The foundation of any rooftop solar installation is its mounting system. This hardware secures your solar panels to the roof, ensuring they remain stable and productive for decades. The type of roof you have—pitched or flat—is the single most important factor in determining the correct roof racking solution. Choosing the right system is critical for the safety, longevity, and performance of your entire solar energy array.

Racking Systems for Pitched Roofs

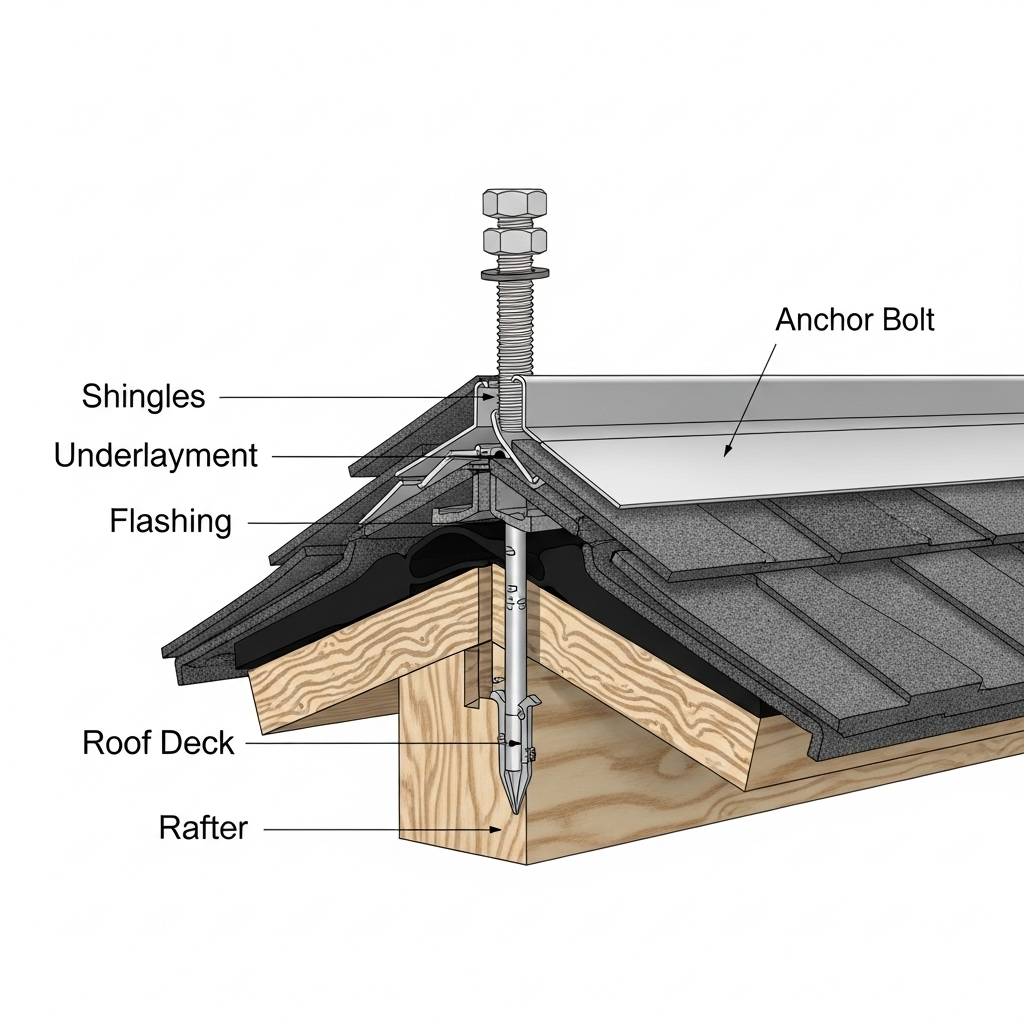

Pitched roofs are the most common type for residential homes. The primary goals for mounting on these surfaces are creating a secure attachment to the roof's structure and ensuring every penetration is perfectly weatherproof. Several proven designs accomplish this.

Rail-Based Mounting Systems

The traditional and most widely used method is the rail-based system. It consists of a series of components working together. First, attachments with flashing are secured directly to the roof rafters for strength. Then, long aluminum rails are mounted onto these attachments. Finally, the solar panels are secured to the rails with specialized clamps. This approach offers excellent strength and evenly distributes the system's weight. Its versatility makes it suitable for a wide variety of roof materials and panel configurations.

Rail-Less Mounting Systems

A more recent innovation, rail-less systems offer a sleeker, lower-profile appearance. Instead of long rails, these systems use a series of smaller mounting blocks or feet that attach directly to the roof rafters. The panels then connect to these individual points. This design uses fewer components, which can speed up installation time. The result is a clean aesthetic where the panels appear to float just above the roof surface. However, they may offer less adjustability on uneven roof surfaces compared to rail-based options.

