Off-grid farms present a unique set of energy challenges. The operation relies on a delicate balance of heavy-duty machinery and sensitive electronics, all powered by a self-contained energy system. When this balance is disrupted by poor power quality, the consequences can range from flickering lights to catastrophic equipment failure. This case study examines the common issues of Total Harmonic Distortion (THD) and surge events on a modern farm, detailing a systematic approach to diagnose and resolve them for a truly resilient power supply.

The Challenge: Unstable Power in a Demanding Environment

An off-grid agricultural operation is a microcosm of a complex power grid. It must support a wide variety of electrical loads, often simultaneously, without the buffer of a utility connection. Understanding the specific scenario and its symptoms is the first step toward a solution.

The Scenario: A Modern Farm's Electrical Ecosystem

Consider a typical mid-sized dairy farm operating entirely off-grid. Its power system consists of a solar array, a central battery bank, and a powerful inverter. This system must energize a diverse range of equipment, including:

- Inductive Loads: Water pumps for irrigation, milking machine vacuum pumps, and large ventilation fans. These are characterized by powerful motors.

- Non-Linear Loads: Variable Frequency Drives (VFDs) on pumps to control speed, modern LED lighting with electronic ballasts, and switch-mode power supplies in computers and control systems.

- Sensitive Electronics: Automated feeding systems, climate control monitors, and security systems that require clean, stable power to function correctly.

Identifying the Symptoms of Poor Power Quality

The farm in this case study experienced a series of persistent issues that pointed toward an unstable power supply. Staff reported frequent flickering of lights, especially when large pumps activated. Motors were running hotter than specified, and several expensive VFDs failed prematurely. Additionally, computerized monitoring systems would randomly reboot, leading to data loss and operational inefficiencies. These are classic indicators of an electrical environment plagued by high THD and uncontrolled surge events.

Diagnosis: Pinpointing the Root Causes

To move beyond treating symptoms, a thorough diagnosis was necessary to identify the fundamental causes of the power instability. This involved analyzing the farm's load profile, measuring power quality metrics, and evaluating the core components of the energy system.

Analyzing Load Profiles and Surge Events

Initial monitoring revealed massive inrush currents whenever the main irrigation and well pumps were activated. These motor start-ups created significant voltage sags across the system, causing the lights to dim and stressing other connected devices. These transient events, or surges, placed immense strain on the inverter, forcing it to supply several times its nominal power rating for brief moments. This repeated stress can degrade electronic components over time.

Measuring Total Harmonic Distortion (THD)

A power quality analyzer was used to measure the system's THD. During peak operation, with VFDs and other non-linear loads active, the THD levels were measured at over 15%, far exceeding the recommended industry limit of 5% for sensitive electronics. This 'noise' on the power line was a primary contributor to the overheating of motors and the malfunction of control systems. The VFDs, while efficient at controlling motor speed, were also the main source of these harmful harmonics.

The Inverter's Critical Role in Power Quality

The investigation turned to the heart of the system: the inverter. While rated to handle the farm's total wattage, its specifications for surge handling and THD mitigation were inadequate. The inverter's efficiency curve showed a sharp drop-off when dealing with the highly dynamic and reactive loads presented by the motors. A power converter's performance is not just about peak output; it's about how it manages real-world conditions. For a deeper understanding of how to evaluate these performance metrics, the Ultimate Reference for Solar Storage Performance provides detailed insights into interpreting efficiency curves and surge ratings. The existing unit was simply not robust enough for the agricultural environment.

The Solution: A Systemic Approach to Power Stability

Solving the farm's power quality issues required a multi-faceted approach, focusing on upgrading core components, filtering electrical noise, and managing loads more intelligently. The goal was to build a system where visibility and controllability were paramount. As the IEA notes, having visibility of power plants and the ability to control them are crucial for maintaining supply security, a principle that applies directly to an off-grid system. According to the IEA's System Integration of Renewables report, ensuring visibility of system conditions is a central element for reliable operation.

