Fire crews need a fast, unmistakable way to shut down rooftop PV. NEC 690.56(C) makes that possible with clear, standardized Rapid Shutdown Device (RSD) labels. This piece pinpoints exactly which labels are mandatory, how they differ by code cycle, what they say, where they go, and how to print them so inspectors sign off the first time.

Scope: What NEC 690.56(C) actually requires

NEC 690.56(C) applies to buildings with PV systems that include rapid shutdown per 690.12. It mandates a permanent field marking at the service equipment that tells responders two things: the system has rapid shutdown, and the extent of conductors de-energized by the RSD. That label must be visible at the service equipment (or grouped service location) and must direct responders to the RSD initiation device. Local amendments can vary, so always match your AHJ’s adopted code cycle and any local notes. Non-legal advice.

Mandatory labels under NEC 690.56(C): by code cycle

The core requirement—mark the building as having rapid shutdown—exists across recent code cycles. The exact label format and wording options depend on the adopted edition.

| NEC Code Cycle | Mandatory Field Marking (Service Equipment) | Graphic/Type | Placement | Typical Letter Size & Colors |

|---|---|---|---|---|

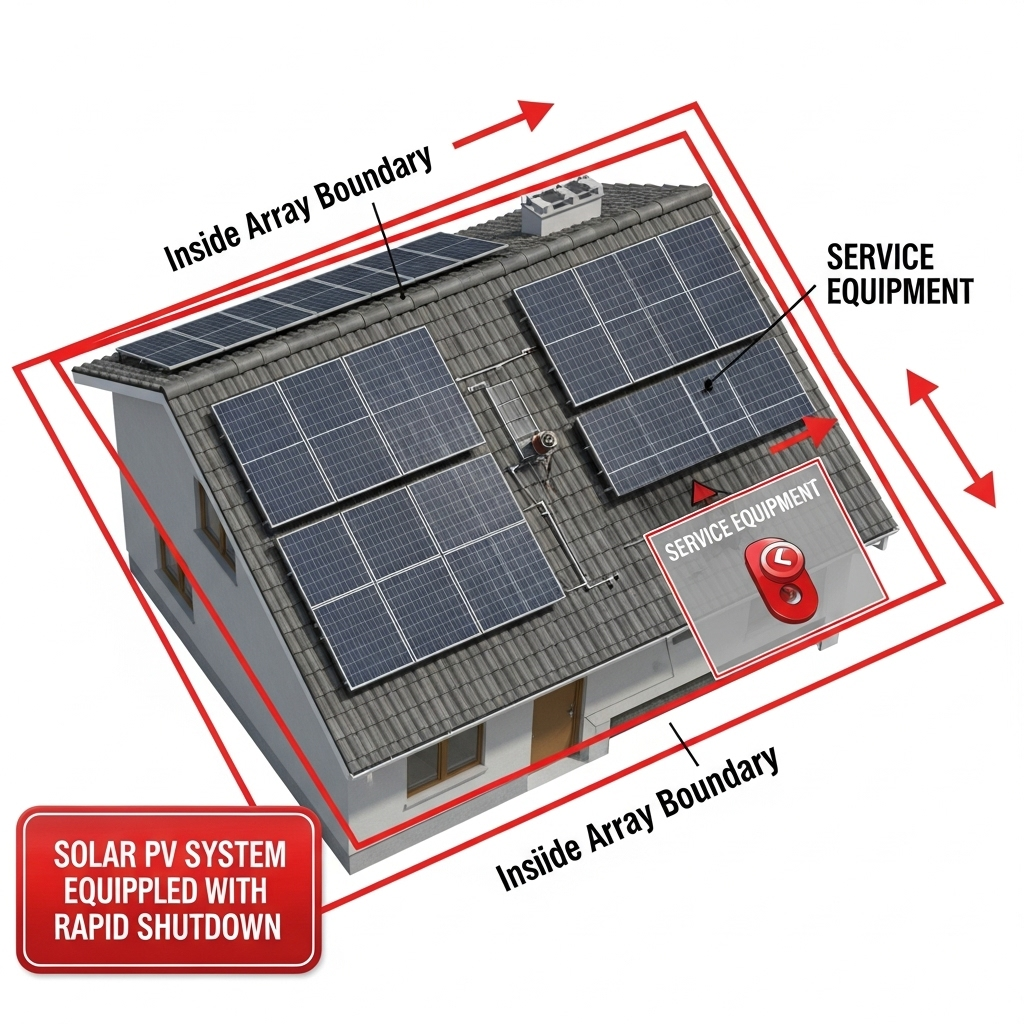

| 2017 (adopted in many jurisdictions) | ‘PHOTOVOLTAIC SYSTEM EQUIPPED WITH RAPID SHUTDOWN’ plus directions to operate the RSD and a boundary note. | Roof outline graphic indicating array boundary; labels distinguish outside vs inside array boundary control. | At service equipment or the service equipment location (visible to responders). | Use durable placard, red background with white text is widely accepted; many AHJs accept ≥ 3/8 in (9.5 mm) uppercase for key text. Verify locally. |

| 2020 | ‘SOLAR PV SYSTEM EQUIPPED WITH RAPID SHUTDOWN’ with one of two label formats: 1) conductors outside array boundary controlled; or 2) conductors inside and outside boundary controlled. | Standardized roof graphic; two variants clarify the control boundary. Label points to the RSD initiation device. | At service equipment; grouped service locations should be placarded at the group. | Same visibility and durability expectations; use contrasting colors (commonly red/white). Follow NEC 110.21(B) for legibility and durability. |

