Setting up a parallel inverter bank is an effective way to scale up your power capacity for an off-grid or backup system. It allows multiple inverters to work as a single, more powerful unit. However, achieving perfect load sharing—where each inverter contributes its equal share of the work—is a technical challenge. When load sharing fails, it can lead to system instability, premature equipment failure, and unexpected shutdowns. Understanding the common pitfalls is the first step toward building a robust and reliable power system.

Mistake 1: Mismatched Inverter Models or Firmware

One of the most frequent causes of parallel operation failures is inconsistency among the inverters themselves. Even units from the same manufacturer can have subtle differences that disrupt synchronization.

The Problem with Incompatibility

Inverters in a parallel system must communicate constantly to synchronize their AC output waveforms and share the load evenly. If one inverter has a different firmware version, its control algorithms or response times might vary slightly. This small difference can cause it to either take on too much of the load or lag behind the others, creating an imbalance that stresses the entire system. Over time, the overworked units will degrade faster, leading to costly replacements.

How to Ensure Consistency

Always use identical inverter models for a parallel bank. Before installation, verify that every unit is running the same firmware version. If you need to add a new inverter to an existing system, contact the manufacturer to ensure compatibility and obtain the correct firmware. Never assume that a newer model will work seamlessly with older ones without confirmation.

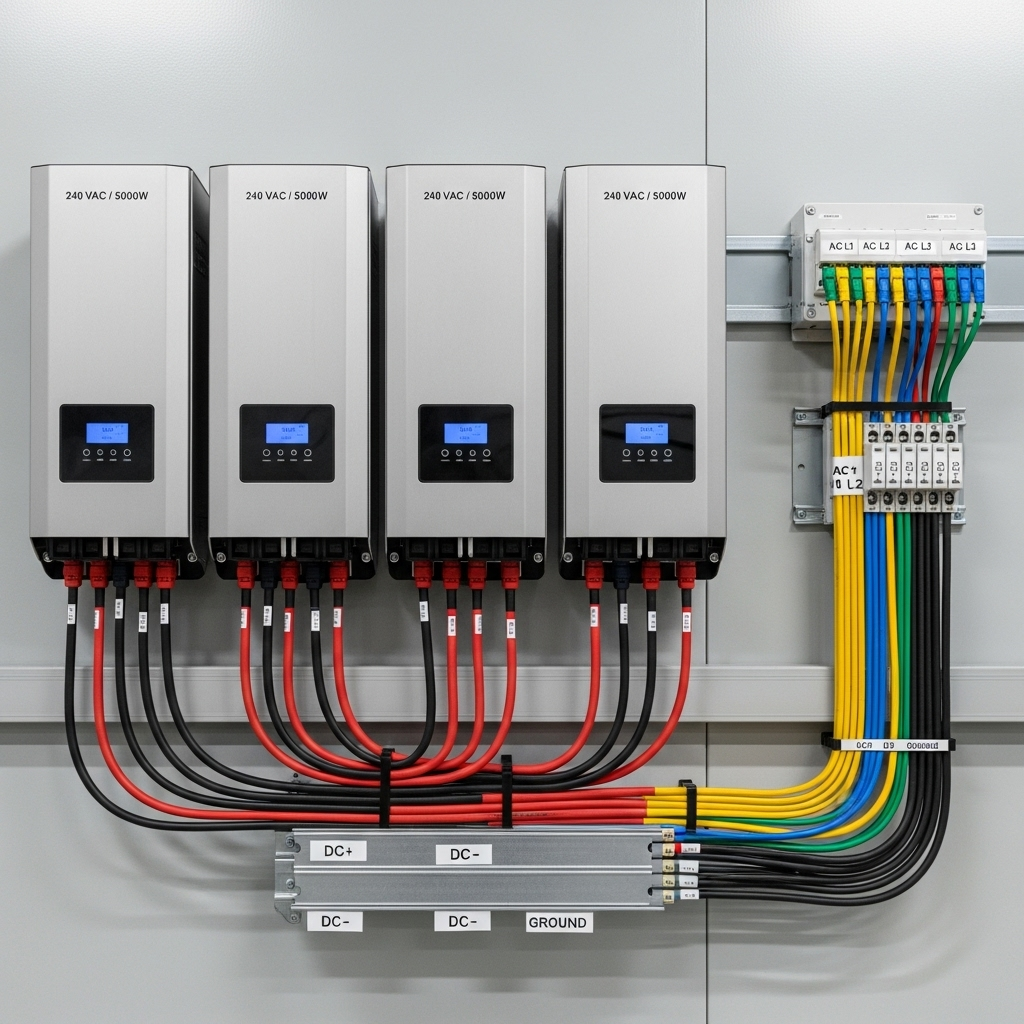

Mistake 2: Incorrect or Unequal Cable Lengths and Gauges

The physical wiring of your inverter bank is just as important as the electronic configuration. Differences in the DC and AC cabling can introduce unequal impedance, which directly impacts load sharing.

