Your solar panel system is a significant investment in energy independence. It sits silently on your roof, harnessing the sun's power day after day. But it's also constantly exposed to powerful environmental forces. Among the most underestimated of these are 3-second gusts—short, violent bursts of wind that can exert extreme stress on your installation. The safety and longevity of your entire system often depend on one critical component: the mounting rails and, specifically, their span.

Understanding the Forces at Play: Wind and Snow Loads

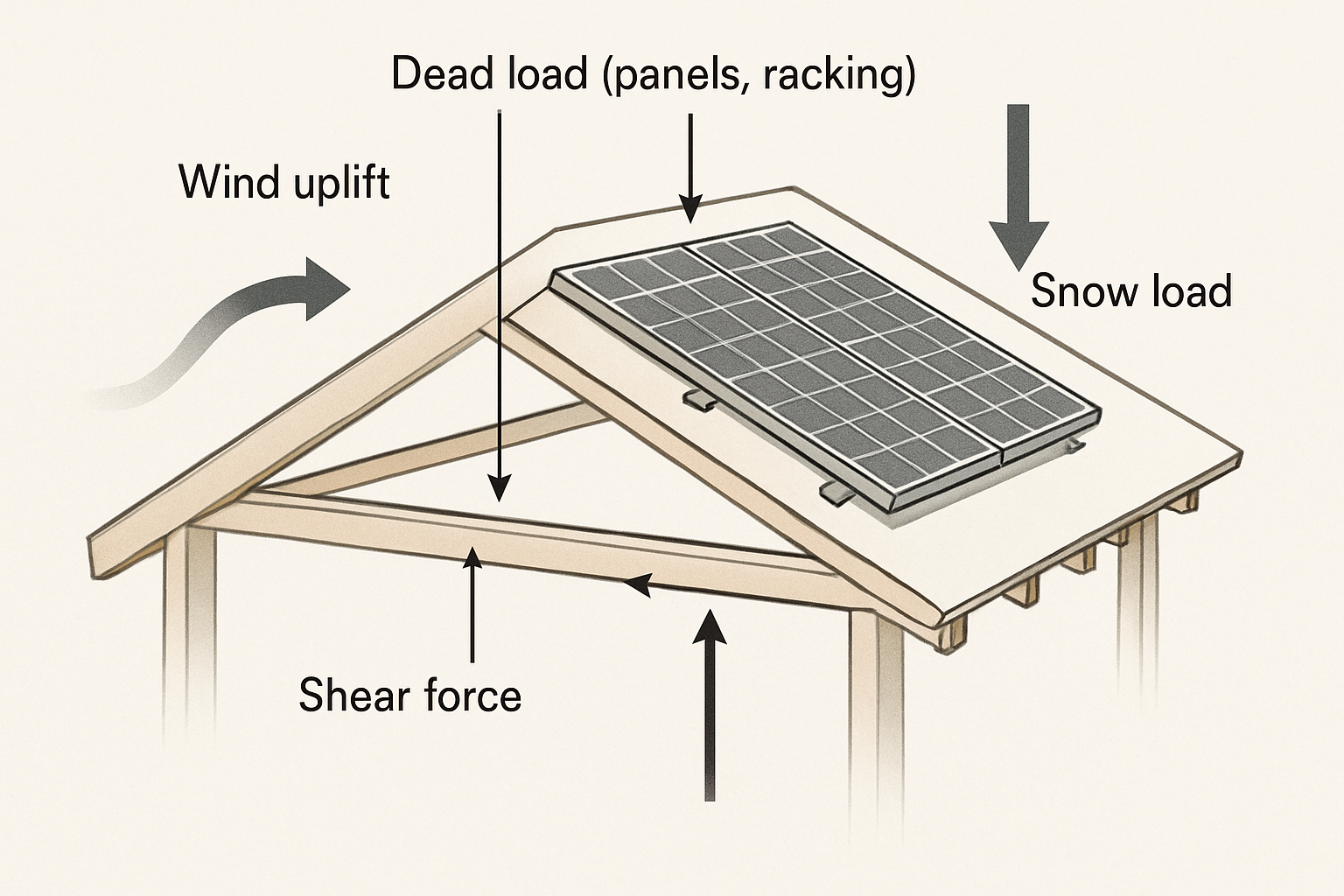

A secure solar installation is an exercise in engineering that accounts for multiple, often simultaneous, environmental pressures. Wind and snow are the primary adversaries, and their behavior is more complex than many realize.

What Are 3-Second Gusts?

While official weather reports often cite sustained wind speeds, it's the sudden, intense gusts that pose the greatest threat to structures. A 3-second gust is the highest average wind speed over a 3-second period. For structural engineering purposes, standards like ASCE 7-16 use this measurement to calculate peak wind loads. These brief, powerful forces can create immense uplift and shear on solar panels, acting like a sail and attempting to rip the array from the roof. A system designed only for average wind speeds may not be prepared for these peak moments of stress.

