As the power-conversion core of any photovoltaic (PV) system, the inverter must be safe by design. IEC 62109 provides a rigorous framework to reduce electrical shock, fire, and mechanical hazards across the product lifecycle. Below is a precise, field-tested checklist that I use to prepare designs and documentation before formal type testing.

IEC 62109 at a Glance—Accurate Scope and Positioning

IEC 62109-1 (General requirements) defines foundational safety principles for PV power conversion equipment (PCE)—insulation systems, protection against electric shock, temperature, mechanical integrity, and fire risk mitigation.

IEC 62109-2 (Inverter-specific) adds particular requirements for PV inverters (e.g., behavior under abnormal conditions, protective functions, markings, and documentation).

How it relates to market access: In the EU, manufacturers typically use harmonized standards such as IEC/EN 62109 to support conformity under applicable legislation (e.g., the Low Voltage Directive). It is a common route—but not the only legal pathway—to demonstrate essential safety requirements. Always align with local law and your notified body’s guidance.

Other standards serve different goals. UL 1741 covers safety and certain tests relevant to North America, while IEEE 1547 sets interconnection and interoperability requirements for distributed energy resources (DERs) on U.S. grids. These are complementary rather than interchangeable.

Authoritative overviews: IEC Webstore, EU Low Voltage Directive, IEEE 1547, UL 1741.

