Navigating the complex world of solar inverter and energy storage system certifications can be a significant hurdle. Gaining UL 1741 SB and IEC 62109 approvals is critical for market access, yet the process is often lengthy and expensive. A streamlined approach not only accelerates your product's entry into competitive markets but also builds credibility and trust. This article outlines seven actionable steps to help you efficiently manage and expedite these essential certification processes.

Understanding the Landscape of Grid-Tied Standards

Before initiating the certification process, a clear comprehension of the standards is fundamental. UL 1741 SB and IEC 62109 are cornerstones of the renewable energy industry, ensuring products are safe, reliable, and compatible with the electrical grid. Misinterpreting their requirements is a common cause of costly delays.

What are UL 1741 SB and IEC 62109?

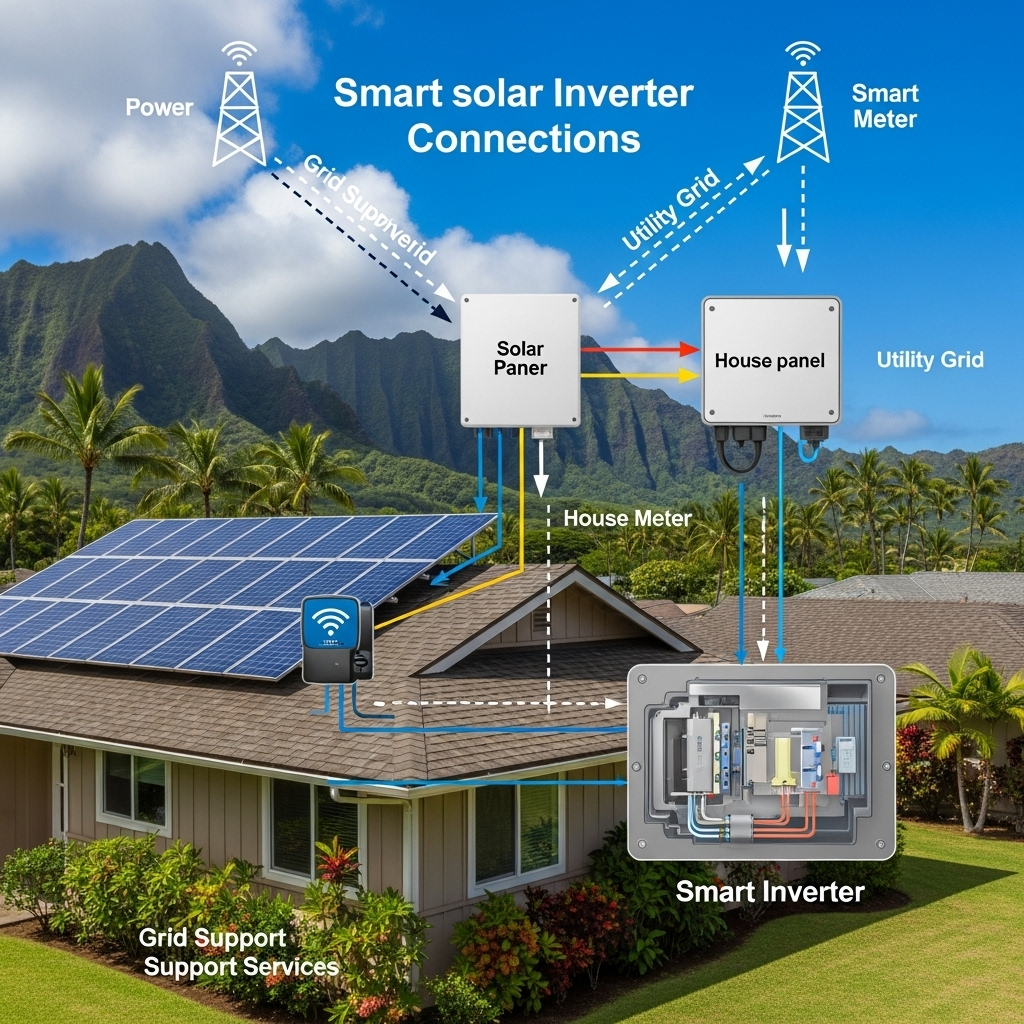

UL 1741 is the primary standard in North America for inverters, converters, and controllers used in distributed energy resource systems. The 'SB' supplement specifically references the latest grid-support requirements derived from IEEE 1547-2018, which dictates how systems interact with the utility grid. On the other hand, IEC 62109 is an international standard focused on the safety of power conversion equipment for photovoltaic systems. It is divided into parts, such as IEC 62109-1 for general safety and IEC 62109-2 for specific inverter requirements. While UL 1741 is tailored for North American grid interconnection, IEC 62109 provides a global benchmark for inverter safety.

Why Compliance is Non-Negotiable

Achieving these certifications is not just about following rules; it's a strategic business imperative. Compliance guarantees market access, as most jurisdictions legally require it for grid connection. According to a report from IRENA, the use of established international standards is crucial for developing quality infrastructure for renewable energy systems. As the report, Quality infrastructure for smart mini-grids, points out, many components in renewable systems can be tested and certified according to standards like UL 1741 and IEC 62109. This ensures safety, fosters consumer confidence, and demonstrates your commitment to quality and reliability.

