The long-term performance of a solar energy system relies heavily on its structural foundation. While panels and inverters often get the spotlight, the racking and mounting components are crucial for ensuring decades of reliable energy production. A well-executed design blueprint that addresses corrosion from day one is fundamental. This involves a three-pronged approach: using isolators to prevent galvanic reactions, designing for effective water drainage, and implementing a robust fastener strategy.

The Science of Corrosion in Solar Installations

Corrosion is a natural process that degrades materials, but in solar installations, it can compromise structural integrity, leading to safety hazards and costly repairs. Understanding its mechanisms is the first step toward prevention.

Understanding Galvanic Corrosion

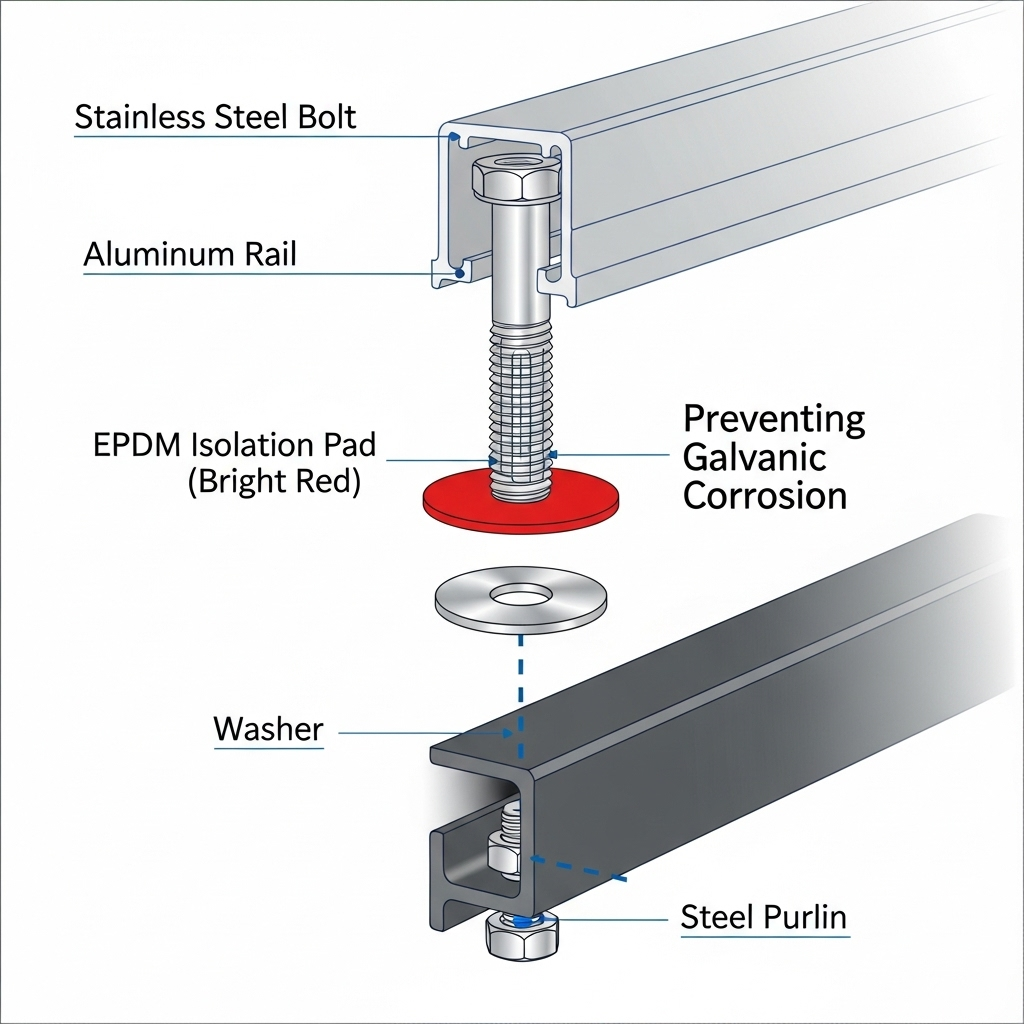

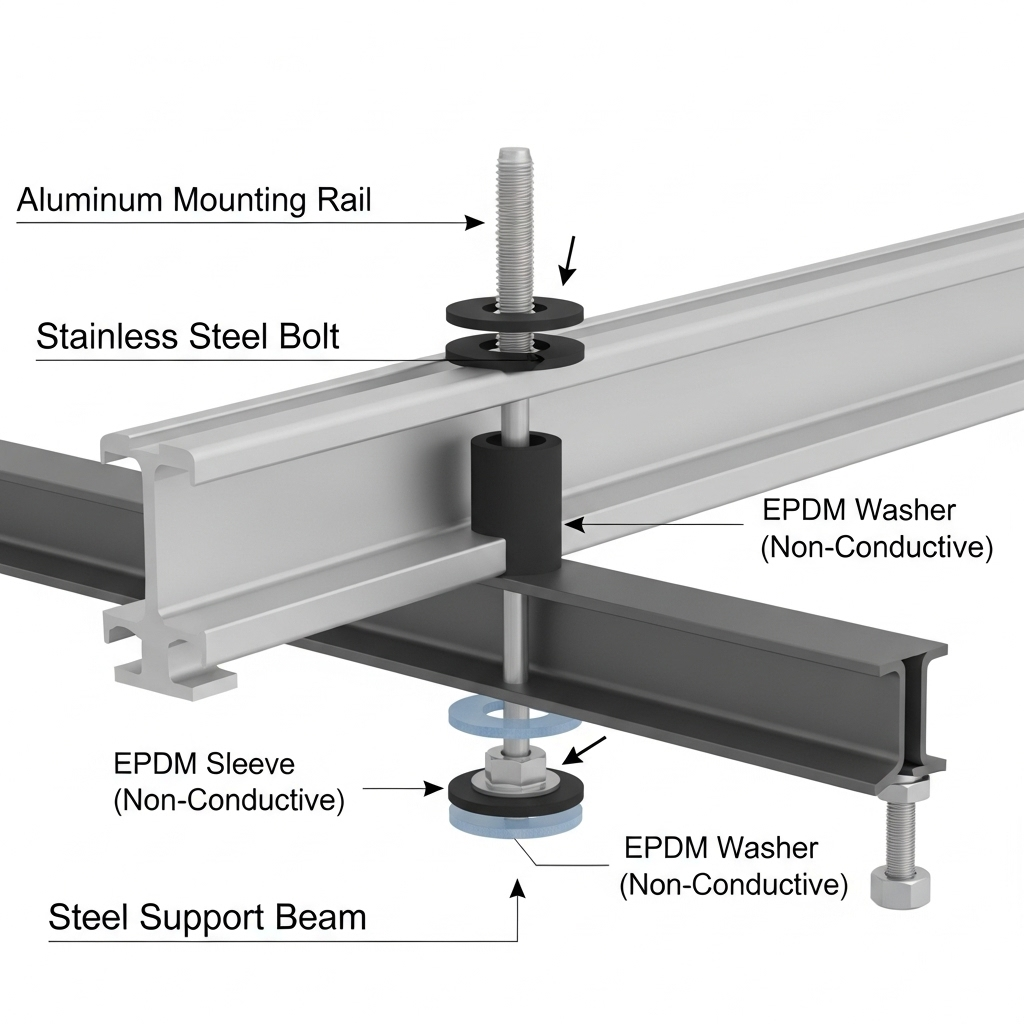

Galvanic corrosion occurs when two different metals are in electrical contact in the presence of an electrolyte, like water. One metal becomes the anode and corrodes at an accelerated rate, while the other becomes the cathode. In solar arrays, common examples include stainless steel fasteners used on aluminum frames or aluminum racking mounted on a galvanized steel substructure. Without a proper barrier, the aluminum will sacrifice itself to protect the steel, weakening the system over time.

Environmental Factors That Accelerate Corrosion

The installation environment plays a significant role in the rate of corrosion. Coastal and marine locations are particularly harsh due to high salt content in the air and humidity, which creates a highly conductive electrolyte. Industrial zones with airborne pollutants can lead to acid rain, which also speeds up material degradation. Even in less severe climates, moisture from rain, snow, and condensation is enough to initiate and sustain the corrosion process if the system is not designed correctly.

Strategic Use of Isolators for Galvanic Isolation

The most direct way to stop galvanic corrosion is to break the electrical circuit between dissimilar metals. This is achieved by using galvanic isolation fasteners and barriers.

What Are Isolation Barriers?

Isolation barriers are components made from non-conductive materials that physically separate dissimilar metals. These can be polymer pads, EPDM rubber washers, or specialized sleeves and coatings. Their function is simple but critical: they prevent electron flow between the metals, effectively halting the galvanic corrosion process before it can begin. This small addition to a system's design can add years to its operational life.

