Modern agriculture demands reliable power. From irrigation pumps to cooling systems, a consistent energy supply is non-negotiable. A farm microgrid offers a powerful solution, providing energy independence and resilience against grid failures. This blueprint focuses on a robust and scalable design using parallel Lithium Iron Phosphate (LFP) batteries and a split-phase 240V system, tailored for the unique needs of agricultural operations.

Understanding the Core Components

A successful farm microgrid relies on choosing the right components that work together seamlessly. The battery chemistry, power output, and overall system design are foundational to its performance and longevity.

What is a Farm Microgrid?

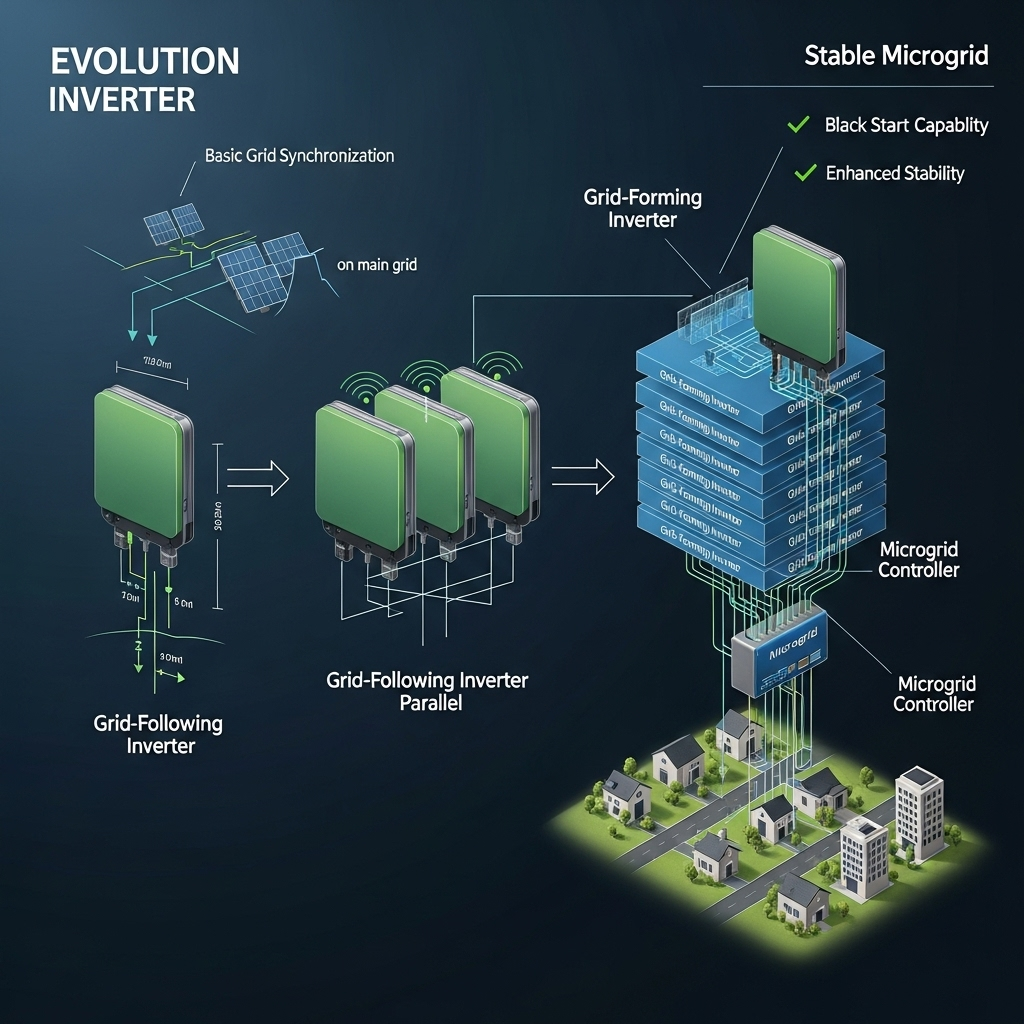

A microgrid is a self-contained energy system that can serve a defined area, such as a farm. It can operate connected to the main utility grid or disconnect and run independently in 'island mode'. This capability is crucial during blackouts, ensuring that critical operations continue without interruption. As interest in renewable energy grows, photovoltaic (PV) based microgrids are becoming increasingly common. According to research on grid infrastructure, these systems are designed to interact with the grid during normal operations but can function as an island during an emergency, significantly boosting resilience.

Why LFP Batteries are the Go-To Choice

The heart of any energy storage system is the battery. For farm applications, Lithium Iron Phosphate (LiFePO4 or LFP) batteries present a compelling choice. Their key advantage lies in their chemical stability, which makes them much safer and less prone to thermal runaway than other lithium-ion chemistries. They also offer a very long cycle life, meaning they can be charged and discharged thousands of times with minimal degradation. This durability makes them a sound long-term investment for a system that will see daily use.

