A 12V LiFePO4 battery is a powerful component in any solar hybrid system, known for its safety and longevity. Yet, its potential lifespan is not guaranteed. Achieving thousands of cycles depends on more than just the initial quality of the battery; it requires a strategic approach to monitoring and management. This case study moves beyond theoretical advice to demonstrate how active hybrid system performance monitoring directly contributes to a longer, more efficient battery life, securing your energy independence for years to come.

Understanding LiFePO4 Battery Health Fundamentals

Effective battery management starts with a solid understanding of the factors that influence its health. While many are familiar with basic metrics, a deeper look at specific performance indicators for Lithium Iron Phosphate chemistry is crucial for lifespan maximization.

Key Performance Indicators Beyond the Basics

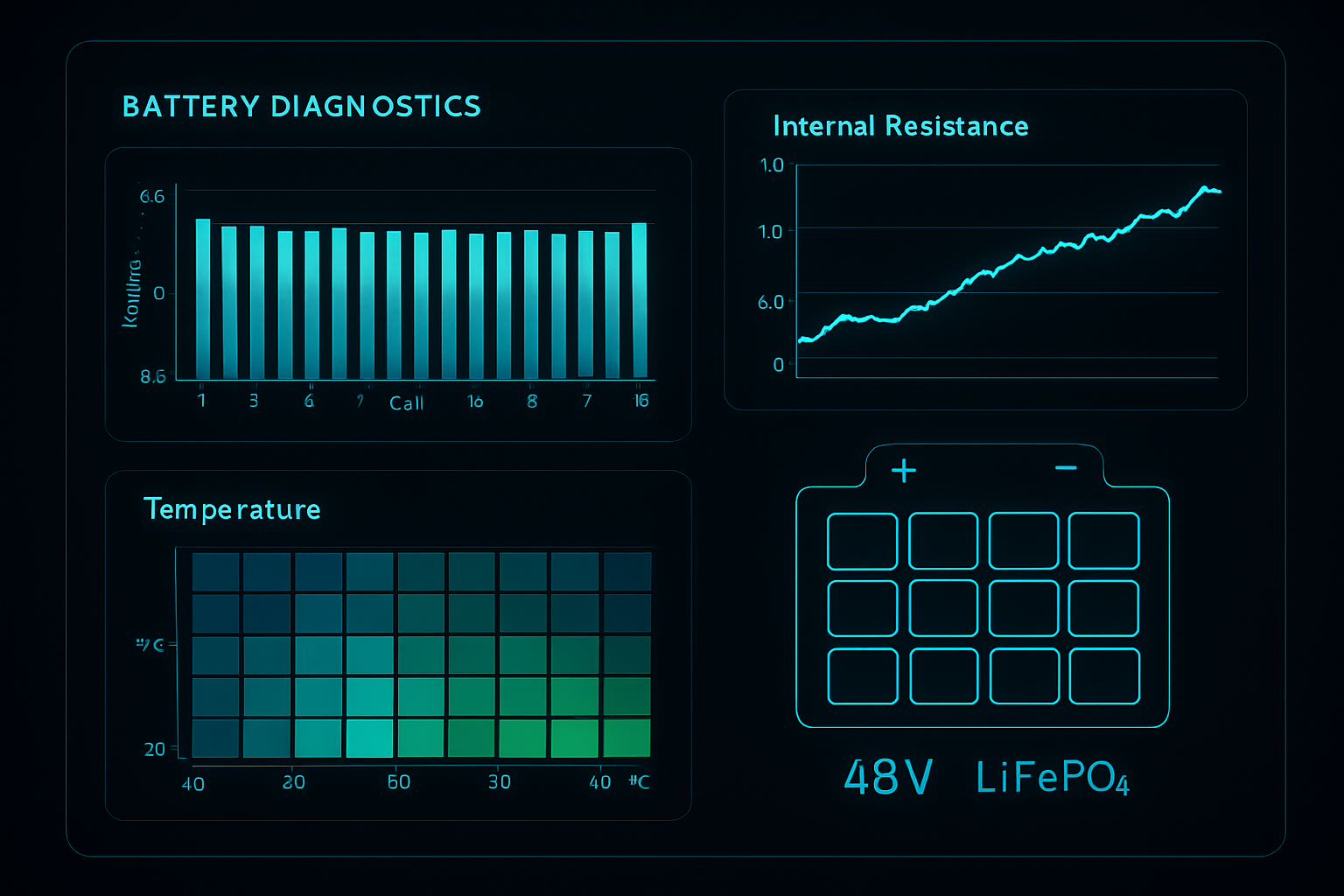

To truly optimize your 12V LiFePO4 battery, you must look beyond State of Charge (SoC). Key indicators include operating temperature, internal resistance, and cell voltage consistency. A gradual increase in internal resistance, for example, signals aging and a reduced ability to deliver high currents. Similarly, monitoring the voltage of individual cells within the pack helps identify imbalances early. A balanced pack ensures that no single cell is over-stressed during charging or discharging, a common cause of premature failure.

