Silence on the water matters. A rattling panel or humming controller ruins the mood and can signal poor installation. This piece shares practical Boat solar wiring and Marine solar mounting techniques to keep your array quiet, reliable, and safe—without adding weight or complexity. According to the Solar Energy Perspectives from IEA, PV systems rely on a balance-of-system that includes inverters, protection, wiring, and mounting. Getting these details right on a moving hull makes the difference between steady power and endless troubleshooting.

Why quiet and vibration-proof matters at sea

Boat motion, wind, and engine harmonics amplify any slack or resonance in solar mounts and cabling. Noise is not the only issue: vibration fatigues terminations, increases contact resistance, and raises fire risk. PV gear is robust, but it needs marine-specific detailing.

Key context from trusted sources supports careful design and installation: PV converts light to DC and usually requires inverters and dedicated balance-of-system components, as summarized by the IEA in Solar Energy Perspectives. The U.S. Department of Energy notes the modular nature of solar and its pairing with storage for dependable power (Solar Energy Topics). Cost declines reported by IRENA keep high-quality hardware within reach, which lowers the temptation to cut corners on mounts, wire, and protection. For an overview of PV fundamentals and performance drivers, see the EIA.

9 field-proven tips for quiet, vibration-proof boat solar

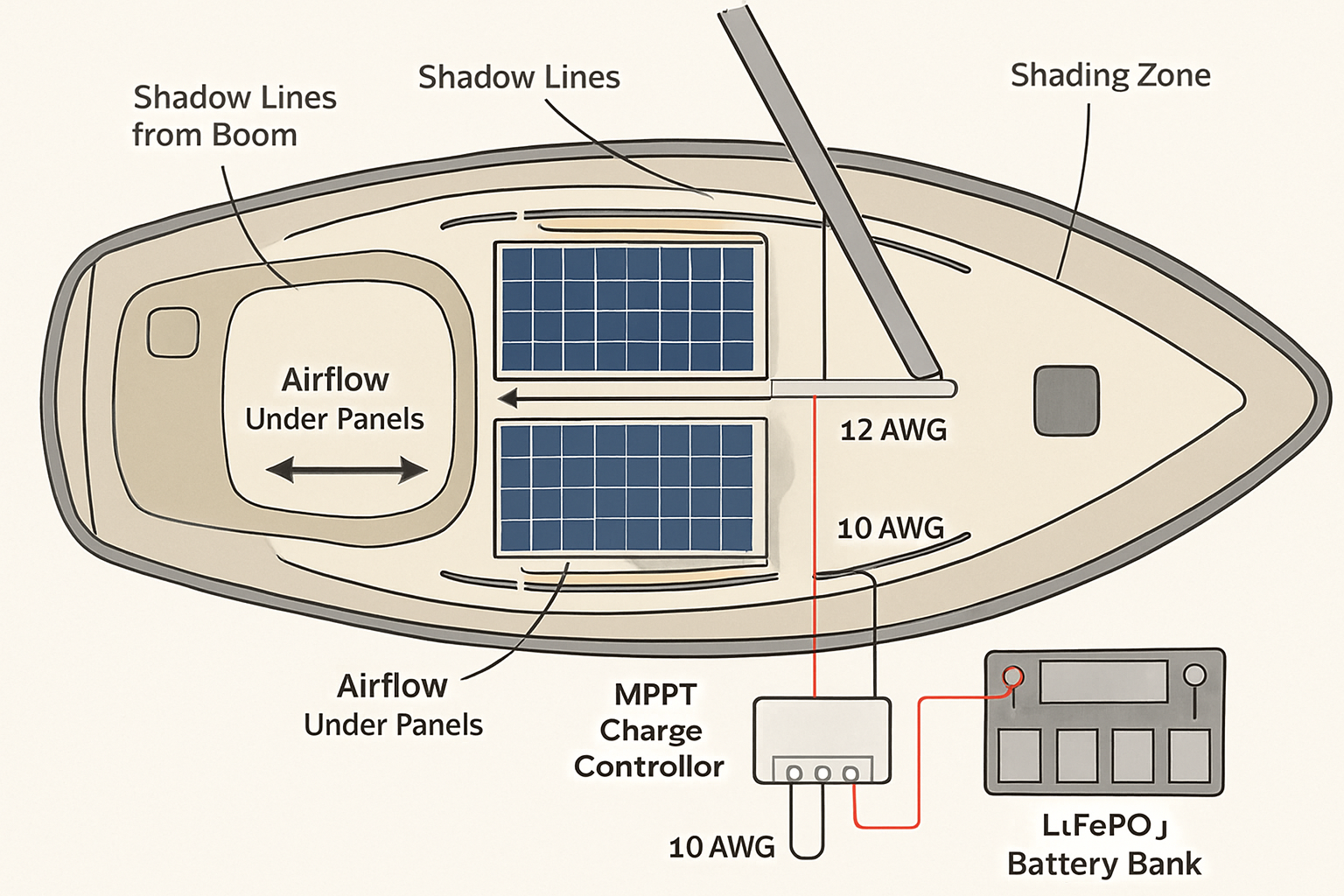

