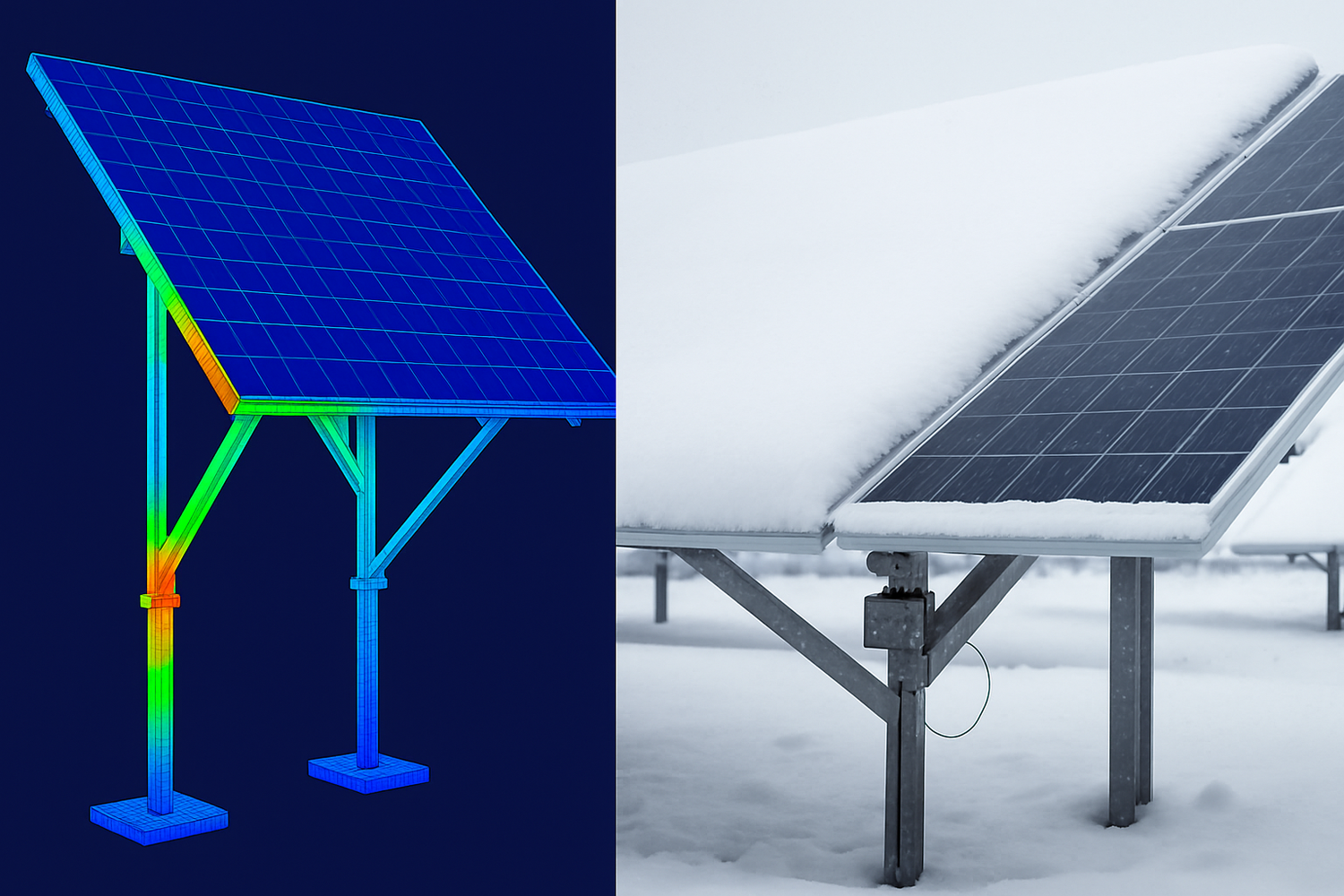

Designing solar racking to withstand heavy snow is a critical engineering challenge. While theoretical calculations provide a starting point, they don't always capture the complexities of real-world conditions. A structural failure is not just an inconvenience; it's a significant financial loss and a safety hazard. This is where a robust validation process becomes essential. By combining the predictive power of Finite Element Analysis (FEA) with tangible field data, you can build confidence in your system's ability to endure the harshest winters.

