High temperatures are a persistent challenge for power electronics. As components work to convert and manage electricity, they generate heat. Without a clear path to escape, this heat can degrade performance, shorten lifespan, and trigger thermal derating—a protective measure where the system intentionally reduces its power output to prevent damage. Effective thermal design is not a luxury; it is fundamental to creating reliable and efficient energy systems.

The Physics of Heat in Power Electronics

Understanding where heat originates and how it travels is the first step toward managing it. The principles are straightforward, but their application determines whether a system thrives or fails under thermal stress.

Where Does the Heat Come From?

Heat generation in power electronics is a direct byproduct of electrical inefficiency. Every component that isn't a perfect conductor or a perfect switch will lose some energy as heat. The primary culprits are semiconductors, such as MOSFETs and IGBTs, which generate heat through two main processes:

- Conduction Losses: This occurs when a transistor is on and conducting current. The internal resistance of the component (known as RDS(on) in MOSFETs) causes some power to be dissipated as heat.

- Switching Losses: Heat is also generated each time a transistor switches on or off. During this brief transition, the component is neither fully on nor fully off, resulting in a momentary spike in power dissipation. At high frequencies, these losses add up quickly.

Other components like transformers, inductors, and even capacitors also contribute to the overall thermal load.

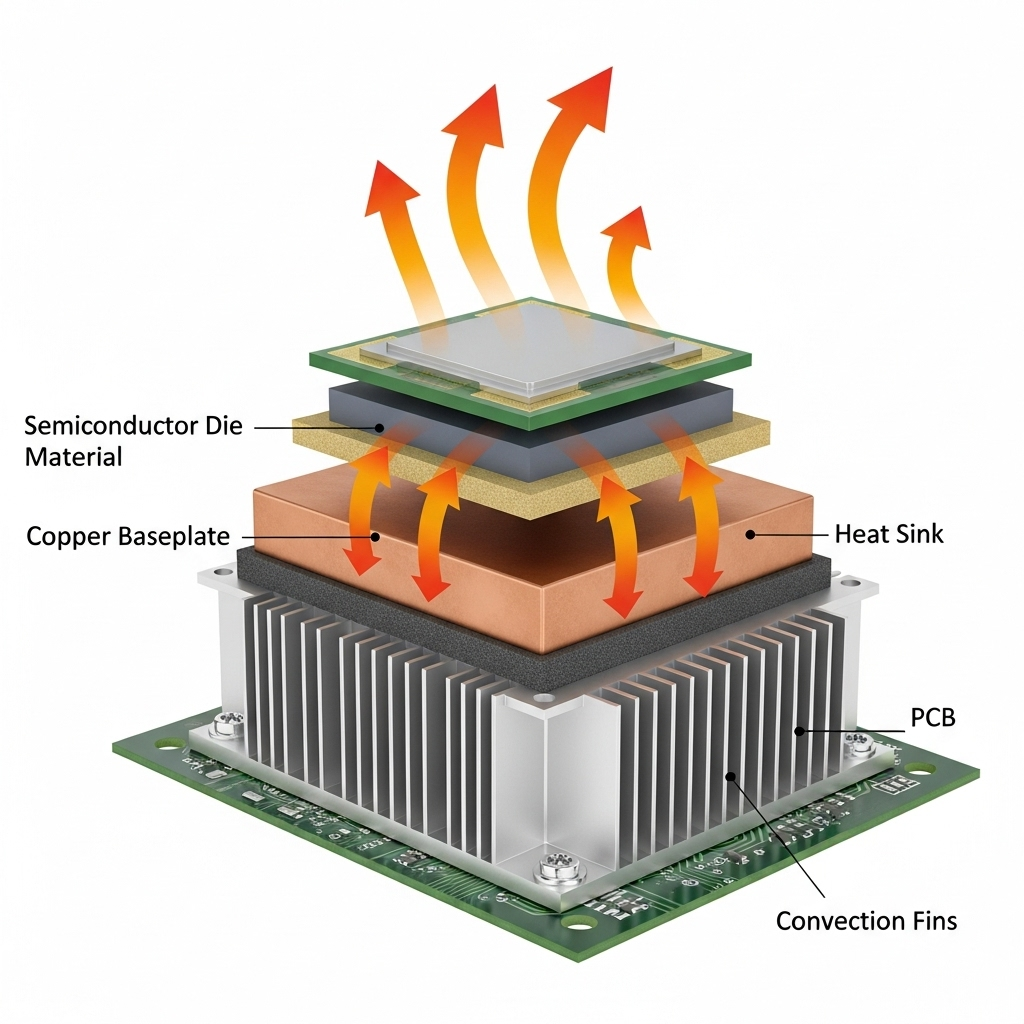

Understanding Thermal Resistance

Think of thermal resistance as a measure of how difficult it is for heat to move from one point to another. The goal in thermal design is to create a low-resistance path from the heat source (the semiconductor die) to the ambient air. This path typically includes several layers: the component's internal structure, the thermal interface material (TIM), the heat sink, and finally, the surrounding air. Lowering the total thermal resistance allows heat to escape more easily, keeping component temperatures in a safe range.

