Many homes rely on 120/240V split-phase power to run high-demand appliances like air conditioners, electric dryers, and well pumps. When designing a solar energy system, a common question arises: can you achieve this by simply connecting two inverters? The answer is more complex than a simple yes or no. While it is possible, it requires a specific method and compatible hardware. Attempting this incorrectly can lead to equipment failure and safety hazards.

Understanding Split-Phase Power Essentials

Before configuring any hardware, it's vital to grasp what split-phase electricity is and why it's the standard for residential power in North America.

What is 120/240V Split-Phase?

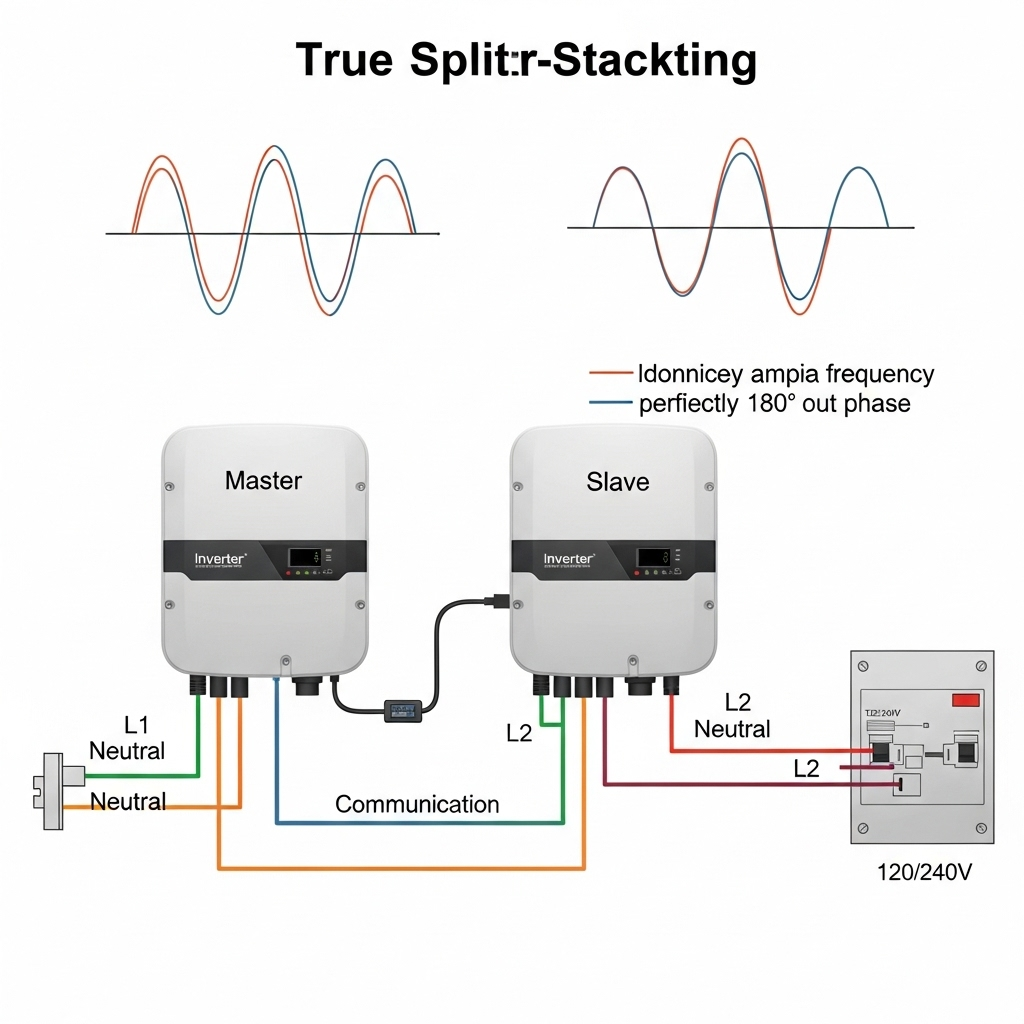

Split-phase systems deliver power through three main wires: two 120-volt 'hot' lines (L1 and L2), a neutral wire, and a ground. The crucial detail is that the sine waves of L1 and L2 are 180 degrees out of phase with each other. This phase opposition is what creates 240 volts of potential between L1 and L2, while the potential between either hot line and the neutral remains 120 volts. This dual-voltage availability makes the system highly versatile for residential needs.

