Solar panels are a powerful symbol of clean energy. They represent a significant step away from fossil fuels. But what happens when these panels reach the end of their operational life after 25 to 30 years? This question is central to the long-term success of the solar industry. The answer lies in fully embracing sustainability and building a circular economy. This approach moves beyond simply generating clean power; it involves creating a regenerative cycle for all the materials involved.

The Lifecycle of a Solar Panel: Beyond Energy Generation

Understanding the complete journey of a solar panel reveals why a circular economy is so important. The process begins long before a panel ever sees a rooftop and continues long after it stops producing power.

From Raw Materials to Rooftop Power

The creation of a solar panel is a complex, global process. It starts with sourcing raw materials like high-purity silicon, glass, and aluminum. The manufacturing supply chain involves several stages, including producing polysilicon, ingots, wafers, cells, and finally, assembling the module. This global supply chain has been instrumental in reducing the cost of solar energy, but it also highlights the need for sustainable practices at every step.

The Operational Lifespan: Decades of Clean Energy

Once installed, a solar panel typically has an operational life of 25 to 35 years. During this time, its energy output gradually declines by a small fraction each year, a process known as degradation. Even after three decades, many panels can still produce a significant amount of electricity. This durability is a key advantage, but the industry must plan for the massive volume of panels that will eventually be decommissioned.

End-of-Life (EoL): A Growing Challenge and Opportunity

As the first waves of large-scale solar installations begin to age, the volume of end-of-life panels is set to increase dramatically. The International Renewable Energy Agency projects that cumulative EoL PV waste in the United States alone could reach up to 1 million tons by 2030. This presents a significant challenge. Landfilling these panels is not a sustainable solution, as it wastes valuable resources and can pose environmental risks. The real opportunity is to view these EoL panels not as waste, but as a resource for the future. You can learn more about this in our article: Stop Landfilling Panels: Build Reuse with Off-Grid ESS.

