In the world of solar inverters, two metrics often stand out: efficiency and Total Harmonic Distortion (THD). A common belief is that an inverter with a very low THD is inherently more efficient and superior. While low THD is certainly a mark of a high-quality power output, the relationship between THD and efficiency is more complex than a simple 'lower is better' equation. Pursuing an extremely low THD can sometimes involve design trade-offs that impact overall system performance.

This analysis clarifies the nuanced connection between these two critical parameters. You will gain a clearer picture of how to evaluate an inverter not just on a single specification, but on its holistic performance, ensuring you select the right component for your energy independence goals.

Understanding the Core Metrics: THD and Efficiency

To appreciate their relationship, it's important to first understand what each metric represents individually. They measure two different, though related, aspects of an inverter's performance.

What is Total Harmonic Distortion (THD)?

Total Harmonic Distortion is a measurement of the purity of an AC power waveform. Ideally, an inverter should produce a perfect sine wave, identical to the power supplied by the grid. In reality, the conversion process from DC to AC introduces some level of distortion, creating unwanted frequencies (harmonics) superimposed on the main waveform. THD quantifies the extent of this distortion as a percentage. A lower THD value indicates a cleaner, more stable power output that closely resembles a pure sine wave. This is crucial for sensitive electronics, which can malfunction or be damaged by 'dirty' power with high THD.

Decoding Inverter Efficiency

Inverter efficiency measures how effectively the unit converts DC electricity from your solar panels or batteries into usable AC electricity for your home. It's expressed as a percentage. For example, a 96% efficient inverter loses 4% of the energy as heat during the conversion process. However, efficiency is not a constant figure. It varies significantly depending on how much power the inverter is handling at any given moment. This dynamic performance is captured by an efficiency curve, which plots efficiency against the load level. Peak efficiency is the highest point on this curve, but it might only be reached under specific operating conditions.

The Interplay: How THD and Efficiency Influence Each Other

The pursuit of ultra-low THD and maximum efficiency can sometimes be conflicting engineering goals. The design choices made to improve one can have consequences for the other, especially under varying load conditions.

