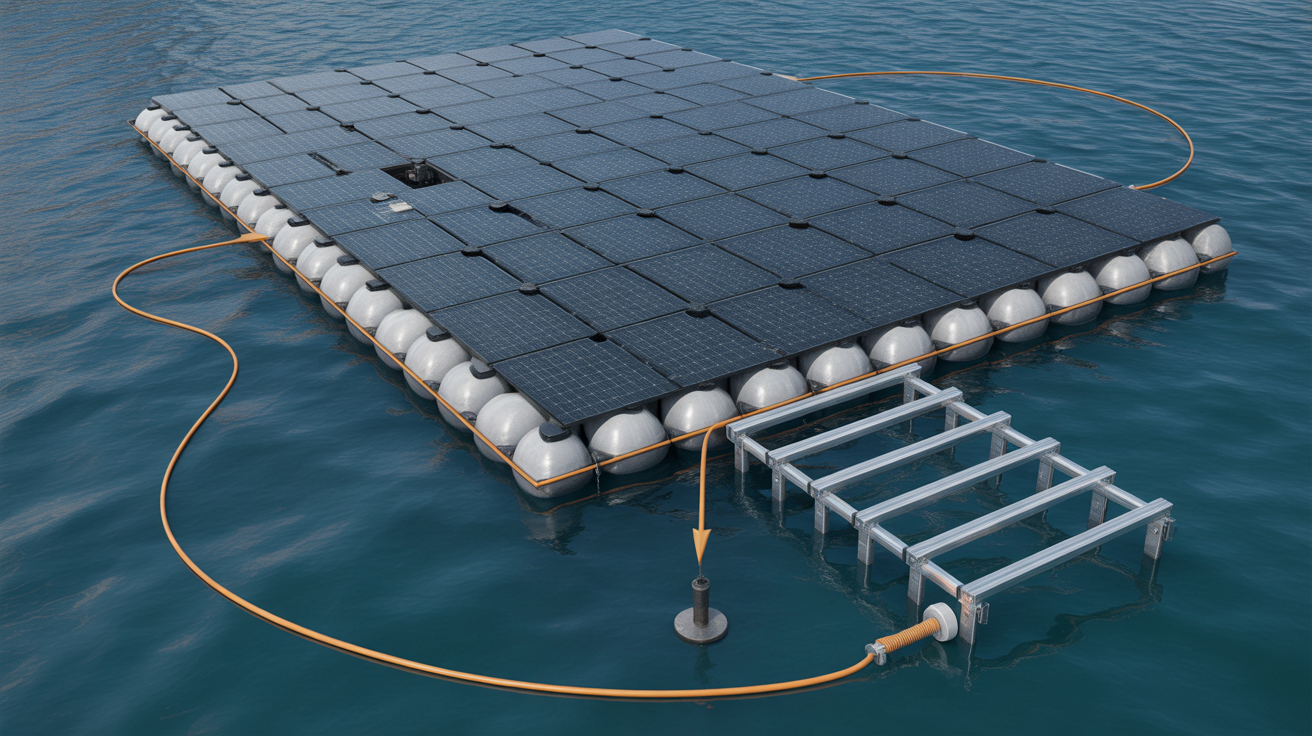

Floating solar installations are rapidly gaining traction as an effective use of space on reservoirs and other water bodies. Yet, this unique environment introduces specific questions about electrical safety, particularly grounding. A common point of confusion is the concept of a "floating DC array." Many mistakenly believe this eliminates certain grounding requirements. This piece clarifies the grounding realities for floating photovoltaic (FPV) systems, comparing the distinct approaches of the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) standards.

The Core Misconception: What a "Floating DC Array" Really Implies

The term "floating" in this context is often misunderstood. It doesn't refer to the array's physical location on water but to its electrical configuration. Understanding this distinction is the first step toward compliant and safe system design.

Defining a Floating (Ungrounded) Array

A floating, or ungrounded, DC array is a system where neither the positive nor the negative DC conductors are intentionally connected to ground. This design is chosen for several technical reasons, including the potential to mitigate Potential-Induced Degradation (PID) in certain PV modules and to simplify some aspects of ground-fault detection. The system's power conductors operate without a direct reference to earth ground.

The Inescapable Water-Ground Connection

Here is the critical reality: while the DC circuit may be ungrounded, the entire mechanical structure is in direct contact with a conductive medium—water. Water acts as a ground plane. Therefore, all non-current-carrying metallic components, like module frames, racking, and mounting hardware, have a direct path to ground. This situation creates significant shock hazards if these components are not properly bonded and connected to a formal grounding system. Ignoring this connection is a dangerous oversight.

NEC Approach to Floating Solar Grounding

The NEC, predominantly used in the United States, takes a highly prescriptive approach to safety. Its rules are designed to clear faults quickly and prevent fires, with personnel protection as a direct outcome.

Equipment Grounding is Non-Negotiable

Under the NEC, the grounding of all exposed, non-current-carrying metal parts is mandatory. This is accomplished using an Equipment Grounding Conductor (EGC). For a floating solar array, this means a continuous, low-impedance EGC must connect the frames of all PV modules, the racking system, and any metallic enclosures back to the main system ground. The purpose is to provide a safe path for fault current to flow, allowing overcurrent protection devices (like fuses or circuit breakers) to operate swiftly.

