A solar inverter is the heart of your renewable energy system, diligently converting the DC electricity from your solar panels into AC power for your home. But when this crucial component gets too hot, it activates a self-protection mode called derating, reducing its power output to prevent damage. This performance loss is often caused by preventable thermal design mistakes. Understanding these errors is key to maximizing your system's efficiency and protecting your investment.

Why Thermal Management is Crucial

Effective heat dissipation is not just a feature; it is fundamental to an inverter's operation and longevity. Every watt of power converted generates a small amount of heat, and managing this thermal load is a constant balancing act.

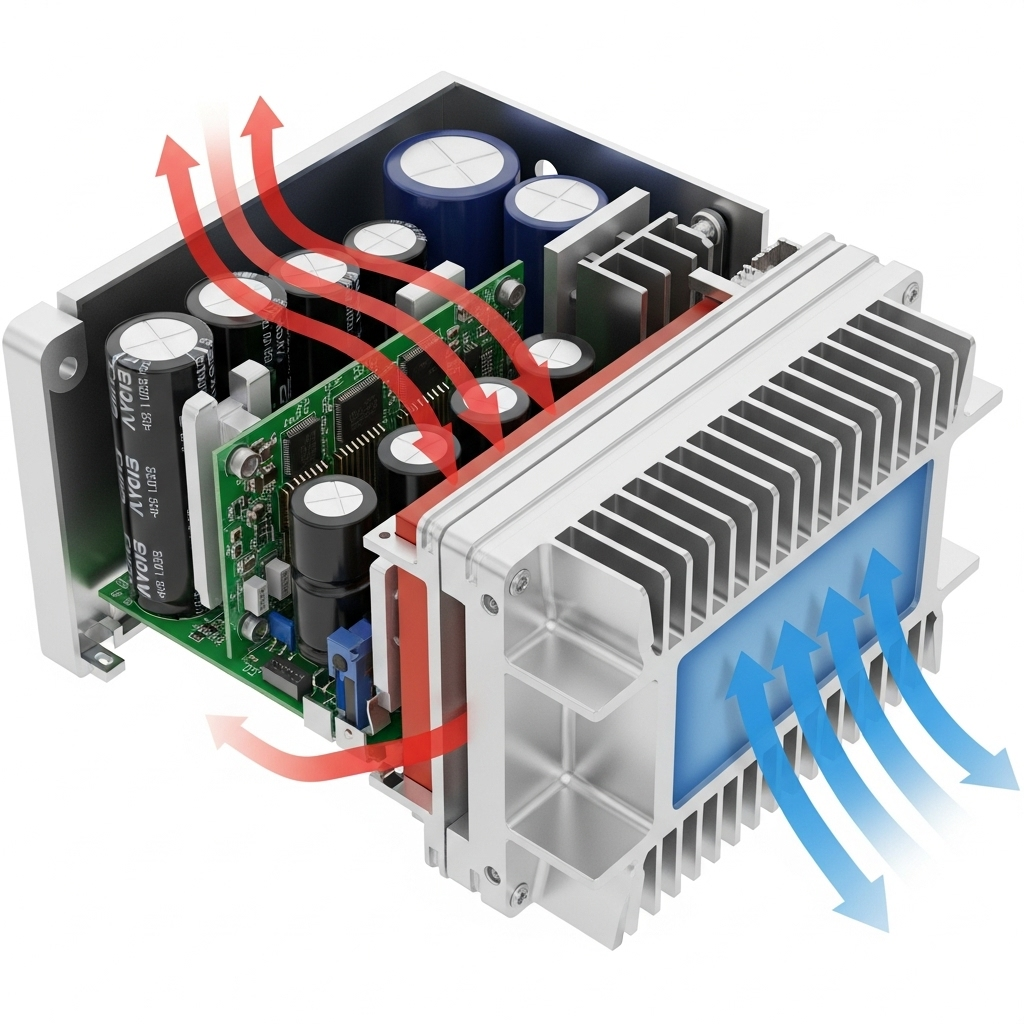

The Physics of Heat in Power Electronics

The process of converting DC to AC power is not 100% efficient. Energy is lost as heat due to switching and conduction within the inverter's semiconductors. Key components like capacitors and transistors have specific operating temperature ranges. When these temperatures are exceeded, their lifespan shortens, and the risk of failure increases. According to research on renewable energy infrastructure, high temperatures can significantly de-rate inverter output and lead to higher failure rates, degrading overall system performance. This is a critical factor in system modeling, as noted in the IRENA report, Quality infrastructure for renewables facing extreme weather.

