Your 12V 100Ah LiFePO4 battery is the core of your energy storage solution. Inside it, a Battery Management System (BMS) works silently to protect your investment. But this BMS is more than a simple safety device; it's a rich source of data. Accessing this information allows you to monitor your hybrid system's health, optimize performance, and ensure longevity. This text explains how to access and interpret the critical data from your battery's BMS.

Understanding the Role of the BMS

The BMS is the brain of your lithium iron phosphate battery pack. Its primary role is to ensure the battery operates within its safe envelope, but its capabilities extend far beyond basic protection. Understanding its functions is the first step in leveraging its data.

More Than Just a Safety Switch

A BMS provides crucial protection against several potentially damaging conditions. It prevents over-charging and over-discharging, which can permanently harm battery cells. It also monitors for over-current situations and extreme temperatures, disconnecting the battery to prevent damage. A key function for a LiFePO4 battery is cell balancing, where the BMS ensures all individual cells within the pack maintain an equal state of charge, which is vital for maximizing both capacity and cycle life.

The Data Your BMS Holds

The BMS continuously tracks a range of parameters that provide a complete picture of the battery's status. Key data points include State of Charge (SoC), which acts as a fuel gauge, along with real-time voltage, current, and internal temperature. It also logs valuable long-term information, such as the number of charge cycles completed and an estimation of the battery's overall State of Health (SoH). This data is invaluable for managing your home battery storage system effectively.

Communication Protocols: The Language of Your BMS

To read battery data, your equipment must speak the same language as the BMS. This is accomplished through various communication protocols, each with its own characteristics. Knowing which protocol your battery uses is essential for establishing a connection.

Common BMS Communication Interfaces

Several standard protocols are used for LiFePO4 BMS communication. RS485 is a robust protocol often used in industrial settings for its reliability over long distances. CAN (Controller Area Network) is another common standard, particularly in automotive and integrated systems, known for its high speed and resilience to noise. For simpler, short-distance connections, UART is often employed. In recent years, many lithium battery manufacturers have also integrated Bluetooth, offering a convenient wireless method to monitor your system via a smartphone app.

Identifying Your Battery's Protocol

The easiest way to determine your battery's communication protocol is to consult the manufacturer's datasheet or user manual. The physical ports on the battery can also provide clues; for instance, an RJ45-style connector often indicates RS485 or CAN. If this information isn't readily available, the manufacturer's technical support should be able to provide the necessary details for your specific 12v 100ah lifepo4 lithium battery.

Practical Methods for BMS Data Acquisition

Once you know the protocol, you can choose a method to connect to the BMS and start reading data. Options range from user-friendly software provided by the manufacturer to more advanced, custom solutions.

Using Manufacturer-Provided Software

Many suppliers of lithium rechargeable battery products offer proprietary software designed to communicate with their BMS. This is often the most straightforward approach. The process typically involves connecting the battery to a computer using a specific interface cable, such as a USB-to-RS485 adapter. Once the software is installed, it provides a graphical interface displaying all the key metrics from the BMS in an easy-to-understand format.