| 2023 | Same intent as 2020 with editorial refinements. The field marking must clearly identify rapid shutdown and the extent of control. | Graphic remains standard practice; choose the inside+outside or outside-only format to match your design. | At service equipment, readily visible to first responders. | Durable, weather-resistant; consistent typography sized for quick reading. Many AHJs still look for red placards with white text. |

Note: Many jurisdictions also expect a directory placard per 690.56(B) identifying all power sources at the service location. That directory is separate from 690.56(C) but often reviewed together.

Exact wording templates you can print

Base statement (always required at service equipment)

- SOLAR PV SYSTEM EQUIPPED WITH RAPID SHUTDOWN

Boundary-dependent wording

- Outside-only control: TURN RAPID SHUTDOWN SWITCH TO THE OFF POSITION TO SHUT DOWN PV SYSTEM. CONDUCTORS OUTSIDE THE ARRAY BOUNDARY REDUCE TO A SAFE LEVEL.

- Inside + outside control (module-level or equivalent): TURN RAPID SHUTDOWN SWITCH TO THE OFF POSITION TO SHUT DOWN PV SYSTEM. CONDUCTORS INSIDE AND OUTSIDE THE ARRAY BOUNDARY REDUCE TO A SAFE LEVEL.

Pointer to initiation device

- RAPID SHUTDOWN INITIATION DEVICE LOCATED:

Keep text in all caps for readability. Use a red background with white letters so firefighters recognize it instantly. NEC 110.21(B) requires field-applied hazard markings to be durable and permanently affixed. UL 969-rated materials and outdoor-grade inks improve pass rates and longevity.

Placement, colors, and materials that pass inspections

- Service equipment: Place the 690.56(C) placard on or adjacent to the service disconnect enclosure where it is plainly visible. In multi-metered or grouped service areas, place at the group location.

- Initiation device: Mark the RSD initiation device location with a clear pointer statement. Many AHJs still want the initiation device labeled ‘RAPID SHUTDOWN SWITCH FOR SOLAR PV SYSTEM’ at the switch handle.

- Colors: Red background, white letters is the common convention recognized by responders.

- Letter height: Use large, high-contrast type. Many AHJs accept ≥ 3/8 in for key text. If in doubt, go bigger.

- Durability: Outdoor UV, heat, and abrasion degrade poor labels. UL 969-tested polyester or polycarbonate with UV-overlam, acrylic adhesive, and rounded corners holds up. Rivet or permanent adhesive to metal enclosures; clean and dry the surface first.

Which label variant fits your PV design?

