Understanding the efficiency of a lithium battery pack is fundamental to designing a robust and cost-effective solar energy storage system. Inefficient batteries waste energy, increase operational costs, and fail to deliver power when it's needed most. This guide provides a clear blueprint for measuring and understanding the factors that define lithium battery pack efficiency, empowering you to make informed decisions for your energy needs.

Understanding Key Efficiency Metrics

Before measuring efficiency, it's important to grasp the primary metrics that define a battery's performance. These figures tell the story of how effectively a battery converts and delivers stored energy.

What is Round Trip Efficiency (RTE)?

Round Trip Efficiency is the most critical measure of a battery's performance. It represents the percentage of energy you get out of a battery relative to the energy you put into it during a full charge-and-discharge cycle. For instance, a battery with 95% RTE means that for every 100 kWh of electricity used to charge it, you can expect to get 95 kWh back. Higher RTE indicates less energy is lost as heat during the cycle. LiFePO4 (Lithium Iron Phosphate) batteries often feature a high round-trip energy efficiency of over 90%.

Coulombic Efficiency vs. Voltage Efficiency

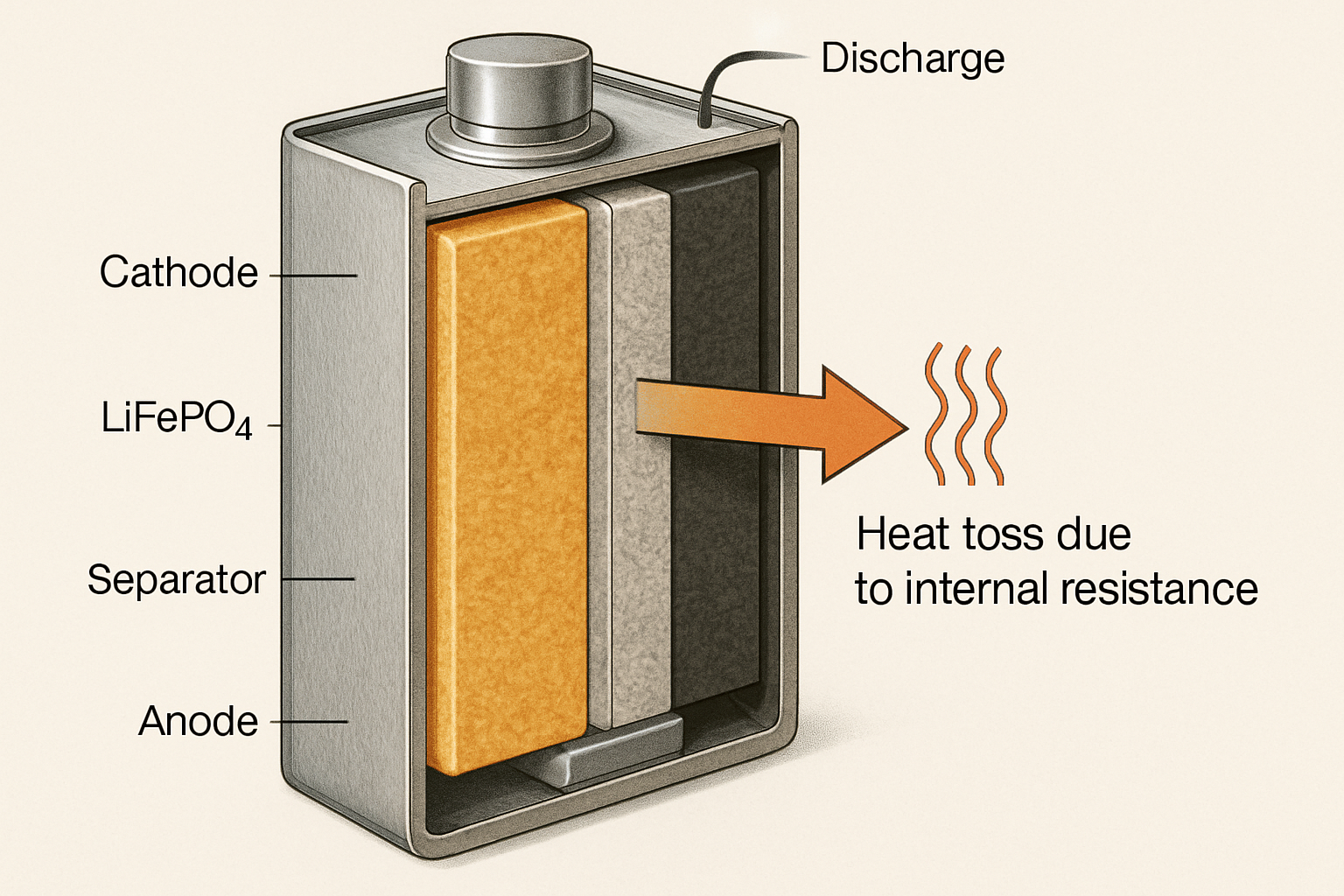

RTE is a product of two other key metrics: coulombic efficiency and voltage efficiency. Coulombic efficiency, or charge efficiency, measures the ratio of charge (in Amp-hours) that can be retrieved from the battery compared to the amount put in. While lithium-ion chemistries typically have a very high coulombic efficiency, often above 99%, it's not the whole picture. Voltage efficiency accounts for the difference between the average voltage during charging and the average voltage during discharging. This difference arises due to the battery's internal resistance. The overall energy efficiency is a combination of these two factors, which is why it is always lower than the coulombic efficiency alone.

Factors Influencing Lithium Battery Efficiency

A battery's nameplate efficiency is just a starting point. Real-world performance is influenced by several operational and environmental factors.

The Impact of Charge and Discharge Rates (C-Rate)

The C-rate describes how quickly a battery is charged or discharged relative to its maximum capacity. A 1C rate means the battery is charged or discharged in one hour. Higher C-rates increase internal resistance and generate more heat, which lowers the round trip efficiency. For example, charging and discharging a battery at a slow 0.2C rate will be more efficient than doing so at a rapid 1C rate. Studies have shown that the C-rate is often the most influential factor affecting battery efficiency.

