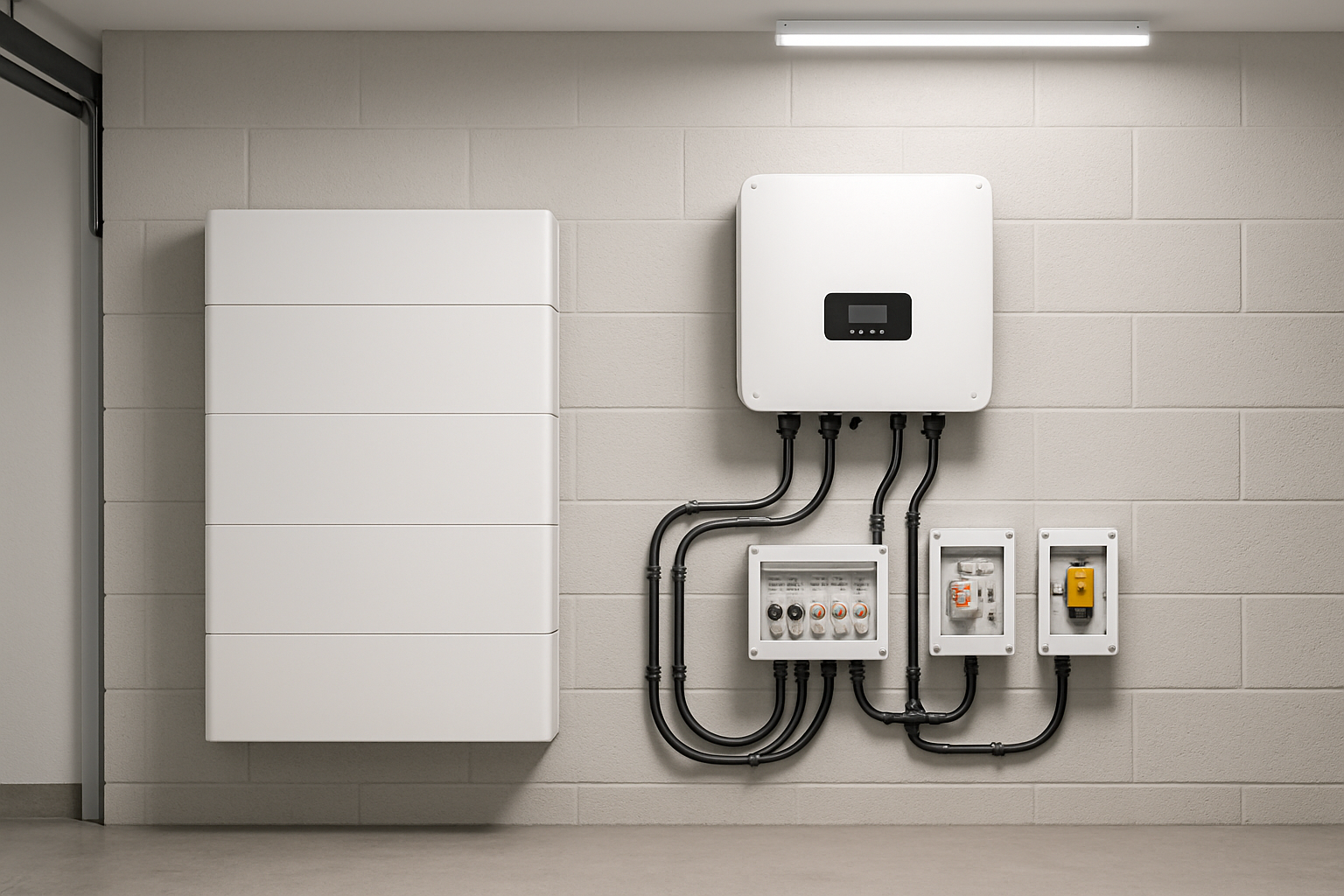

Installing a home energy storage system is a significant step toward energy independence. The core of this system, the battery bank, requires meticulous attention to detail during installation. Proper wiring is not just about performance; it is fundamental to the safety and longevity of your investment. An incorrect connection can lead to equipment failure, reduced efficiency, or even severe safety hazards. This guide outlines seven critical wiring errors to prevent, ensuring your system operates reliably for years.