Core Strategies for Passive Thermal Management

Passive thermal management relies on natural processes like conduction and convection to dissipate heat without consuming additional power. A smart passive design forms the foundation of any robust thermal strategy.

Component Selection and PCB Layout

Effective thermal management begins at the circuit board level. Selecting components with lower internal resistance directly reduces the amount of heat generated. On the printed circuit board (PCB), wide copper traces and thermal vias (small plated holes) can act as mini heat sinks, drawing heat away from critical components and spreading it over a larger area. Strategic placement of hot components can also prevent localized hot spots and facilitate natural airflow.

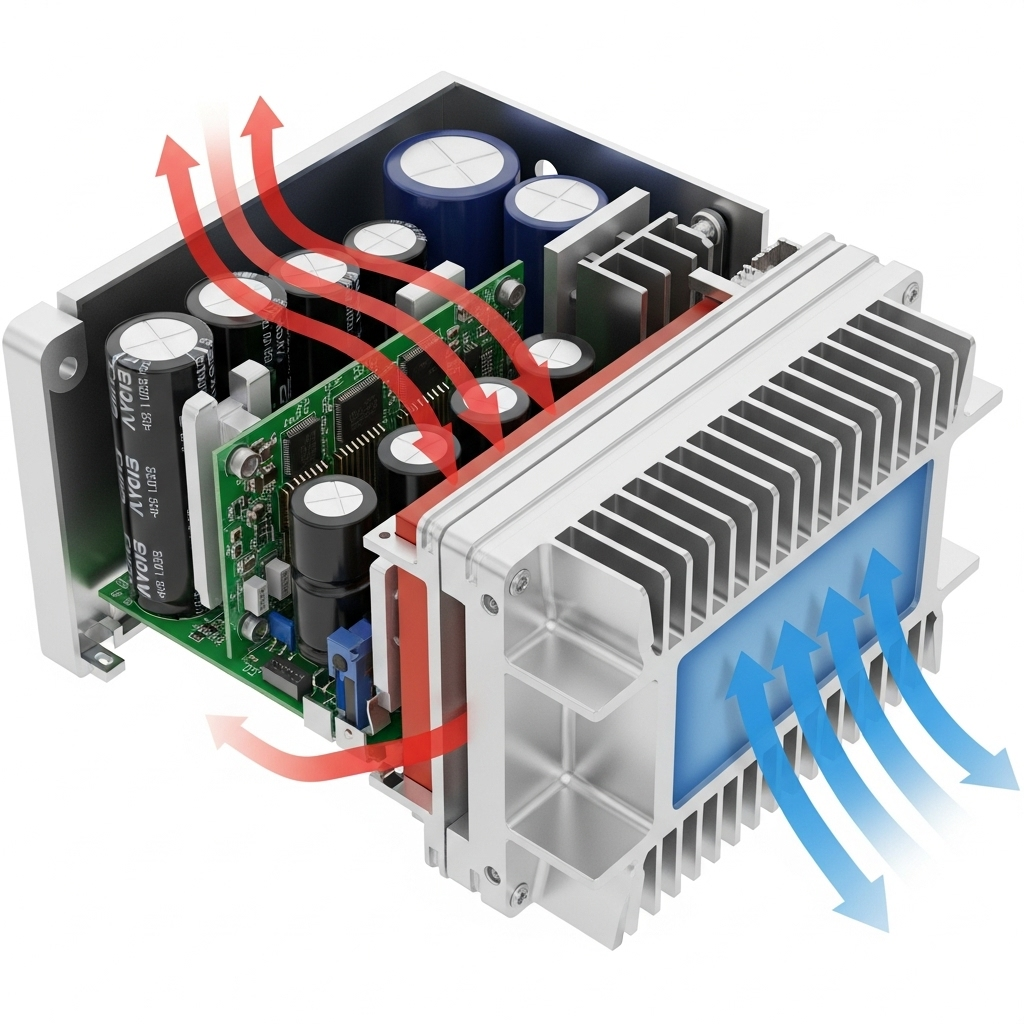

The Role of Heat Sinks and Enclosures

A heat sink's job is to provide a large surface area for transferring heat to the air. While material matters—copper conducts heat better than aluminum, but is heavier and more expensive—the design of its fins is just as important. Fin geometry affects how efficiently air can move through the heat sink and carry heat away. The enclosure itself also plays a critical role. Proper ventilation, including the placement of intake and exhaust vents, encourages natural convection, creating a continuous flow of cooler air through the system.