The Combined Effect of Wind and Snow

Snow load adds another layer of complexity. A heavy blanket of snow adds significant static weight to your entire solar array and roof structure. This weight pre-stresses the mounting rails and attachments. When a powerful wind gust occurs, it can create uplift forces that work against the snow's weight, causing fluctuating loads that can weaken components over time. In other scenarios, wind can cause snow to accumulate unevenly, creating unbalanced loads known as snow drifts. Proper engineering must account for the worst-case combination of these forces as defined by local building codes.

The Critical Role of Rail Spans in System Stability

The foundation of a wind-resistant solar array is the racking system, and the distance between mounting points—the rail span—is arguably the most important design choice.

Defining Rail Spans

A rail span is the distance between the roof attachments (feet or mounts) that support the mounting rail. Think of it like the distance between the support pillars of a bridge. The rail itself must bridge this gap while supporting the solar panels and resisting all environmental forces. A shorter span provides more support points, distributing the load more effectively and increasing the system's overall strength.

How Span Length Impacts Wind Resistance

The relationship between rail span and strength is straightforward: longer spans are weaker than shorter spans. When a rail spans a greater distance, it is more susceptible to bending and flexing under load. During a high-wind event, this flex can transfer stress directly to the solar panel's frame and glass, potentially causing microcracks or catastrophic failure. Shorter spans create a more rigid and robust framework, ensuring that wind forces are transferred efficiently from the panels, through the rails, and into the building structure. Manufacturers provide detailed span tables that specify the maximum allowable distance between attachments for different wind and snow load conditions. Adhering to these tables is not optional; it's essential for safety and warranty compliance.

| Maximum Rail Span | Design Wind Speed (ASCE 7-16) | Assumed Snow Load |

|---|---|---|

| 4 feet (48 inches) | 160 mph | 30 psf |

| 6 feet (72 inches) | 130 mph | 30 psf |

| 8 feet (96 inches) | 110 mph | 30 psf |

Disclaimer: This table is for illustrative purposes only and does not represent any specific product. Always consult the official engineering documentation for your specific racking system.

Material and Profile: Not All Rails Are Equal

The material and shape of the mounting rail are also crucial. Most high-quality rails are made from structural aluminum alloys, which offer an excellent balance of strength and light weight. The rail's cross-sectional profile is engineered to maximize stiffness and resist bending forces. A well-designed rail profile can handle significant loads, but it still must be used within the specified span limits.

Engineering for Safety: Calculation and Best Practices

Ensuring your rail spans are safe involves more than just a guess. It requires careful calculation based on established engineering standards and an understanding of your specific location.

