Many homes and workshops rely on high-power appliances that require a 240-volt connection. Achieving this level of power with an off-grid or hybrid solar system involves a specific technique: stacking inverters. This process allows you to combine multiple hybrid inverters to create a single, powerful, and synchronized split-phase system. Getting this configuration right is critical for both performance and safety. A properly stacked system delivers the power you need for demanding loads, while an incorrect setup can lead to equipment damage or instability.

Understanding Split-Phase Power and Inverter Stacking

Before connecting any wires, it's important to grasp the fundamental concepts behind the technology. This foundational knowledge ensures you make informed decisions during the installation and configuration process.

What is Split-Phase Power?

In North America, standard residential electrical service is a split-phase system. It provides two separate 120-volt lines of alternating current (AC) power (L1 and L2) that are 180 degrees out of phase with each other, along with a shared neutral wire. This setup allows you to power standard 120V appliances by connecting between one line and neutral, or to power high-demand appliances like electric dryers, water heaters, and well pumps by connecting across both lines to get 240V.

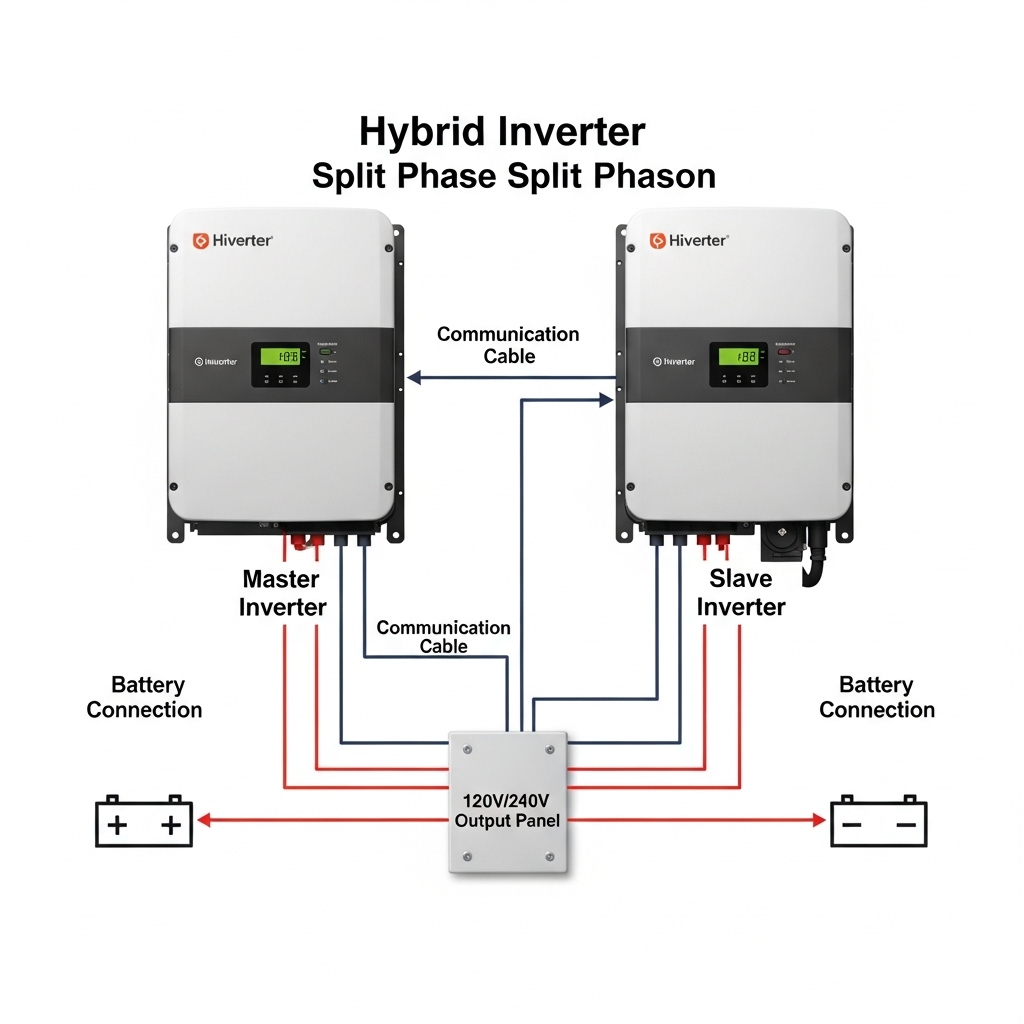

The Core Concept of Stacking Hybrid Inverters

Stacking is the process of electronically linking two or more compatible inverters to function as one cohesive unit. In the context of creating a 240V output, one inverter is configured to produce the L1 voltage, and the second inverter produces the L2 voltage. A dedicated communication cable synchronizes them perfectly, ensuring they remain 180 degrees out of phase. This creates a stable 120/240V split-phase supply identical to what you would get from the utility grid. One inverter typically acts as the 'master' or 'primary' unit, controlling the output voltage and frequency for the entire system, while the other(s) act as 'slaves' or 'secondary' units, following its lead.