The Impact of Charging and Discharging Profiles

How you charge and discharge your battery has a direct impact on its longevity. LiFePO4 batteries thrive on controlled conditions. This includes using a proper charge profile with the correct voltage and current settings—typically not exceeding a 0.5C rate (50 amps for a 100Ah battery). Unlike older battery technologies, they do not require regular full discharge cycles. In fact, consistently using a partial state of charge, such as maintaining a Depth of Discharge (DoD) of 80% or less, can dramatically increase the number of cycles the battery can provide.

The Role of Monitoring in a Hybrid System

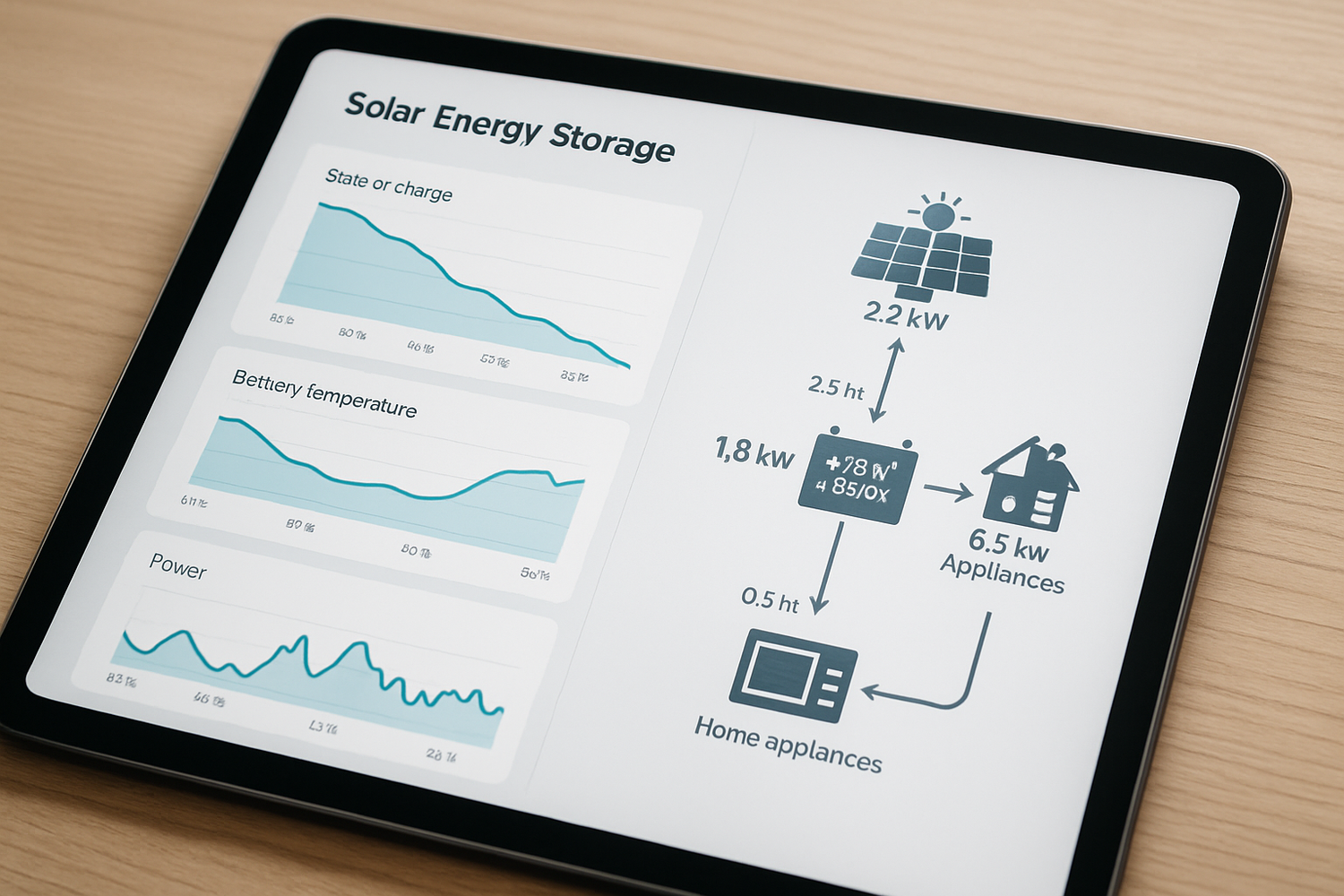

A hybrid energy system is a dynamic environment. Solar input fluctuates, and energy demands change. Continuous monitoring provides the data needed to make intelligent decisions that protect your battery investment and optimize the entire system.

