Small labeling mistakes often create big delays. Utilities review interconnection packets line by line. Labels must match drawings, equipment, and code language. This piece maps the errors that frequently trigger utility rejections and how to correct them fast. You will get practical checklists, code pointers, and data-backed tips for PV and energy storage projects.

Why labeling quality matters to utilities

Utilities need clear, consistent field labels to verify safe operation, emergency response, and settings that affect the grid. As variable renewable energy grows, operators tighten interconnection checks to manage safety and flexibility. A study summarized by the IEA found flexible PV operation delivered cost savings at penetration near 28%, reinforcing the value of clear plant controls and documentation (China Power System Transformation).

Grid code clarity is a recurring theme across energy systems. Guidance from IRENA on grid codes for renewable powered systems urges up-to-date, robust connection requirements. Field labels that reflect those requirements reduce back-and-forth and cut commissioning time. On the product side, the IEA highlights core elements of credible labeling schemes—reliable test protocols, benchmarking, and performance classes—which support defensible claims (Transforming Global Markets for Clean Energy Products).

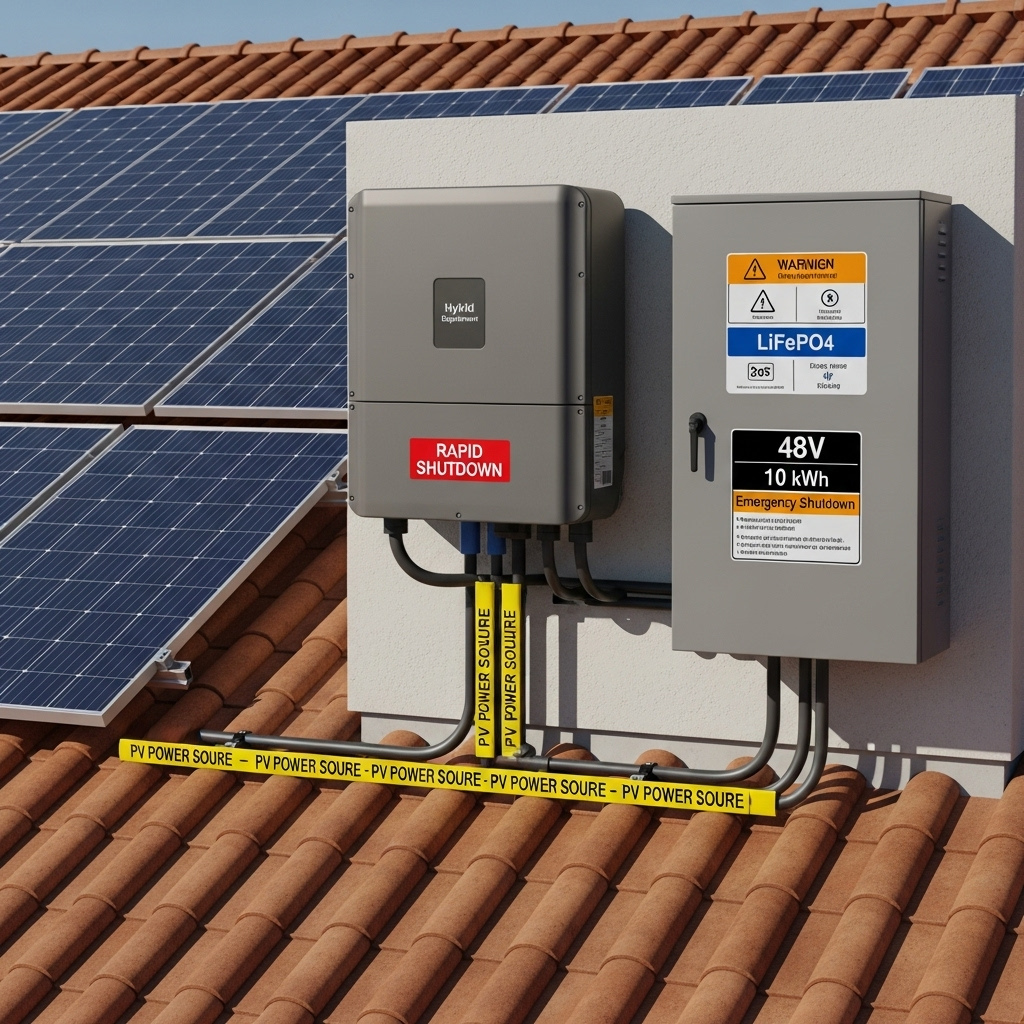

Battery and storage transparency is rising too. Supply-chain diligence and product data are central themes in the IEA’s work on critical minerals (The Role of Critical Minerals in Clean Energy Transitions). On project labels, that translates to clear chemistry, voltage, kWh, and safe shutdown information—details utilities and first responders expect to see.

