When planning a solar energy system, panels and inverters often capture the most attention. Yet, the Balance of System (BOS) components are the essential framework that ensures your system operates safely, efficiently, and reliably. These parts, particularly the electrical hardware, represent a significant portion of the total project expense. This breakdown focuses on three critical electrical BOS areas for 2024: wiring, Rapid Shutdown Devices (RSD), and grid interconnection hardware.

Understanding the Core Electrical BOS Components

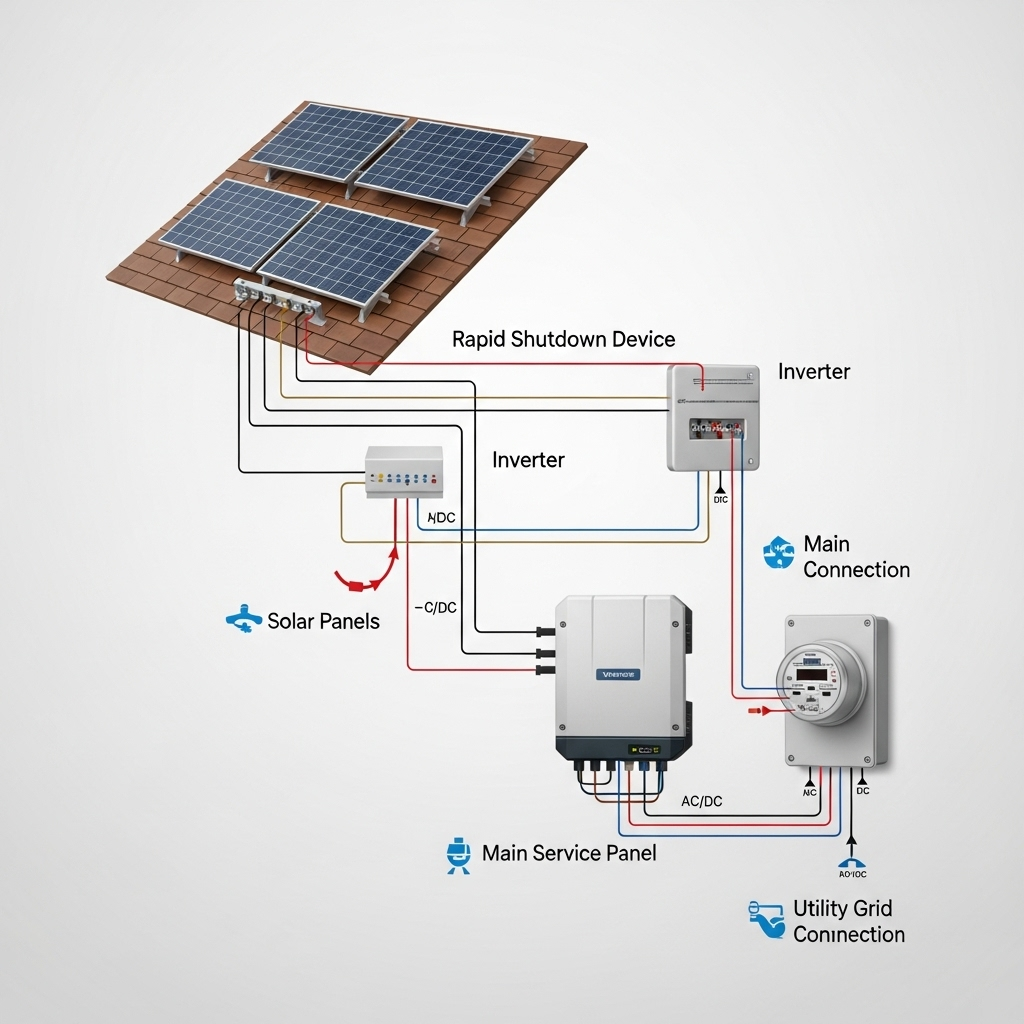

The electrical BOS is the nervous system of your solar array. It carries the power you generate, protects the system and personnel, and connects it all to the grid. A clear understanding of each part is vital for effective project planning.

The Role of Wiring and Cabling

Wiring is more than just a connection; it's the conduit for your system's energy. Different types of wires serve specific functions, including PV wire for connecting panels, AC wiring for connecting to your property's electrical system, and grounding wires for safety. The costs for these materials are influenced by several factors: the price of copper, the required wire gauge (thickness), the total length needed, and whether it must be run through protective conduit. The physical layout and overall size of your solar array directly dictate the amount and type of wiring you will need.

Rapid Shutdown Devices (RSD): A Safety Mandate

A Rapid Shutdown Device is a safety feature mandated by the National Electrical Code (NEC) in the United States. Its purpose is to provide a safe way for firefighters to de-energize the solar panels on a roof quickly. An RSD system consists of an initiator and module-level devices that shut down the DC voltage at each panel. While this adds a layer of safety, it also introduces an additional component and associated cost to the overall BOS budget.

Interconnection Hardware: The Grid Connection Point

Interconnection is the process of physically and electrically connecting your solar system to the utility's power grid. This requires specific hardware to ensure a safe and compliant connection. Key components include AC disconnect switches, circuit breakers, and utility-grade meters. For larger installations, a transformer may also be necessary. The specific requirements and associated costs can vary significantly based on your local utility's rules and the capacity of your solar system.

