Safety in solar design hinges on two distinct ideas that people often conflate: rapid shutdown and earthing (grounding). They solve different hazards and are governed by different rules across regions. In this guide I blend field experience with code references so you can design, inspect, and maintain systems that are both safe and compliant.

The Core Functions: What Each Actually Does

Rapid Shutdown—Controlling Voltage for First Responders

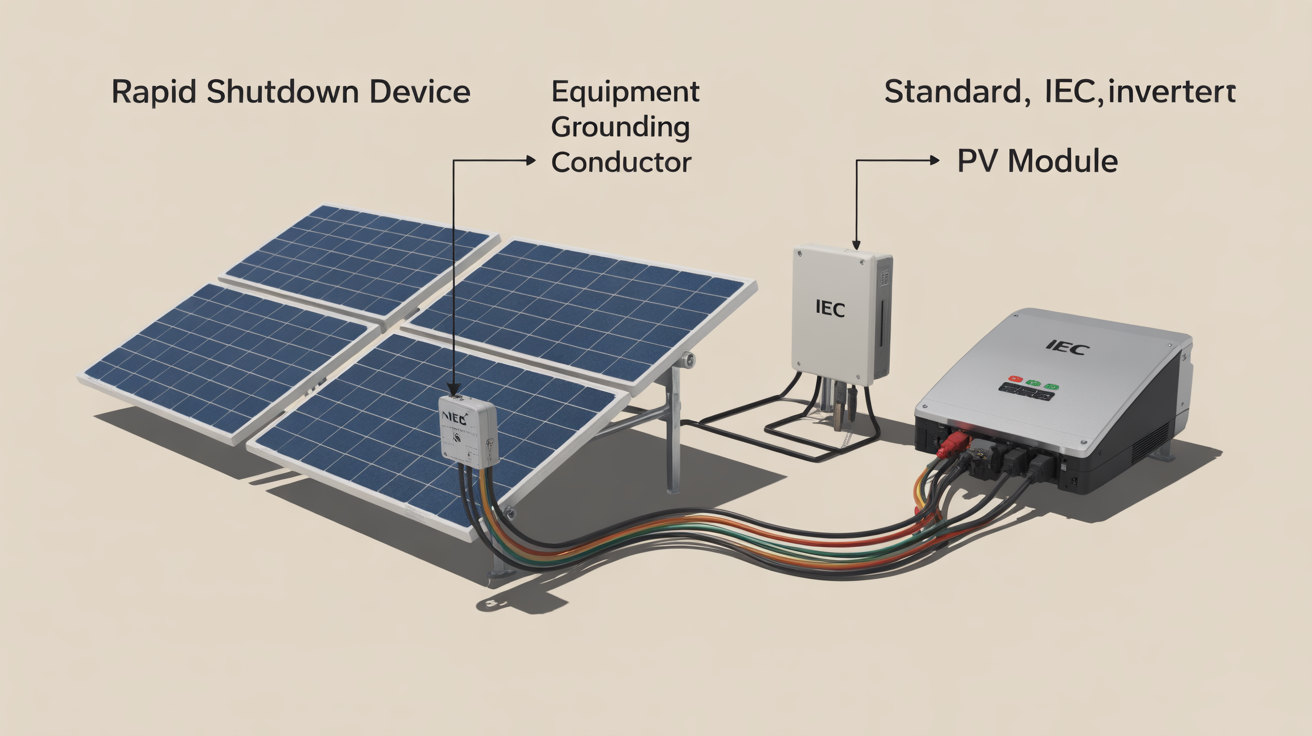

Rapid shutdown is primarily about firefighter safety. PV modules still produce DC whenever illuminated. Rapid shutdown devices bring conductor voltage down quickly when initiated so responders can work on rooftops or near array conductors with reduced shock risk.

Earthing—Managing Faults and Stabilizing the System

Earthing (grounding) provides a low-impedance path for fault current so protective devices operate, stabilizes system voltage, and bonds exposed conductive parts. Frames, racks, and enclosures are tied into the equipment grounding conductor to clear faults rapidly.

