Commissioning can be smooth, repeatable, and inspector friendly. This blueprint turns IEC 62446-1 requirements into field forms, acceptance ranges, and labeling that pass. You get plain language steps and record examples you can adapt to residential, commercial, and ESS-coupled PV.

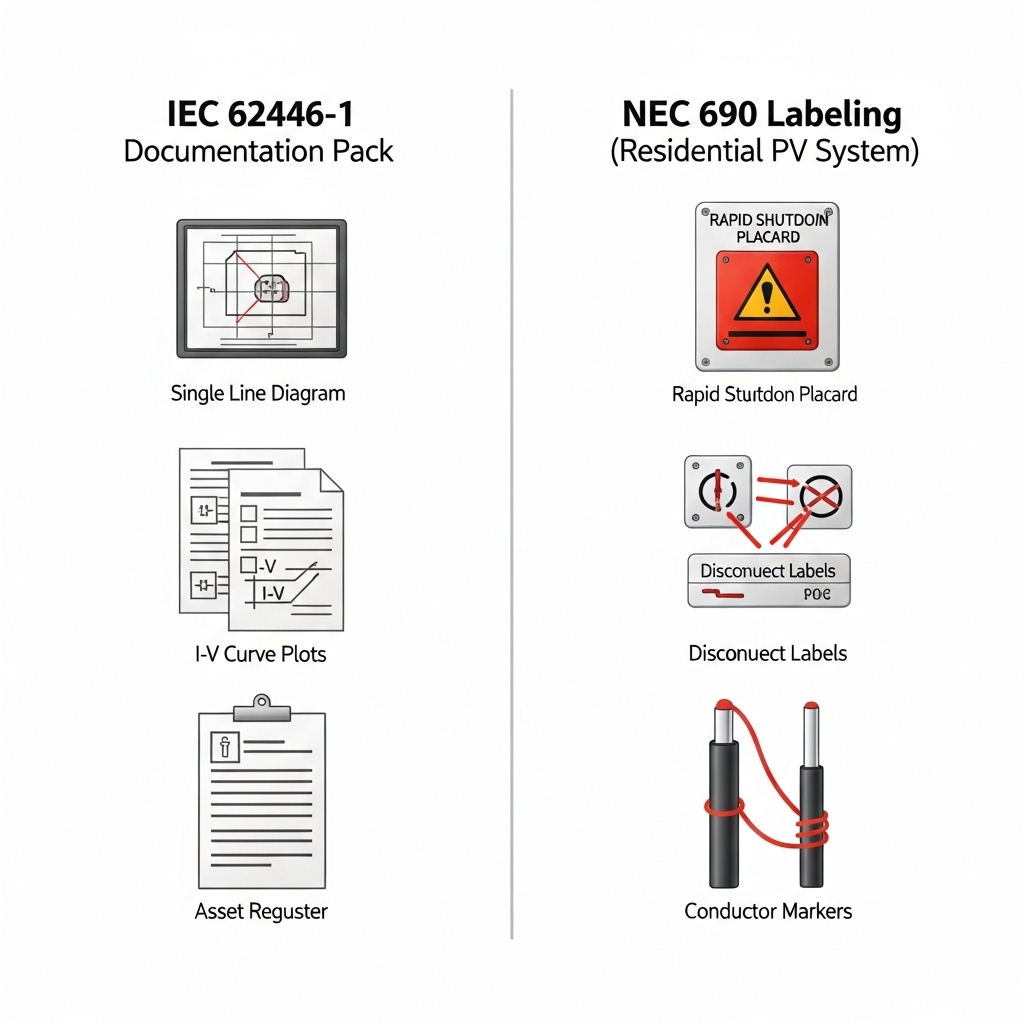

What IEC 62446-1 requires from your records

IEC 62446-1 focuses on system documentation, inspection, and electrical verification for PV commissioning. It tells you what to document and test, and how to present results. The standard sits in a wider quality stack that includes design and installation rules. For context, IRENA’s Quality infrastructure for smart mini-grids lists IEC 62548 for design and installation, IEC 61724 for performance, and IEC 62446 for commissioning. Use them together for a consistent pack.