Analyzing BOS Component Costs in 2024

Budgeting accurately for electrical BOS components requires an awareness of current market prices and technological trends. These costs are not static and can be influenced by supply chains, raw material prices, and evolving regulations.

Wiring and Conduit Cost Factors

Wiring costs can fluctuate, primarily due to changes in the market price of copper. As a general estimate, wiring and conduit can account for 3-7% of a total residential solar project's cost. Thoughtful system design that minimizes the distance between panels and the inverter can directly reduce the amount of expensive DC wiring required.

| Component | Typical Cost Driver | 2024 Estimated Cost Range (Residential) |

|---|---|---|

| PV Wire (Copper) | Per foot | $0.50 - $1.50 per foot |

| AC Wiring | Per foot | $0.75 - $2.00 per foot |

| Conduit | Per foot | $1.00 - $3.00 per foot |

| Grounding System | Per system | $150 - $400 |

The Price of Safety: RSD Costs

The cost of implementing a rapid shutdown system is typically calculated on a per-panel basis. Module-level RSD devices generally range from $30 to $70 each. Some modern inverters are designed with integrated RSD functionality, which can help streamline installation and reduce the need for separate hardware. This integration simplifies the system and can offer a more cost-effective path to compliance.

Interconnection and Switchgear Expenses

Interconnection costs are highly dependent on local utility requirements. For a standard residential system, the necessary hardware like disconnects and breakers can cost between $300 and $1,000. For commercial-scale projects, these costs increase substantially due to the need for more robust switchgear and potentially extensive grid studies and upgrades. It is crucial to consult with your local utility early in the planning process to understand their specific interconnection requirements and associated fees.

Strategies for Optimizing Electrical BOS Costs

Managing BOS expenses is key to improving the financial return of a solar project. Strategic planning and smart component selection can lead to significant savings without compromising safety or performance.

Smart System Design and Layout

One of the most effective ways to control wiring costs is through intelligent system design. A compact panel layout reduces the length of wire runs. Placing the inverter and other equipment in a central location relative to the array can shorten the more expensive DC and AC cable runs. This simple step minimizes material expenses and can also reduce labor time.

Component Selection and Integration

Choosing components with multiple functions can lower the overall BOS cost. For example, selecting an inverter with a built-in DC disconnect and RSD capabilities eliminates the need to purchase and install these items separately. This approach not only saves money but also simplifies the system architecture. Properly sizing wires is also critical; using a wire gauge that is unnecessarily large adds needless expense, while undersizing can lead to energy loss and safety hazards. Optimizing these choices is fundamental, as explained in the ultimate reference for solar storage performance, which details how component synergy impacts efficiency.

Sourcing and Labor Considerations

Purchasing materials from established, reputable suppliers ensures you receive quality components at competitive prices. While a do-it-yourself approach can reduce labor costs, electrical work requires expertise. A professional installation guarantees that the system adheres to all electrical codes and safety standards, preventing costly errors and ensuring safe operation. The International Energy Agency's Energy Technology Perspectives 2024 report underscores the importance of resilient supply chains, which can impact the availability and cost of these high-quality components.

A Forward Look at BOS Components

The solar industry continues to innovate, leading to more integrated and efficient BOS solutions. We are seeing trends toward wireless communication for RSD systems, which could drastically reduce installation complexity and time. Furthermore, advancements in module-level power electronics (MLPE) are packing more safety and monitoring features into smaller devices. These developments, coupled with broader market trends of decreasing renewable energy costs, point toward more affordable and streamlined solar installations. A report from the International Renewable Energy Agency, Renewable Power Generation Costs in 2024, confirms that the costs for key renewable technologies continue to fall, making solar energy more accessible.

Final Thoughts on Your System's Foundation

The wiring, rapid shutdown devices, and interconnection hardware are foundational elements of any solar power system. Viewing them not as mere expenses but as long-term investments in safety, performance, and reliability is crucial. A thorough understanding of the BOS Cost Breakdown for 2024 empowers you to plan your project more effectively, optimize your budget, and build a robust system. This knowledge is a key step on the path toward achieving greater energy independence.

Disclaimer: This article is for informational purposes only. It does not constitute financial, legal, or professional installation advice. Consult with qualified professionals before making any investment or installation decisions.

Frequently Asked Questions

How much do electrical BOS components add to the total solar system cost?

Electrical BOS components, including wiring, conduit, safety devices, and interconnection hardware, typically account for 10% to 20% of the total cost of a residential solar installation. This percentage can vary based on system complexity, local code requirements, and equipment choices.

Can I reduce wiring costs by using aluminum instead of copper?

While aluminum wire is generally less expensive than copper, it is also less conductive. This means a larger gauge aluminum wire is needed to carry the same amount of current as a smaller copper wire. It also has different installation requirements. For certain applications, it can be a cost-effective alternative, but the decision should be made with a qualified electrician to ensure safety and code compliance.

Is a Rapid Shutdown Device always required?

In the United States, most new rooftop solar installations fall under National Electrical Code (NEC) regulations that mandate rapid shutdown capabilities. The primary goal is to protect first responders. Ground-mounted systems may have different requirements. It is essential to check your local building and electrical codes to confirm the specific rules for your area.

Why do interconnection costs vary so much?

Interconnection costs differ because each utility company has its own set of technical requirements and fee structures for connecting a system to its grid. These costs are influenced by the size of the solar system, the existing electrical infrastructure in the area, and the specific hardware the utility mandates for safety and grid stability.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.