A high-performance deep cycle lithium battery is the core of a modern solar energy system, but its potential is only realized through a precise connection to a hybrid charge controller. Proper wiring and configuration are not just about function; they are about unlocking maximum efficiency, ensuring safety, and extending the life of your components. This guide provides the technical details for a powerful and reliable battery connection.

Pre-Wiring Essentials: Tools and Components

Before making any connections, preparation is key. Having the right tools and correctly sized components on hand prevents delays and ensures a secure installation. This initial step is foundational to the system’s overall performance and safety.

The Right Tools for the Job

For a professional-grade installation, you will need a specific set of tools. Gather wire strippers, cable crimpers for secure lug attachments, a set of insulated screwdrivers, and a multimeter to verify voltage and polarity. Always wear safety glasses and insulated gloves to protect yourself during the installation process. Accuracy in your work starts with having the proper equipment.

Selecting Wires and Fuses

Choosing the correct wire gauge (AWG) and fuse rating is critical for both safety and efficiency. Undersized wires can overheat and cause significant voltage drop, starving your system of power. Fuses or circuit breakers are non-negotiable; they protect your equipment from overcurrent events that could lead to damage or fire. A fuse should be placed on the positive line between the battery and the charge controller.

| Current (Amps) | Recommended Copper Wire Gauge (AWG) |

|---|---|

| 0-15 A | 14 AWG |

| 15-20 A | 12 AWG |

| 20-30 A | 10 AWG |

| 30-40 A | 8 AWG |

| 40-60 A | 6 AWG |

Disclaimer: This table provides general recommendations. Always consult your component manuals and local electrical codes for precise requirements.