Shared-Rail Systems

Shared-rail systems present a hybrid solution that blends the concepts of rail-based and rail-less designs. This method uses a single rail to support the edges of two adjacent rows of solar panels, effectively reducing the total amount of railing material by up to a third. This leads to cost savings, fewer roof penetrations, and a quicker installation process. While efficient, these systems require precise layout and planning to ensure proper support and alignment.

Racking Systems for Flat Roofs

Flat roofs, common on commercial buildings and some modern homes, present different challenges. Without a natural slope, the racking system must create the optimal tilt angle for the panels to face the sun. It must also manage wind uplift and drainage effectively. According to a report by the International Energy Agency, the mechanical installation, including the racking system, is a core component of a solar project's cost and structure. As detailed in the Renewable Power Generation Costs in 2024 report, proper installation is fundamental to system viability.

Ballasted Mounting Systems

Ballasted systems are a popular non-penetrating solution for flat roofs. Instead of bolts, this system uses the simple principles of gravity and friction. A tray-like structure holds the panels at the desired angle, and concrete blocks or other heavy materials are placed within the structure to hold it down. This avoids drilling holes into the roof, which is a major advantage for preserving the roof's warranty and preventing potential leaks. However, ballasted systems add significant weight, so a professional structural assessment is always necessary to confirm the roof can support the additional load.

Mechanically Attached Systems

For flat roofs that cannot support the weight of a ballasted system, a mechanically attached or penetrating system is the alternative. This method involves anchoring the racking hardware directly to the roof's structural joists or deck. Similar to pitched roof installations, these penetrations must be meticulously sealed with flashing and high-grade sealants to ensure a watertight finish. This approach is much lighter than a ballasted system and provides superior resistance to wind uplift, making it a secure choice in high-wind regions.

Key Factors in Selecting Your Racking System

Choosing between these options requires a careful evaluation of your specific property and local environment. Several factors will influence the final decision to ensure a safe and productive PV mounting system.

Roof Material and Structure

Your roof's covering dictates the type of attachment hardware needed. Asphalt shingles, standing seam metal, clay tiles, and flat membranes each require specialized components to ensure a secure and leak-proof connection. More importantly, the underlying structure must be able to handle the static load of the solar array and the dynamic forces of wind and snow. A thorough structural analysis is a non-negotiable first step in any solar panel installation project.

Environmental Conditions: Wind and Snow Loads

Racking systems are engineered to withstand extreme weather. The design must account for the maximum expected wind speeds and the heaviest potential snow accumulation in your area. Engineers use local building codes and standards to calculate these forces and ensure the selected racking can handle the stress. As power grids evolve to include more renewables, the physical resilience of each installation becomes paramount. The IEA's analysis in The Role of Critical Minerals in Clean Energy Transitions highlights that robust electricity networks are the 'backbone of secure and reliable power systems,' a principle that applies directly to the structural integrity of individual solar arrays.

System Performance and Tilt Angle

The angle of your solar panels has a direct impact on their energy production. On flat roofs, the racking system is what creates this tilt. On pitched roofs, the panels typically follow the existing roofline. Optimizing the tilt and orientation can significantly boost your system's output. The physical setup is a critical variable in overall efficiency. For a detailed analysis of how these factors influence output, you can review this ultimate reference on solar storage performance, which explains the relationship between system configuration and energy generation.

A Forward Look at Racking Technology

The right solar racking is more than just a mounting bracket; it is a long-term investment in the security and efficiency of your energy system. As technology advances, new materials and designs are making racking systems lighter, stronger, and easier to install. The constant innovation in this area ensures that solar energy remains a reliable and accessible option for more applications. Ultimately, selecting a high-quality PV mounting system designed for your specific roof and climate is the best way to protect your investment and enjoy clean energy for years to come.

Frequently Asked Questions

Does solar racking damage my roof?

Properly installed racking should not damage your roof. Professional installers use flashing and industrial-grade sealants to create watertight seals at every penetration point. Ballasted systems for flat roofs avoid penetrations altogether, preserving the integrity of the roof membrane.

How much weight does a PV mounting system add?

The added weight varies by system type. A typical rail-based system adds about 3-5 pounds per square foot (psf). Ballasted systems are significantly heavier, often ranging from 10 to 30 psf depending on wind zone requirements. A structural engineer must always verify your roof's load-bearing capacity before installation.

Can I install racking on any type of roof?

Most common roof types are compatible with solar, including asphalt shingle, metal, tile, and flat commercial roofs. Each material requires specific hardware and installation techniques to ensure a secure, weatherproof mount. Roofs that are old or have existing structural issues may need repairs or reinforcement before a solar installation can proceed.

What is the main difference between pitched and flat roof racking?

Pitched roof racking primarily focuses on attaching securely to the roof's angled structure while maintaining weatherproofing. Flat roof racking has the dual job of securing the array and creating an artificial tilt for the panels to optimize sun exposure, often using weights (ballasts) instead of structural attachments.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.