In the world of solar and energy storage systems, managing heat is a constant battle. A common belief is that installing the largest possible heat sink is the ultimate solution to prevent thermal derating—the process where components reduce power output to avoid overheating. While well-intentioned, this approach oversimplifies a complex thermal challenge. The reality is that heat sink performance has its limits, and a bigger size does not guarantee an end to derating.

Understanding the nuances of heat dissipation is key to designing efficient and reliable energy systems. It involves looking beyond the heat sink itself and considering the entire thermal environment. This perspective helps you make smarter design choices that truly enhance performance and protect your investment.

The Fundamental Role of a Heat Sink

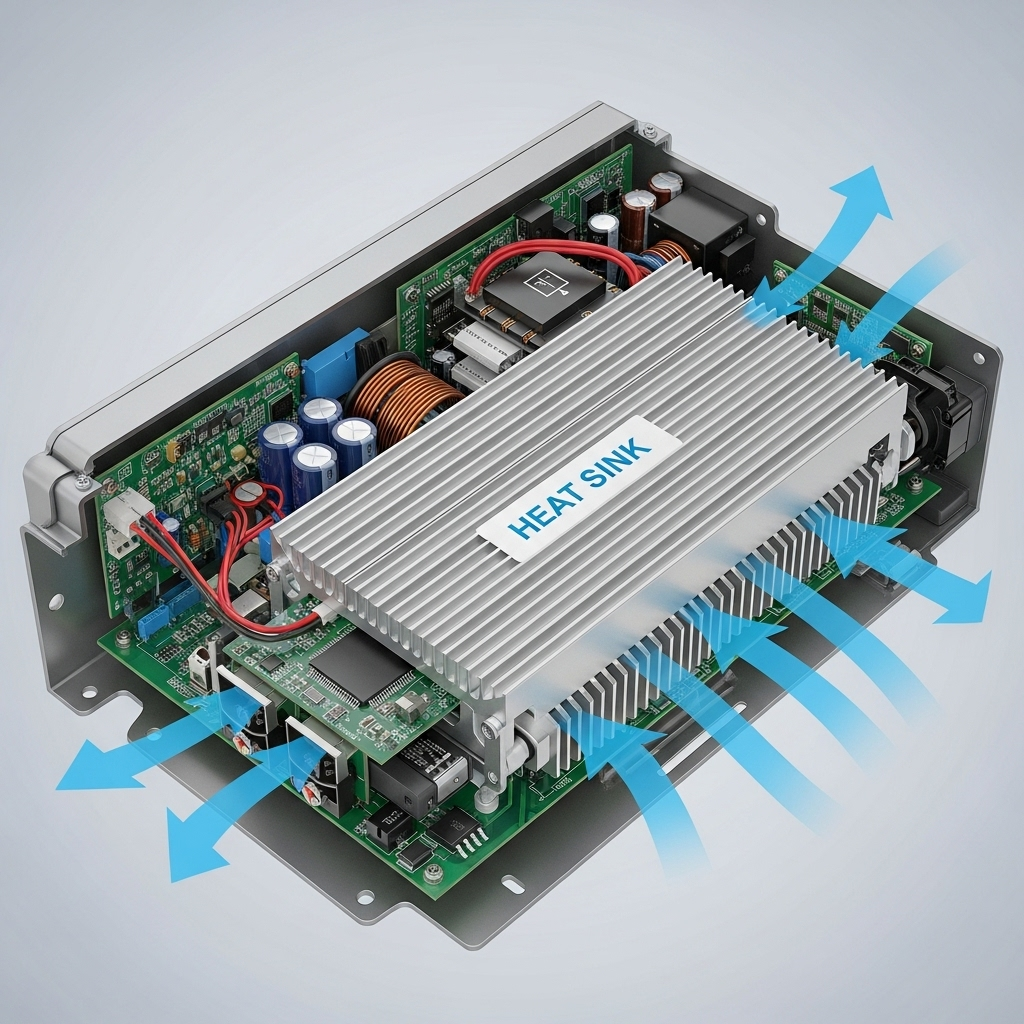

A heat sink's primary job is to move thermal energy away from a critical component, like the processors in a solar inverter, and transfer it to a cooler medium, usually the surrounding air. This process relies on fundamental principles of heat transfer.

