When selecting a solar inverter, you often see Total Harmonic Distortion (THD) listed as a key specification. A common belief is that a lower THD percentage results in a better, and quieter, inverter. While low THD is crucial for powering your electronics safely, it is not a reliable indicator of how much audible noise the unit will produce. The relationship between electrical purity and acoustic performance is far more complex than a single number on a spec sheet.

Understanding Total Harmonic Distortion (THD)

What is THD and Why Does It Matter?

Total Harmonic Distortion is a measurement that quantifies the 'purity' of an AC power waveform. Ideally, the power from an inverter should be a perfect sine wave, just like the power from the grid. However, the process of converting DC power from batteries or solar panels to AC power creates imperfections, or harmonics. THD expresses these distortions as a percentage of the fundamental waveform. High THD can cause problems for sensitive electronics, leading to overheating, malfunctions, or a reduced lifespan. For this reason, most modern inverters aim for a THD of less than 5%, with high-quality units often achieving less than 3%.

How Inverters Generate Harmonics

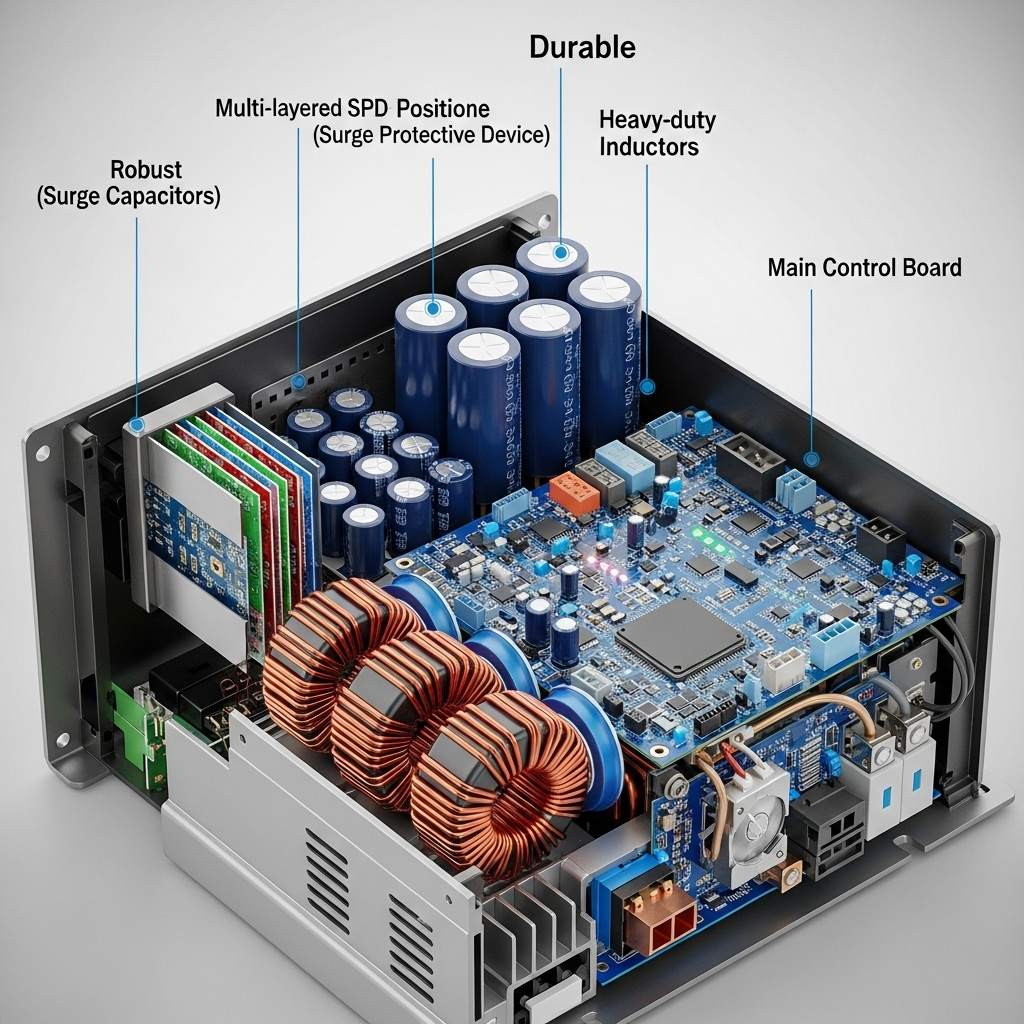

Inverters use high-speed switches, typically transistors like IGBTs or MOSFETs, to chop up DC voltage and reassemble it into an AC sine wave. This process, known as Pulse Width Modulation (PWM), happens thousands of times per second. While incredibly efficient, this rapid switching is the primary source of electrical harmonics. Filters are used to smooth out these harmonics and produce a clean output waveform, but the underlying high-frequency switching and powerful magnetic fields remain, and they are key contributors to noise.