1) Oversize, tinned-copper wiring to cap voltage drop under motion

Use marine-grade, finely stranded, tinned copper. Aim for less than 3% voltage drop on charging circuits for 12 V banks, and less than 2% if you routinely discharge deep or run long cables on arches or davits. Oversizing wire also reduces I²R heating and electrical noise. Keep butt splices to a minimum; run continuous lengths where possible.

2) Route cables for silence and safety

- Keep runs short and avoid large loops; minimize the loop area between positive and negative to reduce EMI pickup.

- Maintain clearance from compasses, VHF/AIS coax, and sensitive instrument buses.

- Add drip loops at every deck penetration; use UV-rated conduit or loom on sun-exposed spans.

- Support cables every 40–45 cm with cushioned stainless P-clamps to prevent cable slap.

3) Crimp like your life depends on it

Use a ratcheting crimper matched to the terminal type. Make double-crimp terminations and cover with adhesive-lined heat-shrink. Add strain relief so vibration is not transmitted to the conductor. Use ferrules for any fine-strand wire landing on screw terminals.

4) Tame controller noise and EMI

Choose charge controllers with documented EMC compliance. Mount them on rubber standoffs or isolation pads to reduce structure-borne hum. Add snap-on ferrite cores near the controller on PV leads and battery leads if you notice radio interference. Keep controller wiring short, and follow manufacturer bonding instructions. For system building blocks and performance considerations, see IEA: Solar Energy Perspectives and DOE Solar Energy.