The seven labeling mistakes that trigger rejections

| Mistake | Why utilities reject | Fast fix |

|---|---|---|

| 1) Missing or incorrect Rapid Shutdown label | Emergency responders cannot verify shutdown method; NEC language or location is wrong | Use code-consistent wording at the service equipment; include diagram if required; align with NEC 690.56 |

| 2) Field labels do not match the one-line | Nameplate ratings, model numbers, or breaker sizes differ from drawings | Update the as-built, reprint labels with final ratings, and sync serials and settings across all docs |

| 3) Illegible, non-durable signage | Sun-faded, low contrast, small font, or peeling labels fail visibility checks | UV-rated material, high contrast (often white-on-red for PV hazards), letter height near 3/8 in (≈10 mm) where specified |

| 4) Missing DC circuit and conduit identification | Unmarked PV source circuits confuse maintenance and safety reviews | Mark ‘PHOTOVOLTAIC POWER SOURCE’ at intervals (commonly ≤10 ft) and at turns/penetrations per NEC practices |

| 5) Incomplete battery/ESS hazard labeling | No chemistry, kWh, nominal voltage, or emergency shutdown information; SDS absent | Label cabinet/pack with LiFePO4, voltage, kWh, BMS disconnect location; attach SDS and UN 38.3/IEC certificates |

| 6) Labels conflict with interconnection settings | Export limit, anti-islanding mode, or trip points on labels do not match utility-approved settings | Record final IEEE 1547 settings on a settings label; add inverter screenshots to the packet |

| 7) Serial numbers and QR codes don’t match docs | Utility cannot trace equipment listing or warranty to the exact hardware | Cross-check serials on labels, invoice, datasheets, and one-line; use a QR code linking to a digital binder |

