Residential energy storage systems are becoming a cornerstone of modern homes, offering energy independence and reliability. To safeguard this significant investment, a systematic approach to protection is necessary. This checklist details the critical measures for keeping your home battery system safe, efficient, and durable. Proper protection ensures your system not only performs optimally but also operates safely for years to come.

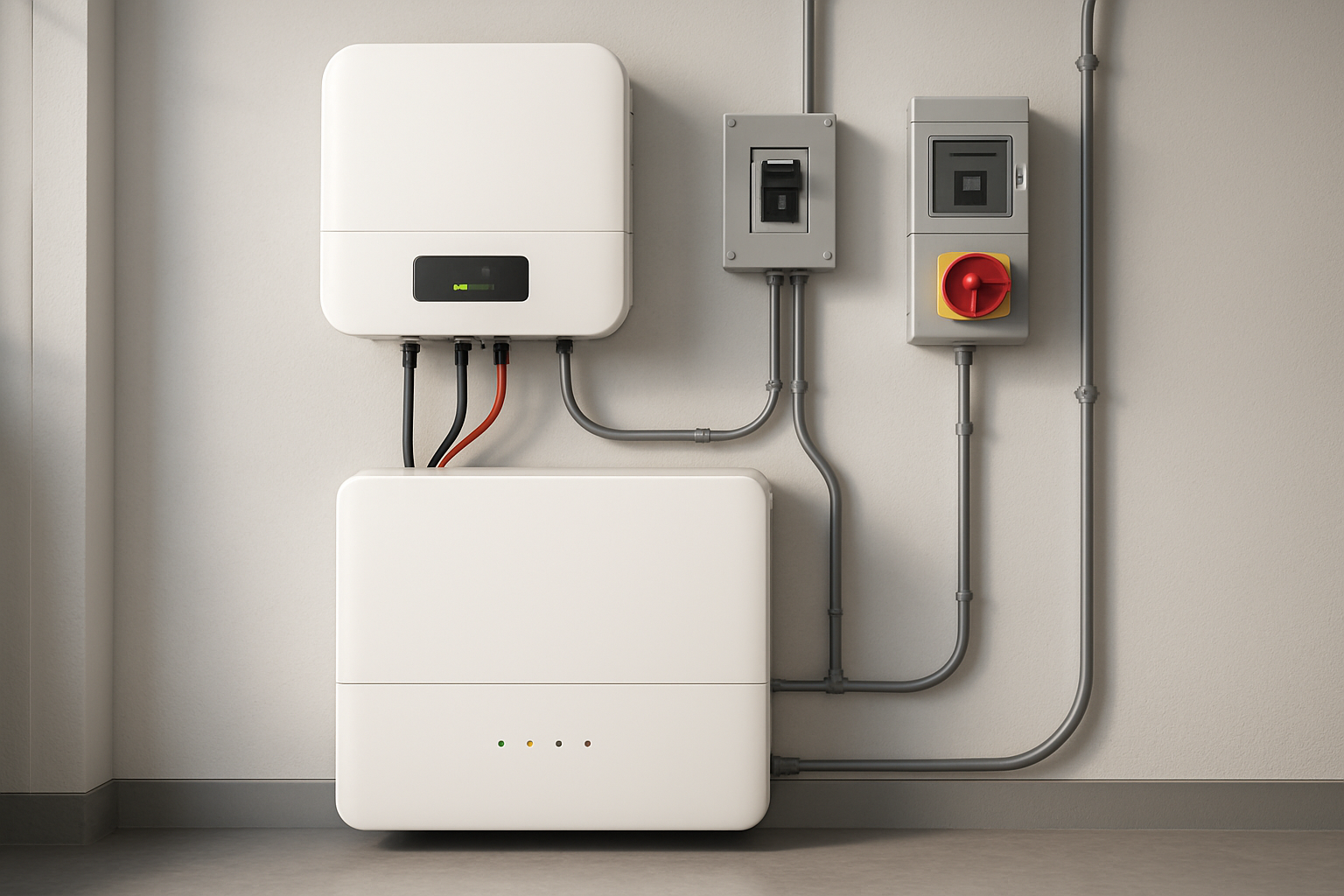

Foundational Electrical Protection

The first layer of defense for any energy storage system involves robust electrical safeguards. These components protect against common electrical faults that could otherwise damage your equipment or pose a safety risk.

