A solar panel system's long-term success often depends on components you cannot see. While panels and inverters get most of the attention, the waterproofing method used for a roof mounting system is what protects your home from the elements. Improperly sealed roof penetrations are a primary cause of leaks, which can lead to costly structural damage and undermine your entire energy investment. This detailed process explains correct flashing installation, a critical skill for any secure and durable solar array.

Understanding the Role of Flashing in Roof Mounting Systems

Flashing is the first line of defense against water intrusion where solar mounting hardware penetrates the roof. Getting this part right is fundamental to the safety and longevity of both your home and your solar power system.

What is Flashing and Why is it Crucial?

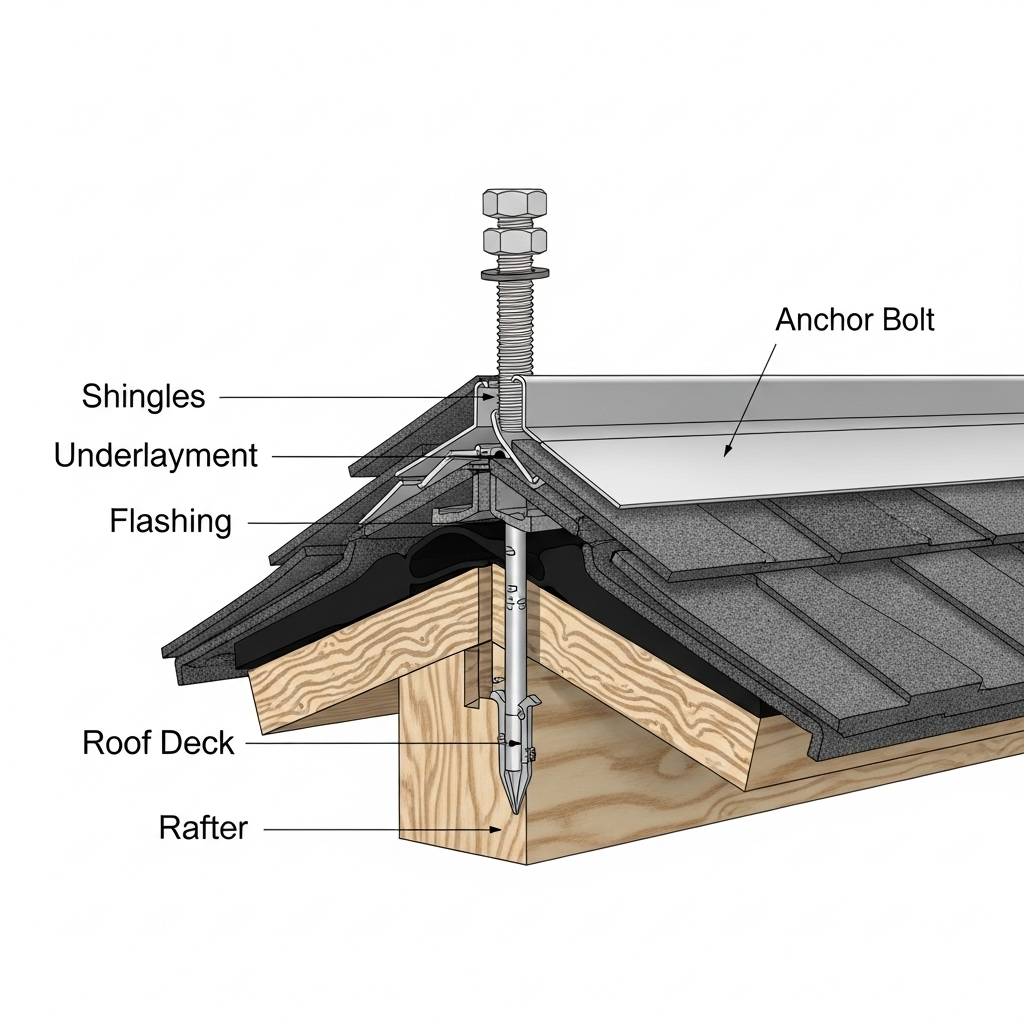

Flashing is a thin material, typically aluminum or galvanized steel, designed to direct water away from critical areas of the roof. For solar installations, it creates a waterproof barrier around each bolt or screw that fastens the racking system to the roof's structural frame. Its function is simple but vital: to maintain the integrity of your roof's water-shedding layers. A failure in the flashing can lead to slow, undetected leaks that cause wood rot, mold growth, and expensive ceiling or attic repairs. Proper flashing techniques ensure that each penetration point is as waterproof as the rest of the roof surface.