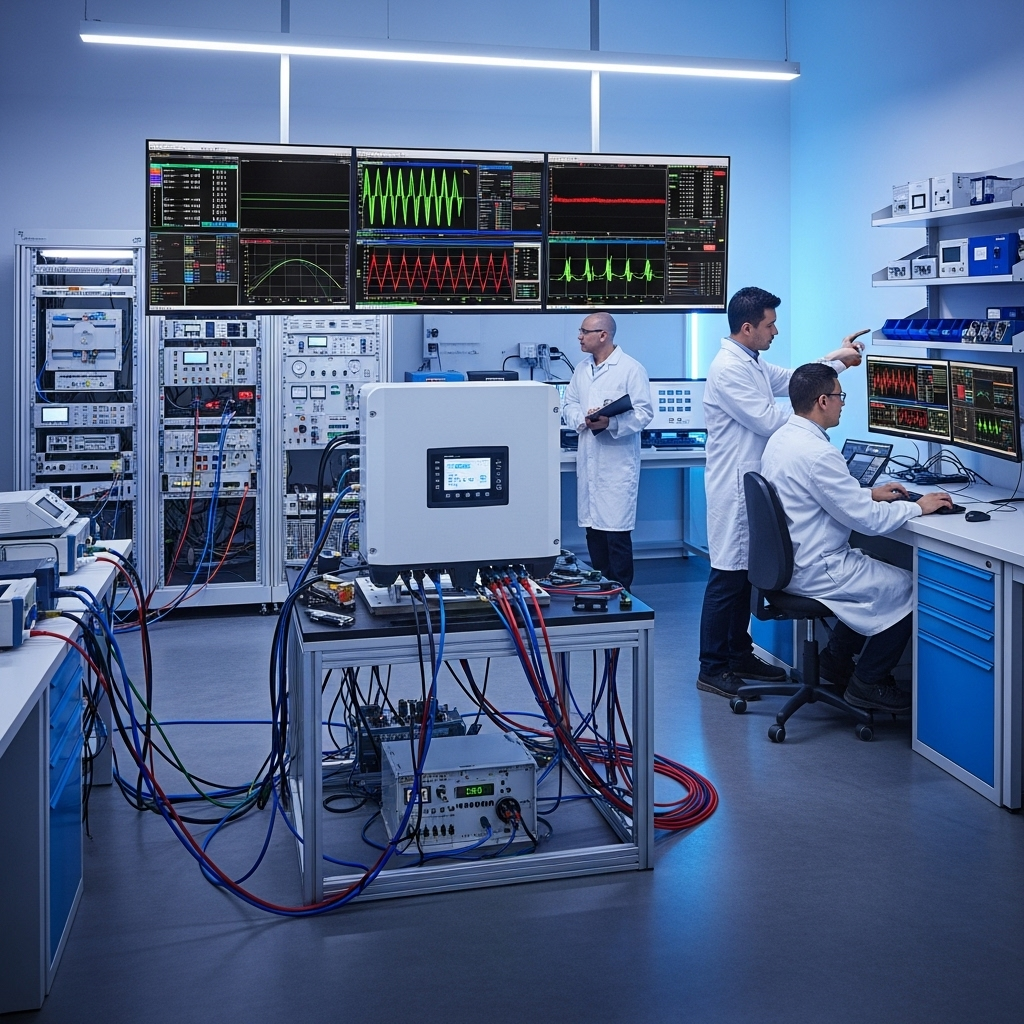

Key Safety Requirements—What Labs Actually Verify

Electrical Shock Protection

- Demonstrate robust insulation systems (basic/supplementary/reinforced) with documented creepage and clearance per rated voltage category and pollution degree.

- Protective earthing: verify continuity, bonding points, and fault-current paths; record measured resistance values.

- Accessible parts: confirm no hazardous live access under normal and single-fault conditions.

Thermal & Fire Risk Control

- Thermal tests at worst-case loads/ambient; verify shutdown/derating thresholds and thermal fusing.

- Material flammability ratings and spacing near hot components; document temperature rise of magnetics and semiconductors.

Mechanical & Environmental Integrity

- Enclosure strength and IP rating per intended environment; gasket aging/UV/salt-mist as applicable.

- Secure fixation of heavy parts; strain relief for DC/AC terminals; vibration/transport robustness.