1. Using Undersized Wires

One of the most frequent and dangerous errors is selecting wires with an inadequate gauge for the electrical current they must carry. This mistake can have severe consequences for your home battery installation.

The Dangers of Inadequate Gauge

Think of a wire like a water pipe. Pushing too much water through a small pipe creates high pressure and friction. Similarly, forcing high amperage through an undersized wire generates excessive resistance. This resistance leads to a voltage drop, which starves your inverter of the power it needs, and causes the wire to heat up. In a worst-case scenario, this overheating can melt the wire’s insulation and become a serious fire hazard.

How to Select the Correct Wire Size

Choosing the correct wire size, or gauge, depends on two main factors: the amperage of the circuit and the length of the wire run. Higher amperage and longer distances require thicker wires (a lower gauge number). Always consult the National Electrical Code (NEC) ampacity charts and the specifications provided by your equipment manufacturer. Using a wire gauge calculator can simplify this process. Investing in correctly sized, high-quality copper wiring is a non-negotiable part of a safe installation.

2. Improper Torque and Loose Connections

A secure connection is an efficient and safe connection. The terminals on your batteries, inverters, and bus bars are designed for specific tightness, and failing to meet these specifications can undermine your entire system.

The Hidden Risk of Arcing

A loose connection creates a point of high resistance. As electricity struggles to jump this tiny gap, it can create an electrical arc. This arc generates intense heat, capable of melting terminal posts and destroying equipment. These hot spots are a significant fire risk and a common point of failure in DIY installations. They also cause intermittent power issues that are difficult to diagnose.

Best Practices for Secure Terminals

The only reliable way to tighten terminal connections is with a calibrated torque wrench. Every manufacturer provides precise torque values (measured in Newton-meters or foot-pounds) for their equipment. Tighten each bolt to this exact specification. It is also good practice to re-check the torque of all connections a few weeks after the initial installation, as wires can settle, and then check them annually as part of routine system maintenance.