Selecting the Right Isolation Materials

Not all non-conductive materials are suitable for solar applications. The chosen isolators must be durable enough to withstand decades of outdoor exposure. Key properties to look for include UV resistance to prevent degradation from sunlight, high compressive strength to avoid being crushed under load, and a wide operating temperature range. EPDM (ethylene propylene diene monomer) and high-quality polymers are common choices due to their proven longevity and resilience in harsh conditions.

The Critical Role of Drainage in System Longevity

Water is a key ingredient for corrosion. Managing its presence effectively is a cornerstone of a durable design blueprint. Where water is allowed to pool, it creates a persistent corrosive environment.

Why Water Management is Essential

Beyond being an electrolyte, standing water can cause other problems. It can concentrate salts and pollutants, creating a more aggressive corrosive solution. In colder climates, trapped water that freezes and thaws can exert immense physical force, potentially warping racking components or compromising connections. Proper drainage is not just about corrosion prevention; it is about maintaining the physical stability of the entire array. As noted in the IEA report Harnessing Variable Renewables, the physical availability and integrity of renewable energy plants are fundamental to their ability to contribute to the grid.

Design Principles for Effective Drainage

Good design guides water away from critical areas. Racking rails should be installed at an angle that encourages runoff. Components that could trap water, such as U-channels, should include weep holes or drainage paths to allow moisture to escape. Avoiding crevice-like designs where water can become trapped through capillary action is also important. Every part of the mounting system should be designed with water's path in mind.

A Robust Fastener Strategy for Long-Term Security

Fasteners are the bolts, nuts, and clips that hold the entire solar array together. Their failure can have catastrophic consequences, making their selection and installation a critical part of the overall design strategy.

Choosing the Right Fasteners and Coatings

The material of a fastener dictates its corrosion resistance. Stainless steel is a popular choice, with grade 316 offering superior protection in coastal environments compared to grade 304. For applications involving aluminum, using stainless steel fasteners with a non-conductive washer and sleeve is an effective galvanic isolation fastener strategy. Additionally, advanced coatings can provide another layer of defense. Zinc-flake and ceramic coatings offer excellent barrier protection, isolating the fastener from the environment and surrounding metals.

Integrating Fasteners with Overall System Performance

A secure physical structure is the prerequisite for optimal electrical output. If components shift or fail due to corrosion, it can lead to damaged wiring, reduced power generation, and safety risks. Ensuring the racking and fasteners remain stable for decades is fundamental to achieving the lifetime energy production goals. This physical reliability underpins the system's ability to meet the performance benchmarks detailed in comprehensive resources like the Ultimate Reference for Solar & Storage Performance. The long-term stability of generating assets is also a key factor in grid integration, as stable operation is necessary to comply with technical requirements. According to an IRENA report, Grid Codes for Renewable Powered Systems, defining and adhering to robust technical requirements is essential for good system functioning.

Synthesizing the Design Blueprint

A resilient solar installation is the result of a holistic design approach where individual components work together to combat environmental threats. Isolators, drainage, and fasteners are not separate items on a checklist; they are part of an integrated strategy to ensure safety, longevity, and performance.

| Feature | Poor Design (High Corrosion Risk) | Good Design (Low Corrosion Risk) |

|---|---|---|

| Metal Contact | Direct contact between aluminum racking and steel purlins | Polymer isolation pads separate dissimilar metals |

| Drainage | Flat rails with no weep holes, allowing water to pool | Tilted design with integrated drainage channels |

| Fasteners | Uncoated steel bolts used in aluminum frames | 316 stainless steel fasteners with EPDM isolating washers |

| Maintenance | Reactive approach, fixing failures as they occur | Proactive design that minimizes future maintenance needs |

By focusing on these foundational design elements, you can significantly enhance the durability and financial return of a solar energy asset. It is a blueprint for building systems that last.

Frequently Asked Questions

Can I use stainless steel bolts directly on an aluminum rack?

It is not recommended. While stainless steel and aluminum are often used together, direct contact creates a galvanic cell that will cause the aluminum to corrode. Always use a non-conductive washer or sleeve to create an isolation barrier between the two metals.

How often should I inspect my solar racking for corrosion?

A visual inspection should be part of your annual system check-up. Look for signs of rust, pitting, or chalky residue, especially around fasteners and connection points. In harsh environments like coastal areas, more frequent inspections (e.g., every six months) may be beneficial.

Are isolation pads necessary in dry climates?

Yes, they are still a very good practice. Even in dry climates, morning dew, condensation, and occasional rain can provide enough moisture to act as an electrolyte and initiate galvanic corrosion. Since isolation pads are a low-cost preventive measure, they provide valuable insurance for the system's long-term health.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.