Overcurrent Protection: Fuses and Circuit Breakers

Overcurrent protection devices are your primary defense against short circuits and overloads. A short circuit can release a massive amount of energy from a battery, creating a severe fire hazard. Circuit breakers and fuses are designed to interrupt the flow of electricity when the current exceeds a safe level. It is crucial to select DC-rated breakers for DC circuits, as they are specifically designed to handle the unique properties of direct current. Sizing these devices correctly depends on the battery's maximum discharge current, the inverter's requirements, and the gauge of the wire used.

Surge Protection Devices (SPDs)

Voltage spikes, often caused by lightning strikes or fluctuations in the utility grid, can instantly destroy sensitive electronics within your inverter and battery system. A Surge Protection Device (SPD) diverts this excess voltage safely to the ground. For comprehensive protection, SPDs should be installed at both the main service entrance and on the circuits connecting to your energy storage system.

Proper Grounding and Bonding

A correct grounding system provides a safe path for fault currents to travel, preventing electrical shock and protecting equipment. All metallic, non-current-carrying components of the system, including battery racks, inverter chassis, and conduits, should be bonded together and connected to the grounding system. This creates an equipotential plane, minimizing dangerous voltage differences between components during a fault.

Battery-Specific Safeguards

Beyond general electrical protection, the battery itself requires specialized monitoring and management to ensure its health and safety, particularly with advanced chemistries like Lithium Iron Phosphate (LiFePO4).

The Role of the Battery Management System (BMS)

The Battery Management System (BMS) is the intelligent core of a modern battery pack. This electronic system continuously monitors cell voltage, current, and temperature. Its primary protective functions include preventing overcharging, stopping discharge before voltage drops too low, and balancing the charge across all cells to maximize capacity and lifespan. A high-quality BMS is an indispensable feature of any reliable LiFePO4 battery system.

Thermal Management and Ventilation

Batteries operate most efficiently and safely within a specific temperature range. High temperatures degrade battery health and can create safety risks. Proper thermal management is therefore critical. This involves ensuring adequate ventilation around the battery to dissipate heat generated during charging and discharging. In regions with extreme temperatures, active heating or cooling systems may be necessary. As noted in the Innovation outlook: Thermal energy storage report by IRENA, innovations in thermal management are key to improving the performance of energy storage devices.

