Scaling AC power by running inverters in parallel sounds straightforward—until different models (or generations) enter the picture. From field audits and lab preparations I’ve done, long-term safety and reliability hinge on tight electrical synchrony and a shared control/communications stack. Below is a practitioner-grade guide to what works, what often fails, and how to decide safely.

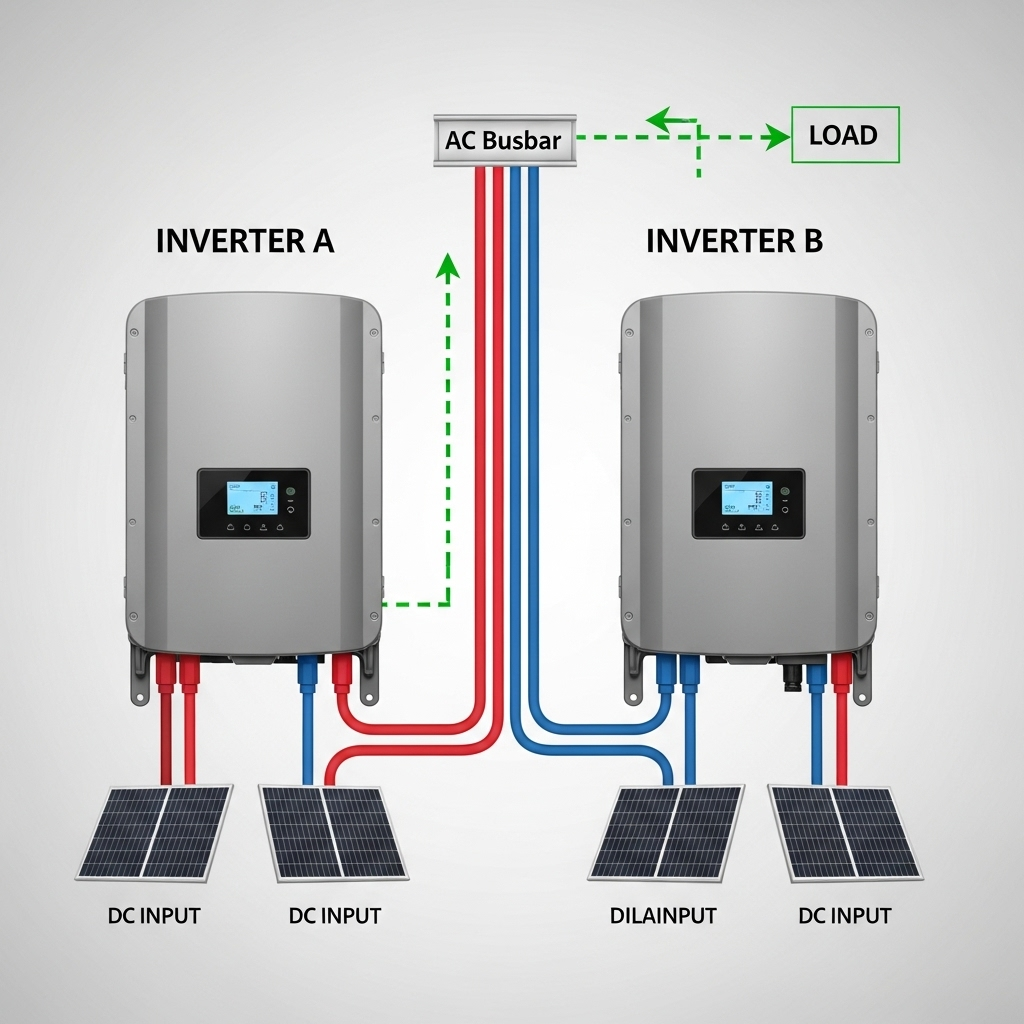

How Parallel Inverters Are Supposed to Work

Parallel operation requires near-identical voltage, frequency, and phase at every instant. Units coordinate through master–follower or droop-control logic and exchange status continuously. When that closed-loop coordination is missing or partly incompatible, load sharing skews, circulating currents grow, and protective functions may trip unpredictably.

Why People Parallel Inverters

Modularity (e.g., two 5 kW units for ~10 kW) and redundancy are the main drivers. Done correctly—with supported hardware/firmware—the approach is robust and serviceable.

Where Mixing Models Goes Wrong

Imbalanced Load Sharing

Minute differences in regulation setpoints, control latency, internal impedance, and thermal behavior push one unit to carry more current. Over time that unit overheats, ages faster, and becomes the chronic “hot” inverter.