The Role of Impedance in Load Balance

Ohm's law tells us that voltage drop is a product of current and resistance (V=IR). Cables have inherent resistance; longer or thinner cables have more resistance. In a parallel setup, if the cables connecting one inverter to the batteries or the main AC busbar are longer than the others, that inverter will experience a slightly higher voltage drop. The inverter's control system interprets this as a lower load requirement, causing it to reduce its output while the other inverters pick up the slack. This imbalance forces some units to work harder than others.

Best Practices for Cabling

To avoid impedance-related inverter stacking issues, follow these rules strictly:

- Equal Lengths: All DC cables (positive and negative) from the battery bank to each inverter must be the exact same length. The same applies to all AC output cables from each inverter to the common AC busbar.

- Sufficient Gauge: Use a cable gauge thick enough to handle the maximum current with minimal voltage drop. Consult the inverter's manual for recommended wire sizes.

- Quality Connections: Ensure all cable lugs are properly crimped and all connections are tightened to the correct torque specifications. A loose connection adds significant resistance.

| Cable Length Difference | Wire Gauge (AWG) | Current per Inverter | Potential Voltage Drop Difference | Impact on Load Sharing |

|---|---|---|---|---|

| 2 feet | 2/0 | 100A | ~0.02V | Minor, but can cause imbalance over time |

| 5 feet | 2/0 | 100A | ~0.05V | Noticeable imbalance, one inverter may carry 5-10% more load |

| 5 feet | 2 AWG | 100A | ~0.1V | Significant imbalance, risk of overloading one unit |

Mistake 3: Faulty Communication and Data Cable Issues

Parallel inverters rely on a dedicated communication link to stay synchronized. Any disruption to this link can cause the system to fall apart, with each inverter acting independently.

The Communication Lifeline

Most parallel systems use a proprietary communication protocol, often transmitted over standard network cables (like RJ45). This cable allows the inverters to share critical data about their load, voltage, and frequency. If this data stream is interrupted or corrupted, the inverters lose their coordination. This can lead to erratic behavior, voltage fluctuations, or a complete system shutdown as a safety measure.

Troubleshooting Communication Failures

Common causes of communication problems include damaged cables, loose connections, or electromagnetic interference (EMI) from running communication cables too close to high-power DC or AC wires. Always use the specific shielded cables recommended by the manufacturer and route them away from power lines. If you suspect an issue, test the cable for continuity and ensure the connectors are securely seated.

Mistake 4: Improper Configuration and Parameter Settings

Modern inverters are highly configurable, but this flexibility also introduces room for error. A single incorrect setting can prevent proper load sharing.

Setting Up for Success

During setup, you must configure one inverter as the 'master' and the others as 'slaves' (or in a peer-to-peer structure, depending on the brand). The master unit typically sets the operational parameters, like output voltage and frequency, for the entire bank. It's crucial that all other settings, such as battery charging voltages and current limits, are identical across all units to ensure they behave as a cohesive system.

Common Configuration Errors

Double-check that all inverters are set to the same battery type (e.g., LiFePO4, AGM). Ensure that any load-sharing or parallel mode is correctly enabled. A common mistake is to update the settings on one unit but forget to apply them to the others, leading to mismatched behavior and poor load distribution.

Mistake 5: Neglecting Battery Bank Health and Consistency

The performance of your inverter bank is directly dependent on the health of your battery bank. An inconsistent or failing battery bank can mimic the symptoms of a faulty inverter.

The Battery's Influence on Inverter Performance

If your battery bank has weak cells or poor connections, it can cause a significant voltage drop under load. If one inverter is connected to a weaker section of the battery bank, it will see a lower input voltage than the other inverters. This will limit its ability to produce power, forcing the other units to compensate. This not only causes load imbalance but also accelerates the degradation of the weaker batteries. The health of your energy storage is fundamental, as detailed in the Ultimate Reference for Solar Storage Performance, which outlines key metrics for evaluating battery health.

Maintaining a Healthy Battery Bank

Regularly inspect your battery terminals for corrosion and ensure all connections are tight. Use a quality battery monitoring system (BMS) to track the health of individual cells or battery modules. A balanced battery bank provides a stable voltage platform, which is essential for stable inverter operation.