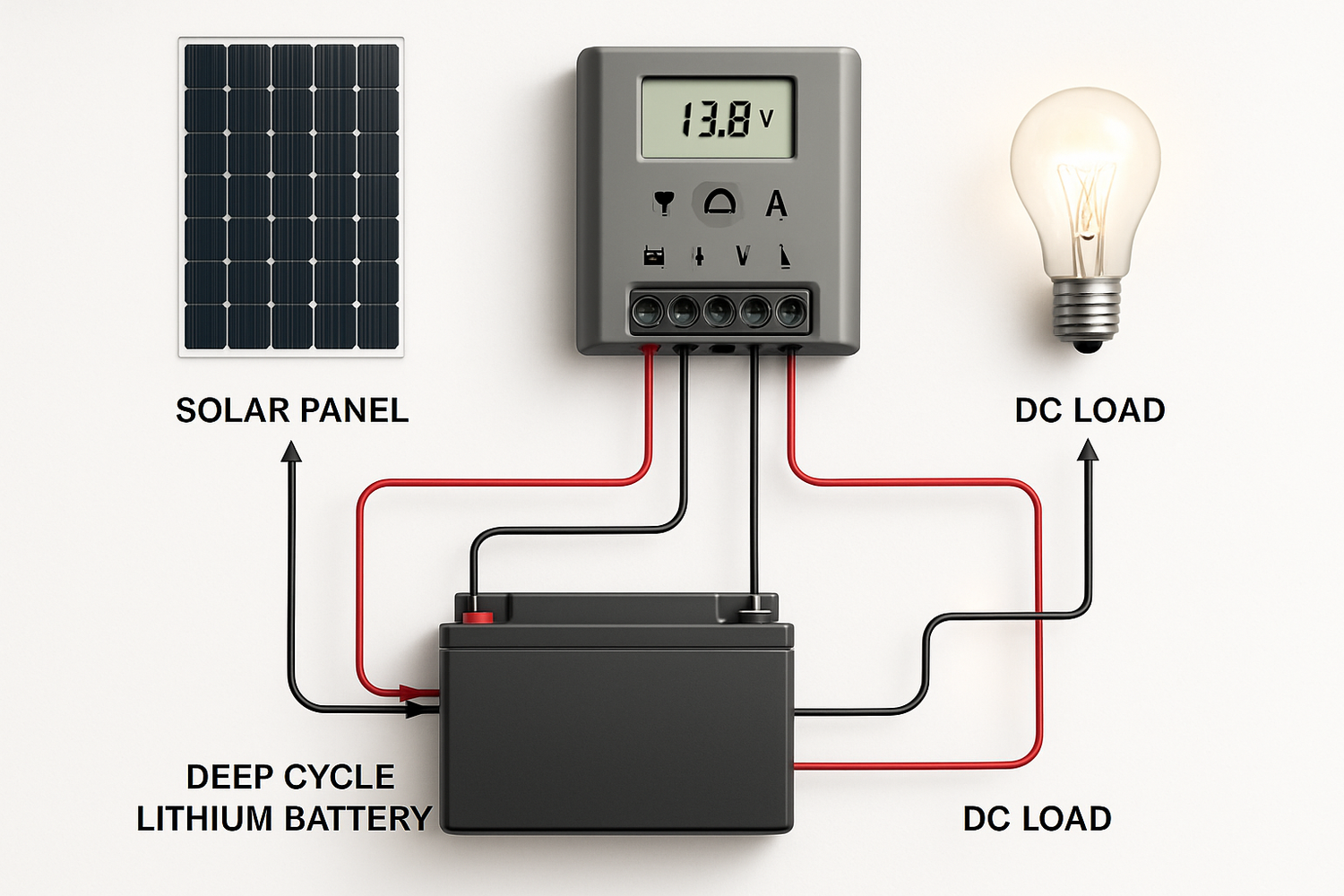

Understanding the Key Players: Battery and Controller

The deep cycle lithium battery and the hybrid charge controller are the two primary components in this process. The battery stores the energy, while the controller acts as the brain, managing the flow of power. Understanding their individual roles is essential for a successful integration.

Deep Cycle Lithium Battery Characteristics

Lithium iron phosphate (LiFePO4) batteries are a leading choice for energy storage due to their long cycle life, inherent safety, and ability to be deeply discharged without significant degradation. Their nominal voltage is typically 3.2V per cell. Unlike lead-acid batteries, they do not require float or trickle charging, which simplifies the charging process. A well-managed LiFePO4 battery is the cornerstone of a resilient off-grid or home backup system.