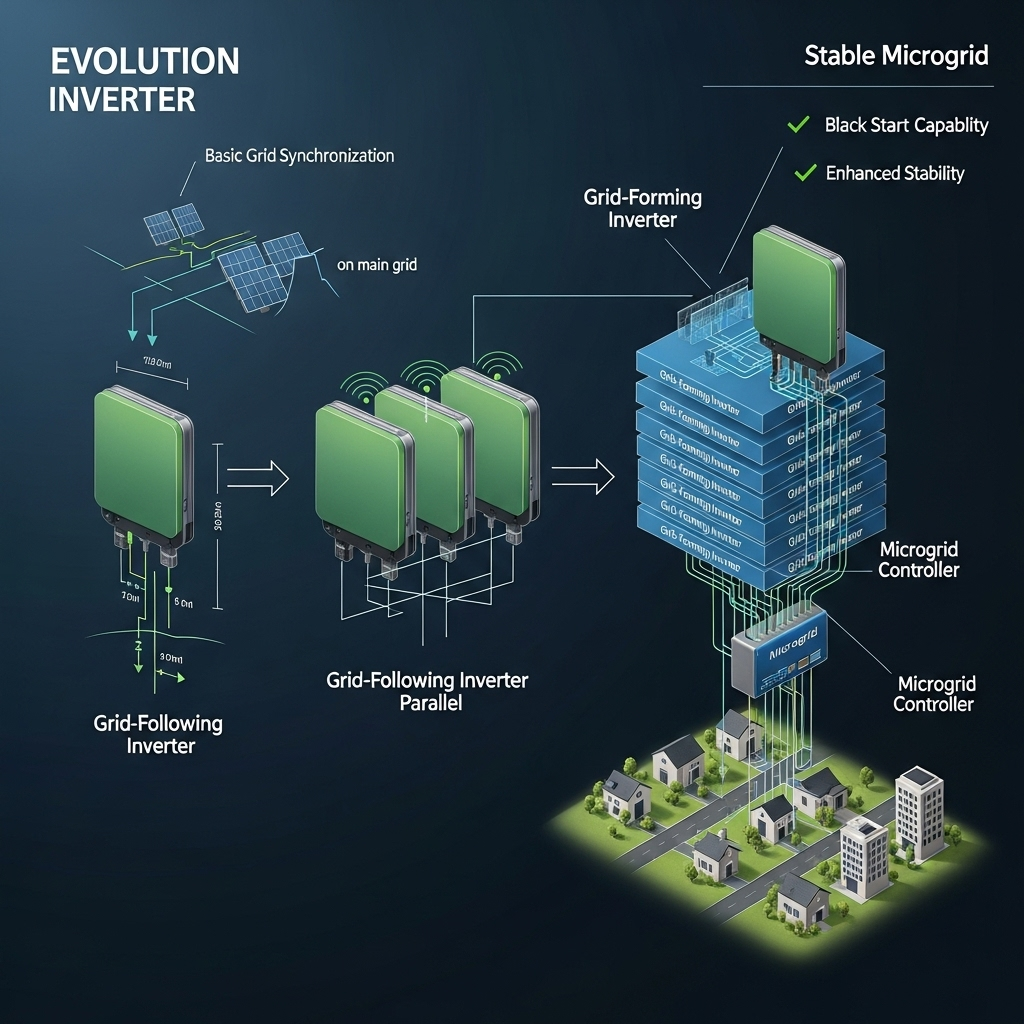

Control/Protocol Conflicts

Parallel features rely on proprietary communications. Different brands—and often different families within a brand—do not coordinate. Without an approved data link, voltage and frequency corrections can fight each other, causing flicker, nuisance trips, or shutdowns.

Component Tolerances & Aging

Electrolytic capacitors, magnetics, and power semiconductors drift differently with temperature and time. Divergence raises harmonic content and makes sharing less stable year by year.

What Standards Do—and Don’t—Cover

IEEE 1547 defines interconnection and interoperability requirements for DERs on U.S. grids (voltage/frequency ride-through, reactive power behavior, etc.), while product safety is handled by standards and schemes appropriate to your market. These frameworks are complementary rather than interchangeable.

Arc-fault protection (AFCI) may be required by local electrical codes (e.g., NEC Article 690.11). Whether your inverter must provide AFCI depends on jurisdiction and installation class—verify locally. For grid-interoperability context, see IEEE 1547 overview. For broader system-quality guidance, see IRENA on quality infrastructure and IEA system transformation.

Safe Configuration Spectrum

| Configuration | Long-Term Safety | Manufacturer Support | Notes |

|---|---|---|---|

| Identical brand & model (same firmware) | High | Yes | Designed for parallel; documented comms and load-sharing behavior. |

| Same platform, cross-rating models | Medium (conditional) | “If approved” | Only when manuals explicitly allow; may require matched firmware and specific wiring. |

| Dissimilar models or brands | Low | No | Absent a supported comms layer, sharing degrades; high risk over time. |

My 8-Step Feasibility Decision Flow

- Start with the manual: Does the vendor explicitly allow parallel operation for the exact model numbers?

- Firmware parity: Confirm required versions and upgrade path; mixed firmwares are a common hidden fault source.

- Communications bus: Use the documented parallel/cluster ports and topology; avoid DIY mixing of RS-485/CAN without vendor guidance.

- Protection coordination: Align OCPD, RCD/GFCI, and ground-fault logic across units.