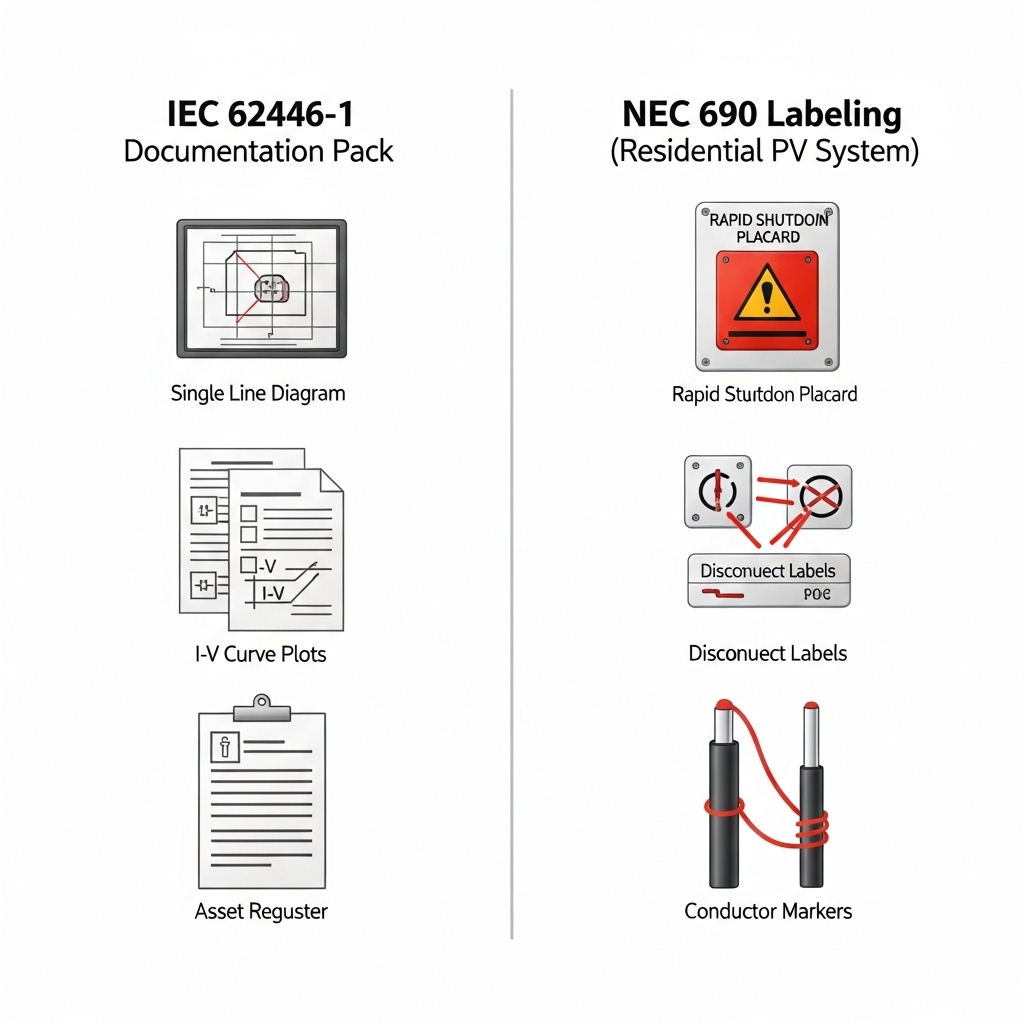

Labeling and documentation requirements that reduce friction

Core label set for PV

- Directory placard at service equipment showing all power sources and their locations.

- Rapid Shutdown label with approved wording and diagram where required.

- AC point of connection label: shows bus rating, breaker rating, and backfeed rules per the adopted code cycle.

- DC hazard labels on combiner, disconnects, and equipment enclosures; polarity and maximum circuit voltage identified.

- Conduit/cable labels ‘PHOTOVOLTAIC POWER SOURCE’ at practical intervals and near penetrations.

Core label set for energy storage

- Battery chemistry (e.g., LiFePO4), nominal voltage, capacity (kWh), and maximum charge/discharge current.

- Emergency shutdown procedure label next to the ESS and at the service equipment if remote-activation exists.

- Ventilation and clearance warnings if applicable; enclosure ingress rating if exposed.

- Compliance references: UL/IEC listings, UN 38.3 transport note, IEC 62619 (cell/module safety) where applicable.

Documentation that utilities expect

- Single-line diagram matching the field installation and labels.

- Datasheets for modules, inverters, batteries; listing marks visible; firmware revision if settings are version-dependent.

- Settings sheet aligned with IEEE 1547-2018/UL 1741 SB features; export limit proof if required.

- Commissioning checklist, photos of labels, and a system directory placard.

The U.S. Department of Energy notes that code compliance and safety steps are integral to solar deployment (Energy.gov Solar Energy). Align labels and documentation with the adopted code cycle in the project location.

Connect performance data to the label

Labeling should reflect performance that planners and operators rely on. A practical resource on storage performance notes that round-trip efficiency for lithium storage commonly exceeds 90%, and cycle life depends strongly on depth of discharge; it also recommends reporting usable capacity clearly to avoid sizing errors (solar storage performance reference). Put the usable capacity (kWh at the planned DoD) on the ESS label and in the packet so utility reviewers see a consistent story.

Module longevity and quality assurance have long been under scrutiny. The IEA observed that legacy qualification tests reduce early failures but do not rank products by lifetime in varied climates (Technology Roadmap - Solar Photovoltaic Energy 2010). Clear labeling of ratings, wiring, and shutdown points does not solve lifetime questions, yet it helps utilities verify that the installed system matches certified data and accepted practices.

Field-tested fixes for each mistake

1) Rapid Shutdown label

Use weatherproof material, high contrast, and the exact phrasing required by the AHJ utility combo. Place it at the service disconnect and any additional disconnect serving first responders. Add a simple line diagram showing the shutdown boundary if requested.

2) One-line alignment

Freeze the as-built, then reprint the settings and nameplate labels so all numbers match. For hybrid inverters, verify the AC breaker size on the label equals the as-built value, not the initial design.

3) Make signage durable

Pick UV-stable substrates with aggressive adhesive or mechanical fasteners. Use letter heights near 3/8 in (≈10 mm) where signage visibility rules apply. Photograph labels in place for the packet.

4) DC and conduit IDs

Apply continuous or spaced markers inside raceways as allowed. On rooftops, mark within practical intervals (commonly ≤10 ft) and within 3 ft of turns and penetrations. Include polarity and maximum voltage on enclosures.

5) ESS hazard and data

List chemistry (LiFePO4), nominal voltage (e.g., 51.2 V), capacity (e.g., 10 kWh), and max current. Add ‘Emergency Shutdown’ label with the switch location and a QR code linking to the SDS and certifications. Keep a printed SDS on site.