Why is Split-Phase Necessary for Your Home?

While standard outlets and small electronics run perfectly on 120V, larger appliances require 240V for efficient operation. A split-phase inverter configuration allows a single solar power system to energize both types of loads. It also enables load balancing, distributing the home's electrical demand evenly across the two phases. This prevents overloading one side of your system and improves overall stability and performance.

The Stacking Method: Synchronizing Inverters for Higher Power

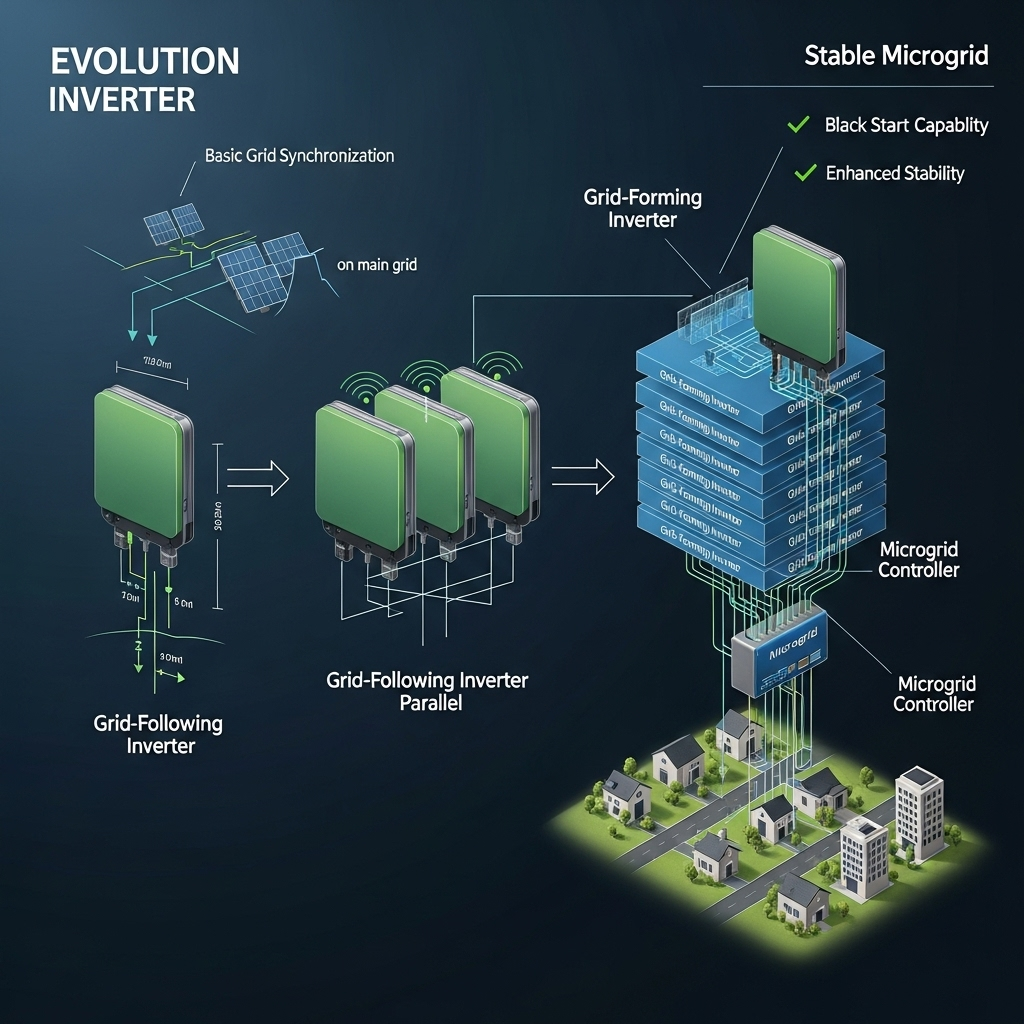

The correct technique for creating a split-phase output from two inverters is called 'stacking'. This is different from a simple parallel connection, which only increases the amperage for a single-phase output.