How Heat Sinks Actually Work

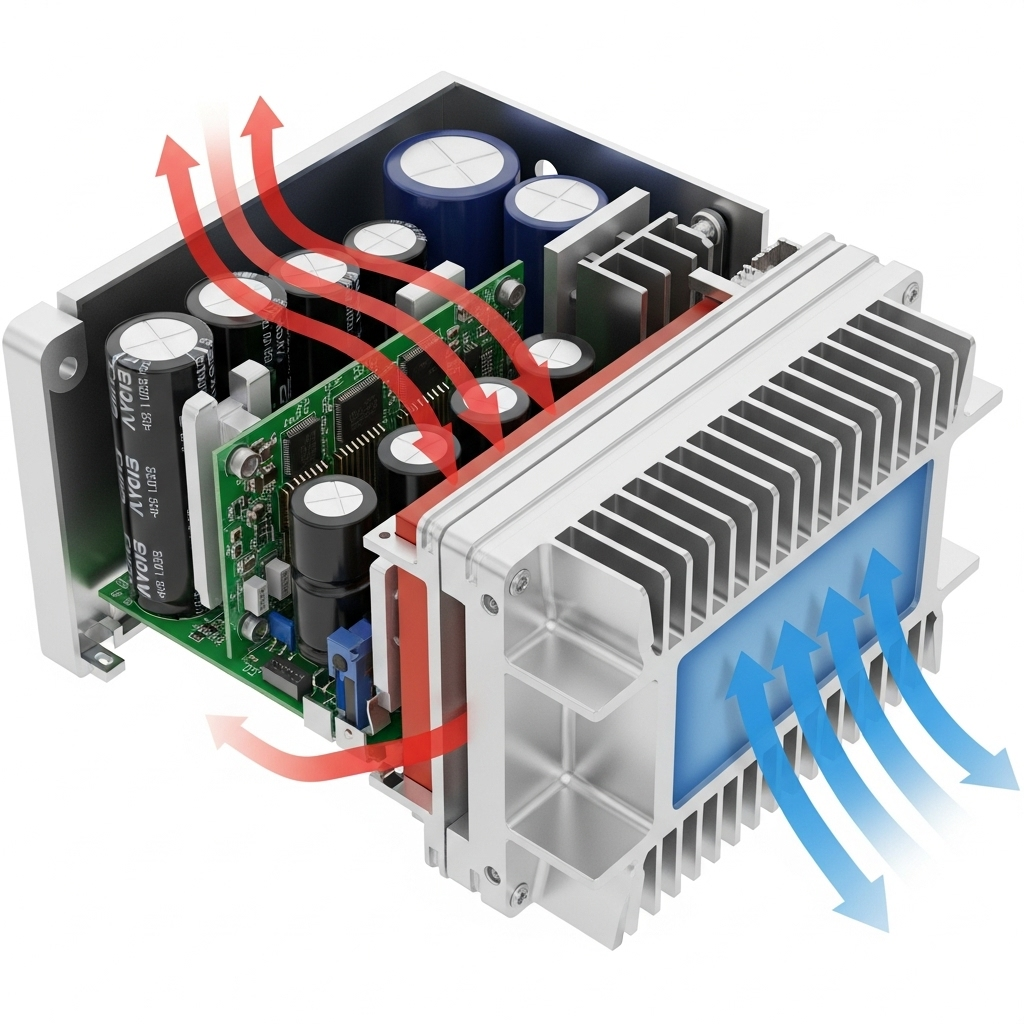

Heat sinks operate through a combination of three heat transfer mechanisms. First, heat moves from the electronic component to the base of the heat sink via conduction. From there, it travels up through the fins. Convection then takes over, as air flowing across the fins carries the heat away. Finally, a smaller amount of heat is released as infrared energy through radiation. The effectiveness of this process depends on the heat sink's material (typically aluminum or copper), its surface area, and the design of its fins.

The Point of Diminishing Returns

There is a common misconception that doubling the size of a heat sink will double its cooling capacity. This is not the case. As a heat sink gets larger, it reaches a point of diminishing returns. The bottleneck in heat dissipation shifts from the heat sink's ability to shed heat to the surrounding environment's ability to absorb it. If airflow is poor or the ambient temperature is high, even a massive heat sink will struggle. The total thermal resistance—a measure of how difficult it is for heat to move from the component to the air—is what matters, and the heat sink is only one part of that equation.

Why a Larger Heat Sink Is Not a Cure-All for Derating

Focusing solely on heat sink size ignores other critical factors that dictate thermal performance. A holistic view reveals that ventilation, ambient temperature, and the interface between the component and the heat sink are equally, if not more, important.

The Overlooked Factor: Airflow and Ventilation

A large heat sink placed in a poorly ventilated enclosure is severely handicapped. Without sufficient airflow to carry heat away, the air surrounding the fins becomes saturated with thermal energy, and the convection process stalls. A smaller, well-designed heat sink with forced airflow from a fan can easily outperform a massive passive heat sink in a stagnant environment. This is why the overall system design, including vent placement and fan specifications, is a critical piece of the cooling puzzle.