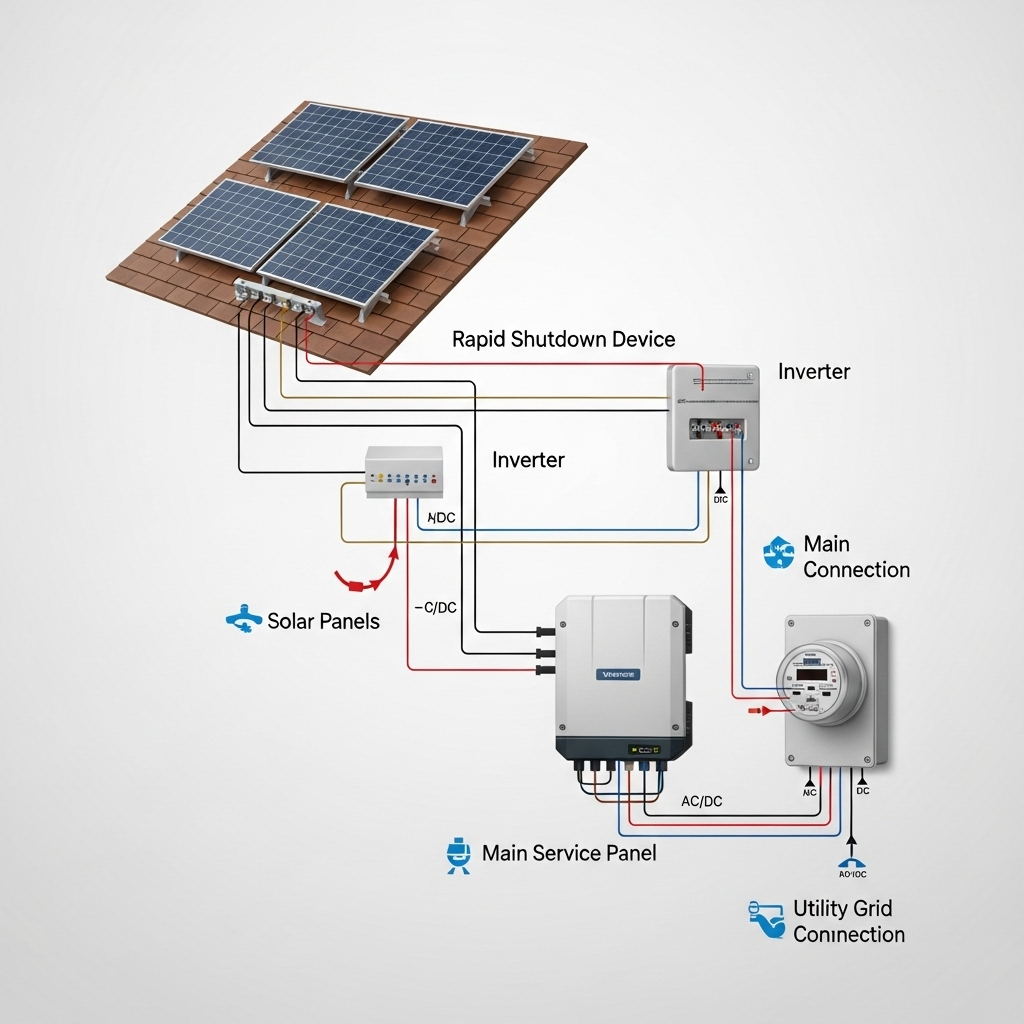

Microinverters or DC optimizers with module-level shutdown

These typically reduce voltage within the array boundary as well as outside it. Use the label stating conductors inside and outside the boundary reduce to a safe level. Add the roof graphic for clarity, with the array boundary line visible.

String inverter with RSD that controls only outside the array

If your equipment de-energizes DC conductors outside the array but leaves conductors inside the array above safe limits until another action occurs, use the outside-only control label. Make sure the boundary in the graphic is clear.

Multiple arrays or split roofs

Use a single service placard that covers all arrays with a readable roof plan. If arrays differ in control type, either provide separate labeled diagrams or a composite graphic that notes the applicable type for each array.