| C-Rate | Typical LiFePO4 Round Trip Efficiency |

|---|---|

| 0.2C | ~98% |

| 0.5C | ~97% |

| 1.0C | ~95% |

Temperature's Role in Performance

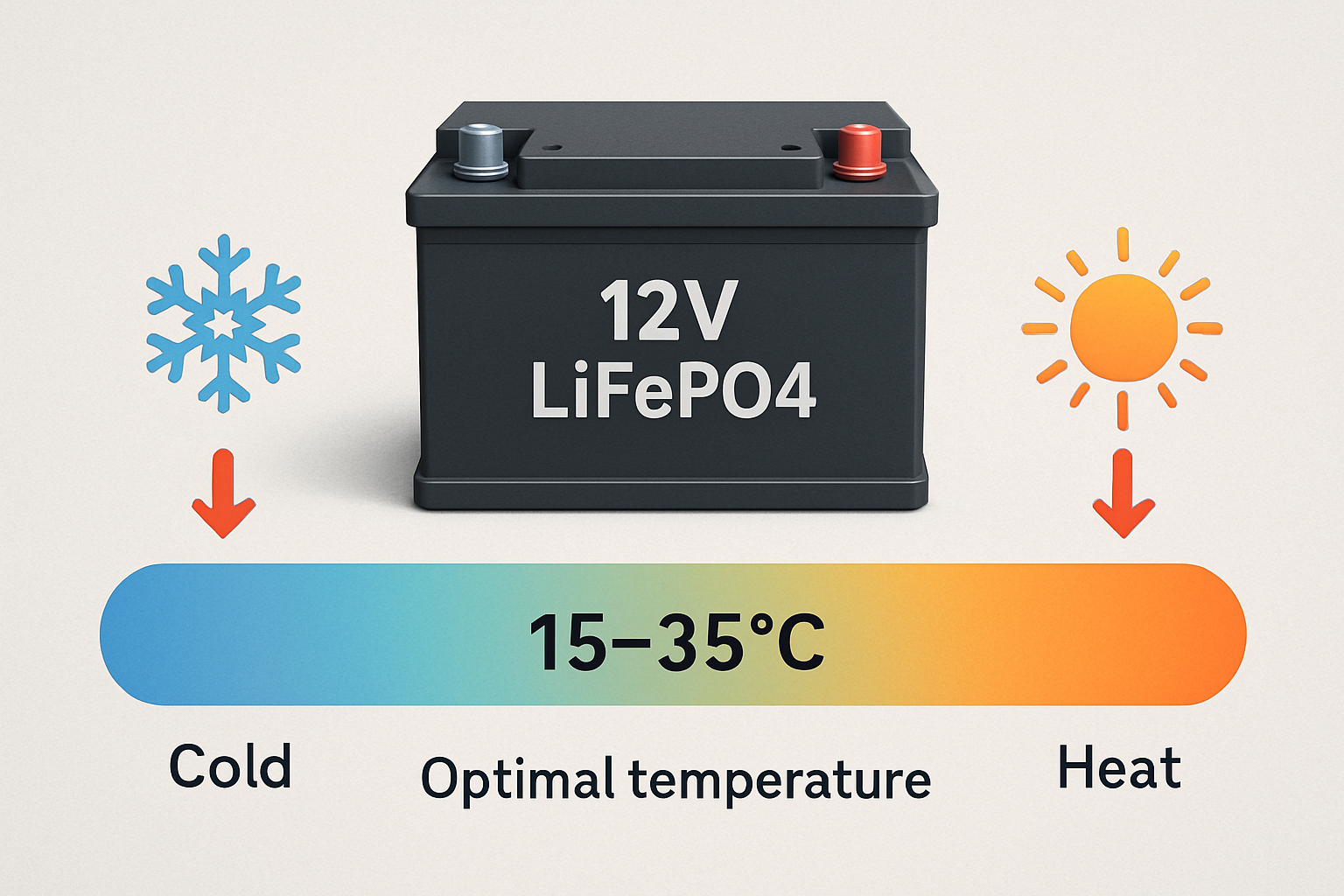

Temperature significantly impacts a battery's electrochemical reactions. The optimal operating temperature for most LiFePO4 batteries is between 15°C and 35°C (59°F and 95°F). At very low temperatures (below 0°C or 32°F), internal resistance increases, reducing efficiency and available capacity. Conversely, high temperatures (above 45°C or 113°F) can accelerate component degradation and reduce the battery's overall lifespan, even though they might temporarily increase performance. Proper thermal management is crucial for maintaining high efficiency.

State of Charge (SoC) and Depth of Discharge (DoD)

Operating a battery at the extremes of its state of charge—either fully charged or completely empty—can stress the components and slightly reduce efficiency over time. LiFePO4 batteries are known for their ability to handle deep discharges without significant degradation. However, for maximum longevity, many experts recommend operating within a 10% to 90% SoC window. This practice reduces strain on the battery and helps maintain high efficiency across its service life.

A Practical Blueprint for Measurement

Measuring battery efficiency accurately requires a controlled process and the right tools. This blueprint outlines a reliable method for testing.

