A solar installation should be a one-time event. Yet, callbacks to fix leaks, loose hardware, or failed inspections can erode profits and damage a company's reputation. The root cause is often a mismatch between the mounting hardware and the roof type. Using the correct, code-compliant mounts is not just about passing an inspection; it's about building a secure, waterproof foundation that lasts for decades. This protects the customer's home and ensures the solar energy system performs as expected.

The Foundation of a Secure Solar Array: Understanding Code Compliance

A successful solar installation begins with a solid understanding of structural and safety standards. Code compliance is the framework that guarantees the long-term integrity of both the solar array and the building it sits on.

What 'Code-Compliant' Really Implies

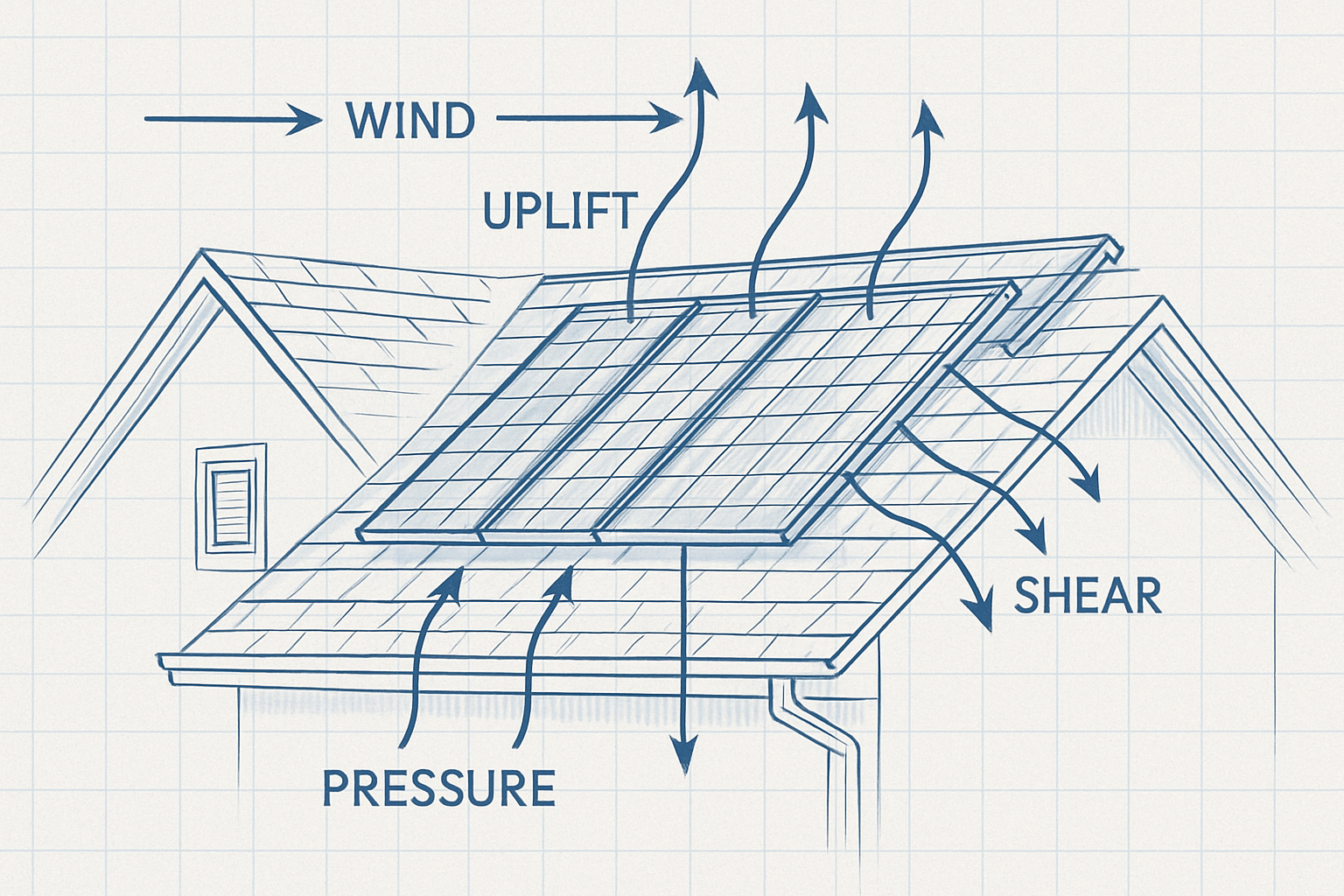

Code compliance is more than a bureaucratic hurdle. It signifies that an installation adheres to established engineering principles designed to handle local weather conditions, such as wind uplift and snow loads. It ensures that all components are installed according to manufacturer specifications and national standards, like the International Building Code (IBC) and the National Electrical Code (NEC). A compliant system is a safe system, protecting against structural failure and electrical hazards.

The High Cost of Non-Compliance

Cutting corners on mounting hardware is a costly mistake. Non-compliant installations lead to failed inspections, requiring expensive and time-consuming rework. More critically, they can cause significant roof damage, from persistent leaks to compromised structural integrity. This can void both the roofing manufacturer's warranty and the solar equipment warranty, leaving the property owner with a significant financial burden. For an installer, the reputational damage can be irreversible.

Mounting Solutions for Asphalt Shingle Roofs

Asphalt shingle is one of the most common roofing materials, but its composition requires a specific approach to mounting to prevent water intrusion and ensure a secure attachment.

The Challenge: Penetrations and Sealing

Every penetration on a shingle roof is a potential leak point. While chemical sealants offer initial protection, they degrade over time due to UV exposure and temperature fluctuations. Relying solely on sealant is a recipe for a future callback. The industry standard is a dual-barrier system that combines mechanical flashing with sealant for robust, long-term waterproofing.