Pre-Installation Checklist: Ensuring Compatibility and Safety

Success lies in the preparation. Rushing this stage is a common source of problems. A methodical approach to component selection and safety checks will prevent costly mistakes and ensure a reliable system.

Verifying Inverter Compatibility

Not all hybrid inverters can be stacked. This capability must be a feature designed by the manufacturer. Always consult the product manual and technical specifications to confirm that your inverter model supports split-phase operation. For a stable system, it is crucial to use identical models from the same manufacturer. Mixing models or even different firmware versions can lead to communication errors and load-sharing problems, ultimately causing the system to fail.

Essential Components for a Stacked System

A successful installation requires more than just the inverters. You will need:

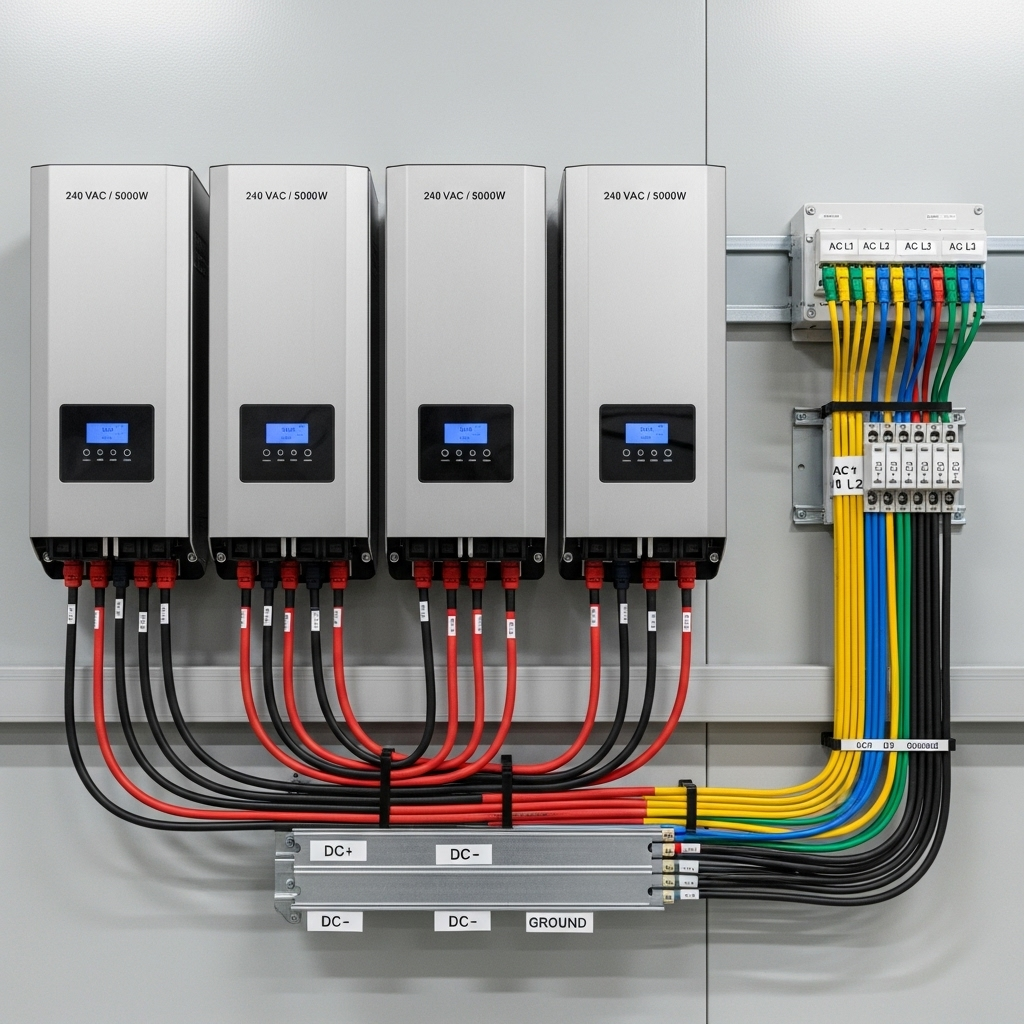

- Communication Cables: These specialized cables are essential for synchronizing the inverters. Use only the cable provided or specified by the manufacturer.