The Trade-off Between Filtering and Efficiency

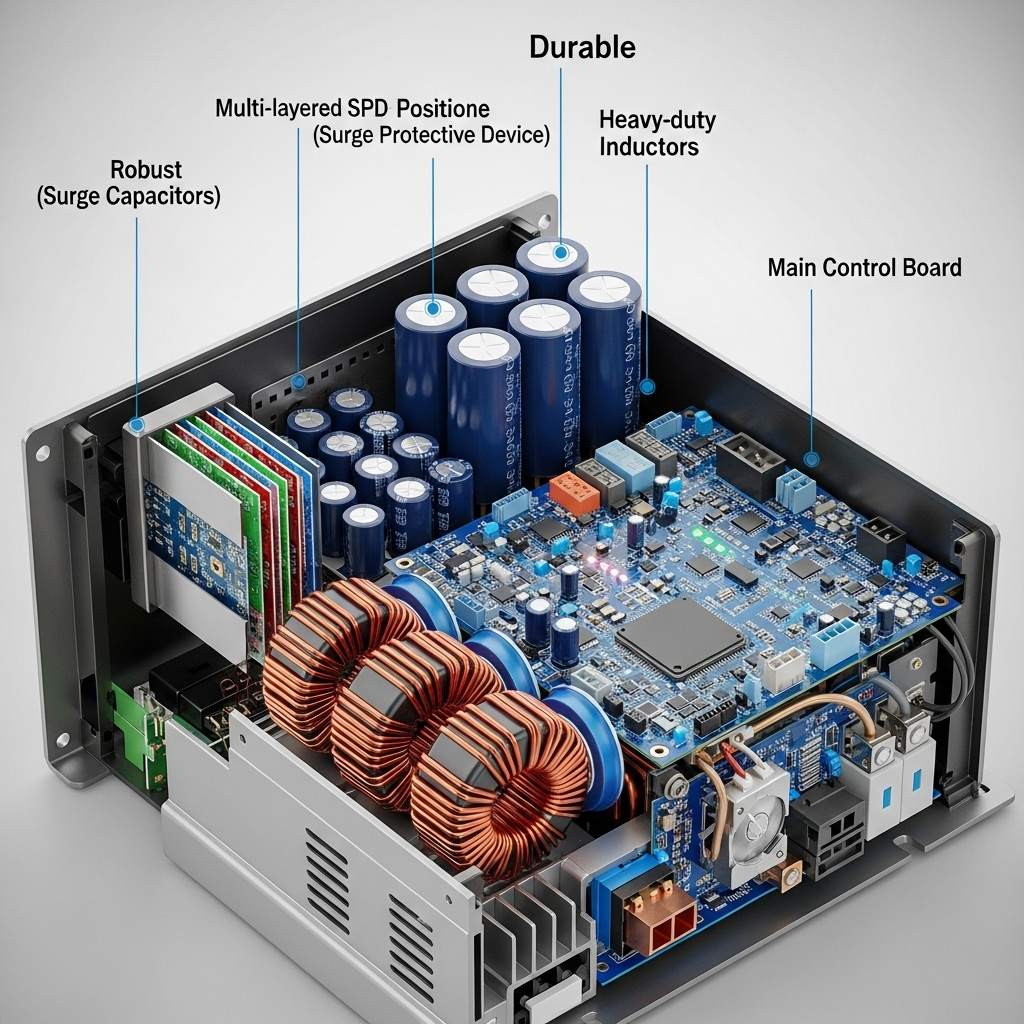

To reduce THD, engineers incorporate sophisticated filtering circuits using components like inductors and capacitors. These filters are excellent at smoothing the AC waveform and stripping out unwanted harmonics. However, these components themselves consume a small amount of power to operate. This power consumption represents an energy loss, which can slightly reduce the inverter's overall efficiency. Therefore, a design that aggressively targets the lowest possible THD might sacrifice a fraction of a percentage point in efficiency compared to a design with a slightly higher but still perfectly acceptable THD.

Load Conditions: The Deciding Factor

The most critical factor influencing both THD and efficiency is the operational load. An inverter rarely operates at its full capacity. Throughout the day, it will experience a wide range of loads, from near-zero at night (phantom loads) to peak output in the middle of the day.

Beyond the Numbers: Efficiency Curves and Surge Handling

A truly robust evaluation moves past single data points and considers the full operational profile of the inverter, including its ability to handle demanding situations like power surges.

Why Efficiency Curves Matter More Than Peak Ratings

The efficiency curve tells the story of how the inverter performs in the real world. Two inverters might have the same 98% peak efficiency, but one might maintain high efficiency across a broad range of loads, while the other's efficiency plummets at loads below 40%. The former will generate significantly more energy over time in a typical residential setting. According to the IEA's Technology Roadmap - Solar Photovoltaic Energy 2010, the final system performance ratio takes into account all losses, including the crucial 'conversion losses in the inverter', which are directly tied to its efficiency curve.

The Hidden Connection to Surge Handling

Surge handling refers to an inverter's ability to deliver a short burst of power far beyond its continuous rating. This is essential for starting powerful appliances with electric motors, like air conditioners, refrigerators, or well pumps. While not directly measured by THD, the design quality and robust components required to produce a stable, low-THD output often contribute to better surge handling capabilities. An inverter built with high-quality transformers and capacitors to ensure a clean waveform is generally better equipped to manage the stress of a large inrush current without faltering. The successful large-scale integration of inverter-based resources has shown that modern designs can ensure system stability even at high penetration levels, as noted by IRENA's report on Grid Codes for Renewable Powered Systems.

Making an Informed Decision: A Practical Checklist

Choosing the right inverter requires a holistic approach. Instead of focusing on a single metric, use this checklist to guide your evaluation.

- Analyze the Full Efficiency Curve: Do not be swayed by peak efficiency alone. Look for an inverter that maintains high efficiency (e.g., above 95%) across the load range where your system will operate most frequently.

- Evaluate THD in Context: A THD rating below 5% is excellent for virtually all residential and commercial applications. Chasing a rating of <1% may not provide any noticeable benefit for standard appliances and could come at a higher cost or a slight efficiency penalty.

- Prioritize Surge Capacity for Your Loads: If you plan to run large motors or appliances with high starting currents, pay close attention to the inverter's surge rating (often specified for a few seconds or milliseconds). This can be more critical than a 1% difference in THD.

- Consider Build Quality and Thermal Management: A well-designed inverter with effective cooling will maintain its performance and have a longer lifespan. High temperatures can degrade both efficiency and the stability of electronic components.

Disclaimer: The information provided here is for educational purposes only and does not constitute financial or investment advice. Always consult with a qualified professional before making decisions about your energy system.

Final Thoughts

Low THD is an indicator of a quality inverter that produces clean, grid-like power. It is an important factor, especially for protecting sensitive electronics. However, it is not the sole determinant of overall performance or efficiency. The relationship is one of balance. The best inverter for your application is not necessarily the one with the absolute lowest THD, but rather the one that offers a superior efficiency curve, robust surge handling for your specific loads, and proven reliability. By looking at the complete picture, you can ensure your investment in a solar and storage system delivers optimal performance and long-term value.

FAQ

Is an inverter with 5% THD bad?

No, an inverter with a Total Harmonic Distortion (THD) of 5% or less is generally considered very good and is suitable for almost all residential and commercial applications. This level of distortion is typically undetectable by common appliances and electronics. Utility standards, such as IEEE 519, often recommend a THD limit at or below 5% for the power grid itself.

How does operating temperature affect inverter efficiency and THD?

High operating temperatures can negatively impact both efficiency and THD. As electronic components heat up, their electrical resistance increases, leading to greater power losses and reduced efficiency. Extreme heat can also affect the stability of the inverter's control circuits, potentially causing a slight increase in THD. This is why proper ventilation and choosing an inverter with a robust thermal management system are critical for sustained performance.

Can a low THD inverter improve the performance of my appliances?

Yes, a low THD inverter can improve the performance and longevity of certain appliances. For example, motors in refrigerators and fans may run cooler, quieter, and more efficiently. Sensitive audio and video equipment is less likely to experience humming or interference. Digital clocks and other timed devices will keep more accurate time. While many modern electronics have robust power supplies, providing them with a clean sine wave from a low THD inverter reduces stress on their internal components.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.