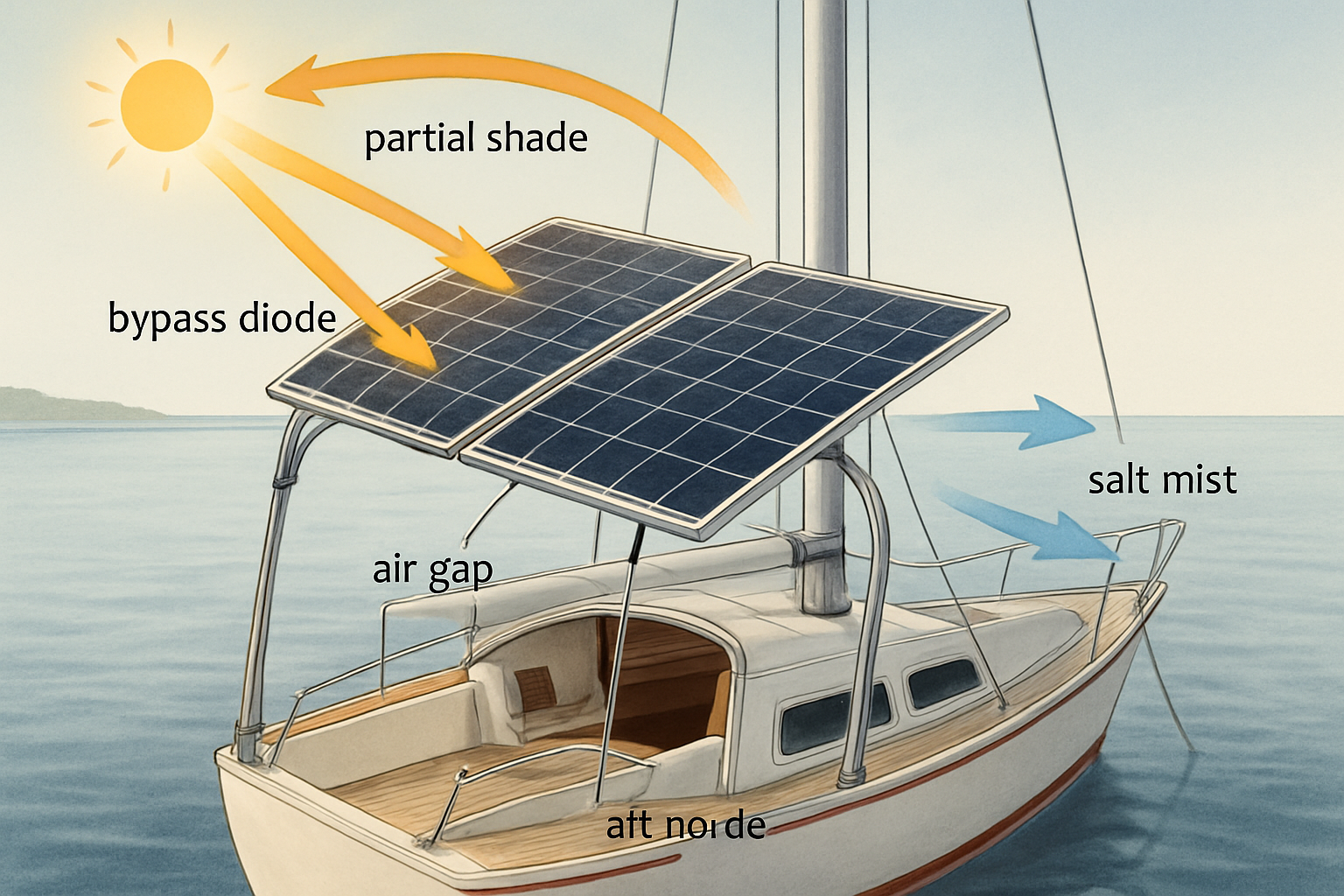

5) Pick the right mounting style for your hull and rig

- Rigid framed panels on rail/arch mounts offer stiffness and low flutter.

- Semi-flexible panels on curved surfaces need uniform bedding; add closed-cell foam under edges to prevent oilcanning.

- Floating frames with cross-bracing cut resonance on long spans.

Favor adjustable tilt only if the mechanism locks solidly. Any play becomes rattle offshore.

6) Through-bolt everything critical, with isolation and anti-seize

- Use through-bolts with large backing plates on cored decks or thin structures.

- Add EPDM or neoprene pads between hardware and deck/rails to decouple vibration.

- Apply marine anti-seize on stainless fasteners; snug to manufacturer torque. Typical A2-70 stainless: M6 ≈ 7–10 N·m, M8 ≈ 18–25 N·m (verify for your hardware).

- Use all-metal locknuts or prevailing-torque nuts; avoid relying on spring washers alone.

7) Seal penetrations to stop leaks and creaks

For cored decks, overbore, remove core locally, and pot with thickened epoxy; then drill the final hole. Bed hardware with butyl tape under the flange and a compatible marine sealant at edges. A dry deck is a quiet deck.

8) Eliminate panel hum and cable slap

- Add thin EPDM edge gaskets where frames meet brackets.

- Use anti-rattle shims on adjustable joints.

- Secure exposed spans with cushioned clamps; use soft ties rather than hard plastic where chafe is a concern.

9) Verify with simple tests

- Sound check: use a phone dB app; compare idle, motor-on, and in gusts. Seek steady readings.

- Electrical check: log PV voltage at the controller vs. module leads under load to spot hidden drops.

- Thermal check: a quick IR scan will flag hot terminations.