- Proper DC and AC Cabling: The DC cables connecting the inverters to the battery bank must be thick enough to handle the high current draw of both units combined. Similarly, the AC wiring must be sized according to local electrical codes to manage the full output power.

- Busbars: High-quality busbars for both the positive and negative DC connections help ensure that each inverter receives equal voltage from the battery bank, which is critical for balanced performance.

- Circuit Protection: Each inverter should have its own dedicated DC circuit breaker between it and the battery bank. On the AC side, a suitable sub-panel with breakers for all 120V and 240V circuits is necessary.

Workspace and Safety Precautions

Always prioritize safety. Work in a clean, dry, and well-ventilated area. Before starting, ensure all power sources are completely disconnected—turn off the battery bank, disconnect solar panels, and shut off any grid or generator feeds. Use properly insulated tools and wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

Step-by-Step Guide to Stacking Inverters for Split-Phase Output

With the preparatory work done, you can proceed with the physical installation and configuration. Follow the manufacturer's instructions precisely, as sequences can vary between models.

Physical Installation and Wiring

First, securely mount the inverters on a non-combustible surface, leaving adequate clearance around each unit for air circulation as specified in the manual. Connect the heavy-gauge DC cables from the battery busbars to the respective DC inputs of each inverter, ensuring correct polarity. Next, wire the AC outputs from each inverter to a new AC sub-panel. One inverter will feed the L1 busbar, the other will feed the L2 busbar, and both will connect to the shared neutral and ground busbars.

Establishing Communication and Configuration

Connect the proprietary communication cable between the designated ports on the master and slave inverters. This link is the brain of the system. Next, set the identity of each unit. This is often done via physical DIP switches or through a software interface. Designate one inverter as the master (or primary) and the other as the slave (or secondary). Finally, access the configuration menu on the master inverter and set the system output to 'Split-Phase 120/240V'. The master unit will then automatically configure the slave.

System Commissioning and Verification

Follow the correct start-up procedure, which typically involves energizing the DC side first by turning on the battery breakers. Once the inverters power on, use a quality multimeter to verify the AC output at the sub-panel. You should measure approximately 120V from L1 to Neutral, 120V from L2 to Neutral, and 240V between L1 and L2. If the voltages are correct, you can test the system with a small load before connecting your main circuits.

Critical Safety Protocols and Advanced Configurations

A running system is not the end of the job. Ensuring its long-term reliability and safety involves understanding its protective features and operational demands.

Load Balancing and Management

For optimal performance and longevity, it is important to balance the 120V loads as evenly as possible between the two phases (L1 and L2). Try to distribute the circuits in your sub-panel so that the anticipated power draw on each leg is roughly equal. An imbalance can cause one inverter to work harder than the other, potentially leading to premature wear or nuisance tripping on the overloaded side.

Understanding Protection Mechanisms

Stacked inverters incorporate multiple layers of protection. A key safety feature required by grid codes is anti-islanding protection. As detailed in the IRENA report Grid Codes for Renewable Powered Systems, this function prevents your system from sending power back to a de-energized utility grid, which is vital for protecting line workers during an outage. The system also includes internal protections against over-current, short circuits, and over-voltage to safeguard your equipment.

A Comparative Look at Configurations

Choosing between a single large inverter and a stacked system involves trade-offs. The table below outlines some key differences.