Types of Flashing for Solar Installations

Different roof types and mounting hardware require specific flashing solutions. Selecting the appropriate type is the first step in a successful leak prevention method. The most common options are designed to integrate seamlessly with existing roofing materials.

| Flashing Type | Best For | Installation Notes | Relative Cost |

|---|---|---|---|

| L-Foot Flashing | Asphalt Shingle Roofs | Slides under an upper course of shingles. Fast and effective for standard compositions roofs. | Low |

| Standoff Flashing | Multiple Roof Types | Uses a metal cone or base that elevates the mounting post, providing a robust, multi-layered seal. | Medium |

| Tile Flashing | Clay or Concrete Tile Roofs | Designed to replace a full tile or slide underneath a lifted tile, matching the roof's contour. | High |

| Mounting Blocks | Metal Roofs | Used on corrugated or trapezoidal profiles. Combined with butyl tape to create a form-fitting, watertight seal. | Medium |

Pre-Installation Checklist: Preparing for a Watertight Seal

Thorough preparation prevents poor performance. Before drilling any holes, gathering the right materials and assessing the work area are necessary steps for an effective roof flashing installation.

Essential Tools and Materials

Having the correct equipment on hand makes the process smoother and safer. Your toolkit should include:

- Pry bar for gently lifting shingles

- Caulking gun for sealant application

- High-quality roofing sealant rated for UV exposure and your specific climate

- Complete flashing kits compatible with your racking system

- Appropriately sized lag bolts or structural screws

- Tape measure and chalk line for accurate layout

- Stud finder to locate roof rafters

- Drill with correctly sized bits

Roof Assessment and Layout Planning

First, always locate the roof rafters. Securing mounts directly to these structural members is non-negotiable for safety and stability. Use a stud finder and snap chalk lines to mark their centers. Next, plan your array layout and mark the precise penetration points. This ensures the final installation is aligned and aesthetically pleasing. Before you begin, inspect the roof's condition. Look for cracked shingles, soft spots, or signs of existing damage. Installing a solar array on a roof near the end of its life is unwise; any necessary repairs should be completed first.

The Step-by-Step Flashing Installation Process

This section details the installation method for standard L-foot flashing on an asphalt shingle roof, one of the most common residential applications. The core principles apply to other systems as well.

Step 1: Preparing the Shingles

Use a flat pry bar to carefully break the seal on the shingle directly above your marked drilling location. Gently lift it just enough to provide access to the area underneath. Avoid bending it excessively, especially in cold weather, as old shingles can become brittle and crack.

Step 2: Drilling the Pilot Hole

Drill a pilot hole through the shingle and roof decking, ensuring it is centered on the rafter you previously located. The pilot hole should be slightly smaller than the diameter of the lag bolt to ensure a tight grip. A clean, precise hole is the foundation for a strong mechanical and waterproof connection.

Step 3: Applying the Sealant

Fill the pilot hole completely with a high-quality roofing sealant. This creates a seal around the threads of the lag bolt. Next, apply a generous layer of sealant to the underside of the metal flashing. This second application will create a gasket between the flashing and the roof deck, preventing any lateral water migration.

Step 4: Installing the Flashing and Mount

Slide the flashing into position, making sure its top edge is situated well underneath the course of shingles above it. The flashing should lay flat and be aligned with the pilot hole. Place the L-foot or other mounting hardware over the flashing's attachment point and drive the lag bolt through it, securing the entire assembly firmly into the rafter. Tighten until the rubber gasket on the mount is slightly compressed, but do not overtighten. Over-torquing can warp the flashing or damage the shingle.