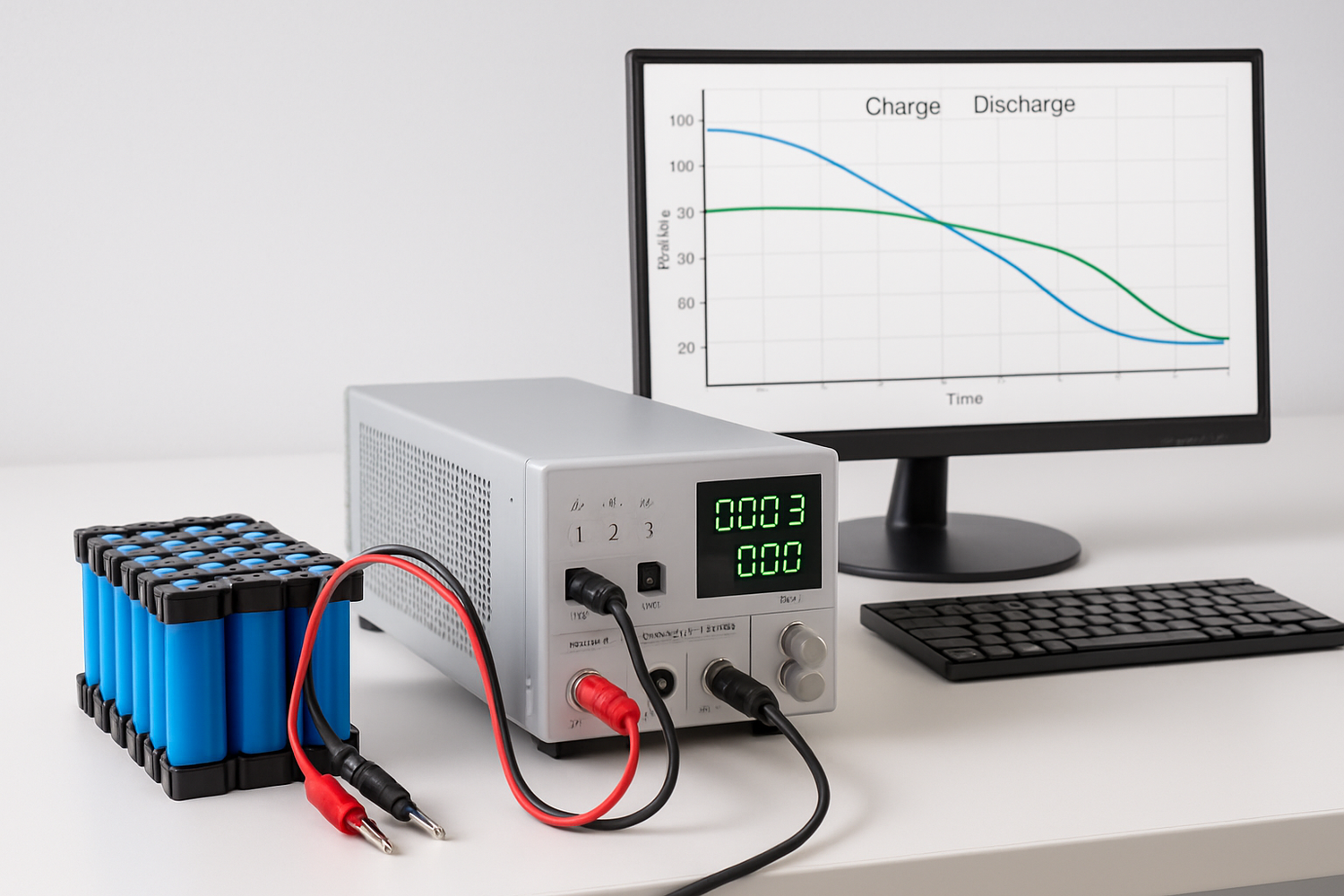

Essential Tools and Equipment

To perform an accurate efficiency test, you will need a few key pieces of equipment:

- A programmable DC power supply for precise charging.

- A programmable DC electronic load to control the discharge rate.

- A battery analyzer or a high-precision data logger to measure voltage, current, and time.

- Temperature sensors to monitor ambient and battery surface temperatures.

Step-by-Step Measurement Process

- Preparation: Allow the battery to rest in a temperature-controlled environment (ideally around 25°C or 77°F) until its temperature stabilizes. Record its initial voltage.

- Charging: Charge the battery using the Constant Current/Constant Voltage (CC/CV) method at a defined C-rate (e.g., 0.5C). Continuously log the voltage and current to calculate the total energy input in watt-hours (Wh).

- Rest Period: Once fully charged, let the battery rest for one hour. This allows the surface charge to dissipate and the voltage to settle, ensuring a more accurate reading.

- Discharging: Discharge the battery at the same C-rate to its specified cutoff voltage. Again, log the voltage and current throughout the process to calculate the total energy output (Wh).

- Calculation: Use the collected data to calculate the Round Trip Efficiency with the formula: RTE (%) = (Total Energy Output / Total Energy Input) * 100.

Interpreting the Results

A healthy LiFePO4 battery should exhibit an RTE of 92% or higher under this test. Lower results could indicate cell degradation, internal issues, or suboptimal testing conditions. Understanding these results helps in optimizing system configurations. For a broader look at how these metrics fit into overall system design, the ultimate reference for solar storage performance provides valuable context on system matching and optimization.

Maximizing Efficiency in Real-World Applications

Accurate measurement is the first step. The next is applying that knowledge to maximize performance in your energy system.

System Design Considerations

Properly sizing your battery bank is critical. An undersized bank will be subjected to high C-rates, reducing efficiency and lifespan. A well-integrated Battery Management System (BMS) is also essential. It protects the battery by preventing over-charging and over-discharging, balancing the cells, and managing thermal conditions.