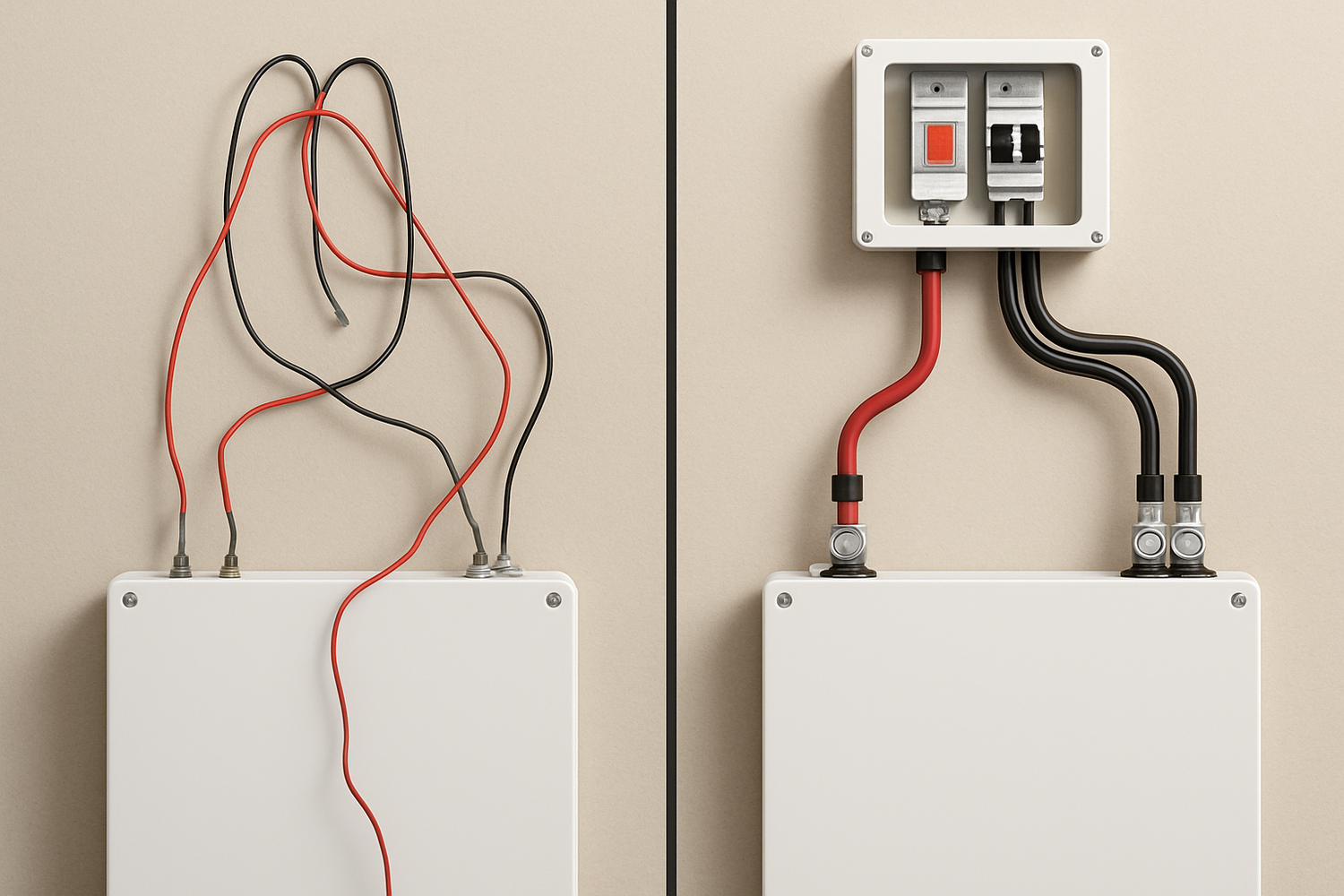

3. Neglecting Overcurrent Protection

Overcurrent protection devices (OCPDs), such as fuses and circuit breakers, are the essential safety gates of your electrical system. They are designed to protect both your wiring and your equipment from damaging current levels.

Fuses vs. Circuit Breakers

Both fuses and circuit breakers interrupt the flow of electricity during an overload or short circuit. Fuses are single-use devices that must be replaced after they blow, while circuit breakers can be manually reset. For main battery connections, high-quality, DC-rated fuses or breakers are necessary. The choice between them often depends on the system design and local code requirements.

Correct Placement and Sizing

An OCPD must be placed on every ungrounded conductor. For a simple battery-to-inverter connection, this means installing a fuse or breaker as close to the battery's positive terminal as possible. The device should be sized to protect the wire. A common rule is to size the OCPD at approximately 125% of the continuous operating current of the circuit. This allows the system to handle normal operation without nuisance tripping while providing immediate protection against dangerous faults.

4. Incorrect Series and Parallel Connections

How you connect multiple batteries to form a larger bank determines the bank's voltage and capacity. A mistake here can lead to poor performance, battery damage, and a shortened lifespan for your energy storage.

Balancing Voltage and Capacity

There are two fundamental ways to wire a battery bank:

- Series Connection: Connecting batteries positive-to-negative increases the total voltage while keeping the amp-hour capacity the same. (e.g., two 12V 100Ah batteries in series become a 24V 100Ah bank).

- Parallel Connection: Connecting batteries positive-to-positive and negative-to-negative increases the amp-hour capacity while keeping the voltage the same. (e.g., two 12V 100Ah batteries in parallel become a 12V 200Ah bank).

Your system's inverter will dictate the required nominal voltage (12V, 24V, or 48V).

Common Errors and Their Consequences

A critical error is mixing batteries of different capacities, ages, or even charge levels within the same bank. This creates an imbalance where stronger batteries overcharge weaker ones, leading to permanent damage and capacity loss. Always build a battery bank using identical batteries purchased at the same time. Ensure all interconnect cables between batteries are the exact same length and gauge to promote balanced charging and discharging.