Understanding the Derating Curve

An inverter's datasheet includes a 'derating curve,' which plots its maximum power output against the ambient temperature. As the temperature rises past a certain point (e.g., 45°C or 113°F), the inverter's maximum output capacity begins to decrease. Reading this chart is vital for designing a system that performs reliably in its intended climate.

Common Mistakes in Inverter Placement and Installation

Where and how you install an inverter has a direct impact on its ability to stay cool. These common placement errors are frequent causes of inverter derating.

Mistake 1: Ignoring Manufacturer's Clearance Requirements

Inverters use heat sinks and fans to dissipate heat into the surrounding air. Manufacturers specify minimum clearance distances (e.g., 12-20 inches on all sides) to ensure adequate airflow. Installing an inverter in a tight space traps hot air, which then gets recirculated, raising the local ambient temperature and triggering derating sooner.

Mistake 2: Installation in Direct Sunlight

Placing an inverter where it is exposed to direct sunlight is a major error. The sun's radiant energy can heat the inverter's external casing to temperatures far above the ambient air temperature. This added thermal load forces the internal components to work harder to stay cool, leading to premature derating, even on moderately warm days.

Mistake 3: Poorly Ventilated Enclosures

Installing inverters in small, unventilated spaces like closets, utility rooms, or non-breathing enclosures creates a 'hotbox' effect. Without a path for hot air to escape and cool air to enter, the temperature inside the space will continuously rise during operation, guaranteeing performance loss.

System Design and Component Selection Errors

Decisions made during the design phase can lock in thermal performance issues that are difficult to fix later.