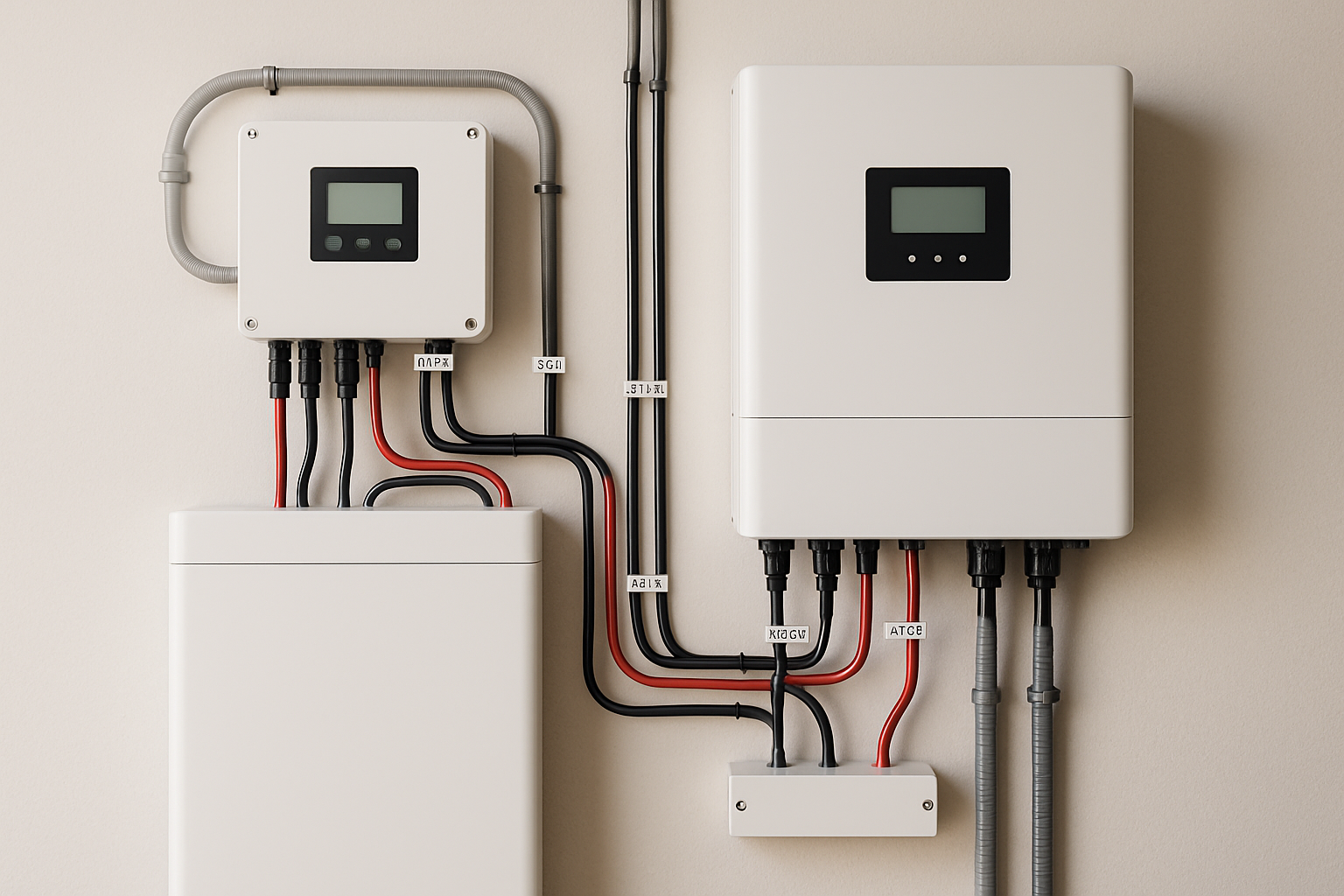

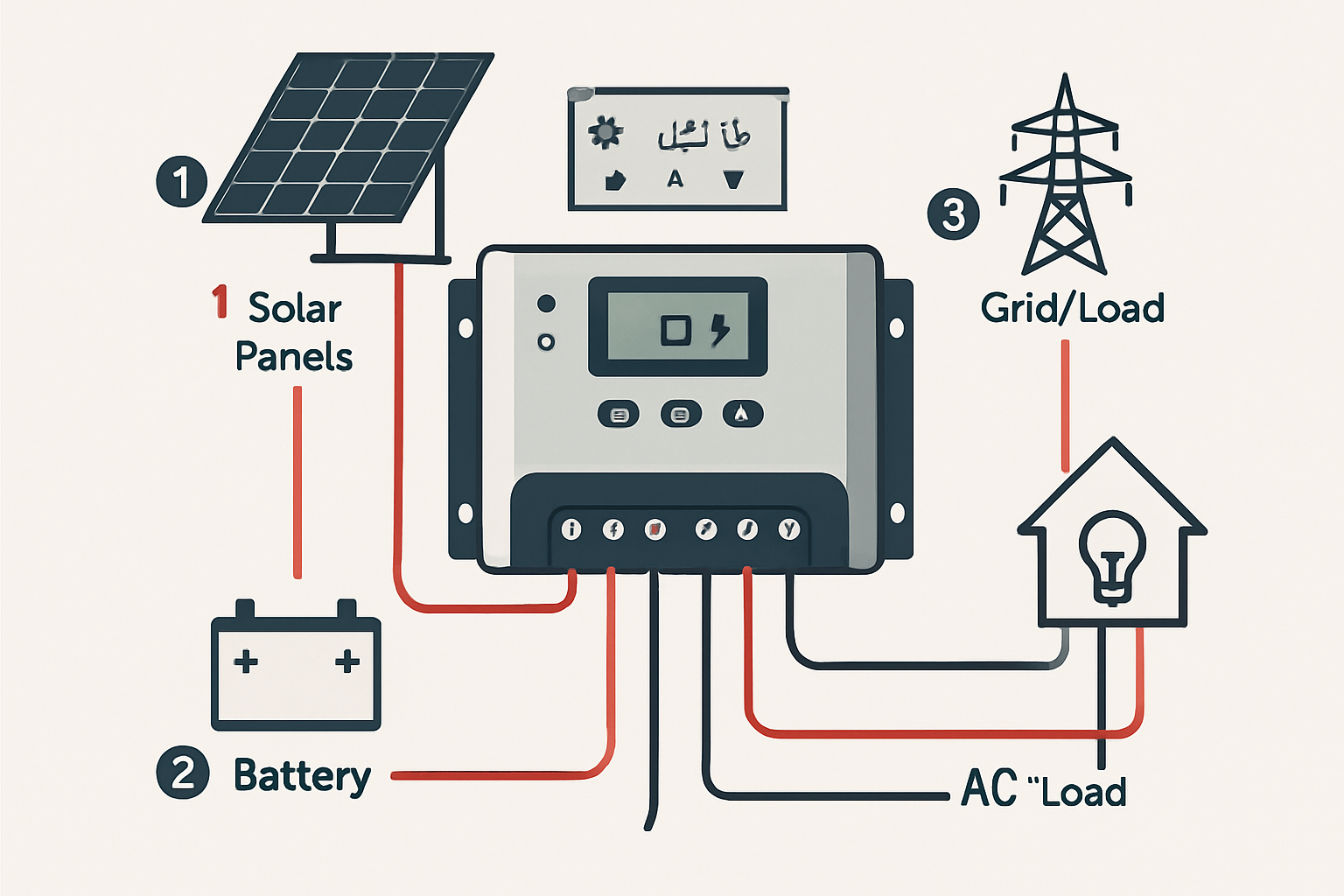

The Role of the Hybrid Charge Controller

A hybrid charge controller intelligently manages power from your solar panels and, if connected, the utility grid. Its primary functions are to prevent battery overcharging and to provide the correct charging voltage. According to a report from the International Renewable Energy Agency (IRENA), smart charging technologies are crucial for grid stability and integrating renewable sources. Your controller is a smart device that optimizes energy flow, ensuring your battery receives a stable and precise charge, which is fundamental to achieving peak power and longevity.