6) Settings transparency

Utilities often ask for visible confirmation of IEEE 1547 settings. Place a small laminated settings card on or near the inverter showing export limit (kW), Volt/VAR, frequency-watt, and anti-islanding mode. Include a time-stamped screenshot in the packet.

7) Traceability

Use a directory placard that lists serials for inverter, battery cabinet, and combiner. A project QR code can open a cloud folder with the one-line, photos, certificates, and commissioning report. This speeds utility audits.

Quick-reference: label spec cheat sheet

| Label | Key content | Placement | Material/format tips |

|---|---|---|---|

| Rapid Shutdown | Exact code wording; shutdown boundary | Service equipment, visible to responders | High contrast, UV-rated, durable adhesive or rivets |

| PV Directory | All power sources and locations | Service equipment | Weatherproof placard; simple diagram helps |

| AC PoC | Bus rating, breaker size, backfeed rule | Main panel or feeder tap point | Letters near 3/8 in where required |

| DC Hazard | Max voltage, polarity, source ID | Combiner, disconnects, inverter DC input | Red background, white text common |

| Conduit ID | ‘PHOTOVOLTAIC POWER SOURCE’ | At intervals and turns/penetrations | Wrap-around markers or printed conduit covers |

| ESS Hazard | Chemistry, kWh, voltage, emergency shutdown | On cabinet and near service equipment | Include QR to SDS and certificates |

| Settings Card | Export limit, grid support functions | Near inverter/controller | Laminated card; date and installer initials |

Process that keeps submittals clean

- Template first: build a standard label pack aligned to your most common utility and code cycle.

- As-built lock: finalize ratings and settings, then generate labels and the one-line together.

- Photo proof: add clear photos of each label in situ to the packet.

- Digital binder: host datasheets, listings, SDS, and settings screenshots behind a QR on the directory placard.

- Periodic review: update templates as utilities adopt new IEEE 1547 profiles and code cycles. IRENA recommends using state-of-the-art rulesets (Grid codes reference).

Realistic utility context

Utilities are managing rising distributed energy volumes. Strong labeling and documentation cut review time because they map equipment to safe operation. Energy agencies have stressed the value of clear product data and credible labeling frameworks (IEA labeling framework). For PV performance and operation, quality assurance reduces early failures but does not replace accurate site labels and directories (IEA PV roadmap).

Storage clarity matters as well. The IEA’s minerals analysis ties system reliability to transparent product information (IEA critical minerals). Echo that on the label: chemistry, energy, and shutdown steps are not negotiable for safe interconnection.

Final takeaways

- Most utility rejections in this space trace back to mismatches and missing details, not exotic technical faults.

- Use a consistent label pack and a synced as-built to remove those gaps.

- Make labels durable, legible, and code-consistent; add a QR to a tidy, permanent documentation set.

- Tie ESS labels to usable capacity and safety data; reference performance metrics as suggested in the storage performance reference.

Disclaimer: This content is for technical education only and not legal advice. Codes, utility requirements, and enforcement vary by jurisdiction. Always follow the latest adopted standards and the specific utility interconnection handbook.

FAQ

What causes utility rejection of PV and ESS labels?

Common causes include missing Rapid Shutdown signage, DC circuit IDs, and mismatches between field labels and the one-line. Utilities also reject packets if ESS labels lack chemistry, kWh, and shutdown steps, or if settings labels conflict with approved profiles.

Are there standard label sizes and colors?

Utilities and AHJs often expect high-contrast labels with durable materials. Many jurisdictions call for letter heights near 3/8 inch for key warnings and white-on-red for PV hazards. Verify local rules adopted with the current code cycle.

How do I show inverter settings to reviewers?

Print a small settings card listing export limit, Volt/VAR, frequency-watt, and anti-islanding mode that align with IEEE 1547 and UL 1741 SB features. Add time-stamped screenshots to the packet and link them via a QR code on the directory placard.

What storage data belongs on the label?

List chemistry (e.g., LiFePO4), nominal voltage, usable capacity (kWh at the planned DoD), maximum charge/discharge current, and the emergency shutdown location. Include a QR code to the SDS and applicable certifications like UN 38.3 and IEC 62619.

Do utilities accept QR codes for documentation?

Many reviewers welcome them as long as the link is stable and the physical labels still meet visibility and wording rules. Keep a printed packet available and ensure QR codes resolve to permanent files.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.