Best Practices for Shingle Mounts

The most reliable method for shingle roofs involves a lag bolt secured directly into a roof rafter, combined with a metal flashing. The flashing slides underneath the shingle course above the penetration point, using gravity to shed water away from the hole, much like the shingles themselves. Accurately locating the rafters is a critical first step. The materials used for mounting components are also vital for longevity. As noted in the International Energy Agency's report on Solar PV Global Supply Chains, materials like aluminum and galvanized steel are chosen for their corrosion resistance and strength, ensuring the mounting structure endures.

| Material | Corrosion Resistance | Cost | Best Use Case |

|---|---|---|---|

| Galvanized Steel (G90) | Good | Lower | Standard environments with moderate humidity. |

| Aluminum | Excellent | Moderate | Coastal areas and regions with high humidity or acid rain. |

Navigating the Complexities of Tile Roofs

Tile roofs, whether clay, concrete, or slate, present unique challenges due to the brittle nature of the material. The primary goal is to transfer the load of the solar array to the roof structure without cracking tiles or creating water channels.

The Risks: Breakage and Water Intrusion

Walking on a tile roof requires care, and drilling into tiles directly is almost never recommended. The concentrated pressure from a mounting stanchion can easily cause fractures, leading to immediate or future leaks. Water flows in unpredictable ways under tiles, so any penetration must be meticulously waterproofed at the roof deck level.

Code-Compliant Hardware: Tile Hooks and Replacements

Two primary code-compliant solutions exist for tile roofs. Tile hooks are metal brackets that slide under a tile and attach directly to the rafter or roof deck. The tile sits back in place over the hook, which has a mounting point that extends from underneath the tile's edge. This method avoids any pressure on the tile itself. Alternatively, tile replacement mounts are flashed metal plates shaped like the surrounding tiles. An existing tile is removed, the mount is installed in its place, and it provides a sturdy, waterproof platform for the racking system.