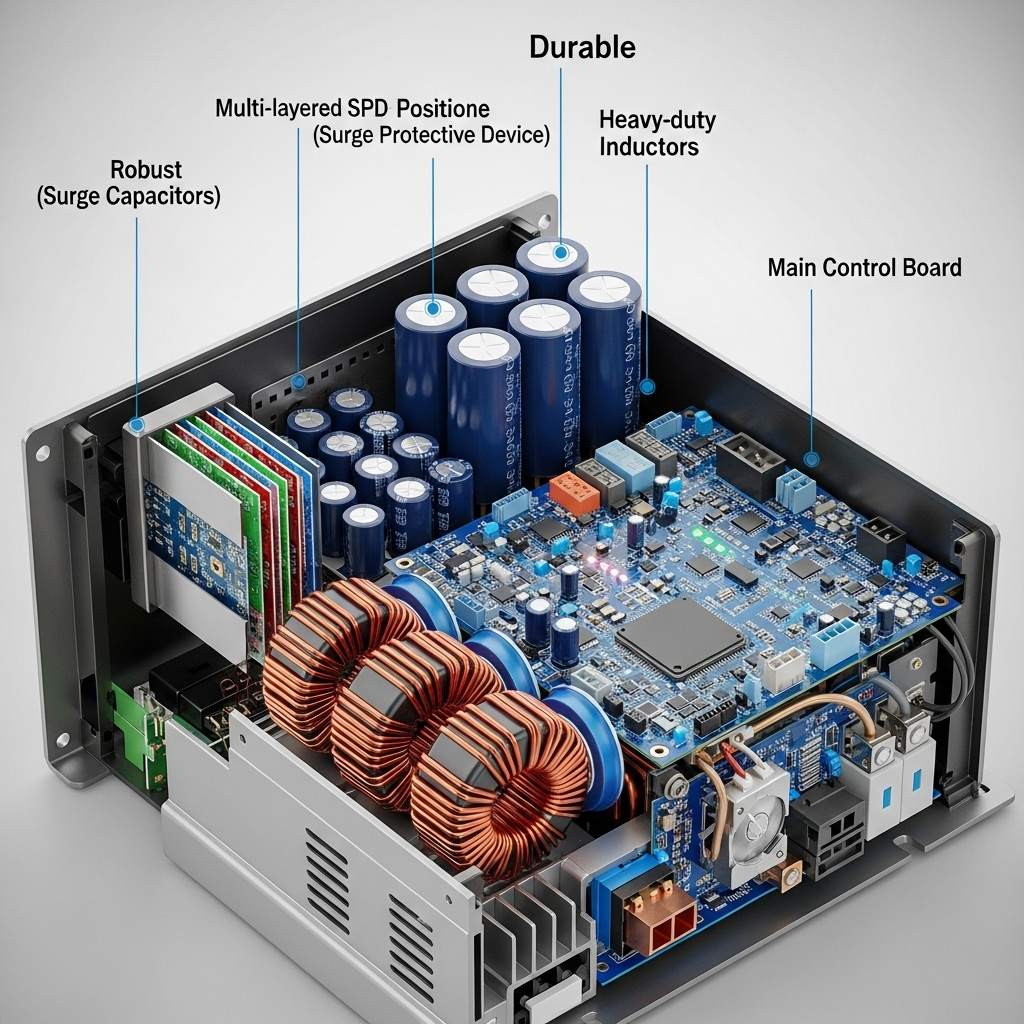

Upgrading the Inverter and Energy Storage

The first step was to replace the underperforming inverter with a modern hybrid inverter specifically designed for off-grid applications. The new unit featured a surge capacity of 2.5x its continuous power rating and an internal design that maintained low output THD (<3%) even under complex loads. This was paired with a LiFePO4 battery system capable of high discharge rates, ensuring it could supply the instantaneous current needed for motor start-ups without causing a system-wide voltage drop.

Implementing THD Control and Load Management

To address the harmonic distortion at its source, passive harmonic filters were installed on the electrical lines feeding the large VFDs. These filters act like a sponge, absorbing the harmonic noise generated by the drives before it can pollute the rest of the farm's electrical system. Furthermore, a new load management strategy was implemented. Soft starters were fitted to the largest motors to ramp up their speed gradually, drastically reducing the initial inrush current. The startup times for major equipment were also staggered to prevent simultaneous power demands from overwhelming the system.

Achieving System-Wide Visibility

A key upgrade was the implementation of a more advanced system controller. This provided real-time data on power production, consumption, and quality. As highlighted in the IEA report, Getting Wind and Solar onto the Grid, the ability for a system operator to see real-time data and act on it is fundamental to stability. This new level of visibility allows farm operators to anticipate needs and manage the system proactively.

Results and Long-Term Benefits

The combined effect of these upgrades was transformative. The changes not only solved the immediate problems but also created a more efficient, reliable, and cost-effective energy system for the long term.

Quantifiable Improvements in Power Quality

Post-implementation measurements confirmed the success of the project. The system's stability and power quality saw dramatic improvements, which are summarized below.

| Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Total Harmonic Distortion (THD) | >15% | <3% |

| Voltage Sag During Motor Start | ~10-15% | <2% |

| Equipment Failure Rate (VFDs, electronics) | High (Quarterly Failures) | Negligible |

| System Downtime | Frequent | Rare |

Enhanced Efficiency and Return on Investment

With clean, stable power, all connected equipment now runs more efficiently and cooler, significantly extending its operational lifespan. The drastic reduction in equipment failures and costly downtime has had a direct positive impact on the farm's profitability. The investment in a properly specified inverter, battery system, and filtering technology delivered a rapid return by protecting more expensive assets and ensuring operational continuity.

Final Thoughts: Building a Foundation for Energy Independence

This case study demonstrates that achieving reliable power on an off-grid farm requires more than just sufficient generation capacity. A successful system must be designed to handle the dynamic and demanding loads specific to agriculture. By focusing on THD control, robust surge handling, and intelligent load management, it is possible to create a power supply that is as stable and reliable as a utility grid connection. This holistic approach is the key to true energy independence and long-term operational success.

Disclaimer: The information provided in this article is for educational purposes only. It does not constitute professional engineering or financial advice. Please consult with a qualified professional before making any decisions regarding your energy system.

Frequently Asked Questions

What is an acceptable THD level for a farm?

For general-purpose loads, a THD level below 8% is often acceptable. However, for environments with sensitive electronics, such as control systems, computers, or modern VFDs, the recommended THD is below 5%. Lower is always better for equipment longevity.

Can a larger battery bank alone solve surge problems?

Not entirely. While a large, high-discharge-rate battery bank (like LiFePO4) is crucial for providing the instantaneous current needed for a surge, it cannot solve the problem alone. The inverter must also be capable of handling and delivering that surge current without being damaged. A balanced system with a capable inverter and battery is the correct solution.

How do efficiency curves relate to surge handling?

An inverter's efficiency curve shows how effectively it converts DC to AC power at different load levels. An inverter that is highly efficient at 25% or 50% load will perform better in a typical off-grid setting where loads vary. While not a direct measure of surge handling, a robust efficiency curve across a wide range often indicates a higher-quality power conversion architecture that is better equipped to handle dynamic loads and brief surges.

Are harmonic filters expensive to install?

The cost of harmonic filters varies based on the size of the load they need to support. However, their cost is almost always significantly less than the cost of replacing a large motor, an expensive VFD, or dealing with the operational losses from system downtime. They are a highly cost-effective investment in power quality and equipment protection.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.