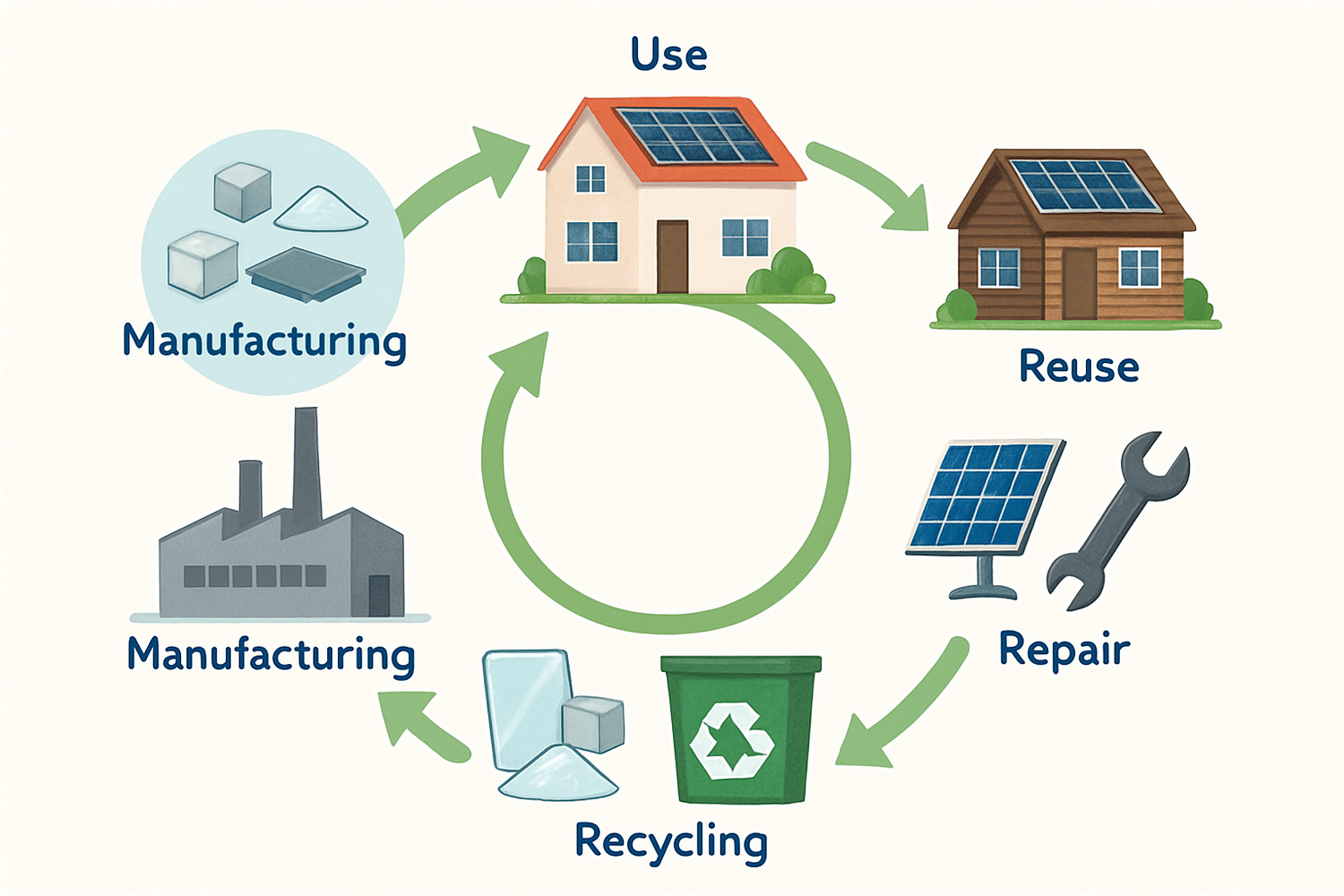

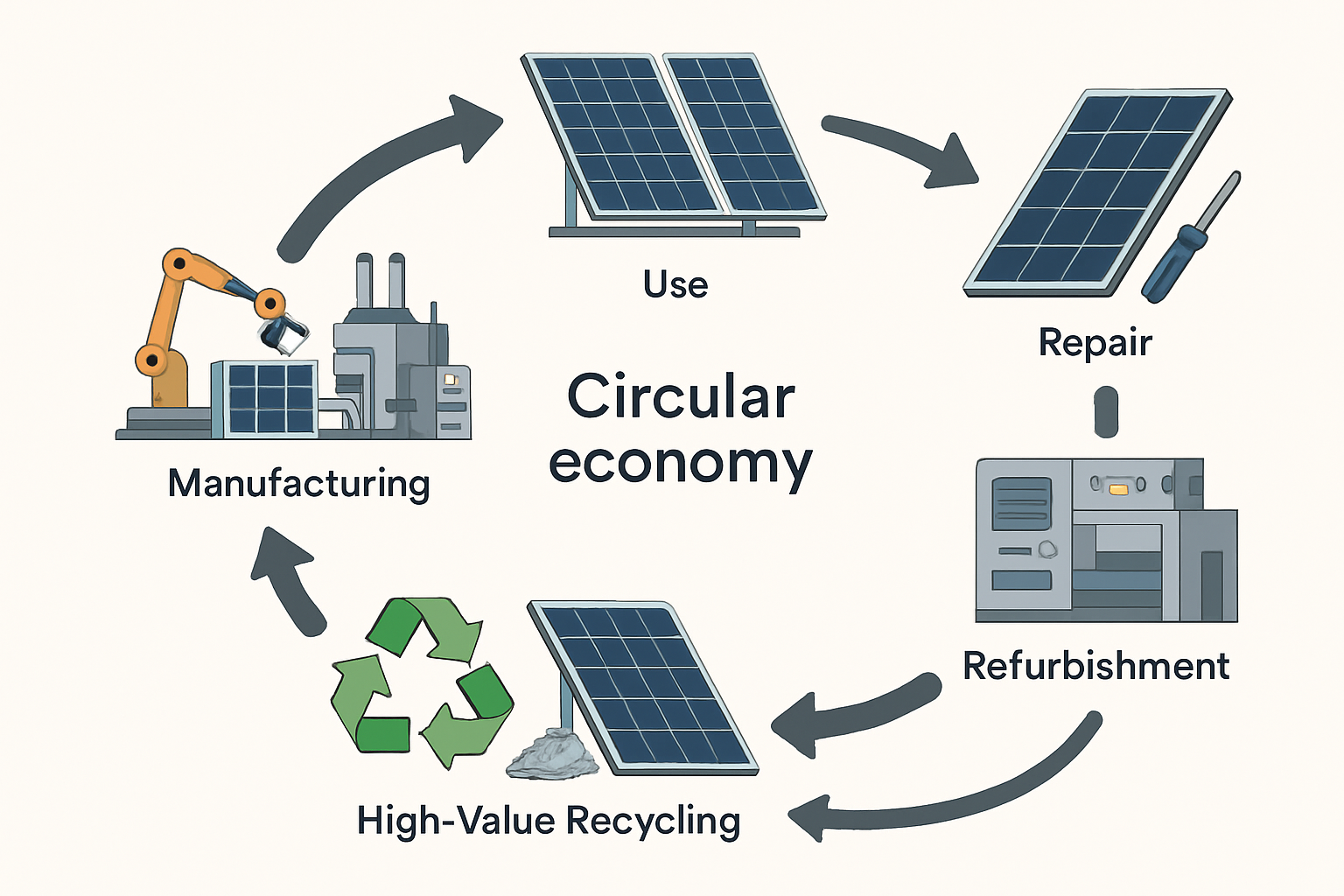

The Circular Economy: A New Framework for Solar

A circular economy offers a powerful alternative to the traditional linear model of "take-make-dispose." Instead of discarding products at the end of their life, a circular approach focuses on keeping materials in use for as long as possible through repair, reuse, remanufacturing, and recycling.