The NEC Approach (United States)

Rapid Shutdown per NEC Article 690.12

NEC defines an array boundary and prescribes time-and-voltage limits for conductors inside and outside that boundary. Many jurisdictions achieve this via module-level power electronics (MLPE) or equivalent equipment that can de-energize conductors rapidly. Always verify the edition adopted locally before quoting exact thresholds.

How Shutdown Interacts with Grounding

Rapid shutdown does not replace grounding principles in NEC Articles 250 and 690. Each shutdown device becomes one more component that must be bonded into a continuous equipment grounding path. In practice I verify continuity end-to-end and confirm overcurrent devices trip as expected under simulated faults.

The IEC Perspective (Europe and Many Other Regions)

Earthing and Protection Philosophy

IEC 60364 recognizes TN/TT/IT earthing systems. Many PV arrays operate ungrounded or functionally grounded with protective measures such as double/reinforced insulation and Residual Current Devices (RCDs) for fault detection and disconnection. The focus is comprehensive fault protection rather than a prescriptive rooftop shutdown mandate.

No Universal “Rapid Shutdown” Rule

IEC does not impose a single global rapid shutdown requirement. Some countries add national provisions for de-energizing PV conductors; others address firefighter safety through building codes and operational tactics. Product design follows international standards, while installation specifics depend on national codes.

NEC vs. IEC at a Glance

| Feature | NEC (NFPA 70) | IEC (60364 family) |

|---|---|---|

| Rapid shutdown | Prescriptive (Article 690.12; details vary by adopted edition) | No universal mandate; national rules vary |

| Primary safety driver | First-responder (firefighter) voltage control | Fault protection, insulation coordination, RCDs |

| Rooftop complexity | Higher (additional electronics/common MLPE) | Often lower (simpler DC routing is common) |

| Grounding interaction | Each shutdown device must be bonded into EGC | Earthing design stands on its own objectives |

| Typical protection set | OCPD, AFCI/GFDI as applicable, rapid shutdown | OCPD, RCDs, insulation monitoring |

My Field Notes: What I Verify On Site

- Boundary and labels: I confirm the array boundary definition matches drawings and that shutdown labeling is clear at service points.

- Bonding continuity: Using a low-resistance ohmmeter, I check frame/rack/device bonding from farthest module to the grounding bus, documenting readings.

- Initiation test: I trigger the shutdown and meter conductor voltage both inside and outside the boundary to confirm rapid decay within the local code’s limits.

- RCD/insulation tests (IEC sites): I verify RCD trip times and perform insulation resistance tests to the values specified for the system voltage class.

Design and Maintenance Nuances

NEC projects: Draw a single-line that shows every shutdown device in the grounding path, specify listed bonding hardware, and include a commissioning checklist for voltage decay verification. Replace electronics that show intermittent bonding or nuisance trips.

IEC projects: Prioritize insulation coordination, correct RCD selection (type and rating), and routine testing intervals. Keep conductor routing tidy to minimize capacitive leakage that could cause unwanted trips.

Common Questions

Does rapid shutdown replace grounding?

No. Rapid shutdown controls voltage exposure for first responders. Grounding manages fault current and touch voltage. Both layers are required where applicable.

Can an inverter certified for IEC markets be used under NEC?

Only if it is certified to the appropriate U.S. standards (such as UL 1741) and the complete system meets NEC, including rapid shutdown and bonding. Many projects achieve this via compatible MLPE or integrated shutdown functions.

Why doesn’t IEC copy the NEC rapid shutdown rule?

Different regulatory philosophies and legacy infrastructure. IEC focuses on system-wide fault protection; national authorities add measures as they see fit. Firefighting tactics and building-code requirements also differ.

Compliance Sources and Further Reading

- NFPA 70 (NEC) — National Electrical Code

- IEC 60364 — Electrical Installations of Buildings

- UL 1741 — Inverters/Converters/Controllers

- IEEE 1547 — Interconnection of Distributed Energy Resources

- NREL — Solar Technical Resources

- IRENA — Quality Infrastructure for Smart Mini-Grids

Disclaimer: Always follow the specific code edition adopted by your authority having jurisdiction (AHJ). This article is informational and not legal or engineering advice.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.