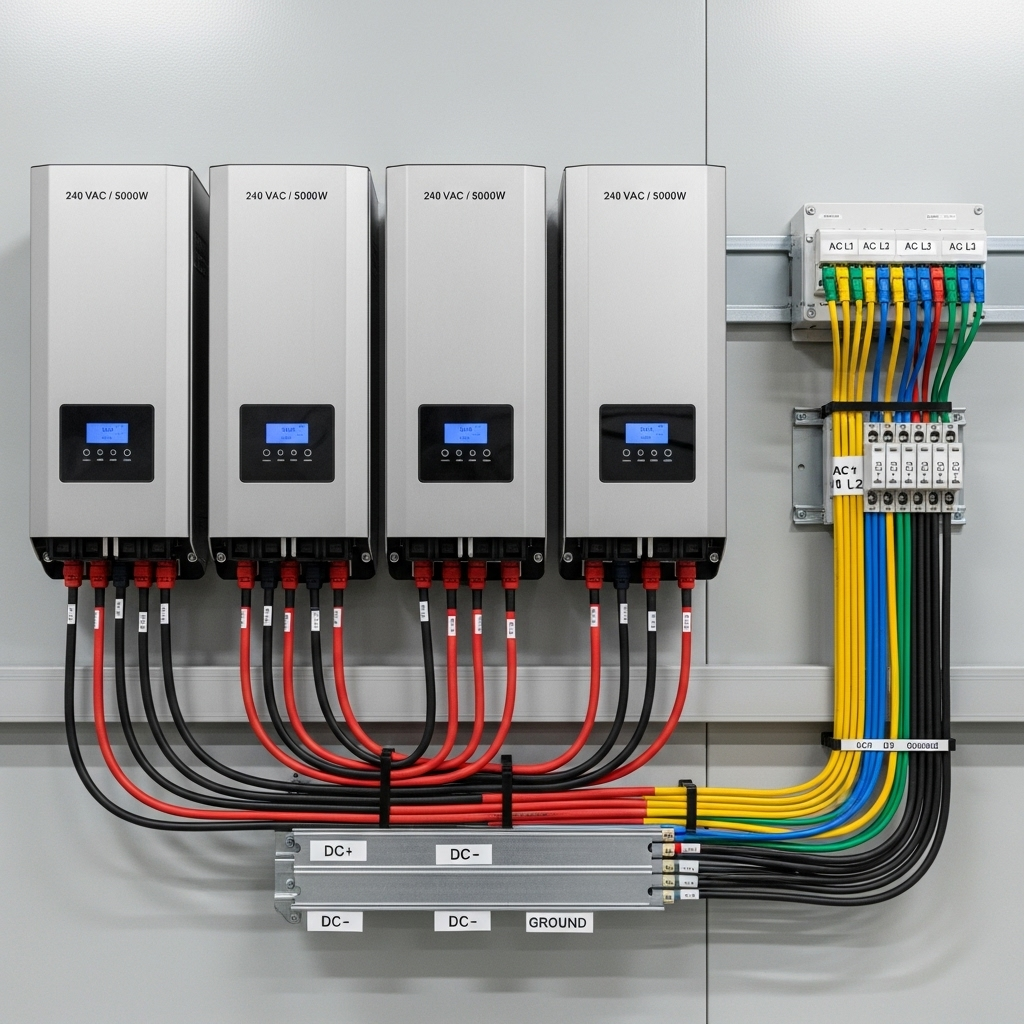

- AC wiring symmetry: Keep feeder length and impedance symmetrical to minimize sharing bias.

- Thermal margin: Verify derating curves; ensure worst-case ambient and altitude still meet nameplate.

- Commissioning tests: Step-load, unbalance, and fail-one-unit tests; record currents per unit.

- Service plan: Define how firmware updates and unit replacements are handled to preserve compatibility over time.

10 Pre-Commission Checks I Use

- Nameplate & firmware screenshots archived for each unit.

- Parallel kit part numbers match the manual’s approved list.

- Identical AC feeder lengths (or measured impedance matching).

- Grounding and bonding verified with continuity measurements.

- No mixed output voltage setpoints; frequency sources unified.

- Thermal imaging under 75–90% load for 30+ minutes.

- Harmonic snapshot (THD%) with and without parallel enabled.

- Nuisance trip check with motor inrush and step loads.

- Fail-one-unit test: remaining unit current within limits.

- Record keeping: test logs, photos, and as-built drawings saved.

Consequences of Ignoring Compatibility

Circulating Currents

Voltage mismatch between outputs creates loop currents that heat components while doing no useful work. Expect lower efficiency and premature capacitor aging.

Instability & Nuisance Trips

Uncoordinated regulation loops can chase each other, causing flicker and trips under transients. Field data often shows one “dominant” unit and one “complaining” unit.

Warranty & Financial Exposure

Most manufacturers exclude damage from unsupported configurations. Absent written approval, failures are typically out-of-warranty.

Bottom Line

Parallel operation is reliable when you follow the vendor’s supported path (identical models/approved families, matched firmware, documented comms). Mixing dissimilar inverters without explicit approval introduces persistent sharing errors and long-term stress. When scalability is a requirement, plan for a single ecosystem from day one or get written confirmation of cross-model compatibility.

Disclaimer: Requirements vary by jurisdiction and product line. Always confirm with the manufacturer’s documentation, your local electrical code (e.g., NEC), and qualified professionals.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.