Key Strategies for PV Module Circularity

Implementing a circular economy for solar panels involves several key strategies that address the entire product lifecycle.

- Design for Disassembly: The process starts at the drawing board. Designing panels that can be easily taken apart allows for more efficient repair and material recovery. For more on this, see the Design for Disassembly: Circular-Ready Solar Module Guide.

- Recycling Technologies: Photovoltaic recycling is a rapidly advancing field. Current processes can recover a large percentage of materials like glass (about 75% of the panel's weight), aluminum frames, and copper wiring. Advanced techniques are being developed to more effectively separate and purify valuable elements like silicon and silver. Explore the specifics in our Data Deep-Dive: Recovery Rates by PV Module Type.

- Reuse and Second-Life Applications: Not every EoL panel needs to be recycled immediately. Many panels that are no longer optimal for a large-scale solar farm are perfectly suitable for other uses. These secondhand panels can be paired with robust off-grid solar solutions and high-performance LiFePO4 batteries to power remote homes, farms, or telecommunication equipment, giving them a valuable second life. This approach is detailed in Your Questions on Solar Panel Reuse, Answered by Data.

Putting Circularity into Practice: Technologies and Policies

Transitioning to a circular model requires a combination of technological innovation, supportive policies, and new ways of measuring success.

Comparing Module Technologies: c-Si vs. Thin-Film

The vast majority of installed solar panels use crystalline silicon (c-Si) technology. Thin-film panels, while representing a smaller market share, use different materials and have their own recycling processes. Understanding the differences is key to developing effective, tailored recycling strategies. A deeper comparison is available in c-Si vs Thin-Film: Which Solar Module Wins Circularity?.

| Feature | Crystalline Silicon (c-Si) Panels | Thin-Film Panels |

|---|---|---|

| Primary Materials | Silicon, Glass, Aluminum, Copper, Silver | Glass, Cadmium Telluride (CdTe) or CIGS, Aluminum |

| Recycling Focus | Recovery of aluminum frame, glass, and metals like copper and silver. Silicon purification is more complex. | Dedicated processes to recover semiconductor materials (e.g., cadmium, tellurium) in addition to glass. |

| Maturity | Recycling processes are more established due to market dominance. | Specialized, often manufacturer-led, recycling programs exist. |

The Role of Policy and Extended Producer Responsibility (EPR)

Policy plays a critical role in making solar panel recycling widespread and economically viable. Frameworks like Extended Producer Responsibility (EPR) hold manufacturers accountable for the entire lifecycle of their products, including collection and recycling. Europe’s Waste Electrical and Electronic Equipment (WEEE) Directive is a leading example that includes solar panels. Such policies create incentives for manufacturers to design more recyclable products. Learn about policy frameworks in the EPR and Take-Back: Policy Playbook for PV Module Makers.

Measuring Success: How to Quantify Circularity

To ensure progress, we need methods to measure it. A Life Cycle Assessment (LCA) is a tool used to evaluate the environmental impact of a product from raw material extraction to its final disposal. By using LCA and other metrics, companies can identify areas for improvement and validate the benefits of their circular strategies. You can find out more in How to Measure PV Module Circularity: LCA, EPR, Yield.

Building a Truly Sustainable Energy Future

The solar industry is at a pivotal moment. Moving forward, true sustainability means looking beyond emissions-free energy generation and building a responsible, circular system for the technologies we use.

Innovations and New Business Models

The future of sustainable solar will be driven by innovation. This includes not only better recycling technologies but also new business models. Concepts like "solar-as-a-service," where customers pay for power instead of owning the panels, can help streamline the take-back and reuse process. Integrated home energy storage systems, which combine solar panels with a reliable lithium battery and a solar inverter, can be managed as a complete package, ensuring all components are properly handled at their end-of-life. Explore these ideas further in 7 Circular Business Models for PV Modules and ESS.

Your Role in the Circular Solar Economy

Every decision contributes to a more sustainable future. Choosing high-quality, durable energy solutions helps maximize the operational life of a system and reduces waste. Reliable components, from high-performance LiFePO4 batteries that offer a long cycle life to efficient solar inverters that optimize energy conversion, are the foundation of a resilient and sustainable energy system. By prioritizing longevity and supporting companies committed to lifecycle management, you help build a truly circular solar economy. This collective effort is our Roadmap to Net-Zero: Circularity Across Solar Module Types.

Disclaimer: The information provided in this text is for informational purposes only and does not constitute legal or investment advice. You should consult with a qualified professional before making any legal or financial decisions.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.