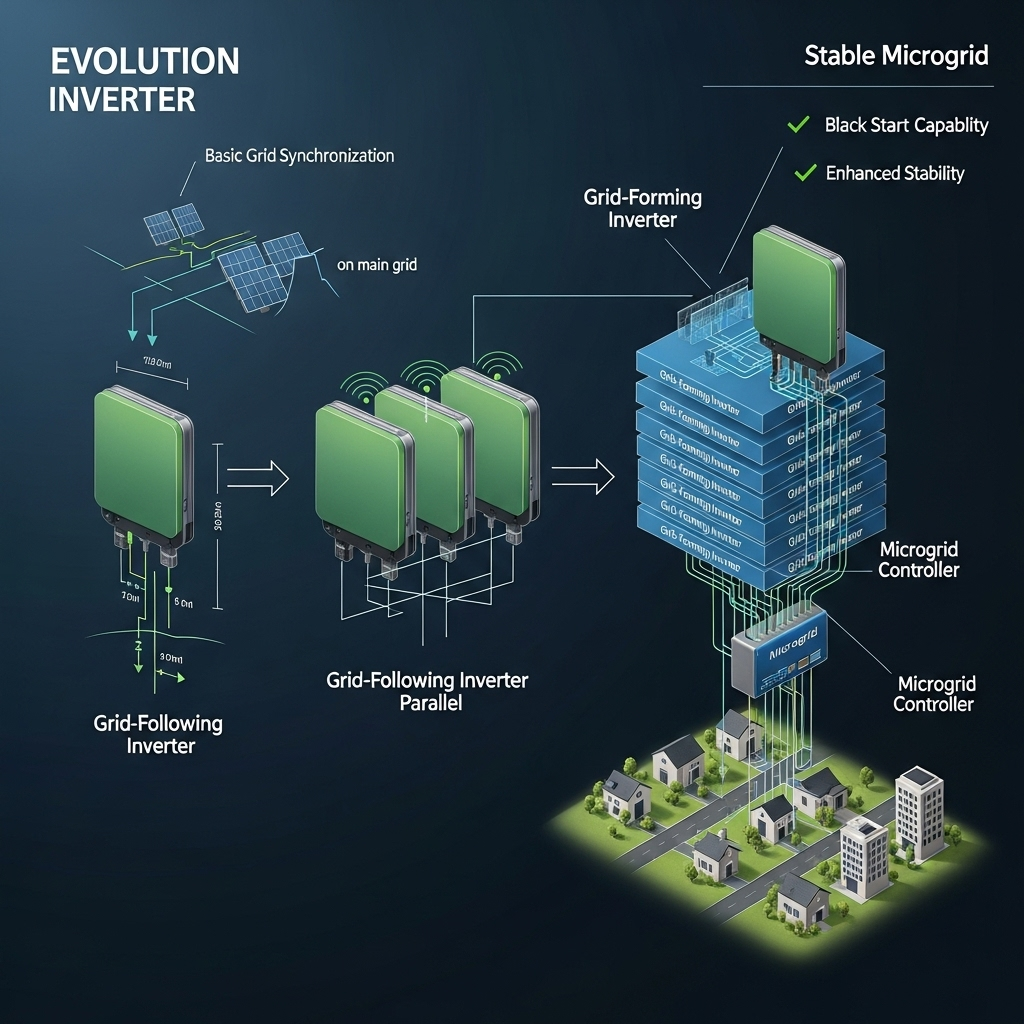

A Forward-Looking Perspective on System Stability

Achieving stable load sharing in a parallel inverter bank is a matter of precision and attention to detail. From ensuring identical firmware to using perfectly matched cable lengths, every component plays a role. As energy systems evolve, the principles of stability and control become even more critical. Research from the International Renewable Energy Agency (IRENA) highlights that as power systems move from synchronous machines to inverter-based generation, stability protocols need to be redesigned. According to their report, Malaysia energy transition outlook, this shift requires careful planning to ensure systems can operate reliably. By avoiding these common mistakes, you build a foundation for a powerful, efficient, and long-lasting energy solution that is ready for the future.

Frequently Asked Questions

What happens if one inverter in a parallel system fails?

Most modern parallel systems are designed with redundancy in mind. If one inverter fails, it should automatically disconnect from the bank. The remaining inverters will continue to supply power, but the total capacity of the system will be reduced. An alarm or error code will typically be displayed to notify you of the failure.

Can I mix old and new inverters in a parallel bank?

It is strongly discouraged. Even if they are the same model, internal components and firmware can change over production years. This can lead to incompatibility and severe load-sharing problems. For system expansion, it is best to consult the manufacturer about compatibility or plan to build a separate, new bank.

How often should I check my parallel inverter connections?

It is good practice to inspect all high-current DC and AC connections at least once a year. Temperature cycles can cause connections to loosen over time. Use a torque wrench to ensure they are tightened to the manufacturer's specifications. This simple maintenance step can prevent many performance and safety issues.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.