Installing a rooftop solar array is a significant step toward energy independence. While much attention is given to panel efficiency and inverter capacity, the underlying support structure—the racking mounted on your roof—is equally critical. A thorough structural load analysis is not just a preliminary step; it is the foundation of a safe, durable, and effective solar energy system. This process ensures your roof can handle the added weight and environmental forces for decades, protecting both your home and your investment.

Understanding the Forces at Play: Dead, Live, and Environmental Loads

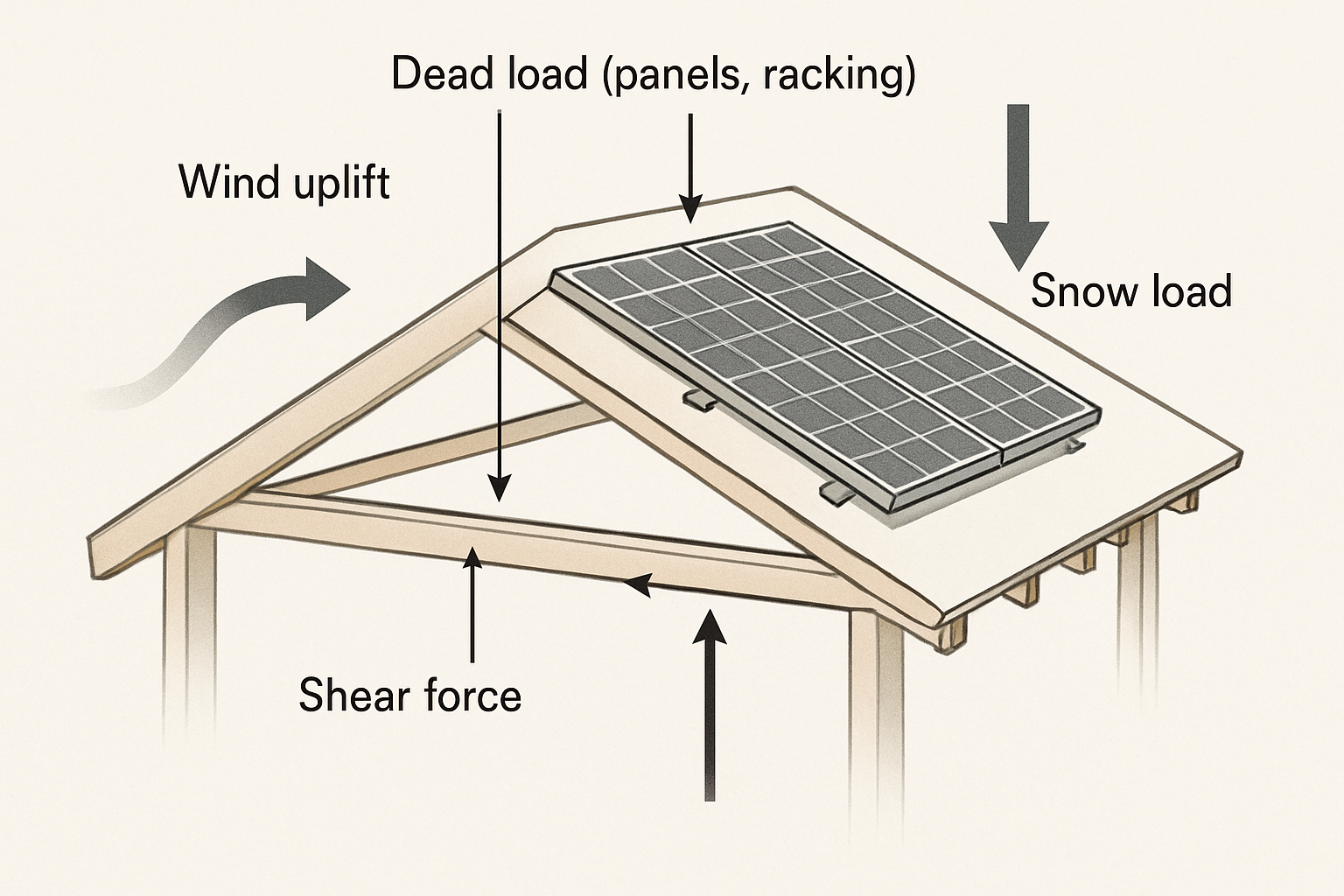

A structural analysis for rooftop PV racking evaluates how different forces interact with your roof. These forces are categorized into three main types: dead loads, live loads, and environmental loads. A complete assessment accounts for all three to ensure PV system structural integrity.

Dead Loads: The Constant Weight of Your System

Dead loads represent the permanent, static weight of the solar installation itself. This includes every component that adds to the roof's burden. The primary contributors are:

- Solar Panels: Typically weighing between 40 to 50 pounds each.

- Racking and Mounting Hardware: The metal rails, clamps, and bolts that secure the panels.

- Inverters and Wiring: Microinverters or power optimizers attached at the panel level also contribute.

On average, a complete solar array adds about 2 to 4 pounds per square foot (psf) to the roof. For a standard 6kW system covering 400 square feet, this translates to an additional 800 to 1600 pounds distributed across the roof structure.