The Significance of Split-Phase 240V Power

Farms run on powerful equipment. Water pumps, welders, large motors, and processing machinery often require a 240-volt supply. A standard 120V system is insufficient for these high-power loads. A split-phase 240V system, which is the standard for residential and light commercial power in North America, provides two 120V 'legs' of power. This configuration allows you to run both standard 120V appliances and heavy-duty 240V equipment, making it the most practical setup for any farm microgrid.

Designing the System: Parallel Operation and Stacking

To meet the high energy demands of a farm, you need a system that can deliver both high capacity and high power. This is achieved through the strategic combination of parallel battery connections and stacked inverters.

The Power of LFP Battery Parallel Operation

Connecting LFP batteries in parallel is the key to building a large-capacity energy reservoir. In a parallel connection, you connect the positive terminals of all batteries together and all the negative terminals together. This technique increases the total amp-hour (Ah) capacity of your battery bank while keeping the system voltage the same. The main benefits of this approach are:

- Scalability: You can start with a smaller battery bank and add more batteries in parallel as your energy needs grow. This modular approach makes the initial investment more manageable.

- Redundancy: In a well-designed system, if one battery unit fails, the others can continue to supply power, enhancing the overall reliability of your microgrid.

For successful LFP battery parallel operation, it is critical to use identical batteries (same manufacturer, model, capacity, and age) and a robust Battery Management System (BMS) to ensure all packs are balanced and operating safely.

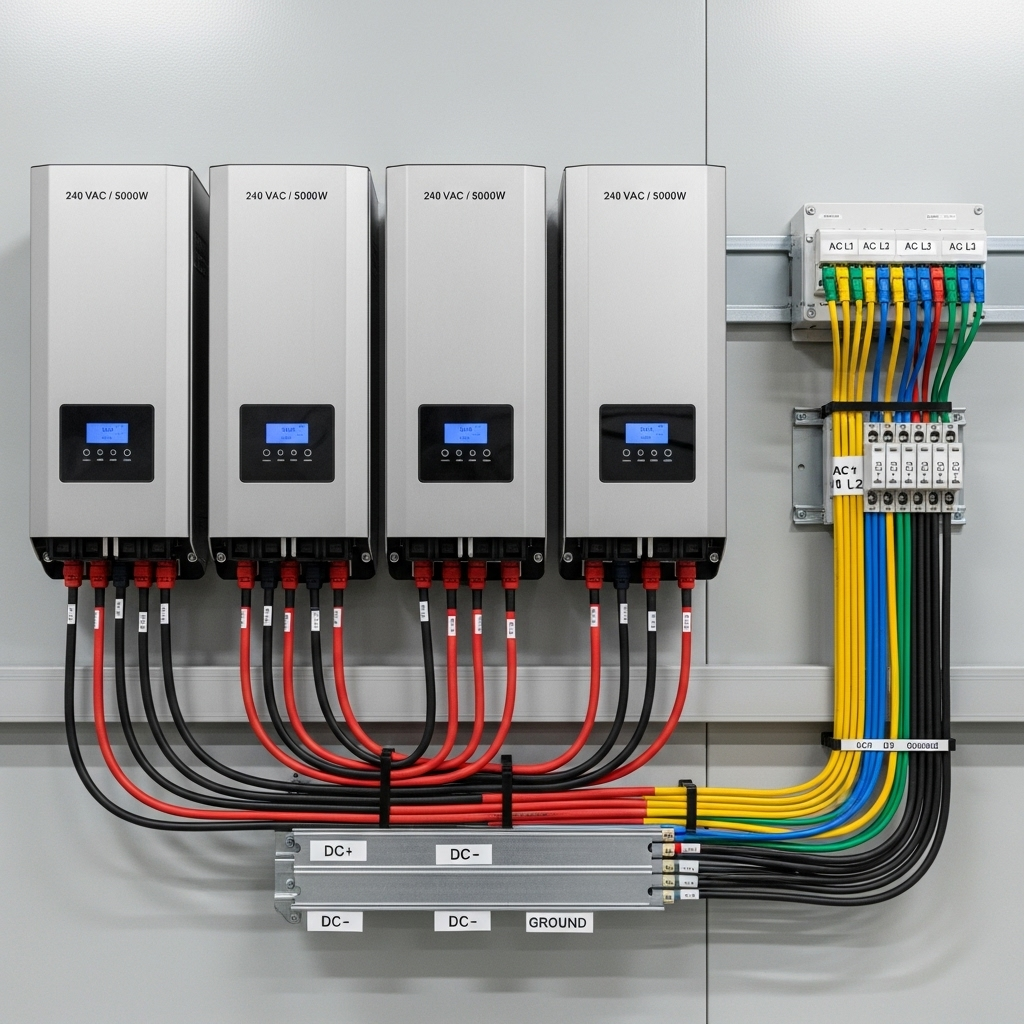

Microgrid Stacking for 240V Output

'Stacking' refers to connecting multiple inverters together to increase the power output. To achieve a split-phase 240V output, you typically stack two or more compatible inverters. Each inverter manages one of the 120V legs, and they synchronize their output to produce the full 240V. This setup not only powers your large equipment but also doubles your overall power output capability compared to a single inverter.