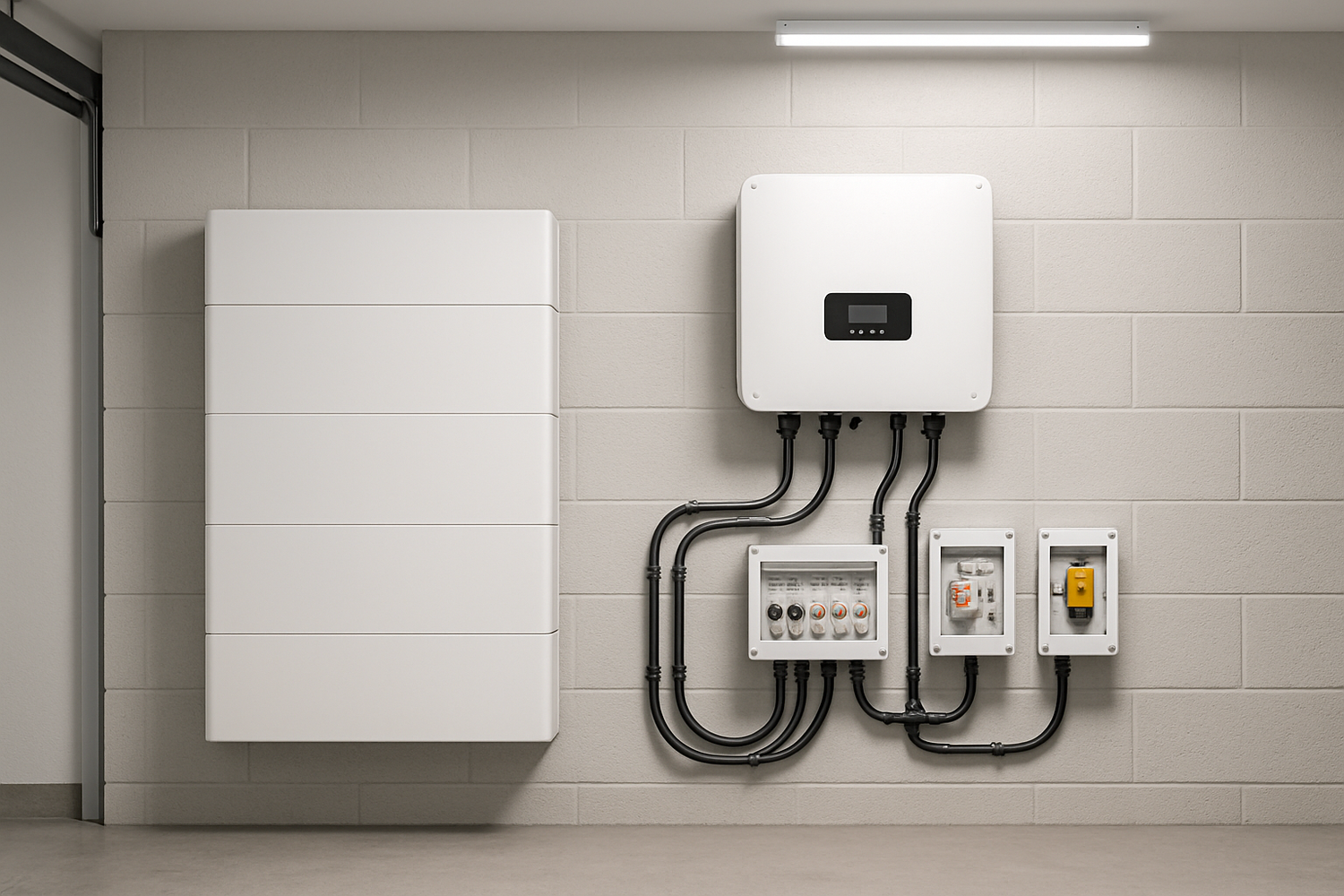

Physical Protection and Location

The physical location of your battery system impacts its safety and longevity. It should be installed in a clean, dry area away from direct sunlight and protected from physical impact. Avoid installation in primary living spaces or areas with flammable materials. Adhering to local building and fire codes for battery placement is mandatory for a safe installation.