The Foundation: Understanding Snow Loads and FEA

Before validating a design, you must first understand the forces at play and the tools used to simulate them. Snow is not a simple, uniform weight. Its behavior is complex, and modeling it accurately is the first step toward a resilient solar installation.

Defining Snow Load Cases

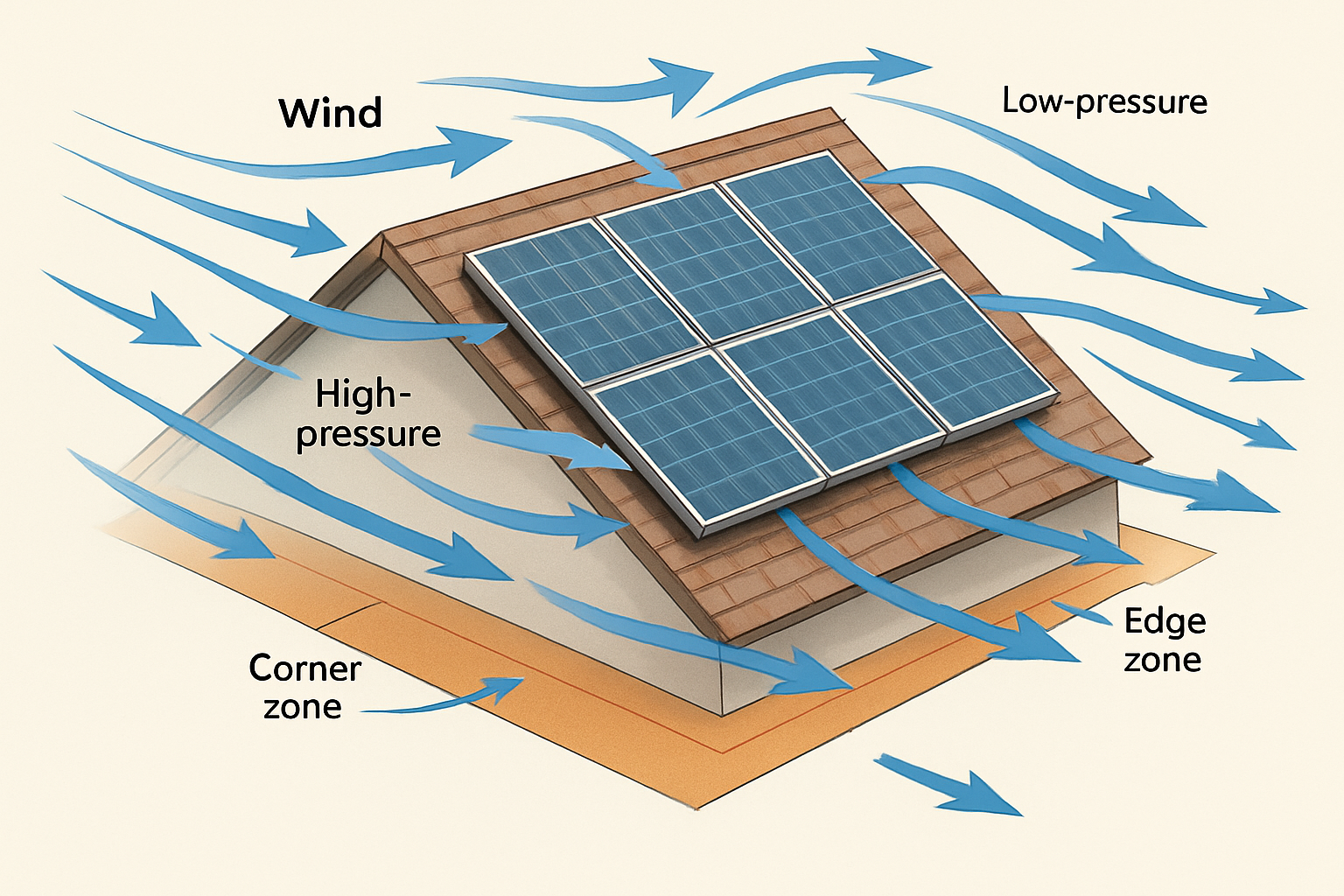

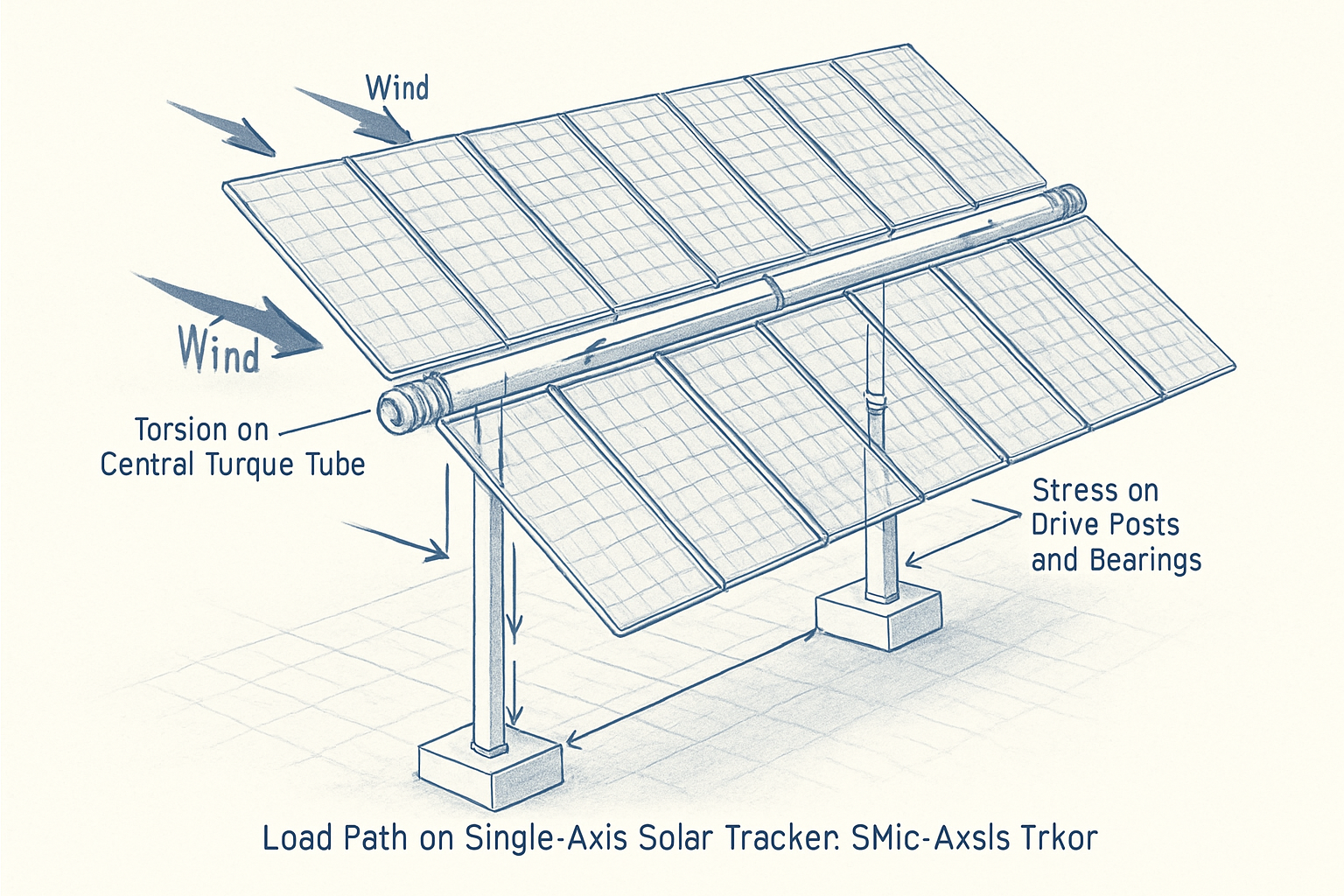

A snow load case is a specific scenario that engineers use to calculate the forces snow exerts on a structure. It goes beyond simply piling weight on top of the solar panels. Key factors include the ground snow load, which is a baseline measurement for a region, but also site-specific conditions like drifting, sliding snow, and unbalanced loads caused by wind or partial melting. The temperature of the PV modules themselves can also influence how snow and ice accumulate, creating unique stress patterns that must be considered in the engineering analysis.