The Master-Slave Configuration

Inverter stacking relies on a master-slave hierarchy. One inverter is designated as the 'master' unit. It generates the primary sine wave and acts as the brain of the operation. The second inverter, the 'slave,' is connected to the master via a dedicated communication cable. The slave's only job is to synchronize its own AC output to be exactly 180 degrees out of phase with the master's signal. This precise synchronization is what makes true split-phase power possible.

Critical Requirements for Successful Stacking

Not just any pair of inverters can be stacked. The following conditions are necessary for a safe and functional inverter configuration:

- Identical Models: The inverters must be the same model from the same manufacturer to ensure they can communicate and operate in unison.

- Stacking Capability: The feature must be built into the inverter's hardware and software. Check the product specifications for terms like 'stackable,' 'split-phase capable,' or 'series stacking.'

- Matching Firmware: Both units should be running the same firmware version. Mismatched firmware can cause communication errors, leading to unstable operation or complete system failure.

The Myth: Why Two Random Inverters Will Fail

A dangerous misconception is that any two inverters can be wired together to produce 240V. This approach ignores the fundamental requirement of phase synchronization and creates a hazardous and non-functional system.

The Synchronization Problem

Without a communication link, two independent inverters have no way to align their AC outputs. Their sine waves will drift in and out of phase randomly. The voltage between their hot outputs would fluctuate unpredictably, never providing a stable 240V. This can create short circuits that destroy the inverters and any connected appliances. The International Energy Agency notes that system integration challenges emerge as power systems grow more complex, a principle that applies directly to moving from single to multi-inverter setups. As detailed in their report Getting Wind and Solar onto the Grid, proper integration is not an afterthought but a core design principle.

Load Imbalances and Voltage Instability

An unsynchronized system cannot share loads properly. One inverter might attempt to carry the entire load, leading to an immediate overload condition and shutdown. The voltage would be erratic, posing a significant risk to sensitive electronics. A stable power supply is a cornerstone of any reliable energy system, and this makeshift approach fails to provide it.

| Feature | Single Inverter | Attempted 'Fake' Split-Phase | True Stacked Split-Phase |

|---|---|---|---|

| Voltage Output | 120V AC | Unstable, fluctuating voltage | Stable 120V (L1-N, L2-N), 240V (L1-L2) |

| Appliance Support | 120V appliances only | Unreliable, damages appliances | Supports both 120V and 240V appliances |

| System Stability | Stable | Highly unstable, prone to failure | Stable and reliable |

| Safety | Safe when installed correctly | Extremely dangerous | Safe when installed correctly |

A Practical Checklist for True Split-Phase Configuration

Achieving a true split-phase system is straightforward with the right components and a methodical approach. Follow this checklist for a successful inverter configuration.

