Choosing the right inverter is fundamental to the performance of your solar energy system. While traditional string inverters are a proven technology, their effectiveness can be compromised by common real-world conditions. Module-Level Power Electronics (MLPE), which include microinverters and power optimizers, offer a powerful alternative. This text examines the specific scenarios of shading, soiling, and module mismatch where MLPE systems provide a distinct advantage, maximizing your energy harvest and enhancing system resilience.

The 'Weakest Link' Challenge in String Inverter Systems

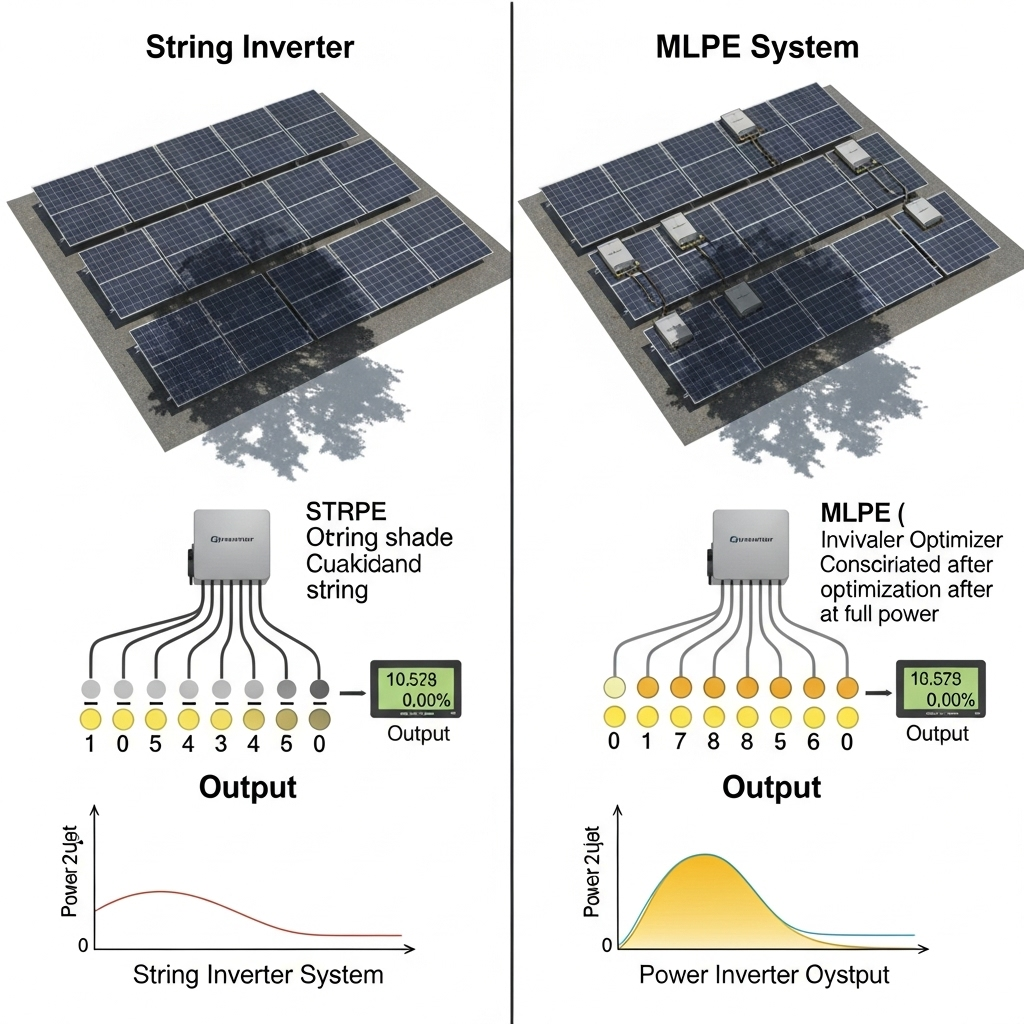

To appreciate the benefits of MLPE, you first need to see the operational model of a standard string inverter. This technology treats a group of solar panels as a single, interconnected unit.

How String Inverters Operate

In a typical residential setup, solar panels are wired together in a series, creating a 'string'. This string feeds direct current (DC) power into a single, centralized inverter. The inverter's job is to convert that DC power into alternating current (AC) for your home. The issue with this design is that the entire string's output is dictated by the performance of the least productive panel. If one panel's output drops, it restricts the flow of energy from all other panels in that string, much like a kink in a garden hose reduces water flow for the entire length.

The Pervasive Problem of Mismatch

Mismatch occurs when interconnected panels have different electrical characteristics. This forces the entire string to operate at a suboptimal level. According to research from the International Energy Agency (IEA), PV modules can become mismatched because they have different initial performance or undergo different degradation. This mismatch results in an energy loss when interconnected modules are forced to operate at the same electrical condition. This is the core limitation that MLPE technology is designed to overcome.