Ambient Temperature: The Real Performance Ceiling

Thermal derating is triggered when a component's internal temperature crosses a predefined safety threshold. This temperature is a direct result of the heat it generates plus the ambient temperature of its surroundings. A heat sink's job is to maintain a temperature difference between itself and the air. If the air is already very hot, the heat sink's ability to dissipate energy is drastically reduced. According to the IEA, managing high temperatures is a central challenge in solar thermal applications, a principle that applies directly to the electronics managing these systems. As described in the Technology Roadmap - Solar Heating and Cooling, developing components that can withstand high temperatures is a key area of research.

The Thermal Interface Bottleneck

Often ignored, the thermal interface material (TIM) is a thin layer of paste or a pad that sits between the electronic component and the heat sink. Its purpose is to fill microscopic air gaps and ensure an efficient conductive path. A low-quality or poorly applied TIM creates a thermal barrier, trapping heat in the component before it can even reach the heat sink. In this scenario, the size and quality of the heat sink become irrelevant, as the primary bottleneck is at the interface.

A Smarter Approach to Thermal Management

Instead of defaulting to the biggest heat sink, a more effective strategy involves a balanced, system-level approach to thermal design. This means optimizing every link in the thermal chain, from the component to the outside air.

System-Level Design Considerations

Effective thermal management starts with the overall enclosure design. This includes ensuring adequate spacing between heat-generating components, designing clear pathways for natural or forced airflow, and selecting an appropriate IP enclosure rating that balances protection from the elements with the need for ventilation. A highly sealed enclosure will trap heat, often negating the benefits of a large internal heat sink and requiring more robust external cooling solutions.

Active vs. Passive Cooling Strategies

Choosing between active and passive cooling involves trade-offs. Passive cooling, which relies on large heat sinks and natural convection, is silent and highly reliable since it has no moving parts. Active cooling, which uses fans or liquid pumps, offers much higher performance in a smaller footprint but adds complexity, noise, and potential points of failure. The best solution often depends on the specific application, environment, and power density. Maintaining optimal operating temperatures is crucial not just for performance but for the longevity of all system components. As detailed in the ultimate reference for solar storage performance, temperature control is a key factor in maximizing the life and efficiency of energy storage systems.

| Cooling Strategy | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Passive Cooling (Large Heat Sinks) | Silent operation, high reliability (no moving parts), no power consumption | Large physical footprint, lower performance, highly dependent on ambient conditions | Low-power devices, systems where reliability is paramount |

| Active Cooling (Fans) | High cooling performance, compact size, effective in high ambient temperatures | Consumes power, generates noise, potential for mechanical failure | High-power inverters, densely packed electronics |

The Role of Advanced Materials

The field of thermal management is continuously evolving. Research into advanced solutions like phase-change materials, which absorb and release large amounts of heat at a constant temperature, offers new possibilities for managing thermal loads. According to a report from IRENA, these advanced technologies are being explored to increase the energy density of heat storage. This same innovation can be applied to dissipation. The Innovation outlook: Thermal energy storage highlights the potential for new materials to revolutionize how thermal energy is managed in various applications.

Putting It All Together: A Balanced Strategy

The belief that a bigger heat sink is always the better solution for derating is a myth. While a properly sized heat sink is a critical component, it is only one part of a complex system. A truly effective thermal strategy is a balanced one that considers the entire heat transfer path. This involves right-sizing the heat sink for the load, optimizing the enclosure for maximum airflow, using high-quality thermal interface material, and choosing the right cooling method—active or passive—for the application. By adopting this holistic view, you can design solar and storage systems that run cooler, perform better, and last longer.

Frequently Asked Questions

Is there a point where a heat sink is too big?

Yes. Beyond a certain size, the added mass and cost provide negligible improvements in cooling because other factors, like airflow or ambient temperature, become the limiting bottleneck. The goal is to find the optimal size that balances performance with cost and space constraints.

How does component temperature affect its lifespan?

High operating temperatures significantly reduce the lifespan of electronic components. A common rule of thumb is that for every 10°C increase in operating temperature, the life expectancy of some components, like capacitors, can be cut in half. Effective cooling is vital for long-term reliability.

Can I improve my existing system's cooling without replacing the heat sink?

Absolutely. Improving ventilation is often the most effective step. This can involve adding case fans, cleaning dust from existing fans and heat sinks, or ensuring the unit has more space around it for better natural airflow. Re-applying a high-quality thermal paste can also make a noticeable difference.

What is thermal resistance and why does it matter?

Thermal resistance is a measure of how difficult it is for heat to pass through a material or from one point to another. In a cooling system, you want the lowest possible total thermal resistance from the electronic component to the ambient air. The heat sink is just one part of this equation; the thermal interface material and airflow also contribute significantly.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.