Step 1: Select Compatible Inverters

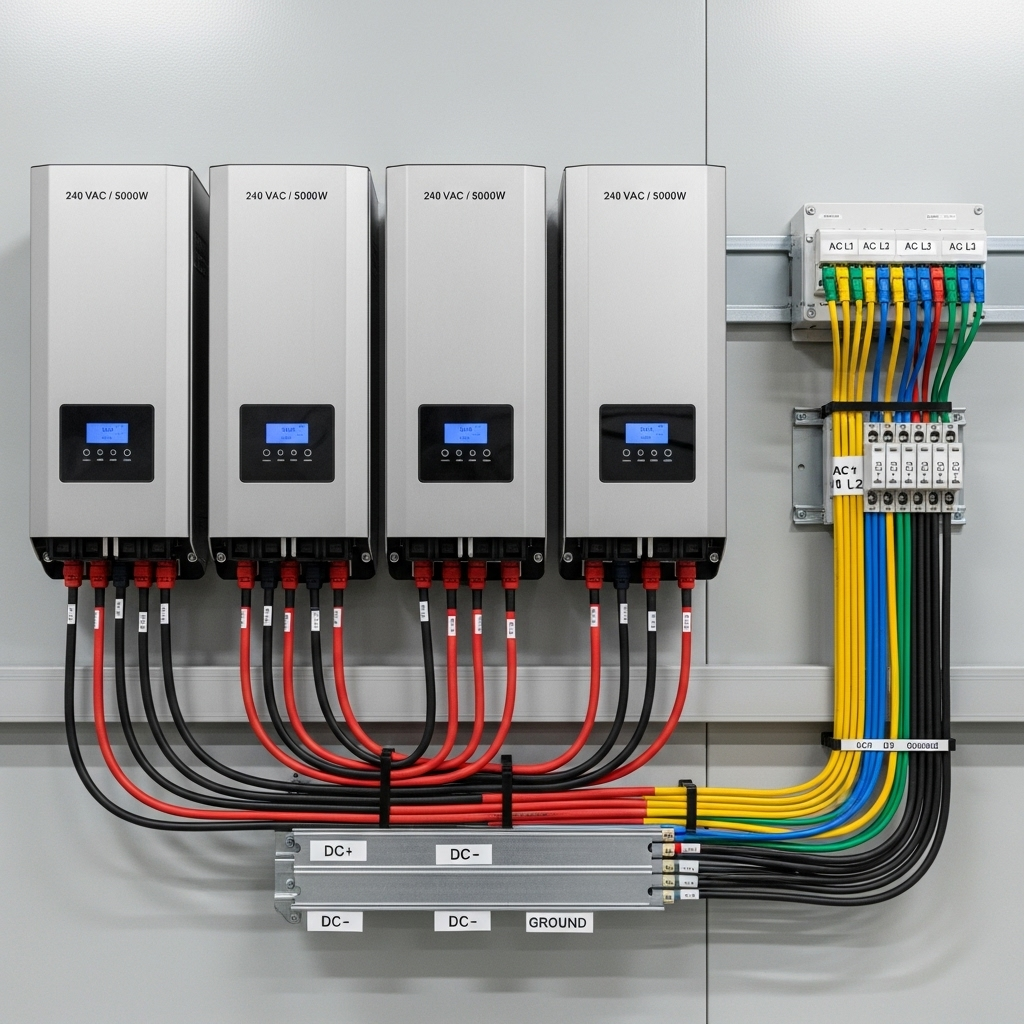

Your first step is sourcing inverters specifically designed for stacking. Read the manufacturer's datasheet and manual carefully to confirm this capability. Investing in the correct hardware upfront prevents costly and dangerous mistakes later.

Step 2: Ensure Proper Wiring and Communication

Once you have the right inverters, installation precision is key. Connect the dedicated communication cable between the master and slave units securely. Wire the AC outputs (L1 from the master, L2 from the slave) and the shared neutral to your main distribution panel. Each inverter must have its own appropriately sized connection to the battery bank, complete with proper fusing.

Step 3: Program the Inverter Settings

Using the inverter's control panel or software, you must configure their roles. Designate one unit as the master (or 'Unit 1') and the other as the slave (or 'Unit 2'). You will also set the output mode to 'Split-Phase' or a similar setting. Modern smart inverters offer a high degree of control. As the International Renewable Energy Agency highlights in its Grid Codes for Renewable Powered Systems report, active power controllability is a key feature for grid stability, and this programming step is where you implement it. For a detailed breakdown of how such configurations impact overall efficiency, the Ultimate Reference for Solar Storage Performance offers valuable data and insights into system metrics.

Disclaimer: This article provides general information and does not constitute professional electrical or financial advice. Always consult with a qualified electrician and follow all local codes and regulations when installing any electrical system.

Final Thoughts on Inverter Stacking

Creating a true 120/240V split-phase system with two inverters is not a myth—it's a proven engineering solution. However, it depends entirely on using inverters specifically designed for stacking and configuring them correctly. The communication link that synchronizes their outputs is the key element that separates a reliable, high-power system from a hazardous failure. By choosing the right equipment and following proper procedures, you can build a robust and versatile energy solution capable of powering your entire home.

Frequently Asked Questions

What is the difference between stacking and paralleling inverters?

Inverter stacking connects two inverters to create a 120/240V split-phase output, effectively doubling the voltage for large appliances. Paralleling connects two or more inverters to increase the total amperage (current) on a single phase, like 120V. It increases power but not voltage.

Can I stack three inverters?

Yes, some advanced inverter systems allow for stacking three identical units to create a three-phase power supply (typically 120/208V). This is common in commercial applications or for running specific machinery, like large water pumps. Always check the manufacturer's specifications to confirm this capability.

What happens if the communication cable between stacked inverters fails?

If the communication link is lost, the slave inverter will typically shut down its output as a safety precaution. The master unit may continue to operate as a standalone 120V inverter, but the 240V output will be lost. This safety feature prevents the system from producing unsynchronized power that could damage appliances.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.