Installing a solar PV system is a significant step toward energy independence. You choose high-efficiency panels and a reliable inverter. But in regions with heavy snowfall, the success of your entire system often rests on something frequently overlooked: the racking. A solar array is only as strong as its foundation. In high snow zones, under-designed or improperly installed PV racks can lead to catastrophic failure, turning your investment into a liability. Understanding the common pitfalls in snow load engineering is the key to building a system that endures winter after winter.

Understanding Snow Load and Its Impact on PV Racks

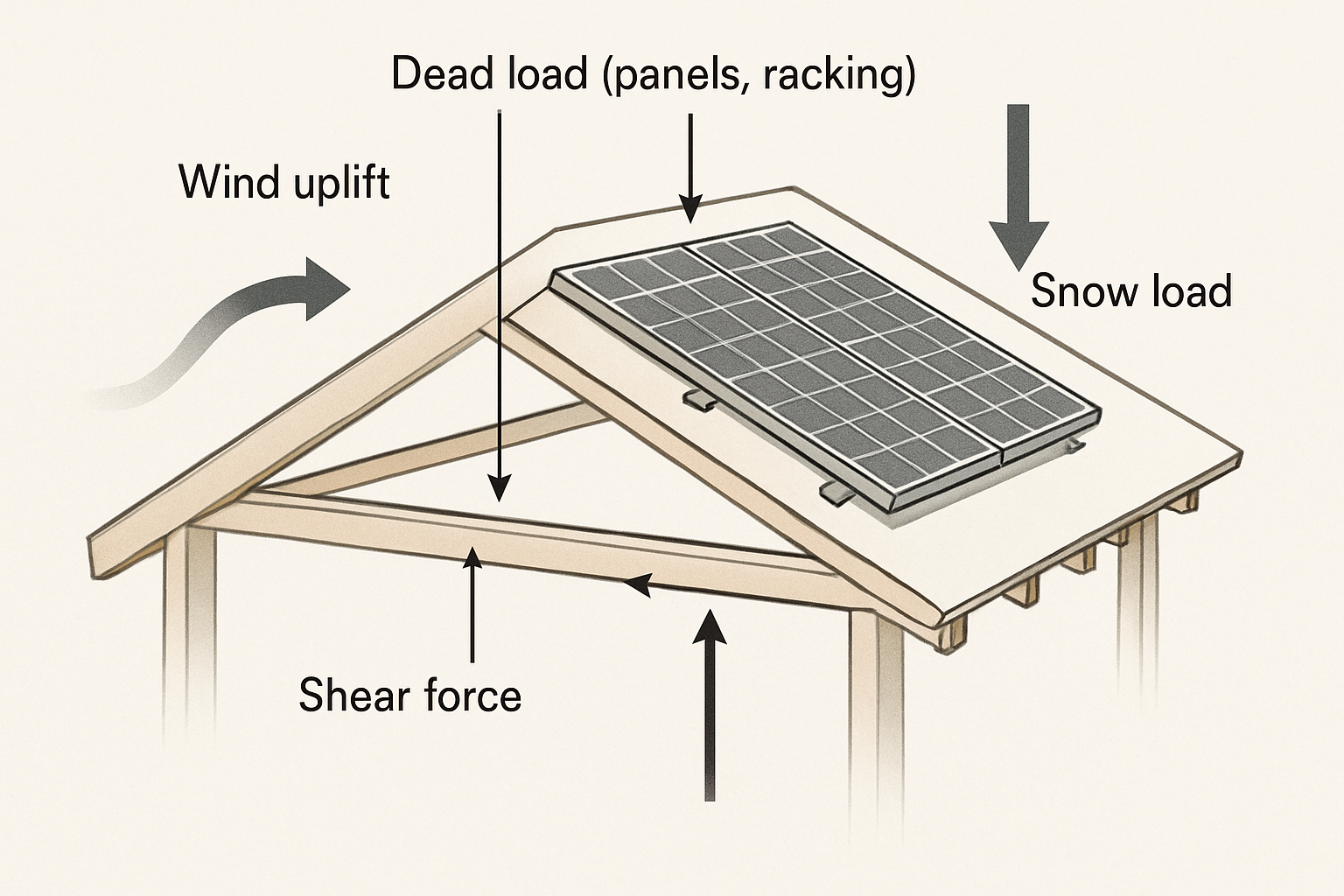

Snow load is the downward force that accumulated snow exerts on a structure. For PV racks, this is a critical design consideration that goes beyond the simple weight of the panels. The forces at play can be immense and complex, requiring careful planning.

The Nature of Snow Load

Snow is not uniform. Its weight can vary dramatically based on moisture content. Light, fluffy snow might weigh very little, while wet, compacted snow can be incredibly dense and heavy. The load also changes. As snow melts and refreezes, it can create ice dams, concentrating weight on specific points of the racking. Furthermore, snow sliding off the panels creates a dynamic load, a sudden force that can be much more damaging than a static, evenly distributed weight.

Why Standard Racking Often Fails

Many off-the-shelf PV racking systems are designed for average climatic conditions. They may be certified for certain wind loads but not for the extreme, prolonged stress of heavy snow accumulation. In high snow zones, using a standard-duty rack is a gamble. The structural integrity of the entire system, from the rails to the smallest fasteners, must be engineered specifically for the anticipated local snow loads to prevent bending, warping, or complete collapse.

The 9 Critical Mistakes to Avoid

Protecting your solar investment starts with avoiding these common but costly errors in PV racking design and installation for snowy environments.