Mastering Metal Roof Installations

Metal roofs are durable and an excellent platform for solar, but the correct mounting approach depends entirely on the roof's profile. An incorrect choice can compromise the roof's integrity and void its warranty.

Standing Seam vs. Corrugated Profile

Metal roofs generally fall into two categories: standing seam and exposed fastener (like corrugated or R-panel). Standing seam roofs have raised ribs, or seams, where the panels connect. Exposed fastener roofs are attached to the structure with screws that penetrate the face of the metal.

Non-Penetrating Clamps for Standing Seam Roofs

The key advantage of a standing seam roof is the ability to mount a solar array without creating any holes. Non-penetrating clamps attach directly to the raised seams using set screws that grip the metal without piercing it. This method is fast, secure, and fully preserves the roof's warranty, making it the preferred solution for this roof type.

Penetrating Mounts for Corrugated Profiles

For corrugated or R-panel roofs, the mounts must penetrate the metal. The proper technique involves using a specialized bracket that attaches to the high point of a corrugation rib. This keeps the penetration point elevated from the main water channels. A high-quality EPDM sealing washer is used under the fastener head to create a long-lasting, flexible, and waterproof seal. It is crucial that the fasteners engage with the underlying structure (purlins or rafters), not just the thin metal sheet.

Ensuring Long-Term Performance and Reliability

A physically secure installation is the first step toward achieving optimal energy production. The mounting system is the critical link between the solar panels and the rest of the energy system.

The Role of System Integration

A robust mounting system ensures your panels remain in the optimal position to capture sunlight and deliver consistent power to your inverter and energy storage system. The efficiency of your entire setup hinges on this mechanical reliability. As detailed in the Ultimate Reference for Solar Storage Performance, matching your system's components is key to achieving energy independence, and that begins with a solid foundation on the roof.

Beyond the Mount: Torque Specs and Quality Checks

Installation quality extends to the fine details. Every bolt and clamp has a manufacturer-specified torque value. Over-tightening can strip threads or damage the roof, while under-tightening can allow components to loosen over time due to thermal expansion and vibration. After installation, a final quality check should confirm that rails are level, all seals are compressed correctly, and no components are under visible stress. This attention to detail is what separates a standard installation from a truly professional one.

A Final Check on Your Installation Strategy

Choosing the right mount for each roof type is a non-negotiable aspect of a professional solar installation. Investing the time and resources to use code-compliant, roof-specific hardware is the most effective way to eliminate callbacks. This approach not only ensures the safety and longevity of the system but also builds a reputation for quality and reliability. The ultimate goal is a secure, waterproof, and durable solar installation that provides clean energy for decades to come, reflecting the high standards needed for modern energy solutions. The International Renewable Energy Agency (IRENA) emphasizes the importance of robust infrastructure for integrating renewables, a principle that starts with each individual installation's quality, as discussed in their analysis of Grid Codes for Renewable Powered Systems.

Frequently Asked Questions

Can I use the same mount for all roof types?

No. Each roof type requires specialized hardware designed to address its unique characteristics, such as material fragility (tile), waterproofing methods (shingle), and profile (metal). Using the wrong mount can cause damage and will not be code-compliant.

Is sealant enough to waterproof a roof penetration?

Sealant alone is not a reliable long-term solution. It can degrade under UV exposure and temperature changes. Code-compliant installations use mechanical flashing, which physically diverts water, as the primary waterproofing method, with sealant acting as a secondary barrier.

Do I always need to attach mounts to the roof rafters?

Yes, for most roof types, attaching directly to rafters or structural purlins is critical. This ensures the system can withstand forces like wind uplift and snow loads. Attaching only to the roof decking is insufficient and will not pass inspection.

Does installing solar panels void my roof warranty?

It can if not done correctly. Using non-penetrating clamps on standing seam metal roofs often preserves the warranty. For other roofs, using manufacturer-approved, code-compliant mounting systems installed by a qualified professional is the best way to protect your warranty.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.