Installing a lithium-ion solar battery is a significant step toward energy independence. These powerful batteries are the heart of a modern home energy storage system. However, the success of your entire setup hinges on one critical detail: the wiring. Incorrect wiring not only compromises performance and efficiency but can also lead to equipment damage and serious safety hazards. Getting it right from the start protects your investment and ensures your system operates reliably for years to come.

Many common wiring problems are easily avoidable with the right knowledge and attention to detail. This overview identifies seven frequent mistakes made when connecting a lithium-ion battery to a hybrid charge controller and explains how to prevent them.

Mistake #1: Using Incorrect Wire Gauge

Why Wire Size Matters

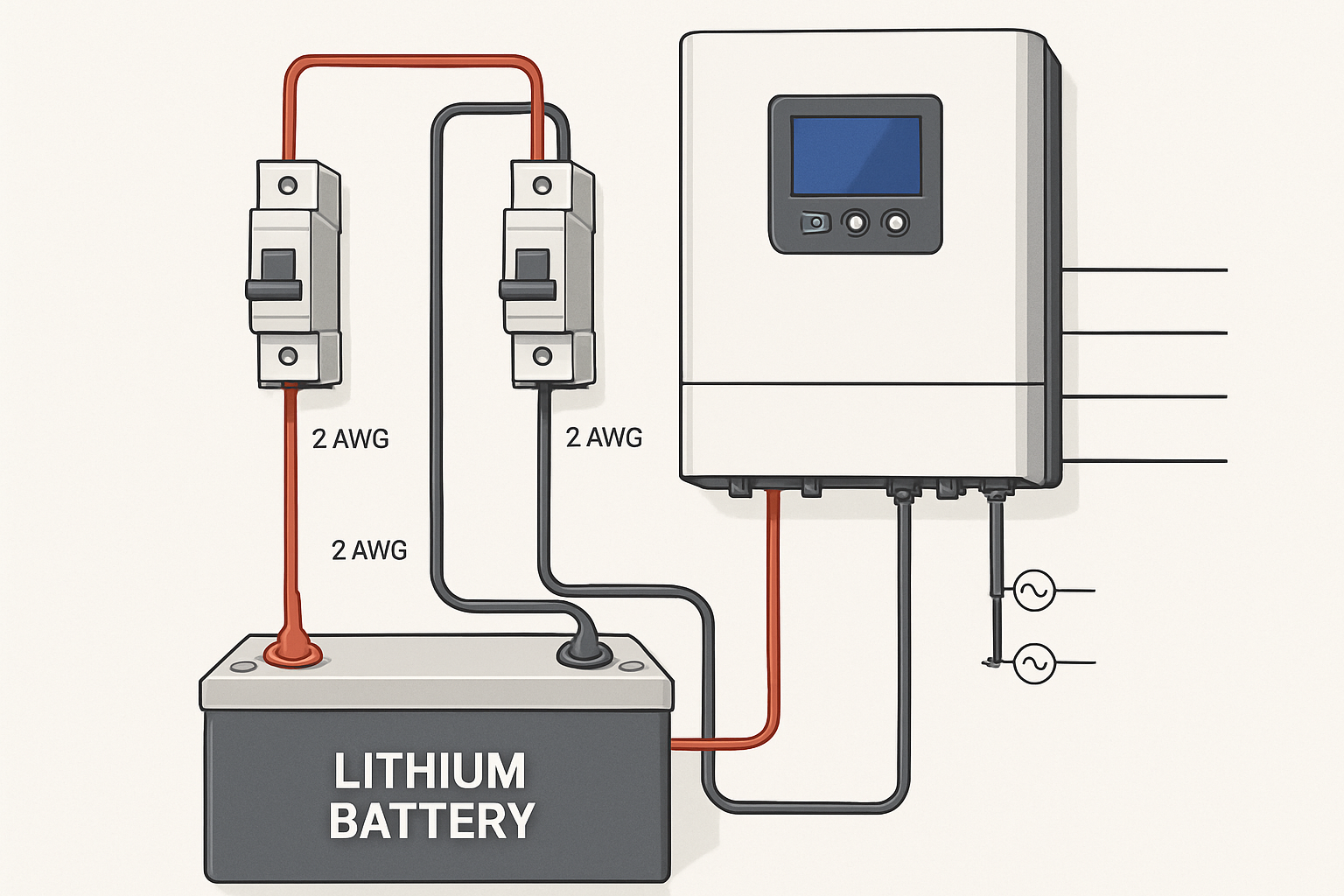

The thickness of a wire, known as its gauge, determines how much electrical current it can safely carry. Using a wire that is too thin for the current is one of the most frequent and dangerous solar battery installation errors. Undersized wires have higher electrical resistance, which causes two primary problems: voltage drop and overheating. Voltage drop means that energy is lost as heat before it even reaches your inverter or appliances, reducing overall system efficiency. More critically, this heat can melt the wire's insulation and create a fire risk.

How to Select the Right Gauge

Wire thickness is measured using the American Wire Gauge (AWG) system, where a lower number indicates a thicker wire. Selecting the correct gauge depends on the maximum current (amperage) of your system and the length of the wire run. Longer distances and higher currents require thicker wires to minimize energy loss. Always consult the specifications provided by your battery and hybrid charge controller manufacturers. These manuals will provide recommended wire sizes for connecting the components.

Mistake #2: Improper Torque and Loose Connections

The Dangers of a Loose Connection

A loose connection at a battery terminal acts like a bottleneck for electricity. This restriction creates a point of high resistance, which generates significant heat as current flows through it. Over time, this heat can damage the battery terminal, melt the surrounding plastic, and pose a severe fire hazard. Loose connections can also cause arcing—sparks that jump across the gap—which can damage sensitive electronics in your charge controller and inverter.

Achieving the Perfect Torque