System Integration and Wiring Best Practices

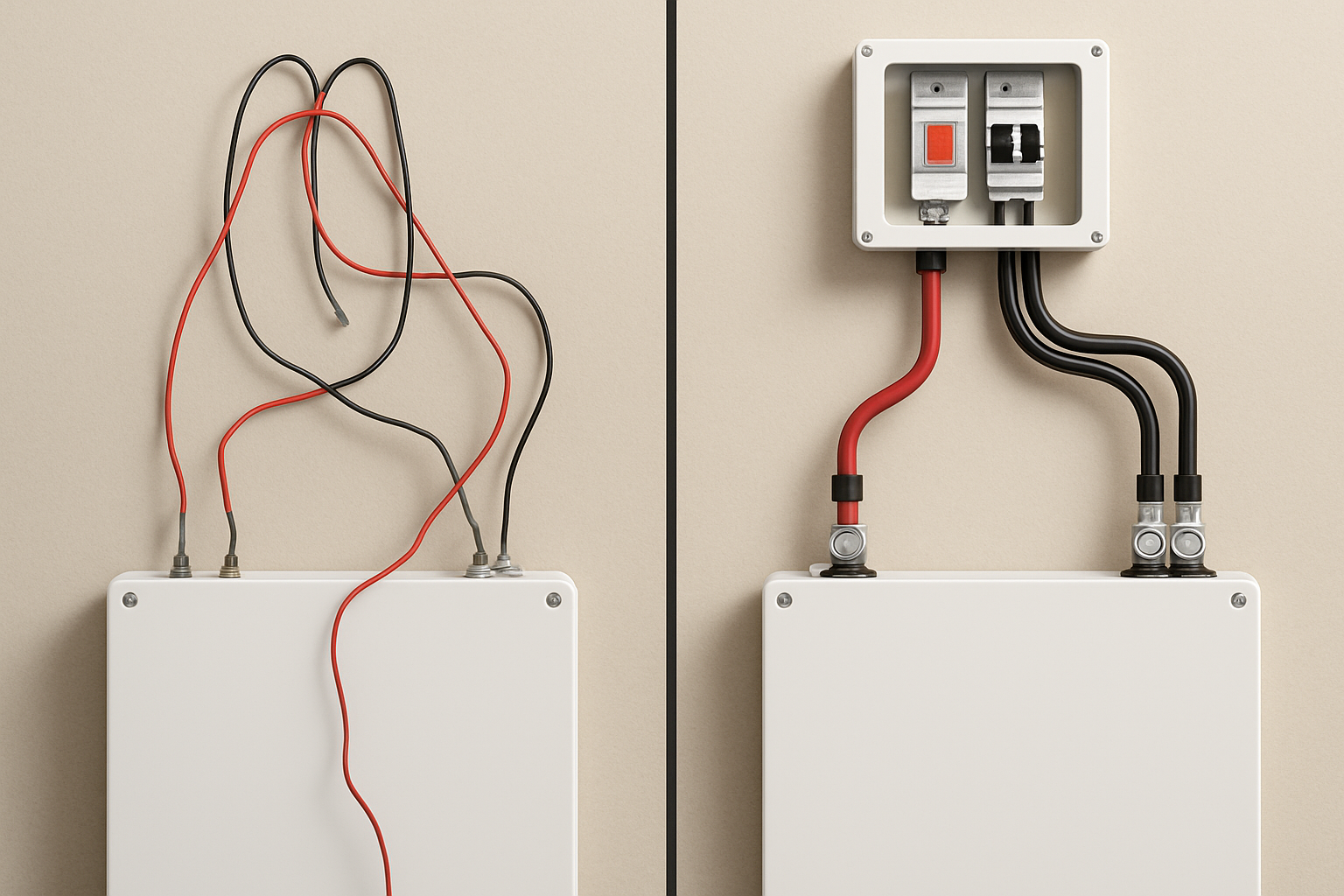

The quality of the installation, especially the wiring, is just as important as the components themselves. Poor wiring practices can undermine the entire system's safety and performance.

Correct Wire Sizing and Type

Using undersized wires is a common and dangerous mistake. Wires that are too small for the current they carry will overheat, melting the insulation and creating a significant fire hazard. Wire size (gauge) must be selected based on the maximum expected amperage and the length of the wire run. The table below provides a general reference.

| Amperage (A) | Recommended AWG Wire Size (Copper) |

|---|---|

| 20A | 12 AWG |

| 30A | 10 AWG |

| 50A | 8 AWG |

| 100A | 4 AWG |

| 200A | 2/0 AWG |

Disclaimer: This table is for illustrative purposes. Always consult the National Electrical Code (NEC) and your equipment's documentation for precise sizing.

Secure Connections and Terminations

A loose electrical connection acts as a point of high resistance. As current flows through it, this resistance generates heat, which can lead to component failure or fire. All connections, especially on high-current battery and inverter cables, must be clean and tight. Using a torque wrench to tighten terminals to the manufacturer's specifications is a professional best practice.

Inverter and Component Compatibility

An energy storage system is more than a collection of parts; it's an integrated system. All components must be designed to work together. This includes matching the battery's voltage to the inverter's input requirements and ensuring communication protocols between the BMS and inverter are compatible. The Solar Energy Perspectives report from the IEA emphasizes that inverters and other balance-of-system components are integral to the proper functioning of a complete solar and storage setup.

Monitoring and Maintenance for Long-Term Reliability

Protection is an ongoing process. Regular monitoring and maintenance are essential for catching potential issues early and ensuring your system provides decades of reliable service.

Implementing a Monitoring System

Modern energy storage systems often include sophisticated monitoring software that allows you to track performance in real-time. Key metrics like State of Charge (SoC), power production, and energy consumption provide valuable insights into your system's health. Setting up alerts for abnormal conditions can help you identify problems before they escalate. For a detailed breakdown of what to monitor, you can consult this ultimate reference on solar storage performance.

Routine Inspection and Maintenance Schedule

Periodic physical inspections complement remote monitoring. On a semi-annual basis, you should visually inspect all components, check that wiring connections are secure, and ensure ventilation ports are clean and unobstructed. The rapid deployment of solar and storage, as projected in the U.S. Department of Energy's Solar Futures Study, underscores the growing need for standardized, long-term maintenance protocols to ensure these assets remain productive and safe.

A System Built for Enduring Performance

Protecting your residential energy storage system is a multi-faceted task that combines correct electrical design, high-quality components, and diligent maintenance. By following a professional checklist that addresses electrical, battery-specific, and installation safeguards, you create a robust system. This comprehensive approach not only protects your hardware but also provides the security and peace of mind that comes with achieving true energy independence.

Frequently Asked Questions

What is the most critical protection device for a home battery?

While all components are important, the Battery Management System (BMS) is arguably the most critical. It directly protects the battery cells—the core of your system—from damaging conditions like overcharging, over-discharging, and extreme temperatures.

How often should I inspect my residential energy storage system?

A visual inspection every three to six months is a good practice. Check for loose connections, signs of corrosion, and ensure ventilation paths are clear. A more thorough professional inspection should be scheduled annually or as recommended by the manufacturer.

Can I use an AC circuit breaker for a DC application?

No, you should always use DC-rated breakers for DC circuits. DC electricity arcs differently than AC when a circuit is broken. Using an AC breaker in a DC system can fail to extinguish the electrical arc, creating a serious fire hazard.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.