Live Loads: Temporary and Variable Forces

Live loads are temporary forces that a roof must be able to support. For a rooftop solar installation, the most significant live load is snow. The potential weight of accumulated snow varies dramatically by geographic location. Building codes provide specific snow load values, often in psf, that a roof must be designed to withstand. The analysis must account for the possibility of snow drifting and accumulating around the panels, which can create concentrated loads on certain areas of the roof.

Environmental Loads: Wind and Seismic Forces

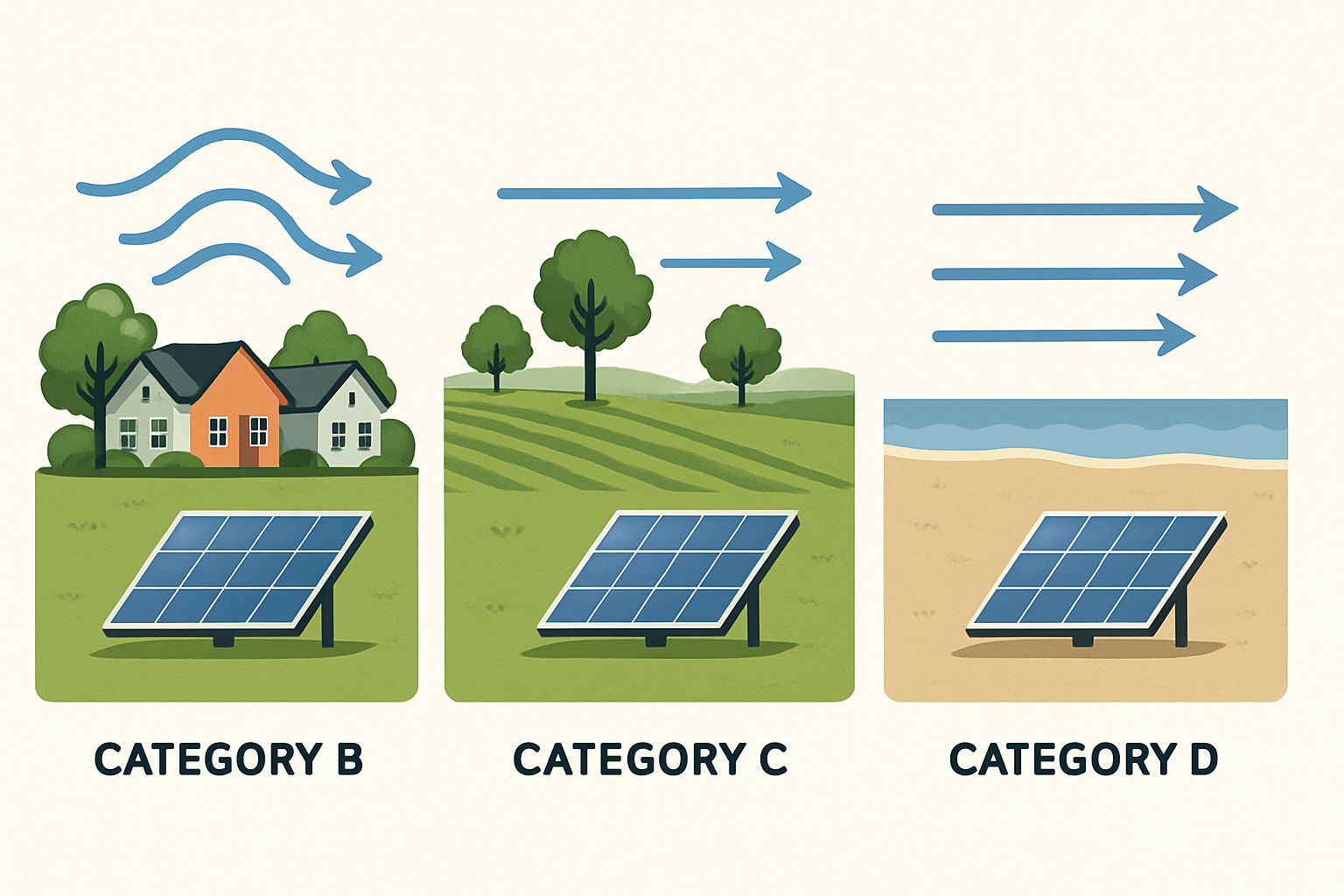

Environmental loads are dynamic forces exerted by nature. Wind is a primary concern, as it can create both downward pressure and significant upward lift on the panels. A proper wind load calculation for solar panels considers factors like basic wind speed in the region, building height, roof shape, and exposure category. Wind uplift can be powerful enough to rip panels from a roof if the racking is not adequately secured. Seismic analysis for rooftop solar is also crucial in earthquake-prone areas. The analysis evaluates how the added mass of the solar array will respond to ground motion, ensuring the racking and its attachments can resist these lateral forces without failing.

The Step-by-Step Process for a Rooftop Structural Analysis

A systematic approach is necessary to accurately assess a roof's ability to support a solar array. The process involves gathering data, performing calculations, and analyzing the results to confirm the roof's capacity.