Shading: The Most Common Performance Killer

For many homeowners, a completely unshaded roof is an unrealistic ideal. Trees, chimneys, vents, and nearby buildings can all cast shadows that move across your solar array throughout the day.

How Partial Shading Cripples a String System

When even a small shadow falls on a single panel in a string, its power production plummets. Because all panels in the string are linked, this single underperforming panel acts as a bottleneck, dragging down the output of every other panel connected to it, even those in full sun. This can lead to a significant reduction in your total energy generation, especially on complex rooflines or properties with mature trees.

The MLPE Solution for Shading

MLPE technology decouples the performance of each panel. A microinverter converts DC to AC at the individual panel, while a power optimizer conditions the DC power from each panel before sending it onward. In both cases, each solar panel operates at its own maximum power point (MPP). If one panel is shaded, it doesn't affect the production of any other panel. The unshaded panels continue to generate energy at their full capacity, leading to a much higher overall system yield in partially shaded conditions.

Soiling and Debris: The Silent Yield Reducers

Shading isn't the only external factor that creates mismatch. The gradual accumulation of dirt, dust, pollen, bird droppings, or fallen leaves can also create performance issues.

The Uneven Effect of Grime

Soiling rarely occurs uniformly across an entire solar array. One panel might collect more dust due to its position, or a single bird dropping can significantly obstruct a few cells. In a string inverter system, this localized soiling has the same effect as shading—the dirtiest panel reduces the performance of the entire string. This can lead to a slow, often unnoticed decline in energy production over time.

Maximizing Harvest with Panel-Level Optimization

With MLPE, a soiled panel's reduced output is isolated. The clean panels in the array are free to produce at their peak, unaffected by the underperforming unit. This ensures you are harvesting the maximum amount of energy possible at all times. This resilience is crucial for maintaining a high performance ratio, a key metric that accounts for all real-world efficiency losses. As explained in the IEA's Technology Roadmap - Solar Photovoltaic Energy 2010, well-designed plants achieve a performance ratio of 80% to 90%, and mitigating losses from factors like soiling is key to staying in that upper range.

Mismatch: The Invisible Threat to Long-Term Performance

Even on a perfectly clean, unshaded roof, mismatch can and does occur. These subtle differences between panels can add up to significant production losses over the 25-year-plus lifespan of a solar system.

Sources of Inherent Panel Mismatch

Several factors contribute to inherent mismatch. Manufacturing tolerances mean that panels labeled with the same wattage have slight variations in actual output. Thermal gradients across the array can cause panels to operate at different temperatures and efficiencies. Most importantly, solar panels degrade over time, and they don't all degrade at the same rate. A string system is always limited by the panel that has degraded the most.

MLPE for Future-Proofed Performance

MLPE systems are inherently resilient to these long-term changes. By optimizing each panel individually, they ensure that the system's performance is not compromised as panels age at different rates. This leads to more predictable and stable energy production over decades, protecting your investment and ensuring you get the most out of your solar asset. Understanding these long-term factors is vital, and for those integrating storage, a detailed analysis of solar storage performance can provide further insights into maintaining system efficiency.

Data and Performance: A Comparative Look

The theoretical benefits of MLPE translate into tangible gains in energy production. The ability to monitor and manage the system at a granular level adds another layer of value.

Quantifying the Energy Gains

While exact gains depend on specific site conditions, the advantage of MLPE in challenging environments is clear. The table below illustrates potential performance differences for a hypothetical 6kW residential system.

| Scenario | String Inverter (Est. Annual Yield) | MLPE System (Est. Annual Yield) | Potential Energy Gain with MLPE |

|---|---|---|---|

| Ideal Conditions (No Shading) | 9,000 kWh | 9,100 kWh | ~1-2% |

| Moderate Shading (Morning/Afternoon) | 7,650 kWh | 8,550 kWh | ~10-15% |

| Complex Roof (Multiple Orientations & Shading) | 6,750 kWh | 8,200 kWh | ~15-25% |

Disclaimer: These are illustrative estimates. Actual performance will vary based on geography, equipment, and specific site conditions.

The Power of Granular Monitoring

A significant advantage of MLPE systems is panel-level monitoring. You can view the performance of each individual panel through a web or mobile application. This makes it incredibly easy to identify a malfunctioning or underperforming panel. With a string inverter, diagnosing a problem is more difficult, as you only see the aggregated output of the entire string. This detailed monitoring simplifies troubleshooting, validates performance, and ensures your system operates at its full potential.