5. Ignoring Battery Ventilation and Spacing

Batteries are chemical devices that generate heat during operation. Managing this thermal output is crucial for performance and safety, even with stable chemistries like Lithium Iron Phosphate (LiFePO4).

Thermal Management is Key

Excessive heat is the enemy of battery longevity. High ambient temperatures can reduce a battery's lifespan and efficiency. While LiFePO4 batteries are far more thermally stable than other lithium chemistries, they still perform best within a specific temperature range. Poor ventilation traps heat, forcing the battery management system (BMS) to work harder and potentially derate performance to protect the cells. According to research on solar storage performance metrics, maintaining optimal temperature is a key factor in achieving the expected cycle life of a battery.

Guidelines for Proper Installation

Follow the manufacturer's recommendations for spacing. A general guideline is to allow at least an inch of clear airspace around each battery to permit natural convection. If the batteries are housed in an enclosure, ensure the enclosure has adequate ventilation ports, preferably with both high and low vents to create a natural airflow path. For larger systems, a thermostatically controlled fan may be necessary.

6. Inadequate System Grounding

Grounding is a critical safety feature that protects you and your equipment from electrical faults. It provides a safe path for stray electrical current to travel to the earth, preventing dangerous shocks.

The Role of Grounding in Safety

In the event of a short circuit where a live wire touches a metal component, a proper ground connection causes the overcurrent protection device to trip immediately, de-energizing the circuit. Without a ground, the metal casing of your inverter or battery enclosure could become energized, creating a lethal shock hazard.

System Grounding vs. Equipment Grounding

An energy storage installation requires two types of grounding: equipment grounding and system grounding. Equipment grounding involves connecting all metallic, non-current-carrying components (like inverter chassis and racking) to the ground. System grounding involves connecting one of the current-carrying conductors (usually the negative side in a DC system) to the ground. Both are essential and must be implemented according to local electrical codes.

7. Disregarding Manufacturer Specifications

Every component in your home energy storage system—the batteries, inverter, solar charge controller—comes with a detailed installation manual. Ignoring these documents is a recipe for failure.

The Manual is Your Best Resource

The engineers who designed your equipment know how to install it safely and effectively. The manual contains critical information, including torque specifications, required wire sizes, OCPD ratings, and environmental operating limits. As the International Renewable Energy Agency (IRENA) points out in its Innovation Outlook on smart charging, standardization and interoperability are key to reliable energy systems, and following manufacturer guidelines is the first step toward that goal.

Warranty and Compliance

Failing to follow the installation instructions provided by the manufacturer will almost certainly void your warranty. More importantly, it can result in a non-compliant and unsafe system that may not pass an electrical inspection. The growth in home energy storage is a vital part of the clean energy transition, as noted by the IEA's Clean Energy Innovation report, and proper installation ensures these systems contribute positively and safely to the grid.

A Final Check for System Integrity

Proper wiring is the foundation of a safe and efficient home energy storage system. By avoiding these seven common mistakes—from sizing wires correctly to respecting manufacturer specifications—you protect your equipment, your home, and your energy independence. A carefully planned and executed installation ensures your system will deliver clean, reliable power for its entire service life. Always prioritize safety and, when in doubt, consult with a qualified professional electrician.

Disclaimer: This information is for educational purposes only. Always follow local electrical codes and consult with a licensed electrician for your specific installation. This is not professional engineering or legal advice.

Frequently Asked Questions

What is the biggest risk of poor wiring in a solar battery system?

The single greatest risk is fire. Overheating from undersized wires, arcing from loose connections, or a failure to contain a short circuit with proper fusing can all lead to catastrophic failure and fire hazards.

Can I use the same size wire for all connections?

No, this is not a safe practice. Wire size must be calculated for each specific connection based on the maximum current it will carry and its length. The main cables connecting the battery to the inverter will need to be much thicker than the wires connecting a charge controller to the batteries, for example.

How often should I check my battery connections?

It is recommended to check the torque on all high-current connections about 30 days after the initial installation to account for any settling. After that, a visual inspection and torque check should be part of an annual system maintenance routine.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.