1. Ignoring Local Building Codes and Snow Load Maps

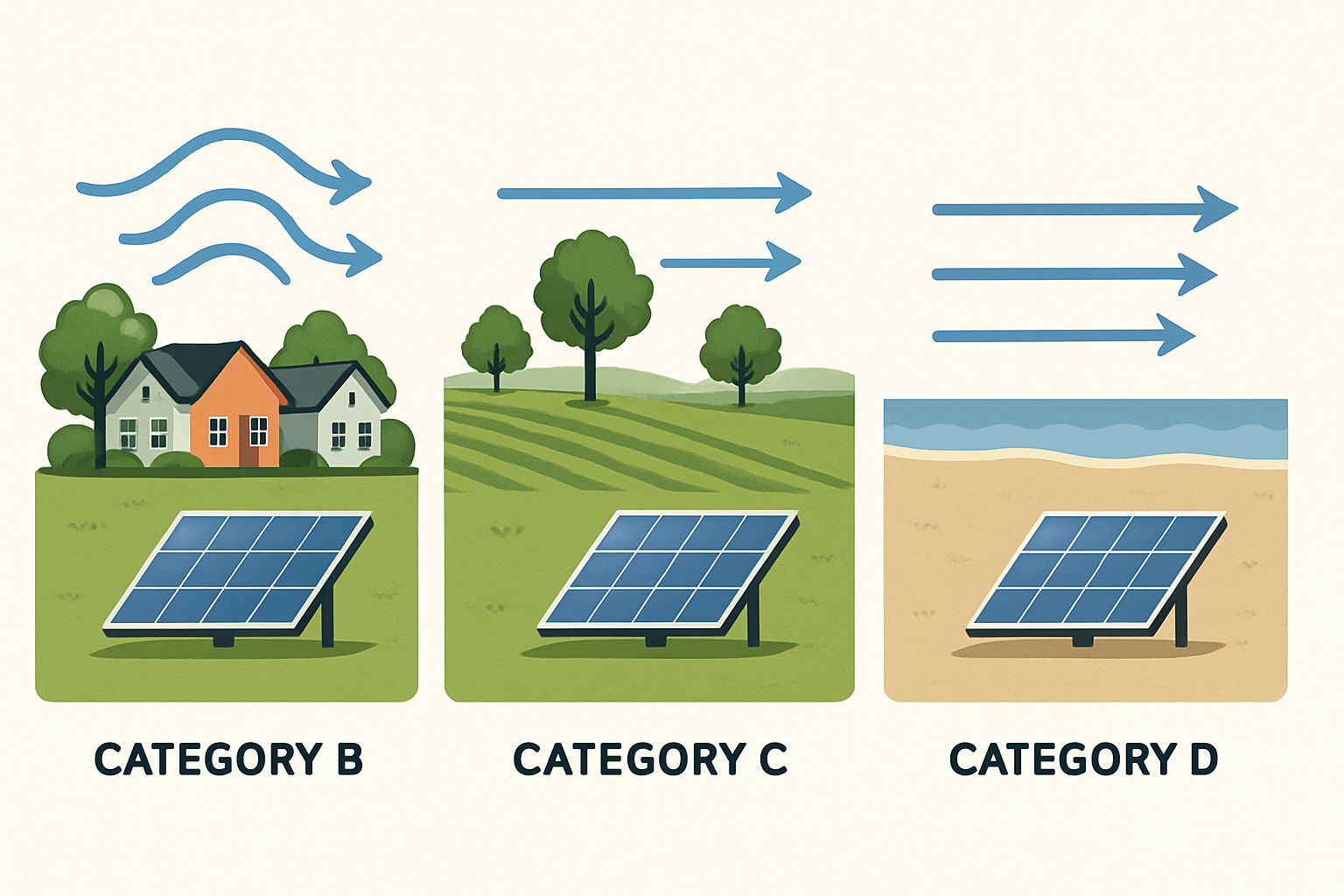

Every jurisdiction with significant snowfall has building codes that specify the ground snow load—a measurement used by engineers to calculate the load on a structure. Ignoring these local requirements is the most fundamental mistake. Always consult your local building authority or a structural engineer to determine the correct design load for your specific location. These codes are not suggestions; they are minimum safety standards.

2. Underestimating the Weight of Wet, Compacted Snow

Many people picture light, fluffy powder when they think of snow. The reality is often much heavier. As snow accumulates and goes through melt-freeze cycles, its density increases dramatically. Designing a racking system based on the weight of fresh snow will leave it vulnerable.

| Snow Type | Approximate Weight per Cubic Foot | Weight on a 200 sq. ft. Array (1-foot depth) |

|---|---|---|

| Light, Fluffy Snow | ~7 lbs (3.2 kg) | ~1,400 lbs (635 kg) |

| Compacted Snow | ~20 lbs (9 kg) | ~4,000 lbs (1,814 kg) |

| Wet, Heavy Snow / Ice | 40-60 lbs (18-27 kg) | 8,000 - 12,000 lbs (3,628 - 5,443 kg) |

3. Using Inadequate Racking Materials

Not all racking is created equal. In high-load environments, material choice is critical. While aluminum is lightweight and corrosion-resistant, heavy-duty steel components may be necessary for long spans or extreme load requirements. Using light-gauge aluminum or components not certified for your area's snow load can lead to material fatigue and failure.

4. Incorrect Rail Spacing and Span Lengths

The distance between roof attachments and the length of the rail that extends past the last attachment point (cantilever) are critical calculations. Exceeding the manufacturer's maximum allowable span for a given load will cause the rails to sag and potentially fail. This is a common shortcut to save on materials, but it severely compromises the system's strength.

5. Improper Fastener and Clamp Selection

The clamps that hold the panels and the fasteners that secure the racking to the roof are the system's connection points. Using the wrong type of clamp (e.g., a top clamp where a mid-clamp is required) or low-quality, unrated bolts can create weak points. Every component must be rated for the calculated load and installed to the correct torque specification.