Real-Time Data Acquisition and Analysis

The core of effective LiFePO4 battery health management is the Battery Management System (BMS). The BMS is the brain, providing protection against over-voltage, under-voltage, over-current, and extreme temperatures. Advanced hybrid systems integrate this BMS data into a central monitoring platform. This allows you to track voltage, current, temperature, and SoC in real time. According to an EERE Success Story on power optimization, real-time monitoring data is fundamental to assessing and improving a PV system’s performance.

Setting Up Your Monitoring Framework

Your monitoring framework can range from the built-in screen on a hybrid inverter to sophisticated software accessible via a web or mobile app. Regardless of the tool, the goal is the same: to gain visibility into your battery's daily operations. This setup allows you to confirm your system is operating within the battery's specified parameters and helps you diagnose issues like unexpected power drain or charging irregularities before they cause lasting damage.

Case Study: A 12V LiFePO4 Battery Over 36 Months

Let's examine a practical example: an off-grid cabin powered by a solar array, a hybrid inverter, and a 12V 100Ah LiFePO4 battery. The owner's goal was to maximize the battery's lifespan to avoid a costly replacement.

Initial Setup and Monitoring Strategy

From day one, a clear monitoring strategy was implemented. The system's charge controller was configured to limit the Depth of Discharge to 80%, preventing the battery from being drained completely. The charging voltage was set to a precise 14.4V for the bulk phase, with a float voltage of 13.8V to keep it topped off without overcharging. Temperature monitoring was also critical, with alerts set if the battery compartment exceeded 45°C (113°F).

Performance Analysis and Adjustments

By tracking performance over three years, the owner could see the direct benefits of this strategy. The consistent management of charge cycles and operating conditions led to minimal degradation. As detailed in a comprehensive guide on solar storage performance, managing the depth of discharge is one of the most effective ways to extend battery life. The data below illustrates the battery's excellent health over time.

| Metric | Month 1 | Month 12 | Month 24 | Month 36 |

|---|---|---|---|---|

| State of Health (SoH) | 100% | 99% | 98% | 97% |

| Average DoD | 65% | 65% | 66% | 65% |

| Average Temperature | 22°C | 23°C | 22°C | 23°C |

| Cycle Count | 105 | 420 | 835 | 1250 |

The results are clear: after over 1200 cycles, the battery retained 97% of its original capacity, suggesting it is on track to far exceed its warrantied life. This outcome was not accidental; it was the result of diligent monitoring and adherence to best practices.

Advanced Strategies for Lifespan Maximization

Beyond the basics, several advanced strategies can further enhance the longevity of your 12V LiFePO4 battery, particularly within the context of a complete hybrid system.

Proactive Temperature Management

Temperature is a critical factor. LiFePO4 batteries should not be charged at temperatures below freezing (0°C / 32°F), as this can cause irreversible damage. High temperatures are equally harmful, accelerating chemical degradation. Ensure your battery is installed in a location with adequate ventilation to dissipate heat during heavy charge or discharge cycles. In colder climates, an insulated battery box may be necessary to maintain a stable operating temperature.

System Integration and Load Management

A well-designed hybrid system treats the battery as a key asset to be protected. This involves intelligent load management. For instance, your system can be configured to automatically shed non-essential loads if the battery's SoC drops below a certain threshold (e.g., 30%). This prevents deep discharges that shorten battery life. The integration of storage is key to system reliability. A report from IRENA on Renewable Power Generation Costs in 2024 highlights that combining solar PV with battery storage enhances grid flexibility and reduces energy curtailment, improving overall system performance.

A Commitment to Longevity

Maximizing the lifespan of a 12V LiFePO4 battery is an active process. It transforms the user from a passive energy consumer into an active system manager. Through diligent monitoring of key metrics like temperature, Depth of Discharge, and charging profiles, you can ensure your battery delivers reliable power for its full potential lifespan. This proactive approach not only protects your financial investment but also strengthens your long-term energy security and independence.

Frequently Asked Questions

What is the ideal Depth of Discharge (DoD) for a 12V LiFePO4 battery?

For maximum lifespan, a DoD of 80% is recommended. While LiFePO4 batteries can handle deeper discharges, consistently limiting the discharge depth significantly increases the number of available cycles.

How does temperature affect my LiFePO4 battery's health?

Temperature extremes are detrimental. High temperatures accelerate degradation, while charging below freezing (0°C or 32°F) can cause permanent damage. The optimal operating temperature range is typically between 20°C and 25°C (68°F and 77°F).

Can I mix old and new LiFePO4 batteries in the same system?

It is strongly discouraged. Mixing batteries of different ages or capacities can lead to imbalances, where one battery is overcharged or over-discharged. This causes accelerated degradation and potential safety risks for the entire battery bank.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.