Active Cooling Solutions for Demanding Applications

When passive methods are insufficient to handle the heat load, active cooling solutions are necessary. These systems use energy to accelerate heat removal, but they introduce their own design considerations.

When to Use Fans and Forced Air

Forced air cooling, using fans, dramatically increases the rate of heat transfer compared to natural convection. This is essential for high-power or compact systems. However, fans add complexity, consume power, generate noise, and are a potential point of mechanical failure. Modern systems often use smart fan controllers that adjust fan speed based on temperature. This approach minimizes noise and power consumption while extending the fan's operational life. As noted in the IEA report, China Power System Transformation, active temperature management can significantly improve operational flexibility, a principle that applies directly to managing heat in power electronics.

Advanced Cooling: Liquid and Phase-Change Systems

For the most demanding applications, air cooling may not be enough. Liquid cooling systems circulate a coolant through cold plates attached to hot components, transferring heat to a remote radiator. These systems offer superior thermal performance but are more complex and costly. Another advanced technology is the heat pipe, a passive phase-change device that can move heat over a distance with very low thermal resistance, often used to transport heat from a constrained area to a larger heat sink.

| Cooling Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Passive (Natural Convection) | Silent, reliable (no moving parts), zero power consumption | Limited cooling capacity, bulky | Low-power applications, systems where reliability is paramount |

| Active (Forced Air) | High cooling capacity, cost-effective, mature technology | Noise, power consumption, potential for fan failure | Most solar inverters, charge controllers, and mid-range ESS |

| Liquid Cooling | Extremely high cooling capacity, enables high power density | Complex, expensive, risk of leaks | High-power grid-tied inverters, EV fast chargers, data centers |

System-Level Integration and Verification

A successful thermal design considers the entire system, not just individual components. Modeling, testing, and understanding performance metrics are all part of a holistic approach.

The Importance of Thermal Modeling

Before building physical prototypes, engineers use software tools for thermal modeling. Computational Fluid Dynamics (CFD) analysis can simulate airflow and temperature distribution within an enclosure, helping to identify potential hot spots and optimize the placement of components and vents. This predictive approach saves time and resources by catching design flaws early in the development process.

Integrating Thermal Storage for System Resilience

At a broader system level, thermal energy storage (TES) can enhance resilience. By storing thermal energy, systems can better manage loads and reduce peak stress on power electronics. According to a report from IRENA, Innovation outlook: Thermal energy storage, TES helps decouple power availability from demand, which in turn alleviates strain on the power conversion equipment that manages energy flow.

Performance Metrics and Real-World Data

Ultimately, the effectiveness of a thermal design is measured by its real-world performance. Manufacturers provide derating curves that show how a device's maximum power output changes with ambient temperature. Understanding how to read these curves is essential for proper system design. For a deeper look at how thermal management impacts overall system output, it is vital to understand key metrics. The ultimate reference for solar storage performance offers valuable insights into measurements like Round-Trip Efficiency, which is directly affected by temperature and component health.

Designing for Reliability, Not Just Power

Effective thermal management is a core pillar of reliable power electronics design. By carefully considering the path of heat from its source to the ambient environment, engineers can create systems that operate efficiently and avoid derating, even in challenging conditions. A proactive, holistic approach to heat dissipation ensures that an energy system delivers consistent power and achieves its expected lifespan.

Frequently Asked Questions

What is the primary cause of overheating in power electronics?

The primary causes are energy losses during operation, mainly conduction and switching losses in semiconductor components like MOSFETs and IGBTs. These inefficiencies convert electrical energy into heat.

How does ambient temperature affect derating?

Higher ambient temperatures reduce the temperature difference between the electronic components and the surrounding air. This makes it harder for heat to dissipate, forcing the system to reduce its power output (derate) to avoid exceeding safe operating temperatures.

Is liquid cooling better than air cooling for all power electronics?

Not necessarily. Liquid cooling is highly effective for high-power-density applications where air cooling is insufficient. However, it adds complexity, cost, and potential points of failure. For many solar and storage systems, a well-designed air cooling system (passive or active) is the most reliable and cost-effective solution.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.