The Grounding Electrode System (GES)

Every NEC-compliant system requires a Grounding Electrode System (GES) to create a physical connection to the earth. For FPV projects, this often involves driving ground rods into the shoreline or the bed of the water body. The GES ensures that the entire electrical system is at the same potential as the earth, which is vital for stabilizing voltage and protecting against lightning and other surges.

IEC Perspective on Protective Earthing for FPV

IEC standards are widely adopted globally and prioritize the protection of individuals from electric shock. The terminology and some methods differ from the NEC, but the safety goal is parallel.

Protective Earth (PE) as the Foundation

The IEC equivalent of the NEC's EGC is the Protective Earth (PE) conductor. Its function is identical: to bond all exposed conductive parts and connect them to the main earth terminal. This ensures that in the event of a fault where a live conductor touches a metal frame, the component does not become dangerously energized. Instead, the fault current is safely directed to the ground, tripping a protective device. As research from the Technology Roadmap - Solar Photovoltaic Energy 2010 highlights, robust standards are essential for ensuring the long-term safety and reliability of PV products in various environments.

System Earthing Configurations

The IEC categorizes system earthing using designations like TN, TT, and IT. An ungrounded DC array is functionally similar to an IT system. A key rule for IT systems is that while the power source is unearthed, all exposed conductive parts of the installation must still be connected to a protective earth electrode. This reinforces the principle that even without a grounded conductor, equipment earthing is a fundamental safety requirement. The enforcement of such grid connection rules, as noted in a report by the IEA, can vary from legal mandates to guidelines, but the underlying safety principles remain constant.

Key Differences and Practical Implications

While both standards aim for safety, their different philosophies result in practical distinctions that installers and designers must navigate. A system designed for an IEC market may not be automatically compliant with NEC requirements, and vice versa.

A Comparative Overview

This table summarizes the core distinctions in their approach to grounding floating solar arrays.

| Feature | NEC (National Electrical Code) | IEC (International Electrotechnical Commission) |

|---|---|---|

| Primary Focus | Fault clearance and fire prevention | Shock protection (personnel safety) |

| Key Conductor | Equipment Grounding Conductor (EGC) | Protective Earth (PE) Conductor |

| DC Array Status | Ungrounded (floating) systems are permitted | IT systems (unearthed) are permitted |

| Metal Component Rule | All exposed non-current-carrying metal parts must be grounded. | All exposed conductive parts must be earthed. |

| Enforcement | Legally mandated in the United States | A set of standards adopted by countries, often with local modifications. |

Bonding and Conductor Sizing

Both standards demand thorough bonding to create an equipotential plane across all metallic components. However, the specific methods for achieving this and the calculations for sizing the EGC or PE conductor can differ. Designers must consult the specific, current version of the applicable code to ensure compliance. The overarching goal, emphasized in grid code frameworks discussed by IRENA, is to ensure system stability and safety under all operating conditions.

Final Thoughts on Compliance and Safety

The central myth to dispel is that a "floating" DC array on water is exempt from rigorous grounding rules. The reality is precisely the opposite. The proximity to a large, conductive ground plane makes proper equipment grounding even more critical. Both NEC and IEC frameworks, despite their differences in terminology and methodology, converge on one non-negotiable principle: all accessible metallic structures must be robustly grounded or earthed. This practice is fundamental to protecting personnel from shock, safeguarding equipment from damage, and ensuring the long-term reliability of the floating solar installation.

Disclaimer: This information is for educational purposes only and does not constitute professional engineering or legal advice. Always consult with a qualified engineer and adhere to local codes and standards for any electrical installation.

Frequently Asked Questions

Is a floating DC array completely isolated from ground?

No. The term "floating" or "ungrounded" refers to the DC power conductors (positive and negative) not being intentionally connected to ground. However, all metallic structures, such as module frames and racking, must be bonded and connected to a grounding system under both NEC and IEC rules to protect against electric shock and faults.

Do I still need a grounding electrode for a floating solar farm?

Yes. A grounding electrode system is required to establish a connection to the earth. For floating solar, this is typically achieved with electrodes driven into the shoreline or the bed of the water body, connected back to the system's equipment grounding conductors. This ensures a reference to true earth potential.

How do NEC and IEC rules for floating solar grounding differ in practice?

The primary practical difference lies in terminology (EGC vs. PE), conductor sizing calculations, and specific bonding methods. The fundamental principle, however, is the same: create a low-impedance path to ground for all exposed metal to clear faults and prevent shock hazards. NEC is often considered more prescriptive in its requirements.

Can water act as the grounding conductor?

While water is conductive, it is not a reliable or safe grounding conductor. Its resistance can vary significantly with purity and temperature. Both NEC and IEC require a dedicated, properly sized metallic conductor (EGC or PE) to ensure a reliable, low-impedance path for fault currents. Relying on the water itself would be a serious safety violation.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.