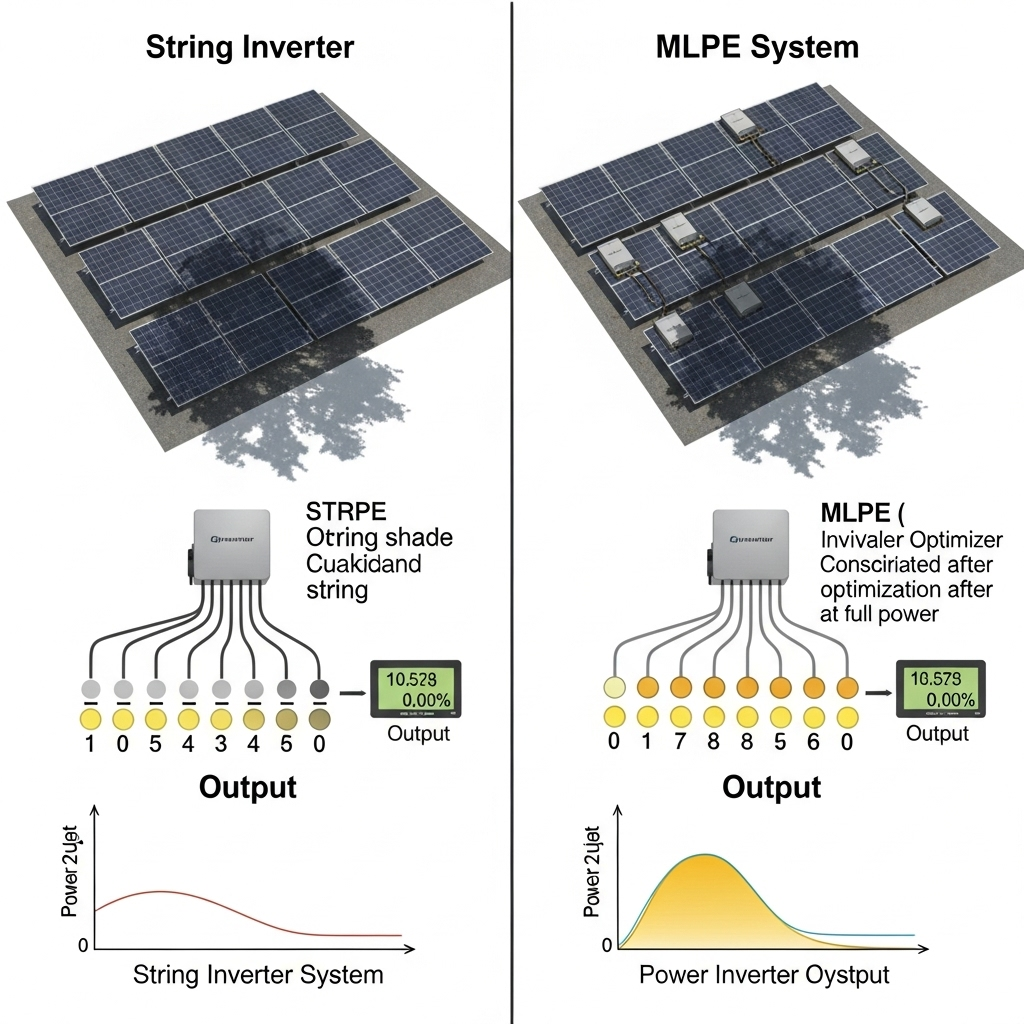

Mistake 4: Excessive PV Array Oversizing

Oversizing a PV array (having a higher DC power rating from panels than the inverter's AC power rating) is a common practice to boost energy harvest in low-light conditions. However, an excessively high DC/AC ratio can force the inverter to operate at its maximum capacity for extended periods during peak sun hours. This constant high load generates more heat and can lead to 'power clipping,' a form of derating where the inverter caps its output to protect itself.

Mistake 5: Neglecting Air Density at High Altitudes

Air becomes less dense at higher altitudes. For inverters that rely on air cooling (convection), thinner air is less effective at transferring heat away from the heat sinks. Many manufacturers provide specific guidelines for derating their equipment based on altitude, a factor that is often overlooked in mountainous regions.

Mistake 6: Inadequate Cable Sizing

Using undersized DC or AC cables increases electrical resistance. This resistance causes the cables to heat up under load (a phenomenon known as I²R loss). This heat can conduct back to the inverter's terminals, adding to the overall thermal burden on the unit and contributing to potential derating.

Maintenance and Operational Oversights

Even a perfectly designed system can suffer from a lack of ongoing care.

Mistake 7: Blocked Vents and Clogged Fans

Over time, dust, leaves, cobwebs, and other debris can accumulate on an inverter's cooling fins and block its ventilation ports. If the inverter has active cooling, fans can become clogged. This obstruction severely restricts airflow and is one of the most common and easily preventable causes of overheating.

Mistake 8: Grouping Multiple Inverters Too Closely

In larger systems with multiple inverters, installation layout is critical. Each inverter expels hot air. If units are placed too close together, one inverter's hot exhaust can become the intake air for its neighbor. This creates a cascading heat problem, where each successive inverter in the line runs hotter than the last.

Mistake 9: Ignoring Harmonic Distortion

Harmonic distortion, which can be caused by certain types of loads or grid conditions, forces the inverter's internal components to work harder. As detailed in the IRENA publication Grid Codes for Renewable Powered Systems, power electronic devices can be a source of these distortions. High harmonic levels can lead to excess heating in the inverter’s magnetic components and capacitors, contributing to thermal stress.

Mistake 10: Disregarding Ambient Temperature Creep

System designers must consider the *actual* operating environment. The temperature inside a garage or on the side of a building can be significantly higher than the reported outdoor weather temperature. It is this localized ambient temperature that the inverter experiences. For a deeper analysis of how various factors affect system output, the ultimate reference on solar storage performance offers valuable data on key performance metrics.

A Smarter Approach to Inverter Thermal Design

Avoiding inverter derating starts with a proactive approach to thermal management. By carefully selecting the installation location, adhering to manufacturer guidelines, and designing the system with real-world conditions in mind, you can ensure your inverter operates efficiently. A system that pairs a well-installed inverter with high-quality components, such as reliable LiFePO4 batteries, provides a robust foundation for achieving long-term energy independence. Regular maintenance, such as cleaning vents and fans, is a simple step that preserves performance for years to come.

| Mistake | Poor Practice | Best Practice | Thermal Impact |

|---|---|---|---|

| Location | Direct sun, unventilated closet | Shaded, well-ventilated area | Reduces ambient temperature by 10-15°C |

| Clearance | Less than 6 inches around unit | More than 12 inches (or manufacturer spec) | Prevents hot air recirculation |

| Maintenance | Clogged fan vents and dusty heat sinks | Annual cleaning of vents and filters | Restores full cooling capacity |

Frequently Asked Questions

What is inverter derating?

Inverter derating is a built-in protective feature where the inverter automatically reduces its power output. This happens to prevent internal components from overheating and sustaining damage when the operating temperature exceeds safe limits.

Can I prevent inverter derating completely?

Completely eliminating it may not be possible during extreme heatwaves. However, following proper thermal design and installation principles can significantly reduce its frequency and severity. This ensures you maximize your energy production under most conditions.

How do I know if my inverter is derating?

Most modern inverters come with monitoring software or a mobile app that displays real-time power output. If you observe a flat-topped production curve on a clear, sunny day when you expect a bell curve, it is a strong indication of power clipping caused by derating.

Does derating damage the inverter?

No, derating itself is a safety mechanism designed to protect the inverter from heat-related damage. While it is not harmful, frequent derating signals a suboptimal system design or installation issue that should be addressed to improve overall performance and energy yield.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.