To ensure a secure and safe electrical connection, you must tighten terminal bolts to the manufacturer's specified torque. Using a torque wrench is the only way to guarantee the correct tightness without over-tightening and damaging the terminal. Torque specifications, usually measured in Newton-meters (Nm) or foot-pounds (ft-lbs), are found in the battery's installation manual. For large solar batteries, this value typically ranges from 10 to 25 Nm. It is good practice to re-check these connections annually as part of your system maintenance.

Mistake #3: Incorrect Polarity (Reversed Connections)

The Immediate Consequences

Connecting the positive (+) terminal of the battery to the negative (-) terminal of the charge controller, or vice versa, is a simple but potentially catastrophic mistake. Reversing the polarity creates a direct short circuit. This can instantly blow fuses, damage the battery's internal Battery Management System (BMS), and destroy the sensitive electronics inside your hybrid charge controller. In some cases, the damage can be permanent and require costly component replacement.

Best Practices for Prevention

Preventing this error requires careful, methodical work. Always use color-coded cables—red for positive and black for negative—and verify the markings on both the battery and the controller terminals before making a connection. Connect one cable at a time to avoid confusion. As a final check, use a multimeter to confirm the voltage and polarity at the end of the cables before connecting them to the charge controller.

Mistake #4: Neglecting Overcurrent Protection

The Role of Fuses and Circuit Breakers

Overcurrent protection devices (OCPDs), such as fuses and circuit breakers, are non-negotiable safety components in any solar battery system. Their job is to protect the wiring and components from excessive current that could result from a short circuit or equipment failure. According to the U.S. Department of Energy, ensuring system safety and reliability is critical for accelerating solar deployment. Without an OCPD, a fault could cause wires to overheat and start a fire.

Sizing and Placement

The fuse or breaker must be correctly sized for the wire it is protecting. A common guideline is to size the OCPD at 125% of the maximum continuous current of the circuit. For safety, the device should be installed on the positive wire as close to the battery terminal as possible. This placement ensures that the entire circuit is protected in the event of a fault. As noted in reports from the International Energy Agency (IEA), components like wiring and protection devices are a crucial part of the 'balance of system' that ensures overall performance and safety.

