ inspection comes down to demonstrating a commitment to safety and code compliance. This is achieved through detailed planning, the use of certified equipment, and meticulous installation practices that adhere to both NEC 690 and 706. Always consider communicating with your local AHJ before the project begins to understand any specific local amendments or interpretations. A system that passes inspection is not just compliant; it is a safe, reliable, and high-performing asset. For a deeper look into system performance, you can review the ultimate reference on solar and storage performance metrics.

Frequently Asked Questions

What is the single most common reason for failing an inspection?

Improper or missing labeling is a frequent and easily avoidable reason for failure. Another common issue is the incorrect implementation of rapid shutdown systems, as the requirements are very specific.

Can I use my own custom-built battery system?

While possible, it is highly challenging to pass an inspection. AHJs typically require equipment to be listed by an NRTL like UL. A custom system would need an extensive field evaluation, which is costly and time-consuming. Using a pre-certified system with a UL 9540 listing is the most direct path to compliance.

Do I need a separate permit for the battery if I already have a solar permit?

Yes, in almost all jurisdictions. Energy storage is covered under NEC 706 and often has its own set of permitting and inspection requirements separate from the PV system under NEC 690. Always check with your local building department.

How do I find out my local AHJ's specific requirements?

The best approach is to contact your local city or county building department directly. They often provide checklists or guidelines for solar and energy storage installations on their website or upon request. This proactive step can clarify expectations and streamline the entire process.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.