System Sizing and Load Management

Properly sizing your system is the most critical step in the design process. An undersized system will fail to meet your needs, while an oversized one represents a wasted investment. A detailed load analysis is the starting point.

Calculating Your Farm's Energy Needs

Begin by listing every electrical device on your farm. For each item, determine its wattage and estimate how many hours it runs per day. Multiplying these two numbers gives you the daily energy consumption in watt-hours (Wh). Be sure to account for seasonal variations—for example, irrigation pumps may run much longer in the summer.

| Appliance | Power (Watts) | Hours of Use / Day | Daily Energy (Wh) |

|---|---|---|---|

| Well Pump | 1500 | 4 | 6000 |

| Barn Lighting | 400 | 8 | 3200 |

| Refrigeration Unit | 800 | 10 (cycle time) | 8000 |

| Workshop Tools (average) | 1000 | 2 | 2000 |

| Total | 19200 (19.2 kWh) |

Sizing the Battery Bank and Solar Array

Once you know your daily energy consumption, you can size the battery bank. A good rule of thumb is to size the bank to provide two to three days of autonomy, protecting you during extended periods of cloudy weather. For a 19.2 kWh daily need, a three-day battery bank would require at least 57.6 kWh of usable capacity. Your solar array must be large enough to power your daytime loads and fully recharge your battery bank. The specific size will depend on your geographic location and the average number of peak sun hours you receive per day. For a more detailed analysis of battery metrics, the Ultimate Reference for Solar Storage Performance offers valuable data on how factors like Depth of Discharge (DoD) and C-rates influence system health and longevity.

Integration and Control

A modern microgrid is more than just panels and batteries; it's a smart, integrated system. The inverter and control systems are the brains of the operation, managing energy flow and ensuring stability.

The Role of the Hybrid Inverter

A hybrid inverter is a multi-functional device that acts as the central hub of the microgrid. It can convert DC power from the batteries to AC power for your loads, manage the charging of the batteries from the solar panels, and even draw power from or sell excess power back to the utility grid if connected. Advanced inverters can also provide fast frequency response, a feature that helps stabilize the local grid, a topic explored in Grid Codes for Renewable Powered Systems by IRENA, which is crucial for systems with high renewable penetration.

Ensuring System Resilience

The ability to provide power during a grid outage is a primary benefit of a microgrid. This resilience is particularly vital in disaster-prone areas. As highlighted in the Southeast Asia Energy Outlook 2024, microgrids can ensure continuity for critical loads when the main grid fails. For a farm, this means irrigation systems, coolers for produce, security systems, and communication equipment can remain operational, protecting your assets and livelihood.

Building Your Energy Independent Farm

Implementing a microgrid with parallel LFP batteries and a split-phase 240V system is a strategic move toward energy self-sufficiency. This configuration provides a reliable, scalable, and powerful energy source capable of meeting the rigorous demands of modern agriculture. By carefully planning your loads, properly sizing your components, and investing in high-quality LFP technology, you can build a resilient energy future for your farm.

Disclaimer: This article provides general information and is not a substitute for professional engineering or financial advice. Consult with qualified professionals before designing or installing any energy system.

Frequently Asked Questions

Can I expand my solar microgrid system later?

Yes. A key advantage of using a parallel LFP battery configuration is its scalability. You can begin with a battery bank that meets your current needs and budget, and then add more identical battery units in parallel later to increase your total energy storage capacity as your farm's demands grow.

What is the main difference between 120V and split-phase 240V?

A 120V supply is suitable for most standard appliances and lighting. Split-phase 240V provides two 120V conductors, which can be combined to deliver 240V for high-power equipment like large pumps, welders, and electric motors. A split-phase system gives you the flexibility to power both types of loads, which is essential for most farms.

How important is the Battery Management System (BMS) in a parallel setup?

The BMS is absolutely critical in any lithium battery system, especially one with parallel connections. It protects the batteries from over-charging, over-discharging, and extreme temperatures. In a parallel setup, a quality BMS also ensures that all battery packs are balanced, meaning they share the load and charge evenly. This balancing act is vital for maximizing the performance and lifespan of the entire battery bank.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.