Step 5: Final Sealing and Finishing

The final step is to ensure the upper shingle lays flat over the newly installed flashing. The flashing is engineered to direct water down and over the shingle below it, maintaining the roof's natural water-shedding properties. No sealant should be applied to the exterior surface of the flashing, as this can trap water and impede proper drainage.

Advanced Considerations for Different Roof Types

Not all roofs are the same. Tile and metal roofs require specialized flashing techniques to ensure a leak-proof installation that lasts.

Flashing on Tile Roofs

Installing solar on tile roofs is more complex because of the brittle nature of the material. The process often involves removing a tile, installing a deck-level flashing and standoff, and then replacing the original tile after cutting or grinding it to fit around the standoff. Alternatively, specialized flashing products are available that completely replace a tile, offering an integrated and highly reliable seal.

Flashing on Metal Roofs

For standing seam metal roofs, non-penetrating clamps are the preferred method, as they attach directly to the seams without creating any holes. For corrugated or trapezoidal metal roofs, mounts are secured to the high points of the profile. These systems use specialized mounting blocks with a thick butyl gasket on the bottom that conforms to the roof's shape, creating a durable, compression-based seal.

Long-Term Performance and Maintenance

A proper installation is the basis for decades of reliable performance. Protecting your investment involves not just the hardware itself, but ensuring it is mounted on a secure, waterproof foundation.

The Role of System Monitoring

Once your hardware is securely in place, understanding its output is key. Monitoring helps you gauge the effectiveness of your setup and ensures you get the most from your investment. For a deeper look into system metrics, the ultimate reference on solar storage performance provides valuable insights into tracking and optimizing your energy generation. A well-installed physical system is the foundation for the performance data you will track for years to come.

Inspection and Leak Prevention

Periodic visual inspections of your roof, perhaps once a year, can help you spot potential issues before they become serious problems. Check the sealant around the flashing for any signs of cracking or degradation. Ensure no leaves or debris have accumulated around the mounts, which could obstruct water flow. Governments and international bodies recognize that proper installation practices are vital for the growth of solar energy. As noted by the IEA, complex local regulations can sometimes be a barrier to adoption. According to the IEA's report, Barriers to Technology Diffusion: The Case of Solar Thermal Technologies, simplifying permitting processes can remove legal barriers and encourage safer, more widespread adoption of solar technologies.

A Foundation for Energy Independence

Correct flashing installation is a non-negotiable part of any rooftop solar project. It is a detailed task where precision and the right materials make all the difference. While it may seem like a small step in the overall process, it is the one that directly protects your home from water damage. By following these steps, you ensure your solar array is built on a solid, secure, and waterproof foundation, ready to provide clean energy for decades while preserving the integrity of your home.

Frequently Asked Questions

Can I use roofing tar instead of specialized sealant?

It is not recommended. Specialized roofing sealants are formulated for longevity, UV resistance, and compatibility with flashing materials. Roofing tar can degrade more quickly under sun exposure and may not provide a durable, flexible seal, leading to premature failure.

How tight should the lag bolts be?

The lag bolts should be tightened until the gasket on the L-foot or mount is compressed, creating a seal. Avoid overtightening, as this can damage the shingle, warp the flashing, or create a depression where water can pool. Following the manufacturer's torque specifications is always the best practice.

Do I need flashing for every roof penetration?

Yes. Every point where a fastener penetrates the roof's water-shedding surface must be properly sealed with flashing. Skipping even one can compromise the entire roof and lead to significant water damage over time. There are no shortcuts to proper waterproofing.

What is the most common mistake during flashing installation?

A common mistake is improper placement of the flashing. The flashing must be installed so that the upper course of shingles covers the top of the flashing, allowing water to flow over it, not under it. Another frequent error is relying solely on sealant without a mechanical flashing component, a method often referred to as 'sealant-only' which is not a durable long-term solution.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.