6. Neglecting the Impact of Snow Sliding (Dynamic Load)

When a large sheet of snow and ice slides off a solar array, it exerts a powerful, sudden downward and outward force on the bottom edge of the panels and racking. This dynamic load can rip panels from their clamps. According to a report by the IEA, the initial impacts of renewable energy systems are often felt locally. As noted in *Getting Wind and Solar onto the Grid*, this principle applies physically too; your array must handle hyper-local forces like sliding snow. Installing snow guards or retention bars on the panels can help break up snow and prevent this dangerous phenomenon.

7. Poor System Design and Panel Orientation

A steeper panel tilt angle helps shed snow more effectively, reducing the static load. While a lower tilt might be optimal for summer sun exposure, in snowy climates, a compromise is often necessary. Placing panels in landscape orientation at the bottom of an array can also create a 'shelf' that catches sliding snow, increasing the load on that row.

8. Skipping Geotechnical Analysis for Ground Mounts

For ground-mounted systems, the foundation is everything. Without a proper geotechnical analysis of the soil, you risk installing a system on ground that cannot support the load. Factors like soil type and frost heave—where frozen soil expands and pushes foundations upward—can compromise the entire structure over time.

9. Overlooking Regular Maintenance and Inspection

Installation is not the final step. A resilient system requires periodic inspection. After major snow events, check for any signs of bending, loose hardware, or damage. Regular checks allow you to address small issues before they become major failures. The goal of a solar installation is long-term, reliable power generation, a topic explored in the IEA's *System Integration of Renewables* report, and that reliability starts with physical integrity.

Best Practices for Snow-Resilient PV Racking

Avoiding mistakes is one half of the equation. The other is proactively implementing best practices. This involves selecting robust components, relying on professional design, and using proper installation techniques to create a system built for the long haul.

Choosing the Right Materials and Components

Opt for racking systems from reputable manufacturers that provide detailed engineering specifications and load tables for their products. Look for high-strength aluminum alloys or structural steel with appropriate corrosion-resistant coatings like galvanization. Ensure all hardware, from bolts to clamps, is made from stainless steel or has a durable protective coating.

The Role of Professional Engineering

For any installation in a high snow zone, a professional structural assessment is a wise investment. An engineer can verify snow loads, calculate appropriate spans and spacing, and produce a stamped letter confirming the design's adequacy. This not only ensures safety but is often required for permits and insurance. Proper planning is essential for successful energy projects, a theme echoed in the IEA's analysis of energy system transformation in *The Power of Transformation*.

Integrating Energy Storage for Year-Round Reliability

A robust racking system protects your ability to generate power. The next step is ensuring you can use that power whenever you need it, especially during long winter nights or power outages. Pairing your securely mounted solar array with a battery storage system creates a truly resilient energy solution. To maximize the energy captured by your panels, understanding solar storage performance is key. A well-designed system ensures you can store this energy effectively. You can find a detailed breakdown of performance metrics in this ultimate reference on solar storage performance.

A Final Check on Your System's Resilience

Building a solar PV system in a high snow zone is a testament to the versatility of renewable energy. However, it demands a higher level of diligence. By understanding and avoiding these nine critical mistakes, you move beyond simply installing panels. You are engineering a durable, long-term power asset that can withstand the harshest conditions, providing clean, reliable energy for decades.

Frequently Asked Questions

How do I find the specific snow load requirements for my area?

The best sources are your local municipal building department or a licensed structural engineer. They can provide the official ground snow load data for your exact address, which is the basis for all structural calculations.

Can I add reinforcements to an existing PV rack?

Retrofitting an existing system is possible but can be complex. It may involve adding more roof attachments to shorten rail spans or installing stiffer rails. Any modification should be designed and approved by a qualified engineer to ensure it effectively increases the load capacity without causing new problems.

Does the tilt angle of my solar panels affect snow load?

Yes, significantly. A steeper tilt angle (e.g., 30-45 degrees) helps snow slide off more easily, reducing the amount of accumulation and the overall load on the structure. A lower tilt angle will hold more snow for longer periods.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.