Making the Right Choice for Your System

While a string inverter can be a cost-effective choice for large, uniform, and unshaded solar installations, its limitations become apparent in the variable conditions that most residential and commercial roofs face. Shading, soiling, and inherent module mismatch can substantially reduce the energy yield of a string-based system. By optimizing power at the individual module level, MLPE systems—both microinverters and power optimizers—provide a robust solution that maximizes energy harvest, enhances long-term performance, and delivers valuable monitoring capabilities. For anyone with a complex roof or potential shading, MLPE technology is a superior choice for achieving true energy independence.

Frequently Asked Questions

Are MLPE systems always better than string inverters?

Not necessarily. On a large, unshaded, uniformly oriented roof, a string inverter can be highly efficient and more cost-effective upfront. MLPE excels in challenging, real-world conditions where individual panel performance varies.

Do MLPE systems cost more?

Yes, MLPE systems typically have a higher initial hardware cost. However, this can be offset by increased energy production over the system's lifetime, especially in shaded environments. The financial calculation should include this long-term gain.

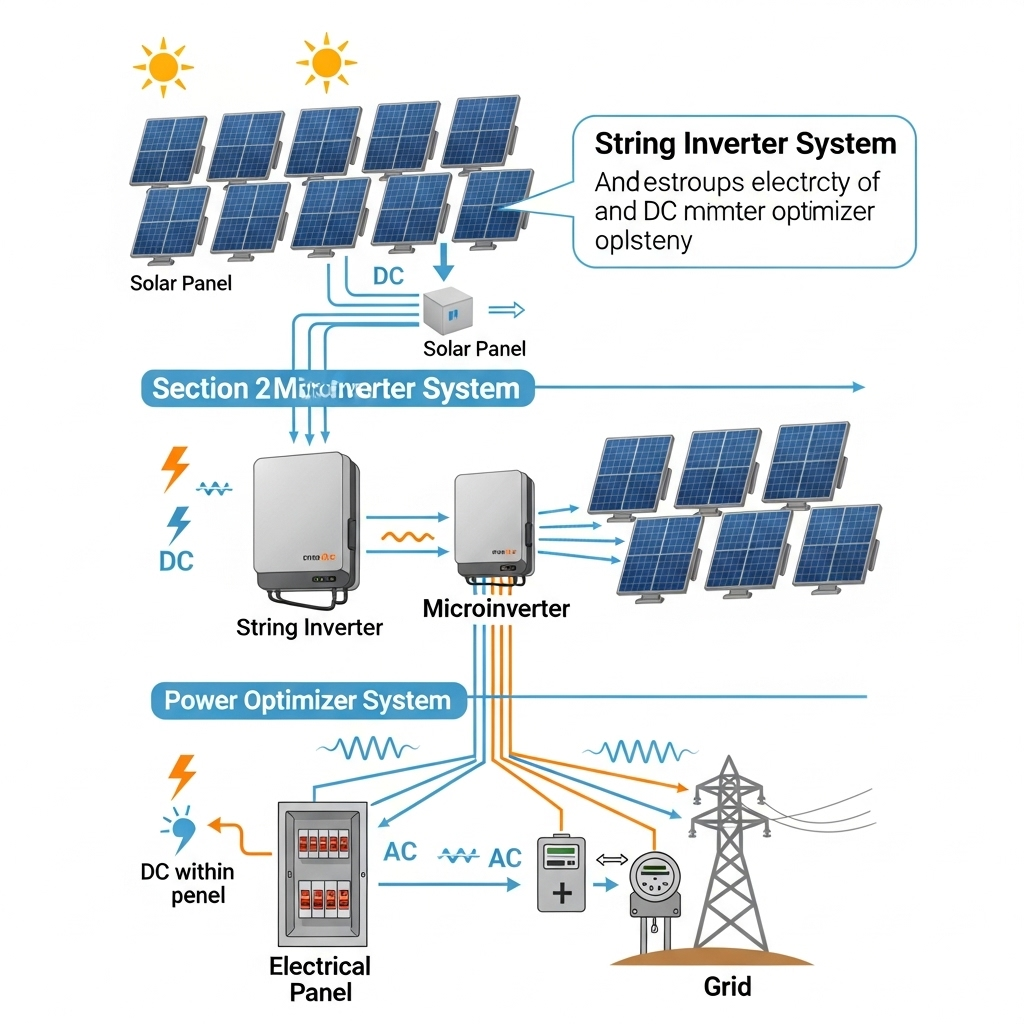

What is the difference between a microinverter and a power optimizer?

Both are MLPE technologies. Microinverters convert DC to AC power directly at each panel. Power optimizers are also installed at each panel, but they condition the DC power before sending it to a central string inverter for conversion. Both solve the mismatch problem, but with different architectures.

How does module-level monitoring help me?

It allows you to see the real-time and historical performance of every single solar panel. If a panel fails or is underperforming due to dirt or a defect, you can identify it immediately. This simplifies maintenance and ensures your system is always producing at its peak potential.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.