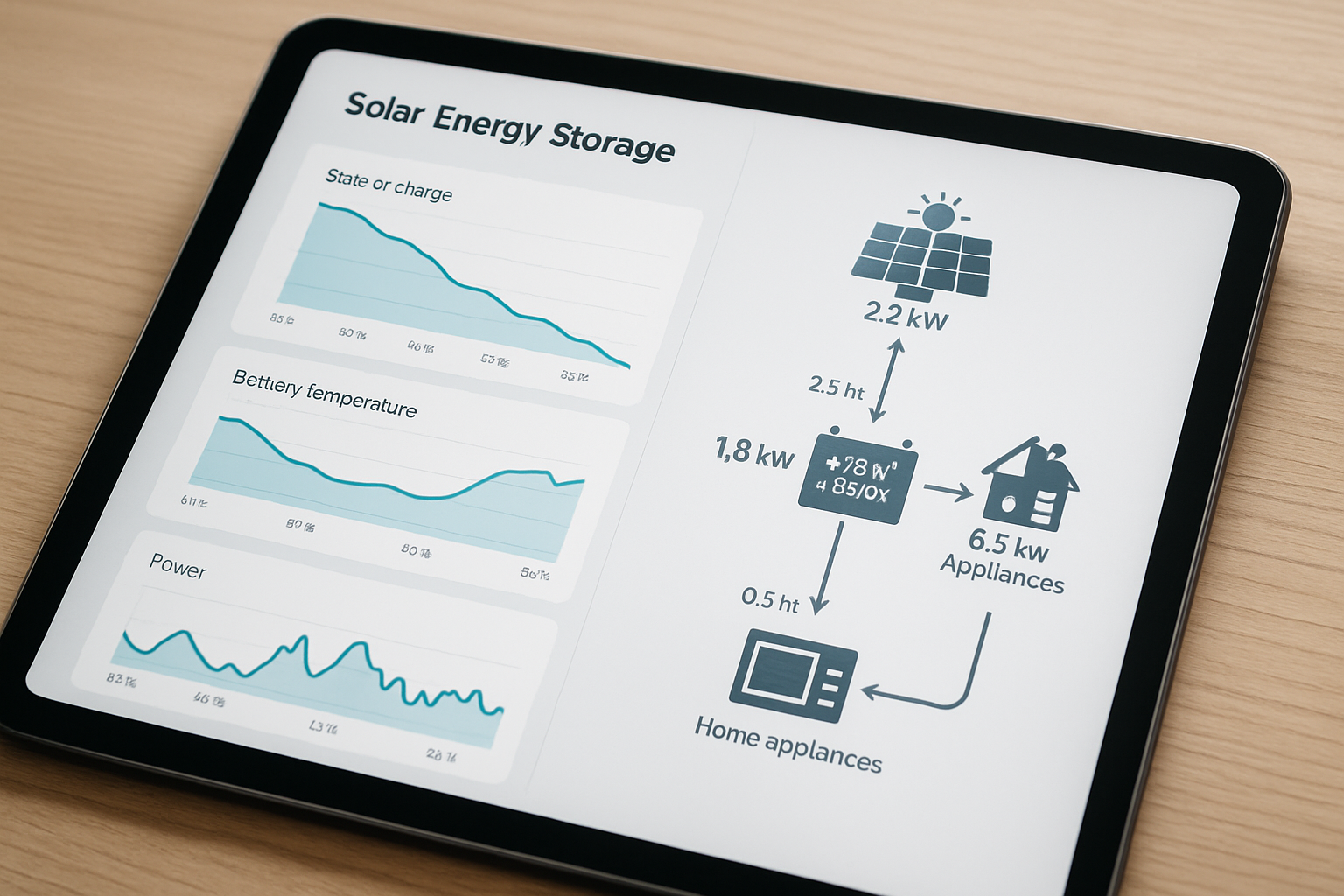

Third-Party Monitoring Systems

For a more holistic view, you can integrate your battery into a larger solar energy storage system monitor. These devices are designed to communicate with multiple components, including solar inverters and charge controllers, in addition to the battery BMS. This provides a centralized dashboard where you can see how all parts of your system are interacting, allowing for more sophisticated energy management.

Interpreting the Data for Optimal System Performance

Collecting data is only half the battle; understanding what it means is how you truly optimize your system. By monitoring a few key metrics, you can make informed decisions that enhance safety and extend the life of your deep cycle lithium battery.

Key Metrics and What They Tell You

Certain data points offer direct insight into your battery's operational health. Proper battery management, informed by this data, not only extends service life but also aligns with broader sustainability goals. As noted in the IEA's report, The Role of Critical Minerals in Clean Energy Transitions, efficient use and end-of-life management are crucial for a sustainable energy future. The following table breaks down the most important metrics.

| Metric | What It Is | Why It Matters | Optimal Range/Action |

|---|---|---|---|

| State of Charge (SoC) | The battery's current charge level, expressed as a percentage. | Prevents deep discharging that can shorten battery life and helps in planning energy usage. | Maintain between 20% and 80-90% for maximum lifespan. Avoid dropping below 10%. |

| Cell Voltages | The individual voltage of each cell inside the battery pack. | Highlights imbalances. A healthy BMS will keep all cell voltages very close to each other. | Variation between the highest and lowest cell should be minimal (typically under 0.05V). |

| Current (A) | The rate at which the battery is charging (positive value) or discharging (negative value). | Ensures you are operating within the battery's specified continuous and peak current limits. | Should not exceed the manufacturer's ratings to prevent overheating and stress. |

| Temperature | The internal temperature of the battery pack. | High temperatures accelerate degradation, while very low temperatures can inhibit charging. | Ideal operating range is typically 15°C to 35°C. Follow manufacturer guidance for charging in cold weather. |

Leveraging Data for Longevity

By actively monitoring BMS data, you can adopt practices that prolong your battery's life. For example, tracking your typical Depth of Discharge (DoD) helps you understand your usage patterns. As detailed in the Ultimate Reference for Solar Storage Performance, consistently limiting the DoD can significantly increase the number of cycles your battery can deliver. Intelligent operation, informed by data, is key. According to a report from the International Renewable Energy Agency, Renewable Power Generation Costs in 2024, the full benefit of a battery depends on how it is operated within a specific electricity market.

A Smarter Energy Future

Learning how to read your BMS data transforms your 12V 100Ah LiFePO4 battery from a passive power source into a transparent and manageable asset. This visibility provides peace of mind, knowing your system is operating safely and efficiently. More importantly, it empowers you to maximize the return on your investment by extending the lifespan of your equipment. In the world of decentralized energy, data-driven management is essential for building reliable and resilient energy storage solutions. As the International Energy Agency's Status of Power System Transformation 2019 report points out, battery storage is a key enabler of power system flexibility, a benefit that is fully realized through intelligent control and monitoring.

Frequently Asked Questions

Can I connect any monitoring device to my LiFePO4 battery's BMS?

No, compatibility is key. The monitoring device must support the specific communication protocol (e.g., RS485, CAN) and data format used by your battery's BMS. Always check the manufacturer's specifications for both the battery and the monitoring tool before making a purchase.

What tools do I need to physically connect my computer to the BMS?

You will typically need a specific interface cable, often a USB-to-RS485 or USB-to-UART adapter. The exact type depends on the communication port on your 12v 100ah lifepo4 lithium battery. Some modern batteries may offer a wireless connection via a Bluetooth app, eliminating the need for cables.

Is it safe to build a DIY BMS reader?

While possible for those with advanced electronics and programming skills, it carries risks. An incorrect connection or command could potentially damage the BMS or the battery. For most users, it is safer and more reliable to use the manufacturer's recommended software and hardware. Disclaimer: Proceed with DIY solutions at your own risk. This information does not constitute professional advice and is for informational purposes only.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.