Installing a ground-mounted solar array is a significant undertaking. The foundation is the critical starting point that ensures the stability and longevity of the entire system. But what happens when the ground itself is the biggest challenge? Rocky terrain can bring a solar project to a grinding halt, causing costly delays and compromising structural integrity. This analysis examines two primary foundation methods for these difficult conditions: traditional driven posts and modern screw piles.

Understanding the Challenge: Rocky Installation Sites

Not all land is ideal for construction. Parcels available for solar development are increasingly on hilly or rocky terrain, which presents unique geotechnical hurdles. A thorough site assessment is the first step in any successful installation, as it reveals what lies beneath the surface.

What Defines a 'Rocky' Site?

A 'rocky' site isn't a single definition. It can range from soil with dense gravel and scattered cobbles to solid, impenetrable bedrock just below the topsoil. Geotechnical studies are essential to classify the site conditions accurately. These investigations involve soil sampling and analysis to determine the load-bearing capacity and identify potential hazards like large boulders or unstable formations that could derail an installation.

Why Standard Installation Methods Fail

The most common foundation for solar projects on ideal land is the driven post or I-beam. Installers use powerful hammers to drive these steel posts into the ground. On rocky sites, this method often leads to 'refusal.' Refusal occurs when a post cannot be driven to the specified depth because it hits an obstruction. This can damage the post, compromise the foundation's strength, and lead to significant project delays and budget overruns as crews struggle to remediate the issue.

The Contenders: A Head-to-Head Comparison

When faced with difficult soil, the choice of foundation becomes a critical decision point. Driven piles are a cost-effective option for typical sites, but screw piles often provide a more reliable solution for challenging terrain.

Driven Posts: The Traditional Approach

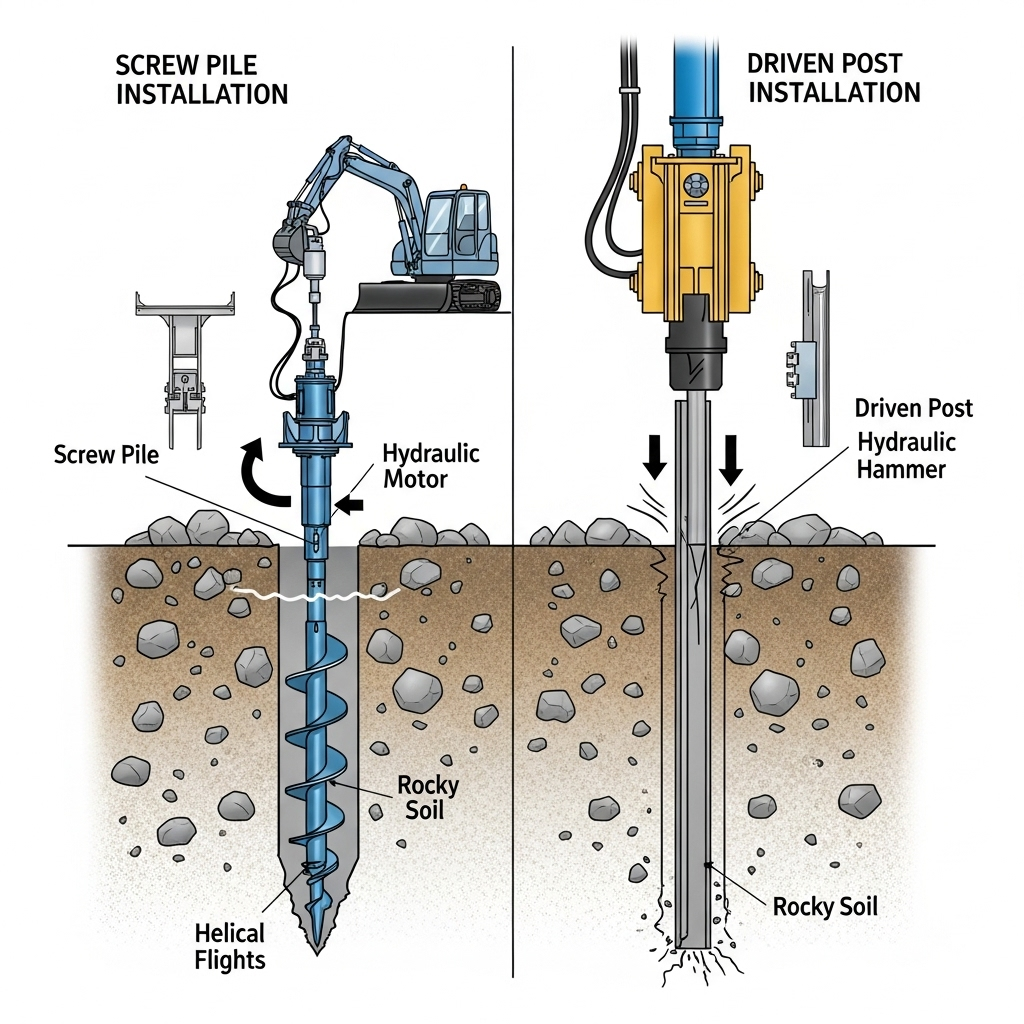

Driven posts are steel beams (like I-beams) hammered directly into the earth. In soft, uniform soils, this method is fast and economical. However, their effectiveness plummets in rocky conditions. The repeated, high-impact force can damage the pile itself and the installation equipment. The primary drawback is the high risk of refusal, which requires costly and time-consuming remediation, such as pre-drilling holes or abandoning the location entirely.