Step 1: Pre-Certification Assessment and Planning

A proactive strategy begins long before you submit your product to a lab. Thorough planning and assessment can uncover potential issues early, saving immense time and resources down the line.

Conduct a Thorough Gap Analysis

Start by meticulously comparing your product's design, components, and software against every clause in the UL 1741 SB and IEC 62109 standards. This gap analysis will highlight areas of non-compliance that need to be addressed. Identifying these discrepancies during the design phase is far more efficient than discovering them during official testing.

Develop a Detailed Project Timeline

Create a comprehensive project plan that maps out every stage of the certification process. This should include design reviews, component sourcing, in-house testing, documentation assembly, lab submission, and potential re-testing cycles. Assign realistic timelines and allocate the necessary personnel and budget to each stage to maintain momentum.

Step 2: Design for Compliance from Day One

Integrating compliance requirements into the initial design phase is the most effective way to avoid costly redesigns and delays. A 'design for compliance' mindset treats certification as a core product feature, not an afterthought.

Integrating Safety and Grid Support Features

Your engineering team should focus on key design elements critical for certification. This includes thermal management to prevent overheating, proper circuit layout to ensure electrical safety, and robust software controls to manage the advanced grid-support functions required by UL 1741 SB. The standard addresses potential fire hazards, overload conditions, and software control, making these areas vital for compliance.

Material and Component Selection

Using pre-certified or listed components can significantly simplify the approval process. When a component is already recognized by a Nationally Recognized Testing Laboratory (NRTL), it reduces the level of scrutiny on that part of your system. Maintain a detailed Bill of Materials (BOM) with datasheets and certification documents for every component to present a clear and organized submission package.

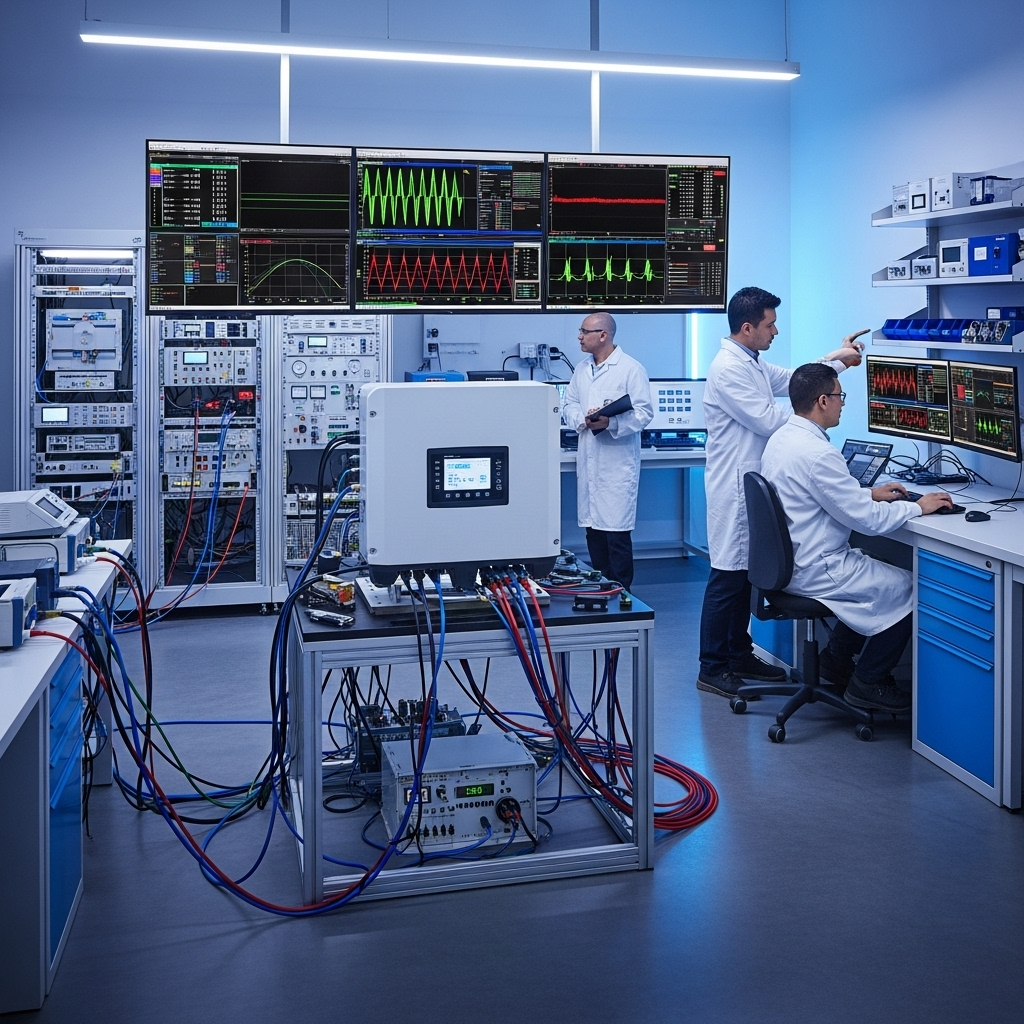

Step 3: Rigorous In-House Pre-Testing

Investing in in-house testing capabilities allows you to identify and resolve failures before they occur in a certified lab. This step is crucial for minimizing delays and managing costs effectively.