Quick reference: wiring and mounting choices

Voltage drop examples for typical runs

Assumptions: copper at ~20 °C; two-conductor loop length equals 2 × one-way length.

| System (V) | Current (A) | One-way run (m) | Wire AWG | Estimated drop (V) | Drop (%) |

|---|---|---|---|---|---|

| 12 | 8 | 10 | 12 | ~0.83 | ~6.9% |

| 12 | 8 | 10 | 10 | ~0.52 | ~4.4% |

| 12 | 8 | 10 | 8 | ~0.33 | ~2.8% |

| 24 | 8 | 10 | 10 | ~0.52 | ~2.2% |

| 24 | 8 | 10 | 8 | ~0.33 | ~1.4% |

Mounting approach and vibration behavior

| Mounting method | Damping | Typical hardware | Noise-control notes |

|---|---|---|---|

| Rail/arch, through-bolted with EPDM pads | High | Stainless brackets, backing plates | Low resonance; re-torque each season |

| Adjustable strut frame with cross-brace | Medium–High | Telescopic struts, locknuts | Add shims; lock out for passage-making |

| Direct deck adhesive mount (semi-flex) | Medium | Adhesive, bedding compound | Uniform bedding prevents oilcanning hum |

| Aluminum bimini frame with isolation bushings | Medium | Rail clamps, rubber bushings | Check clamp slippage; add diagonal brace |

| Rail clamps without backing | Low | Simple clamps | Prone to rattle; avoid for offshore use |

Real-world snapshot: 38-foot cruiser

A 2 × 175 W rigid array on an aft arch produced a noticeable buzz at anchor in gusts. Changes made: EPDM isolation pads, diagonal cross-brace, P-clamps every 40 cm, ferrites on PV and battery leads, and upgraded runs from AWG 12 to AWG 10. Sound readings near the array dropped from ~53 dBA to ~46 dBA in 18–22 knots true wind. Under a 12 A charge, controller input voltage sag improved by ~0.3 V, stabilizing charge behavior. Results will vary by hull, rig, and hardware condition.

Storage and inverter pairing for smoother power

A quiet array shines with a well-matched storage bank and inverter. Many cruisers favor LiFePO4 for stable voltage and weight savings, paired with a hybrid inverter-charger. DOE notes the growing role of storage in smoothing solar output and bolstering reliability (Solar Energy Topics). Improved system costs tracked by IRENA have made higher-quality components attainable, which supports better acoustic and mechanical performance offshore.

Tip: Keep the inverter’s cooling path clear, mount it on isolation standoffs, and secure DC cables to cut fan cycling and resonance. For system architecture and BOS considerations, see IEA: Solar Energy Perspectives and the EIA for PV context across applications.

Maintenance checklist you can do at the dock

- Feel every termination after a sunny motor run; anything warmer than adjacent wire needs attention.

- Re-torque accessible fasteners each season; re-bed any suspect seals.

- Replace sun-brittled clamps and loom; keep a few spare ferrites and adhesive heat-shrink on board.

- Log voltage drop under a known load twice a year; drifting numbers point to corrosion or looseness.

Safety notice: Electrical work on boats can be hazardous. Follow marine electrical standards and manufacturer instructions. Non-legal advice.

Wrapping it up

Quiet boat solar installation comes from dozens of small choices: oversize, tinned wire; proper crimping; ferrites where needed; isolation pads; through-bolting with backing; and careful sealing. These Solar panel boat mounting tips deliver a system that stays silent in a squall and charges hard under way. That is the core of reliable, vibration proof solar at sea.

FAQ

Do flexible panels make more noise than rigid ones?

They can if not bedded uniformly. Use a continuous adhesive bed and add thin foam at edges to stop oilcanning. Secure leads to prevent flap and slap.

Will solar interfere with VHF or AIS?

Poor layouts can. Keep PV and battery leads away from RF coax, minimize loop area, add ferrites near the controller, and ensure all DC negatives are cleanly bonded. Test transmit/receive after installation.

Is PWM quieter than MPPT on boats?

Both can be quiet. Quality MPPT units often run at higher switching frequencies and with better filtering, which reduces audible artifacts. Solid mounting and short leads matter more than the control method alone.

How do I size wire for a 24 V bank?

Target similar percentage drop as 12 V, but percent loss halves for the same absolute drop. Use the voltage drop table above as a starting point and upsize one gauge if runs are hot or long.

Do I need to bond panel frames?

Follow your controller and boat bonding scheme. Many installations bond frames to ship’s DC ground or a lightning ground. Keep corrosion and stray current risks in mind. Non-legal advice.

References

Key ideas summarized from Solar Energy Perspectives, Renewable Power Generation Costs in 2024, U.S. EIA, and U.S. DOE Solar Energy Topics.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.