Properly commissioning a Photovoltaic Energy Storage System (PV-ESS) is the final, critical step that transforms a collection of components into a safe, reliable, and efficient power source. This process verifies that the system is installed correctly and operates according to design specifications. Adherence to established standards, primarily the National Electrical Code (NEC) in North America and International Electrotechnical Commission (IEC) standards globally, is fundamental. Following these rules ensures safety for operators and first responders, maximizes energy production, and secures the long-term viability of the investment.

Understanding the Regulatory Landscape

Navigating the commissioning of PV-ESS systems requires a clear understanding of the two main regulatory frameworks. While both prioritize safety and performance, their approaches differ, impacting how verification is planned and executed.

The National Electrical Code (NEC): A Prescriptive Approach

The NEC, developed by the National Fire Protection Association (NFPA), serves as the benchmark for safe electrical design and installation in the United States. It follows a prescriptive model, providing specific rules and requirements that must be followed. For PV-ESS, key articles include Article 690 (Solar Photovoltaic Systems), Article 705 (Interconnected Electric Power Production Sources), and Article 706 (Energy Storage Systems). Commissioning to NEC standards involves a detailed inspection to confirm that every aspect of the installation—from wire sizing and conduit fill to labeling and overcurrent protection—matches the code's explicit instructions.

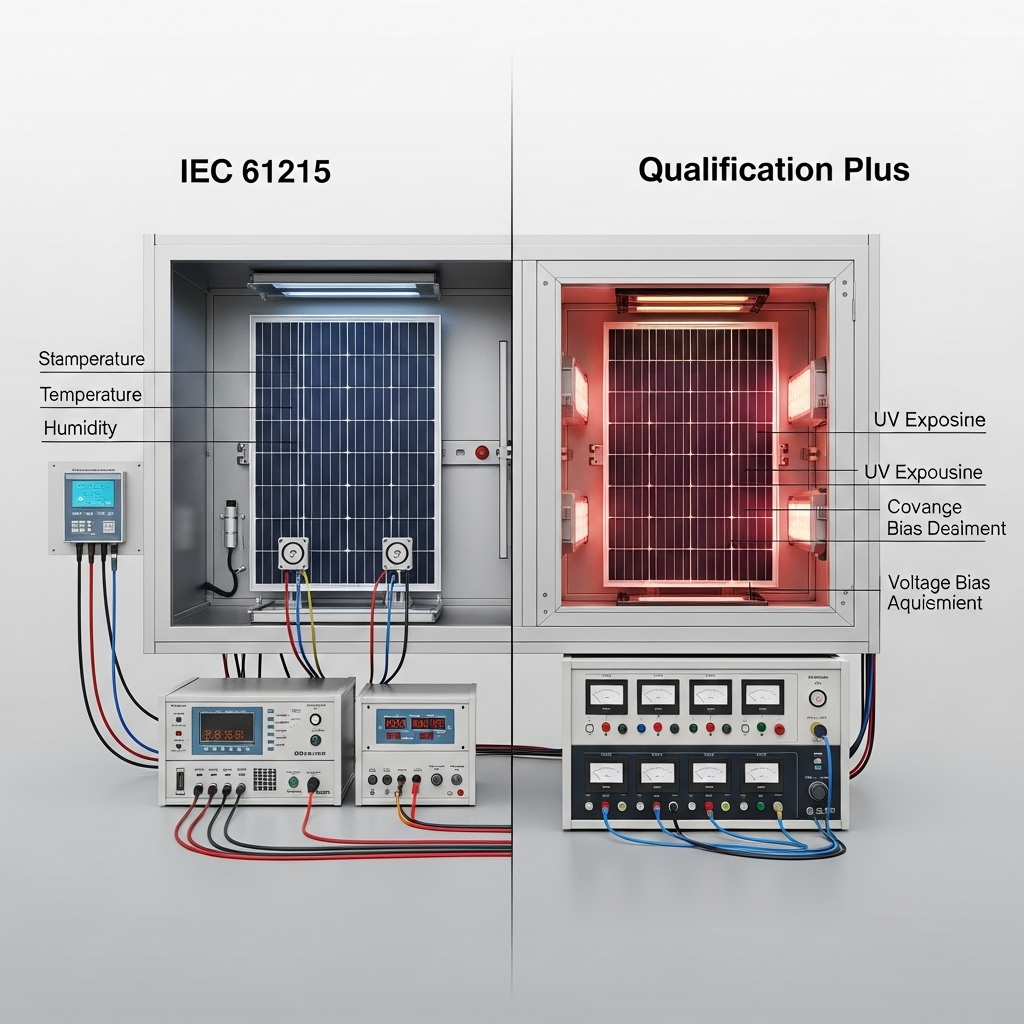

The International Electrotechnical Commission (IEC): A Performance-Based Framework

The IEC creates international standards that are adopted or referenced by numerous countries worldwide. Unlike the NEC's prescriptive nature, IEC standards are generally performance-based. They define the objectives and outcomes a system must achieve, allowing for more flexibility in design and technology application. For instance, the IEC 62446 series outlines requirements for testing, documenting, and maintaining PV systems. Commissioning under IEC rules focuses on a series of tests to verify that the system performs safely and meets specific operational benchmarks. As noted in the IRENA report, Solar PV supply chains: Technical and ESG standards for market integration, verification is a key element of quality infrastructure, confirming that a product or system meets specified requirements through testing and inspection.