The Step-by-Step Wiring Process

With your components understood and tools ready, you can proceed with the connection. The sequence of these steps is critical. Following the correct order ensures the charge controller correctly initializes and recognizes the system's voltage, preventing potential damage.

Safety First: Powering Down

Before you begin, ensure all power sources are completely disconnected. This includes covering your solar panels with an opaque blanket and switching off any breakers connected to the grid or your main electrical panel. Your safety is the top priority.

Connecting the Battery to the Controller

The most important rule in this process is to **connect the battery to the hybrid charge controller first**, before any other component. This allows the controller to receive stable power and correctly auto-detect the system voltage (e.g., 12V, 24V, or 48V). Connect the positive wire from the battery to the positive battery terminal on the controller, and then connect the negative wire to the negative terminal. Double-check that the polarity is correct and the connections are tight.

Integrating Solar Panels and Loads

Once the controller is powered on by the battery, you can connect the other components. Connect the positive and negative wires from your solar panel array to the corresponding PV input terminals on the charge controller. If you have DC loads, like lights or a water pump, connect them to the load terminals on the controller. This ensures the controller can manage power delivery and protect the battery from over-discharge.

Critical Configuration: Setting Up Your Charge Controller

Wiring is only half the battle. To truly unlock peak power, you must configure your hybrid charge controller's settings specifically for your deep cycle lithium battery. Using default or incorrect settings can reduce performance and may even damage your battery over time.

Selecting the Right Battery Type

Navigate to the battery settings menu on your charge controller. Select the 'Lithium' or 'LiFePO4' option. This adjusts the charging algorithm to a two-stage process (Constant Current and Constant Voltage) suitable for lithium chemistry, bypassing the unnecessary float and equalization stages used for lead-acid batteries.

Key Voltage Parameters

Precise voltage settings are vital for battery health. For a 12V LiFePO4 battery, typical settings are:

- Bulk/Absorption Voltage: 14.2V to 14.6V. This is the voltage at which the battery is charged. A setting of 14.4V is commonly recommended.

- Float Voltage: 13.5V to 13.6V. While LiFePO4 batteries don't require a float charge, this setting provides a voltage floor to power daytime loads directly from solar, preventing the battery from discharging unnecessarily.

- Low Voltage Disconnect: Set according to the battery manufacturer's recommendation, often around 10.8V to 11.0V, to protect the battery from deep discharge.

Fine-tuning these parameters has a direct impact on your system's output. For an in-depth analysis of how different settings affect battery health and efficiency, the Ultimate Reference for Solar Storage Performance offers valuable data-driven comparisons.

Equalization: A Setting to Avoid

Equalization is a controlled overcharge designed to de-sulfate lead-acid battery plates. This process is harmful to lithium batteries and must be disabled in your charge controller's settings. Applying an equalization charge to a LiFePO4 battery can lead to permanent cell damage.

Finalizing Your High-Performance Setup

By carefully following the correct wiring sequence and precisely configuring your charge controller, you establish a robust foundation for your energy independence. This meticulous approach ensures every component works in harmony, delivering the full power potential of your deep cycle lithium battery. Your system is now prepared to provide reliable, efficient energy for years to come.

Frequently Asked Questions

What happens if I connect the solar panels to the charge controller before the battery?

Connecting the solar panels first can send unstable voltage to the charge controller without a stable battery to regulate it. This can cause the controller to fail its system voltage detection, potentially leading to improper charging or even damage to the controller's sensitive electronics.

What wire size should I use for my deep cycle lithium battery?

The wire size depends on the maximum current (amperage) of your system and the distance between the battery and controller. A common size for systems up to 30 amps is 10 AWG copper wire, but you should always use a wire gauge chart and adhere to your equipment's specifications to prevent voltage drop and overheating.

Do I need a fuse between the battery and the hybrid charge controller?

Yes, absolutely. A correctly rated fuse or circuit breaker on the positive line between the battery and charge controller is a critical safety device. It protects against short circuits and overcurrent situations that could damage your equipment or cause a fire.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.