Simulating Certification Test Scenarios

Set up a testing environment that can replicate the conditions and procedures used by NRTLs. Controller-Hardware-in-the-Loop (C-HIL) test platforms can be particularly effective, allowing for faster design iterations without requiring expensive power equipment. This allows you to test for everything from temperature rise and dielectric strength to anti-islanding protection and fault current response.

Key Performance and Safety Tests to Conduct

Beyond basic safety, your pre-testing should validate the performance metrics that ensure real-world reliability. Rigorous internal testing not only prepares your product for certification but also ensures it meets high operational benchmarks. Understanding key metrics, such as those detailed in this ultimate reference for solar storage performance, can provide a valuable framework for your internal testing protocols and confirm your product's capabilities.

Step 4: Meticulous Documentation Preparation

Your documentation is the primary communication tool with the certification laboratory. Incomplete, inaccurate, or poorly organized files are a leading cause of delays.

Assembling a Comprehensive Technical File

The technical file should be a complete dossier of your product. It must include detailed design schematics, the full Bill of Materials, component datasheets, user and installation manuals, software version control, and a thorough risk analysis report. Every claim made about your product's safety and performance must be substantiated with clear evidence in this file.

Ensuring Clarity and Accuracy

Review all documents for clarity, consistency, and accuracy. Ensure that part numbers, software versions, and schematics match the physical product submitted for testing. A well-organized and precise technical file enables the lab's engineers to work efficiently and reduces the likelihood of time-consuming requests for information.

Step 5: Choosing the Right Certification Partner

The laboratory you choose to work with can have a significant impact on the speed and success of your certification project. Selecting the right partner is a critical strategic decision.

Evaluating Nationally Recognized Testing Laboratories (NRTLs)

An NRTL is an independent organization recognized by OSHA to certify products for safety. When selecting an NRTL, consider its accreditation scope, experience with UL 1741 SB and IEC 62109, and reputation within the industry. Inquire about their typical lead times, communication processes, and project management support. A lab with deep expertise in renewable energy systems can provide valuable guidance throughout the process.

Building a Strong Relationship with Your Lab

Establish a collaborative relationship with your chosen lab. Engage them early for preliminary design reviews and maintain open, proactive communication. A strong partnership helps navigate unexpected challenges and ensures both parties are aligned on timelines and requirements. This approach transforms the lab from a simple service provider into a valuable partner in your product's success.

Step 6 & 7: Streamlining Submission and Post-Submission

A smooth submission process and a rapid-response plan for any issues that arise are the final pieces of an accelerated certification strategy.

The Submission Process

Familiarize yourself with the lab's submission portal and procedures well in advance. Prepare all required forms and documentation, and ensure the physical test samples are properly labeled and shipped. A clean submission package allows the lab to schedule and begin testing without delay.

Managing the Testing Phase and Addressing Non-Conformance

Stay in close contact with the lab during the testing phase. If a non-conformance issue is identified, it is crucial to respond quickly. Have a dedicated engineering team ready to analyze the failure, develop a solution, and provide the necessary documentation or modified samples to the lab. A swift and effective response minimizes downtime and keeps the project on track.

Final Thoughts on Accelerating Market Access

Securing UL 1741 SB and IEC 62109 certifications is a complex but manageable process. By adopting a proactive and systematic approach—from initial design to final submission—you can significantly reduce delays and control costs. These seven steps provide a robust framework for navigating the certification journey efficiently. Investing in thorough planning, design for compliance, and rigorous pre-testing ultimately accelerates your time to market and solidifies your product's reputation for quality and safety.

Frequently Asked Questions

How long does the UL 1741 SB and IEC 62109 certification process typically take?

The timeline can vary significantly based on product complexity, the preparedness of the manufacturer, and the laboratory's schedule. A well-prepared project can take several months, but the process can extend to a year or more if significant non-conformance issues are found. For instance, the IEEE 1547.1-2020 standard, which informs UL 1741 SB, is substantially more complex than previous versions, potentially extending testing time to three months or longer.

What are the most common reasons for delays in certification?

Common delays stem from incomplete or inaccurate documentation, product failures during testing (especially for safety-critical functions), use of non-certified components, and poor communication with the testing laboratory. A failure to plan for the certification process from the beginning of the design cycle is often the root cause.

Can I use a component that is not UL or IEC certified?

Yes, but it will require additional scrutiny and testing by the NRTL, which can add significant time and cost to your project. The lab will need to evaluate the uncertified component to ensure it meets the safety and performance requirements of the end-product standard. Using pre-certified components is highly recommended to streamline the process.

Do I need to recertify my product if I make a minor change?

It depends on the nature of the change. Any modification to safety-critical components, software, or construction may require a full or partial re-evaluation. It is essential to consult with your NRTL before implementing any changes to a certified product. They will determine if the modification impacts compliance and what, if any, additional testing is required.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.