Core record sets

- As-built documentation: single-line diagram, array layout, device datasheets, firmware versions, and cable schedules.

- Inspection checklist: mechanical integrity, labeling, cable routing, bonding, and enclosure ingress protection ratings.

- Electrical test results: polarity, continuity, insulation resistance, Voc/Isc per string, functional checks, and inverter start-up.

- Performance baseline: initial operating data and notes on irradiance and temperature conditions.

Sign-off, traceability, and calibration

- Tester identity, signature, and date for each section.

- Instrument model, serial number, calibration date, and certificate ID. Most AHJs accept calibration within 12 months.

- Photo evidence with timestamps for key checkpoints: labels, terminations, isolators, and nameplates.

Digital practices that save time

- Embed QR codes on labels that link to PDF packs and test records.

- Name files with a consistent key: site code, array ID, string ID, test type, and date.

- Store raw data from I‑V tracers and loggers to back up summary forms.

Commissioning tests and acceptance ranges that pass

IEC 62446-1 defines what to verify. Acceptance ranges are set by project specs and local rules. The table below lists practical ranges used on many jobs aligned to the standard forms. Confirm values with the engineer of record and local regulations.

| Test item | What to record | Typical acceptance range | Notes |

|---|---|---|---|

| Polarity check (DC) | Each string polarity at combiner and inverter input | No reversals; voltage sign correct | Record method and meter used |

| Continuity and bonding | Continuity of protective conductors and bonds | Low resistance path; values documented | Torque values and lug sizes noted |

| Insulation resistance (IR) per string | Test voltage, measured MΩ, conditions | ≥ 1 MΩ per string at suitable test voltage | De-energize; dry modules; note temperature |

| Open-circuit voltage Voc per string | Measured V, expected V at test conditions | Within about ±5% of expected | Correct for temp and irradiance |

| Short-circuit current Isc per string | Measured A, expected A | Within about ±10% of expected | Match module binning and tilt |

| I‑V curve (if used) | Curve file, Pmp, Voc, Isc, FF | Shape normal; Pmp within modeled tolerance | Document plane-of-array irradiance |

| RCD / GFDI check | Trip current and time | Within device specification | Record model and setting |

| Inverter start-up and anti-islanding | Startup time, protection events, reconnection time | Meets utility rules; stable operation | See IRENA listing of IEC 62116 |

| AC voltage, frequency, THD | At point of interconnection | Within utility code limits | Record instrument and location |

| Performance baseline | PR estimate, system output snapshot | Consistent with irradiance and temp | Refer to IEC 61724 |

Anti-islanding checks reference IEC 62116, which covers test procedures for inverters connected to mini-grids. This linkage is noted in the IRENA quality infrastructure overview. For US readers, see the U.S. Department of Energy solar energy page for inverter safety topics in plain terms.

Labeling and documentation requirements that align with tests

Good labeling lets inspectors map records to hardware in seconds. It also reduces return visits.

Hardware labels that match records

- Combiner boxes: unique ID, string range, maximum fuse rating, and short-circuit current rating.

- DC isolators: voltage rating, current rating, and lockout method.

- Inverters: equipment ID, firmware, fault codes legend, and clear AC and DC ratings.

- PV arrays: warning labels for DC hazard, arc flash boundary where required, and emergency shutdown legends.

Cable and string identification

- String IDs at module tail, combiner input, and inverter input.

- QR codes that link to the string test sheet and photos.

- Conduit and trench labels for route tracing, with depth or tray level where helpful.

ESS integration notes

For hybrid PV with storage, include battery nameplate data, BMS limits, and isolation points. A practical overview of storage performance metrics such as round-trip efficiency and capacity retention is summarized in this reference from our industry: Ultimate Reference: Solar Storage Performance. Use these metrics to set commissioning benchmarks for charge and discharge tests and to document initial state of health.