Mistake #5: Poor Crimping and Terminal Lugs

What a Bad Crimp Looks Like

A crimp is the connection between the wire and the metal lug that attaches to the battery terminal. A poor crimp—one that is too loose or made with the wrong tool—creates a weak point in the circuit. This weak connection increases resistance, generates heat, and can fail under load. Signs of a bad crimp include loose wires, visible gaps between the wire and the lug, or a flattened, distorted appearance from using improper tools like a hammer or pliers.

Using the Right Tools for the Job

Achieving a solid, reliable crimp requires the right tool. A hydraulic or heavy-duty mechanical crimper is designed to apply even, immense pressure to create a cold weld between the copper wire and the lug. This ensures a durable, low-resistance connection. Also, make sure the lug size matches the wire gauge perfectly. A properly crimped connection is both electrically sound and strong enough to withstand vibrations without loosening over time.

Mistake #6: Ignoring Battery Management System (BMS) Communication

Why BMS Communication is Critical

A modern lithium-ion solar battery contains a sophisticated Battery Management System (BMS). The BMS is the brain of the battery, monitoring cell health, temperature, and state of charge to ensure safe and optimal operation. Many advanced hybrid charge controllers are designed to communicate directly with the BMS. This communication allows the controller to receive real-time data from the battery, enabling it to adjust charging parameters for maximum efficiency and longevity.

Connecting the Communication Cable

Failing to connect the communication cable (typically an RS485 or CAN bus cable) between the battery and the controller is a common oversight. Without this data link, the charge controller operates on generic voltage settings, which may not be ideal for your specific lithium battery. This can lead to inefficient charging, premature battery degradation, or inaccurate state-of-charge readings. Always check both manuals to ensure you are using the correct cable and configuring the communication protocol correctly.

Mistake #7: Incorrect Series/Parallel Configuration

Understanding the Impact on Voltage and Capacity

Connecting multiple batteries together can increase your system's overall voltage or capacity. Wiring batteries in series (positive to negative) increases the voltage while capacity (Amp-hours) stays the same. Wiring in parallel (positive to positive, negative to negative) increases capacity while the voltage remains the same. Understanding this distinction is fundamental to designing a system that matches your hybrid charge controller's requirements.

Common Configuration Errors

A frequent error is mixing batteries of different capacities, ages, or even manufacturers in the same bank, which leads to an imbalance where some batteries are overworked while others are underutilized. Another issue is using connecting cables of different lengths in a parallel setup. This creates unequal resistance, causing uneven charging and discharging across the batteries. For optimal system health, it is vital to maintain balance, a key factor in achieving top-tier solar storage performance. Always use identical batteries and ensure all connecting cables are the exact same length.

Building a Foundation for Reliable Energy

Properly wiring your lithium-ion solar battery is the foundation of a safe, efficient, and long-lasting energy storage system. By avoiding these seven common mistakes, you ensure that every component, from the battery to the hybrid charge controller, works in harmony. Paying close attention to details like wire gauge, torque specifications, and overcurrent protection will save you from future headaches and costly repairs. With a correctly installed system, you can confidently take a major step toward achieving true energy independence.

Frequently Asked Questions

What happens if I use a wire that is too thin for my lithium battery?

Undersized wires create high resistance, leading to a significant voltage drop that reduces your system's efficiency. More dangerously, the resistance causes the wire to overheat, which can melt the insulation and create a serious fire hazard.

Can I mix old and new lithium batteries in the same bank?

It is strongly discouraged to mix batteries of different ages, capacities, or brands. Doing so creates an imbalance during charging and discharging cycles. The older or weaker battery will be over-stressed, which significantly shortens the lifespan of the entire battery bank and compromises performance.

How often should I check my battery wiring connections?

It is a good practice to visually inspect all wiring connections at least once a year. Check for any signs of corrosion, discoloration from heat, or loose bolts. For systems in mobile applications like RVs or in areas with significant temperature fluctuations, checking the torque on terminal connections every six months is a wise precaution.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.