Step 1: Information Gathering and Site Assessment

The first step is a comprehensive evaluation of the existing structure. This involves collecting key documents and performing a physical inspection. Essential information includes:

- Original Building Plans: These provide details on rafter or truss dimensions, spacing, and material specifications.

- Roof Age and Condition: An inspection identifies any existing damage, such as sagging, water damage, or deteriorated materials.

- Structural Measurements: Manually verifying rafter size and spacing is important if plans are unavailable or outdated.

- Roofing Material: The type of roofing (asphalt shingle, tile, metal) affects mounting options and load distribution.

Step 2: Calculating the Loads

With the site data collected, the next step is to quantify the forces. The dead load is calculated by summing the weights of all solar components and dividing by the area they cover. For live and environmental loads, engineers refer to established standards, such as ASCE 7 (Minimum Design Loads for Buildings and Other Structures) in the United States. The wind load calculation is particularly complex, involving formulas that account for wind velocity, building geometry, and topographic factors to determine pressure and uplift forces on the array.

Step 3: Analyzing the Roof's Capacity

The final step compares the total calculated loads to the roof structure's load-bearing capacity. This analysis determines if the rafters or trusses can support the combined weight and forces without excessive deflection or failure. It is crucial to consider point loads—the concentrated forces where the racking feet attach to the rafters. If the analysis shows that the loads exceed the roof's capacity, structural reinforcement will be necessary before the solar installation can proceed.

Key Factors Influencing PV Racking and Structural Integrity

Beyond the numbers, several practical factors influence the outcome of the structural analysis and the long-term health of the system.

Racking System Selection

The type of rooftop PV racking chosen has a direct impact on load distribution. Rail-based systems typically use standoffs to create point loads on the rafters. Rail-less systems distribute the weight more evenly but may require more attachment points. The selection of the racking system should be an integral part of the structural analysis, not an afterthought.

Attachment and Flashing Techniques

The method of attachment is paramount for PV system structural integrity. The mounting hardware must be secured directly to the roof's structural members (rafters or trusses), not just the decking. Each penetration must be properly sealed with high-quality flashing to prevent water leaks, which could lead to wood rot and compromise the roof's strength over time.

The Role of High-Performance Components

A secure foundation is the first step toward a reliable solar energy system. This principle extends to all components, from the racking to the energy storage solution. High-performance, durable equipment ensures the entire system operates safely and efficiently for its full lifespan. For a deeper look at how component quality affects overall system reliability, the ultimate reference on solar storage performance provides valuable data on long-term efficiency and durability.

When to Call a Professional Structural Engineer

While some aspects of a load analysis are straightforward, the complexity of wind and seismic calculations often requires professional expertise. A qualified structural engineer is essential in several scenarios.

Red Flags That Demand an Expert Opinion

You should always consult a professional engineer if your project involves:

- An older building with no available structural plans.

- Visible signs of roof distress, such as sagging ridges or cracked rafters.

- Unusually long rafter spans or complex roof geometry.

- Locations with very high snow loads or hurricane-level wind speeds.

What to Expect from a Professional Report

A professional structural analysis concludes with a formal report or a stamped letter. This document certifies that the roof has sufficient capacity to support the proposed solar array. If the roof is found to be inadequate, the report will specify the necessary structural upgrades, such as sistering rafters or adding support beams.

Disclaimer: This information is for educational purposes only and does not constitute professional engineering or legal advice. Always consult with a qualified structural engineer and adhere to local building codes for any solar installation.

A Look Forward: Ensuring Long-Term System Safety

A structural load analysis is a snapshot in time. Ensuring the long-term safety of a rooftop PV system also requires periodic inspections to check for loose hardware or signs of roof degradation. According to a report by the IEA, The Power of Transformation, proper system design and installation are foundational for the successful large-scale deployment of renewable energy. This starts at the individual project level. Furthermore, as noted in the IEA's System Integration of Renewables analysis, robust technical standards are critical as renewable energy becomes a larger part of the power grid. These standards inherently include structural safety and reliability. Even economic studies, such as IRENA's report on Renewable Power Generation Costs in 2024, identify that soft costs like system design and structural analysis are a key part of project expenses, underscoring their importance in a successful installation.

Frequently Asked Questions

How much weight does a typical solar panel system add to a roof?

A typical rooftop solar system adds approximately 2 to 4 pounds per square foot (psf). The exact weight depends on the type of panels and the racking system used. Most modern roofs are designed to handle loads far exceeding this, but an analysis is required to confirm this for your specific structure.

Can my roof be reinforced to support a solar array?

Yes, in many cases, a roof can be reinforced. A common method is 'sistering,' which involves attaching new joists alongside the existing rafters to increase their strength and stiffness. A structural engineer can design the most effective and economical reinforcement plan.

Is a structural analysis legally required for a solar installation permit?

Most local building departments require a structural analysis or a letter from a licensed engineer as part of the permitting process for a rooftop solar installation. This requirement ensures that the installation complies with local safety standards and building codes. Always check with your local authority having jurisdiction (AHJ).

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.