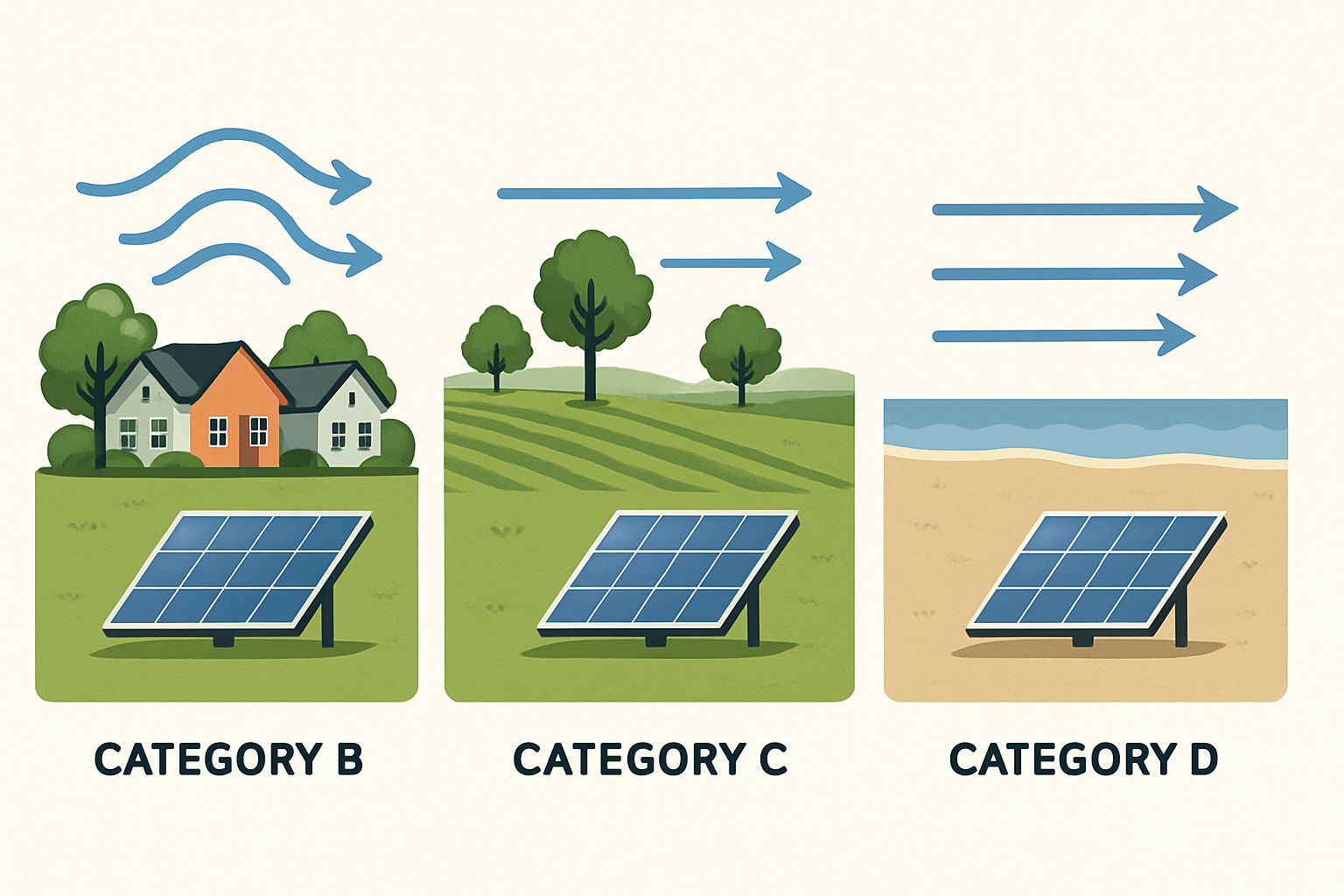

The Basics of Load Calculation

Structural engineers use standards from the American Society of Civil Engineers (ASCE) to determine environmental loads on buildings and other structures. The calculations for wind load are complex, involving factors like basic wind speed, risk category of the building, exposure category (urban vs. open terrain), building height, and specific roof zones (corners and edges experience higher forces). These calculations produce a design pressure (in pounds per square foot) that the solar installation must withstand. Racking manufacturers use these principles to create their certified span tables.

Practical Steps for a Secure Installation

For a safe and compliant installation, always follow these steps:

- Consult Manufacturer Span Tables: This is the most critical step. The manufacturer has performed the necessary engineering calculations for their product. Never exceed the maximum span listed for your site's wind and snow load conditions.

- Know Your Local Codes: Your local building department can provide the required design wind speed and ground snow load for your area.

- Consider All Components: The entire system is only as strong as its weakest link. Use high-quality, compatible components, including mounting feet, flashing, bolts, and clamps, to ensure a secure load path from the panel to the roof structure.

- Seek Professional Guidance: If you are unsure about any aspect of the design, consult a qualified solar installer or a structural engineer. Their expertise can prevent costly and dangerous mistakes.

A secure physical foundation is the first step toward a reliable energy system. Just as proper rail spans ensure your panels withstand the elements, understanding the performance of all your components is key to achieving energy independence. For a deeper look into system efficiency, the ultimate reference for solar storage performance offers valuable insights into maximizing your energy investment.

Final Thoughts on Securing Your Energy Investment

The integrity of your solar panel installation rests on the engineering that underpins it. Three-second wind gusts are a powerful and unavoidable force of nature. Your primary defense against them is a properly designed mounting system with safe and compliant rail spans. Compromising on the distance between roof attachments to save a small amount on hardware is a risk that is not worth taking. By respecting the principles of wind load engineering and strictly following manufacturer guidelines, you ensure your solar energy system remains a safe, reliable, and productive asset for decades.

Frequently Asked Questions

Can I use longer rail spans to save on mounting feet?

While it might seem cost-effective, extending spans beyond the manufacturer's specifications is dangerous and can lead to system failure. The reduced cost of hardware is insignificant compared to the potential for damage to your roof, solar panels, or property. Always adhere to engineered span tables.

How do I find the correct wind speed for my area?

Your local building authority or a qualified structural engineer can provide the design wind speed for your specific location, based on standards like the ASCE 7 maps. This is a critical piece of data for designing a safe solar installation.

Does the type of roof I have affect the rail span?

Yes. The type of roof structure (e.g., trusses, rafters) and its condition determine how and where mounting feet can be attached. The spacing of these structural members often dictates the maximum possible rail span, which must then be checked against the wind and snow load requirements to ensure it is within the allowable limits.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.