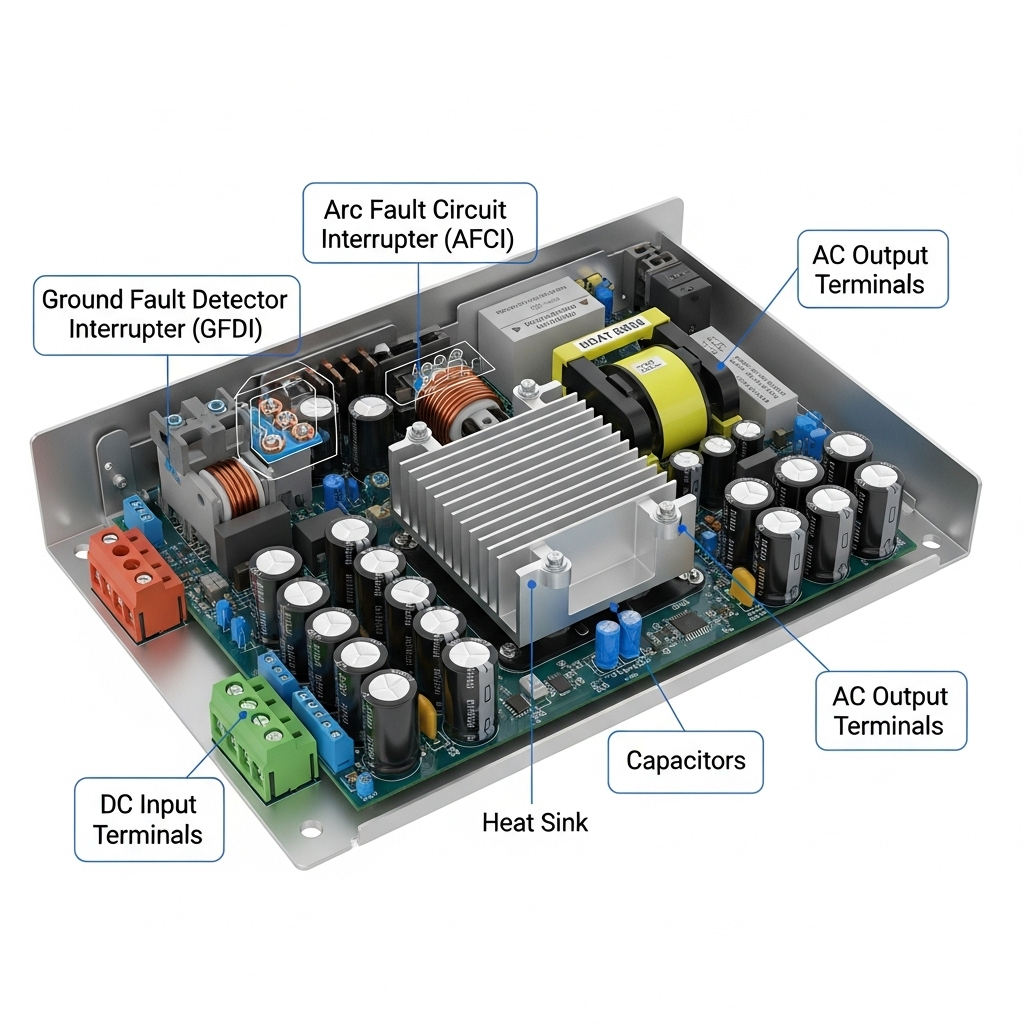

Functions Often Confused

- Anti-islanding/GFDI: Safety-related behaviors are evaluated within IEC 62109-2 and/or regional standards. Provide detection logic, trip times, and test evidence.

- Arc Fault (AFCI): May be required by local codes (e.g., NEC 690.11) or standards like UL 1699B. IEC 62109 focuses on reducing fire/electric hazards but does not by itself mandate AFCI in every jurisdiction. Align with the local rule set.

My Pre-Compliance Checklist (12 Items)

- Schematic & FMEA: Identify single-fault scenarios; map protection layers to IEC 62109 clauses.

- Creepage/Clearance Matrix: Tabulate per net class, pollution degree, overvoltage category, and pcb stack-up.

- Insulation Evidence: Certificates/datasheets for transformers, opto-isolators, relays; dielectric strength test plans.

- Protective Earth Plan: PE layout, bonding fasteners, torque specs, continuity test points.

- Thermal Budget: Derating curves, sensor setpoints, trip behavior, hottest-spot validation photos.

- Material & Flammability: Enclosure and insulators with ratings; separation distances near hotspots.

- Enclosure/IP: Gasket selections, vent strategy, condensation control; intended installation orientation.

- Markings/Labels: Ratings, hazards, terminals; permanence and language requirements for target markets.

- Manuals: Safe transport, installation torque, conductor sizes, OCPD specs, maintenance intervals.

- Abnormal/Single-Fault Tests: Shorted sensors, fan failure, blocked airflow, over-temperature response.

- Regional Add-Ons: AFCI (if mandated), rapid shutdown (if applicable), grid support per local code.

- Test Samples & Spares: Same BOM as production; provide extra fuses, shunts, fans, and thermistors.

Documentation Package—What I Submit with Samples

- Bill of Materials (BOM) with safety-critical parts highlighted and alternatives pre-approved.

- Safety critical component certificates (transformer system, wires, plastics, relays) with expiration dates.

- Risk analysis (FMEA) cross-referenced to design safeguards and verification tests.

- Marking artwork (silk, label) and user manual PDFs; installation diagrams showing conductor sizing and PE.

Impact on Reliability and Bankability

Designs that pass IEC 62109 type tests generally exhibit better long-term reliability. In my projects, early pre-compliance has consistently reduced redesign loops and helped insurers and lenders treat systems as lower risk. For broader context on quality infrastructure in renewables, see IRENA’s guidance: IRENA—Quality infrastructure and IRENA—Grid codes overview.

Common Non-conformities I Watch For

- Underspecified creepage on polluted or humid sites; missing documentation for reinforced insulation.

- Thermal controls not fail-safe (e.g., single sensor dependency without plausibility checks).

- Marking durability and manual omissions (conductor size, torque, OCPD ratings).

FAQ

Is IEC 62109 “mandatory” everywhere?

No. It is widely used to demonstrate safety conformity (e.g., under the EU LVD), but local laws dictate the exact route. Engage your lab/notified body early.

Can an inverter carry both IEC 62109 and UL 1741 evaluations?

Yes. Global products often undergo multiple schemes. Expect overlap in fundamentals and differences in regional add-ons and test methods.

Does IEC 62109 cover hybrid/battery inverters?

It addresses the power-conversion safety portion for PV applications. Storage interfaces may invoke additional standards; always scope by topology and market.

Disclaimer: Safety and certification requirements vary by jurisdiction and product category. Always confirm with your certification partner and local regulations.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.