Why this matters: data-backed context

PV deployment keeps scaling, which raises the stakes for responder-safe labeling. The U.S. Solar Futures work highlights large growth in distributed PV and storage across scenarios, increasing rooftop system density in coming years; see the overview on energy.gov. The IEA has documented rapidly rising PV deployment and shifting system needs that favor clear operational practices for safety and reliability; see Next Generation Wind and Solar Power. Supply-chain shifts further accelerate adoption, as shown in Energy Technology Perspectives 2024. Broader PV scale also ties to materials trends described in The Role of Critical Minerals in Clean Energy Transitions, and global deployment tracked by IRENA and U.S. data from EIA. As PV and ESS volumes increase, small documentation gaps can cause outsized inspection delays.

Storage performance also shapes label planning and documentation. A practical reference on storage behavior notes typical LiFePO4 round-trip efficiency in the 90–95% range and multi-thousand cycle life with moderate depth of discharge, which affects system sizing and the number of rooftop circuits and disconnects that need clear placarding; see this storage performance reference.

Field examples that satisfy 690.56(C)

Example A: 7 kW rooftop with microinverters

- Placard at service: ‘SOLAR PV SYSTEM EQUIPPED WITH RAPID SHUTDOWN.’ Use the inside+outside boundary label format with roof graphic.

- Pointer: ‘RAPID SHUTDOWN INITIATION DEVICE LOCATED: RIGHT OF MAIN SERVICE DISCONNECT.’

- Directory: Separate 690.56(B) placard lists PV AC source at the main panel.

Result: AHJ approves on first pass because the roof diagram matches the as-built and the label text is unambiguous.

Example B: 12 kW string inverter with RSD (outside-only)

- Placard at service: outside-only variant.

- Initiation device label: at the PV system disconnect handle.

- Graphic: boundary line drawn at 305 mm (12 in) from the array edge to help responders visualize the safe approach area.

Result: Fire department notes the quick identification of the RSD switch and the difference between the array interior and the controlled zone.

Printing checklist

- Artwork: All caps, high contrast, no small serif fonts. Include arrow or text pointing to the RSD switch location.

- Material stack: Polyester or polycarbonate face stock, UV-stable inks, UL 969 or equivalent, acrylic permanent adhesive, UV overlam.

- Mounting: Clean metal surface, firm pressure, edge sealing if needed. For textured surfaces, use rivets or screws.

- Recordkeeping: Photo of installed placards in commissioning report; add a QR code on the placard that links to the as-built one-line and RSD instructions stored in your project portal.

Key takeaways for NEC labeling requirements

- Always include the 690.56(C) placard at service equipment.

- Pick the correct boundary variant to match your PV RSD design.

- State the initiation device location in plain words.

- Use durable, high-contrast materials and adequate letter height.

- Pair with the 690.56(B) directory and keep records for AHJ review.

Non-legal advice. Always verify the adopted NEC cycle and local amendments with your AHJ.

FAQ

What are the mandatory labels under NEC 690.56(C) for PV RSD?

You need a permanent placard at the service equipment stating the PV system is equipped with rapid shutdown, indicating the shutdown boundary (outside-only or inside+outside array), and pointing to the initiation device location.

Do I need the roof graphic?

Yes in most jurisdictions following 2017, 2020, or 2023 NEC. The graphic clarifies the array boundary. Some AHJs provide a template; ask the plans examiner.

What colors and sizes pass inspections?

Red background with white letters is widely accepted. Many AHJs accept ≥ 3/8 in uppercase for key text. Follow NEC 110.21(B) for durable markings and confirm local preferences.

Is a label needed at the RSD switch?

Label the initiation device location on the service placard, and place a device label at the switch itself so responders can find and operate it immediately.

How do multi-meter buildings handle this?

Place the 690.56(C) placard at the grouped service location and ensure each initiation device is clearly identified. Add the 690.56(B) directory to map sources.

Does pairing with storage change 690.56(C)?

RSD labels remain the same, but extra directories and ESS signage may apply under other codes. Storage performance references, such as this overview, help document system behavior for inspectors.

Where can I find authoritative context on PV growth and safety needs?

See PV and storage scaling analysis from energy.gov, deployment and system trends in IEA reports, market data from IRENA and EIA, and technology outlooks in ETP 2024.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.