Screw Piles: The Modern Alternative

Screw piles, also known as helical piles, are large steel screws drilled into the ground using a hydraulic motor. Instead of relying on brute force, they turn their way into the earth, displacing soil minimally. This technique is far more effective at navigating around smaller rocks and cobbles. For larger obstructions, a pilot hole can be drilled to allow the screw pile to be installed securely. Installation torque is measured in real-time, providing a predictable and verifiable load capacity for each foundation point.

| Feature | Driven Posts | Screw Piles (Helical Piles) |

|---|---|---|

| Installation Method | Impact hammering | Rotary hydraulic drilling |

| Best Use Case | Soft, uniform soils with no obstructions | Varied soil, rocky conditions, sloped terrain |

| Rocky Site Performance | High risk of refusal, potential for pile damage | Low refusal risk, navigates around obstacles |

| Environmental Impact | High noise and vibration, significant ground disturbance | Low noise and vibration, minimal soil displacement |

| Cost Profile | Lower upfront material cost, but high risk of extra costs from refusals | Higher upfront material cost, but predictable total installation cost |

Case Study: A Solar Farm Project in a Challenging Terrain

To illustrate the practical differences, consider a hypothetical 5 MW solar farm project on a site with mixed soil conditions, including areas with dense cobble and shallow bedrock.

Project Overview and Initial Assessment

The initial plan, driven by a desire to minimize upfront material costs, specified driven posts for all foundations. The geotechnical report indicated variable ground conditions, with potential for refusal in over 30% of the project area. Despite this warning, the project moved forward with the traditional approach.

The Driven Post Trial: Encountering Refusal

During the first week of installation, the crews immediately ran into problems. The refusal rate exceeded 40%, significantly higher than the initial estimate. Each refusal required a decision: attempt to pre-drill, which was slow and expensive, or move the pile location, which compromised the array layout and engineering design. The project fell behind schedule within days, and costs began to escalate due to wasted labor, damaged materials, and equipment downtime.

The Switch to Screw Piles: A Problem-Solving Approach

Faced with mounting delays and costs, the project managers made the decision to switch to screw piles for the remaining 80% of the foundations. The new installation process was immediately more efficient. The screw piles were installed with minimal issue, easily penetrating the dense cobble. In areas with bedrock, a smaller pilot hole was drilled, allowing the screw pile to be securely set. This adaptability eliminated the refusal problem and put the project back on track. A stable foundation is paramount, as it ensures the racking and panels remain secure, protecting the investment and guaranteeing the system can deliver its expected output for years to come. This is a key factor in achieving the best ultimate reference in solar storage performance.

Analyzing the Outcome: Cost, Time, and Performance

The decision to switch foundation types had a clear impact on the project's success. While the material cost for screw piles was higher, the overall project cost was lower.

A Deeper Look at Project Costs

Studies show that while ground screws may cost more upfront, driven piles can quickly become more expensive when refusal rates are high. One analysis found that at a 29% refusal rate, screw piles become the more cost-effective option from an installation perspective. In our case study, the initial 'savings' from choosing driven posts were completely erased by remediation costs, labor overruns, and project delays. The predictable, all-in cost of the screw pile installation proved to be the more economical choice.

Long-Term Reliability and System Integrity

A secure foundation is not just about surviving installation; it's about ensuring decades of reliable energy production. Foundations that shift or fail can cause panel misalignment, racking stress, and reduced system output. The verified, torque-based installation of screw piles provided a higher degree of confidence in the long-term stability of the array, reducing the need for future maintenance and ensuring the solar farm performs optimally throughout its lifespan.

Final Thoughts on Foundation Selection

Choosing a foundation for a ground-mounted solar project is not a one-size-fits-all decision. While driven posts remain a viable option for sites with ideal soil conditions, they introduce significant financial and scheduling risks on rocky terrain. As this case study demonstrates, screw piles offer a predictable and reliable alternative that can save a project from costly overruns and ensure long-term structural integrity. The key takeaway is to invest in a thorough geotechnical investigation and weigh the total cost of installation—including potential risks and delays—rather than just the upfront material price.

Frequently Asked Questions

Can driven posts ever be used on rocky sites?

Yes, but it often requires costly mitigation efforts. Pre-drilling pilot holes for each post is a common solution, but this adds a significant step to the installation process, increasing both time and expense. In many cases, the combined cost of driving and pre-drilling exceeds the cost of using screw piles from the start.

Are screw piles suitable for all types of rock?

Screw piles are highly effective in dense soils, gravel, cobble, and softer, weathered rock. For solid bedrock, they are typically installed into a pre-drilled socket and sometimes grouted in place, creating a hybrid rock anchor. A geotechnical engineer can determine the most effective installation method based on the specific rock characteristics.

How does foundation choice impact the solar panel's performance?

The foundation is the literal base for your energy production. An unstable or failing foundation can cause the entire solar array to shift or settle. This can lead to panel misalignment, which creates shading and reduces energy output, or in severe cases, cause structural failure of the racking system. A robust foundation ensures the panels remain at their optimal angle for decades.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.