The Real Sources of Audible Noise in Inverters

The noise you hear from an inverter is a physical phenomenon, not an electrical one. It originates from components vibrating in response to the electrical forces inside the unit. The THD specification measures the electrical output, not the mechanical noise produced during its creation.

Magnetostriction: The Hidden Hum

The most common source of a low-frequency hum in inverters is magnetostriction. This effect occurs when magnetic materials, like the iron core in a transformer or inductor, physically change shape in response to a changing magnetic field. As the inverter cycles power at 50 or 60 Hz, these core components expand and contract minutely, creating a vibration that you perceive as a constant hum. An inverter can have a perfectly clean electrical output (low THD) while its transformer vibrates audibly.

Cooling Fans and Component Vibration

Another obvious source of noise is the cooling fan. Under heavy load, such as during peak solar production or when powering large appliances, the inverter generates significant heat. Fans are necessary to dissipate this heat and protect the internal components. The speed of these fans often varies with the load, which is why an inverter might be silent in the morning but become much louder in the afternoon. Other components, like capacitors, can also vibrate and contribute to high-frequency buzzing sounds.

Does a Low THD Guarantee a Quiet Inverter?

The answer is a clear no. An inverter's THD value tells you about the quality of the power it delivers to your appliances, not the acoustic noise it generates in the process. A low THD is vital for protecting your equipment, but it should not be used as a proxy for how quiet the inverter will be.

Comparing Inverter Technologies

The design of an inverter plays a significant role in its noise level. Transformer-based and transformerless inverters, for example, have different acoustic profiles. A high-quality design with better components often leads to quieter operation. As detailed in the ultimate reference for solar storage performance, investing in well-engineered components is crucial for both performance and user comfort.

| Inverter Type | Primary Noise Source | Typical THD | Key Characteristics |

|---|---|---|---|

| Transformer-Based | Magnetostriction from the large transformer (low-frequency hum) | <5% | Extremely robust, excellent surge handling, but heavier and can be noisy. |

| Transformerless (High-Frequency) | Cooling fans, high-frequency coil vibration (buzzing) | <3% | Lighter, often more efficient, can be quieter at low loads but fan noise can be significant. |

Load Conditions and Installation

Noise is not constant. It changes based on how much power the inverter is handling. An inverter might be nearly silent at night with a very light load but hum and buzz noticeably during the day. The installation location is also critical. Mounting an inverter directly to a wall in a living space can transfer vibrations through the structure, amplifying the noise. According to the International Energy Agency, inverter technology has seen a dramatic reduction in material use over the past decade, but the fundamental physics of power conversion remain. As mentioned in the Technology Roadmap for Solar Photovoltaic Energy, this evolution has focused on efficiency and cost, with acoustics being a secondary consideration for many designs.

Making an Informed Choice

Instead of relying solely on THD, you should look for a noise rating, usually specified in decibels (dB), on the inverter's datasheet. If a dB rating is not provided, read reviews from other users and pay attention to comments about noise. Consider the inverter's placement carefully. A garage, basement, or dedicated utility room is a far better location than a hallway or kitchen. Modern smart inverters, often called grid-forming inverters, are also becoming essential for grid stability. Research supported by the U.S. Department of Energy highlights their ability to autonomously restore power systems after an outage, a critical feature for energy independence.

A Balanced Perspective on Inverter Performance

Choosing the right inverter requires a balanced approach. While a low THD is essential for the health of your electronic devices, it is a poor indicator of audible noise. The true sources of noise are mechanical vibrations from magnetic components and cooling fans. To ensure a quiet and reliable energy system, you must look beyond THD and consider the inverter's acoustic rating, its underlying technology, and its planned installation location. This holistic view ensures your system not only performs efficiently but also integrates seamlessly into your living environment.

Frequently Asked Questions

Is a humming inverter dangerous?

A consistent, low-level hum is typically a normal operating sound caused by magnetostriction in the transformer and inductors. However, if you notice a sudden change in the sound, such as loud buzzing, crackling, or clicking, it could signal a fault. In that case, it is best to consult a qualified installer or the manufacturer for inspection.

Can I soundproof my inverter?

While you can't soundproof the inverter itself, you can manage its noise. Building a well-ventilated enclosure around the unit using sound-dampening materials can help. It is crucial that you never block the inverter's air vents, as this will cause it to overheat and fail. Proper mounting on a solid surface with vibration-dampening pads can also reduce noise transfer.

Why is my inverter louder at certain times of the day?

Inverter noise is directly related to its workload. It will be loudest when it is converting the most power. This typically occurs during peak sun hours when your solar panels are at maximum output or when you are running high-power appliances like an air conditioner or an electric stove. At night, with minimal load, the inverter should be much quieter.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.