Operational Best Practices

To get the most out of your battery system, operate it within its ideal temperature range and avoid consistently deep discharges. According to the U.S. Department of Energy, implementing best practices for energy efficiency and storage can significantly increase the reliability and resilience of your power system. Simple steps, like ensuring proper ventilation for your battery bank, can make a tangible difference in performance and longevity.

A Forward Look at Battery Performance

Mastering the measurement of lithium battery pack efficiency is not just an academic exercise; it's a practical step toward achieving energy independence. A highly efficient battery system stores more of your hard-earned solar power, reduces waste, and delivers reliable energy day and night. This blueprint provides the foundation for evaluating battery performance, enabling you to build a more resilient and cost-effective energy solution for the future. The International Energy Agency (IEA) highlights that batteries are a pivotal technology for the clean energy transition, making efficiency a key factor in their large-scale deployment.

Frequently Asked Questions

What is a good round trip efficiency for a lithium battery?

For LiFePO4 (Lithium Iron Phosphate) batteries, a typical round trip efficiency is between 92% and 98%. This high efficiency is one of the primary advantages of this chemistry for solar energy storage, as it minimizes energy loss during charge and discharge cycles.

How does round trip efficiency differ from battery capacity?

Battery capacity, measured in Amp-hours (Ah) or kilowatt-hours (kWh), is the total amount of energy a battery can store. Round trip efficiency is a percentage that describes how much of that stored energy is successfully retrieved. A high-capacity battery with low efficiency will waste a significant amount of energy during each cycle.

Can I measure battery efficiency without specialized equipment?

While a precise measurement requires dedicated tools, you can get a rough estimate using a quality battery monitor that tracks energy in (Wh during charging) and energy out (Wh during discharging). The accuracy will be lower than a controlled lab test but can provide useful insights for a home system.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.