| Feature | Single Large Inverter | Stacked Hybrid Inverters |

|---|---|---|

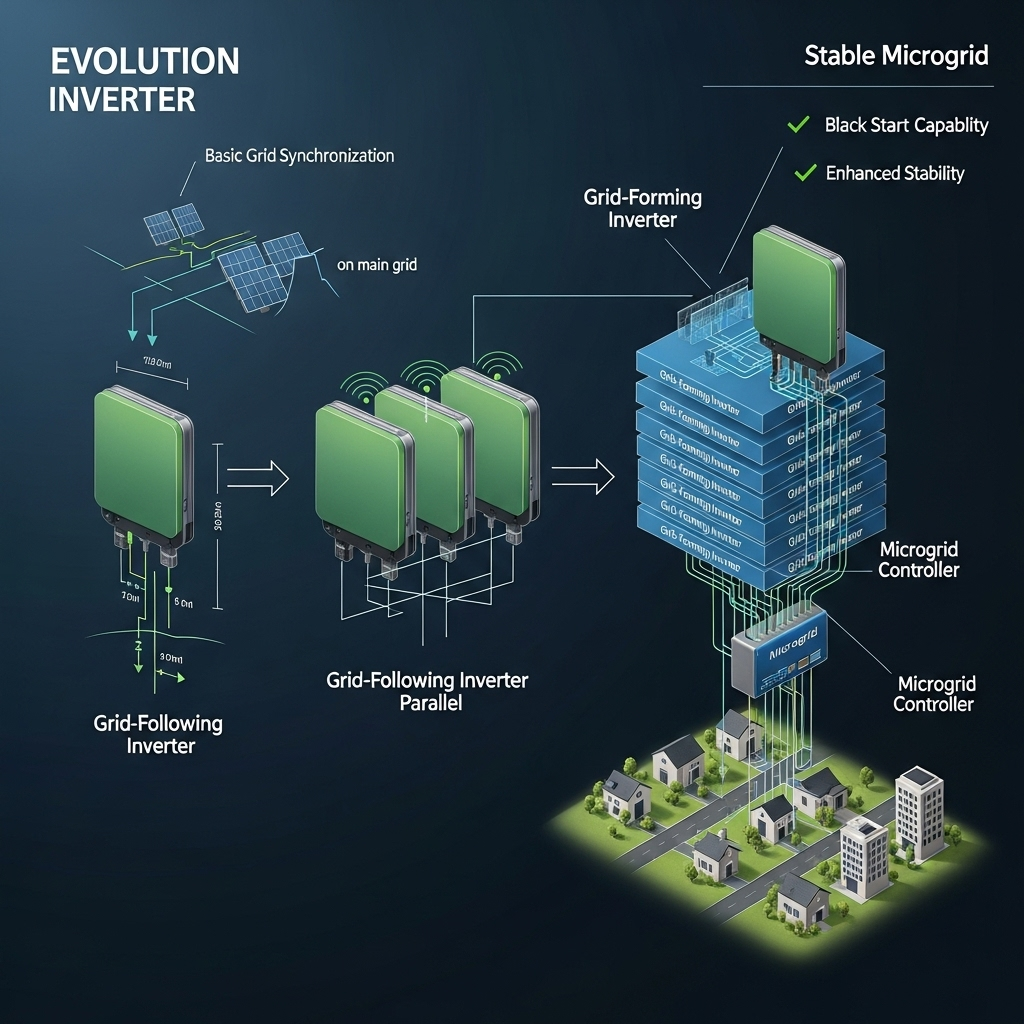

| Scalability | Limited to the unit's maximum capacity | High; capacity can be increased by adding more units |

| Redundancy | Represents a single point of failure | Offers partial redundancy; one leg may operate if the other fails |

| Installation Complexity | Generally simpler wiring and configuration | More complex due to synchronization and communication wiring |

| Cost | Can have a higher initial upfront cost | Allows for a phased investment as power needs grow |

| Split-Phase 240V | Available on specific, often larger, models | A primary benefit achieved through stacking |

Building a Resilient and Powerful Energy System

Stacking hybrid inverters is an effective method for creating a robust, high-capacity 120/240V split-phase power system. It provides the energy necessary for large residential homes, farms, and off-grid workshops, offering both power and flexibility. While the process is more complex than a single inverter installation, a carefully planned and executed setup results in a scalable and resilient energy solution. By focusing on component compatibility and adhering strictly to safety protocols, you can build an energy system that delivers reliable power for years to come. Evaluating key metrics is essential for confirming system health; for more on this, the ultimate reference for solar storage performance offers insights into analyzing efficiency and discharge rates. Ultimately, this configuration is a significant step toward achieving true energy independence.

Frequently Asked Questions

Can I stack inverters from different brands?

It is strongly discouraged. For stable and safe operation, you must use identical inverter models from the same manufacturer, ideally with the same firmware version. Mismatched units cannot synchronize correctly, leading to system failure or damage.

What happens if one inverter in a stacked system fails?

This depends on the system's design. In many cases, the remaining inverter can continue to supply power to its connected loads (one leg of the 120V service), offering a degree of redundancy. However, 240V appliances will not function. You should consult your inverter's manual for specific failure mode behavior.

Is stacking inverters the same as paralleling them?

No. Paralleling connects inverters to increase the total amperage (current) at the same voltage (e.g., combining two 5kW 120V inverters to get 10kW at 120V). Stacking for split-phase connects them to create a 120/240V service, where the two inverters are 180 degrees out of phase with each other.

Do I need a special battery bank for a stacked system?

You don't need a special type of battery, but the battery bank must be sized to handle the combined load of all inverters. The DC cabling from the battery to each inverter must also be appropriately sized to handle the high current draw safely.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.