IEC 62446-1 commissioning test record examples

Example: 10 kW roof PV with AC-coupled ESS

- System description: 10 kWdc PV, 8 kWac inverter, 10 kWh LiFePO4 storage with integrated BMS.

- As-built: single-line, layout with string map A1–A5, device datasheets, and torque schedule.

- Instruments: insulation tester 1000 V rated, DMM CAT III, clamp meter, irradiance meter, and temperature probe. All with calibration IDs.

Record snippet for one string:

- String ID: A3

- Module count: 12

- Polarity: correct

- IR at 500 V: 3.2 MΩ, dry, 22 °C

- Voc measured: 489 V; expected: 480–505 V

- Isc measured: 9.1 A; expected: 8.8–9.7 A

- I‑V trace: stored as CSV and PNG; fill factor normal

- Notes: connectors inspected; torque verified per schedule

Inverter checks:

- Startup and reconnection behavior stable. No nuisance trips.

- Anti-islanding functional test referenced to IEC 62116 procedure notes. Limits match utility settings.

- RCD test: device trips within label spec; times recorded.

ESS checks:

- Charge and discharge verification at rated power. Temperatures within BMS limits.

- Round-trip test window documented with timestamps. Performance metrics logged for baseline, with reference to storage performance reference.

Why these packs pass first time

Alignment with recognized frameworks

IRENA’s Grid Codes for Renewable Powered Systems highlights the value of structured testing, measuring, recording, and post processing for compliance. That mirrors this blueprint: clear forms, calibrated instruments, and traceable data. IEA research on conformity policies shows that even with common IEC procedures, regions interpret and enforce details differently. Well labeled records reduce interpretation gaps for local inspectors. Broad deployment makes this urgent; the U.S. EIA tracks rapid solar growth, which increases the number of sites that must pass commissioning cleanly. The DOE solar energy page further underlines safety and grid integration topics that show up in field inspections.

Data quality that holds up

- Use irradiance and temperature corrections for Voc and Isc comparisons. Note plane-of-array irradiance and backsheet temperature.

- Include raw I‑V trace files. Summaries without raw data can be challenged.

- Attach manufacturer datasheets and serial ranges used on each string.

- Keep calibration records accessible inside the pack. Include expiration dates.

Practical tips and pitfalls

- Schedule IR testing in dry conditions. Wet glass and connectors can depress readings.

- Label strings at both ends. Many failed packs show mismatched IDs between roof and combiner.

- Document torque values with tool model. Handwritten checks without tool traceability cause rework.

- Record all protection settings. Screenshots of inverter menus help.

- For ESS, log BMS alarms and clear them with notes. Show pack isolation points on the single-line.

Bringing it all together

Build a pack that combines clean labeling, structured IEC 62446-1 test records, and a performance baseline. Inspectors can navigate it in minutes, and O&M teams can use it for later diagnostics.

Compliance and safety note: this content is practical guidance and not legal advice. Local codes and utility rules apply. Confirm final acceptance criteria with the authority having jurisdiction.

FAQ

What documents should sit in an IEC 62446-1 commissioning pack?

As-built drawings, inspection checklists, electrical test records, performance baseline, calibration certificates, datasheets, photos, and sign-off pages.

How do I set acceptance ranges for Voc and Isc?

Use module datasheets and correct for measured irradiance and temperature. Many teams use about ±5% for Voc and about ±10% for Isc. Confirm with project specs.

Is I‑V curve testing mandatory?

IEC 62446-1 allows different verification methods. Many projects add I‑V curves for higher confidence and to support future troubleshooting.

How do I document anti-islanding checks?

Record procedure, settings, and timings. Reference IEC 62116 and note local utility requirements. Include screenshots and event logs.

What about performance monitoring after handover?

Create a baseline and reference IEC 61724 for ongoing metrics. Align SCADA tags with your commissioning pack for traceability.

Do I need to add storage records in a PV-only standard?

If the site includes ESS, add BMS data, charge and discharge checks, and isolation points. See this storage performance reference for common metrics used as benchmarks.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.