Setting the Stage for a Smooth Commissioning Process

Thorough preparation before system startup is the most effective way to prevent delays and ensure a successful outcome. This pre-commissioning phase focuses on documentation review and physical inspection, catching potential issues before they become costly problems.

Comprehensive Design and Documentation Review

The PV-ESS installation verification process begins with a meticulous review of all project documents. This includes the single-line diagram, equipment specifications, site plans, and structural calculations. The goal is to confirm that the design itself is compliant with all applicable NEC or IEC rules. Verifying details like equipment listings, conductor ampacity, and interconnection methods on paper ensures the physical installation has a solid, code-compliant foundation.

Physical Installation Inspection

Once the documentation is verified, a visual inspection of the physical installation is next. This is a methodical check of every component. Technicians inspect the quality of workmanship, ensuring that all mechanical and electrical connections are secure. Key inspection points include verifying proper torque on terminals, checking for correct grounding and bonding, confirming module racking is secure, and ensuring all required labels are in place. This step validates that the system was built according to the approved design and manufacturer instructions.

Step-by-Step System Verification

With pre-commissioning complete, the next phase involves a series of electrical tests to confirm the integrity and functionality of each major subsystem before the entire system is energized.

PV Array Testing (IEC 62446-1)

The PV array is the heart of the system, and its health is paramount. Standard tests include:

- Insulation Resistance Test: This safety-critical test measures the resistance between the conductors (positive and negative) and ground. A low reading indicates a potential ground fault, which could create a shock hazard or cause a fire.

- Polarity Check: Verifies that the polarity of all series strings is correct before they are connected to the combiner box or inverter. Incorrect polarity can cause severe equipment damage.

- Open-Circuit Voltage (Voc) and Short-Circuit Current (Isc): These measurements are taken for each string and compared against the manufacturer's specifications, adjusted for ambient temperature and irradiance. Significant deviations can indicate wiring problems, module mismatch, or defective modules.

Energy Storage System (ESS) Verification

The ESS requires its own set of checks. This involves verifying all battery connections are torqued to the manufacturer's specification and that the required overcurrent protection is installed correctly. Technicians also confirm that the communication wiring between the Battery Management System (BMS) and the inverter is properly connected, as this link is crucial for safe and efficient operation. Finally, the initial battery state of charge (SoC) and terminal voltage are recorded to ensure the battery is healthy before its first cycle.

Inverter and Power Conversion Equipment (PCE) Checks

The inverter is the brain of the PV-ESS system. Verification includes confirming that all AC and DC connections are correct and secure. A critical step is checking the inverter's software settings. These must be configured to comply with local utility and grid code requirements, such as voltage and frequency trip points. As explained in an IRENA publication, Grid Codes for Renewable Powered Systems, technical requirements for generators, including voltage control and reactive power supply, are increasingly standardized to ensure grid stability.

Ensuring the System Operates Safely and as Intended

After all subsystems are individually verified, the final step is to energize the system and perform functional tests. These tests confirm that all components work together as a cohesive, safe, and efficient unit.

System Energization and Functional Operation

Energization follows a strict, sequential startup procedure to prevent equipment damage. Once running, the system is tested in all its intended operating modes. This could include self-consumption, where solar energy is prioritized for on-site loads and battery charging, or backup power mode, where the system's ability to power critical loads during a grid outage is verified. Charge and discharge cycles are initiated to confirm the system responds correctly to control signals. For a deeper understanding of what to measure, the ultimate reference for solar storage performance provides key metrics that are useful for evaluating operational data.

Critical Safety Function Tests

Safety is the top priority. Several tests are performed to verify the system's protective features. The anti-islanding test confirms the inverter will cease to export power to the grid during an outage, protecting utility line workers. For systems subject to the NEC, a rapid shutdown test is performed to verify that the system can be de-energized to a safe voltage level quickly. This is a vital safety feature for firefighters. Finally, any emergency stop (E-Stop) buttons are tested to ensure they function as designed, providing a fail-safe method to shut down the system.

A Foundation for Long-Term Reliability

A structured commissioning process guided by NEC and IEC rules is more than just a procedural formality. It is a comprehensive quality assurance check that validates the system's safety, confirms its ability to perform optimally, and mitigates long-term operational risks. By methodically verifying every detail from documentation to full functional testing, you establish a strong foundation for a durable and productive renewable energy asset, safeguarding the investment for its entire operational life.

Frequently Asked Questions

What is the main difference between NEC and IEC commissioning requirements?

The NEC provides prescriptive rules, detailing specific installation methods and safety measures primarily for North America. IEC standards are performance-based and used internationally, focusing on verifying that the system meets certain safety and operational benchmarks through standardized testing.

Why is insulation resistance testing so important?

This test detects potential faults in wiring, connectors, or modules that could lead to ground faults, fire hazards, or poor system performance. It is a fundamental safety and quality check performed before energizing the PV array to prevent serious issues.

Can a system be compliant with both NEC and IEC rules?

Yes. Many components are certified to both UL (aligned with NEC) and IEC standards. A commissioning plan can incorporate tests from both frameworks to create a comprehensive verification process, which is often necessary for projects with international financing or stakeholders.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.