The Role of Finite Element Analysis (FEA)

Finite Element Analysis is a powerful computer-based method used to simulate how an object reacts to physical forces. In solar engineering, FEA allows designers to create a detailed 3D model of a racking system. They can then apply simulated snow loads to predict areas of high stress, strain, and potential deformation. The accuracy of an FEA model depends heavily on its inputs, which include the precise geometry of the components, the mechanical properties of the materials used, and how the different parts are connected and anchored.

Bridging the Gap: Collecting and Utilizing Field Data

An FEA model is only a simulation. To confirm its accuracy, you need to compare it against real-world measurements. Field data provides the ground truth that turns a theoretical model into a validated, reliable engineering tool.

Methods for Gathering Real-World Data

Collecting accurate field data requires a strategic approach. Instruments like load cells placed on key structural members can directly measure the forces exerted by snow. Strain gauges can be applied to racking components to record deformation under load. Beyond direct measurements, analyzing historical weather data provides context for extreme snowfall events. Modern techniques such as drone surveys equipped with LiDAR or photogrammetry can create detailed 3D maps of snow distribution, revealing complex drift patterns that are difficult to predict. As noted in the IEA report, Harnessing Variable Renewables, using empirical time series data is crucial for accurately assessing the impact of variable environmental conditions.

Interpreting Field Data for Validation

Raw data from sensors is just the beginning. This information must be processed and analyzed to identify peak load events and compare them to the assumptions used in the initial design. Long-term data collection is particularly valuable, as it increases the likelihood of capturing the one-in-50 or one-in-100-year weather events that truly test a system's limits. This data-driven approach allows engineers to move from assumptions to evidence-based conclusions about structural performance.

The Validation Process: Comparing FEA Models to Reality

With a predictive model and real-world data in hand, the final step is to bring them together. This correlation and refinement process is where the true strength of the design is confirmed.

Correlating Simulation with Measurement

The validation process involves applying the measured snow loads from the field directly to the FEA model. Engineers then compare the stress and deflection predicted by the simulation with the actual measurements from strain gauges and other sensors. If the model's predictions closely match the field data, it validates the model's accuracy and, by extension, the structural integrity of the design. Discrepancies, however, point to areas where the model needs refinement.

| Parameter | FEA Predicted Value | Field Measured Value | Variance |

|---|---|---|---|

| Max Rail Deflection (mm) | 15.2 | 16.5 | -8.5% |

| Max Support Post Stress (MPa) | 185 | 178 | +3.9% |

| Anchor Bolt Tension (kN) | 25.4 | 28.1 | -9.6% |

Refining the Model for Future Accuracy

When the simulated results do not align with field data, engineers must investigate the cause. The discrepancy could stem from assumptions about connection stiffness, material properties, or how the load was distributed in the model. By adjusting these parameters, the model can be calibrated until it accurately reflects reality. This iterative process creates a highly reliable and precise engineering tool. The International Renewable Energy Agency (IRENA) states in its guide, Grid Codes for Renewable Powered Systems, that combining simulation tests with on-site commissioning is the most effective way to ensure compliance and safety.

Practical Implications for Solar Project Development

Validating snow load cases is not just an academic exercise. It has direct and significant impacts on the safety, bankability, and cost-effectiveness of a solar project.

Enhancing Safety and Reducing Risk

A validated design provides a high degree of confidence that a solar array will not fail under expected snow loads. This is fundamental to protecting the asset, ensuring the safety of personnel, and preventing costly damage to property. For developers, having a design backed by both FEA and field data can be a critical factor in securing project financing and insurance, as it demonstrates a commitment to rigorous engineering and risk mitigation.

Optimizing Design and Cost

Without validation, engineers often have to be overly conservative, leading to over-engineered systems that are more expensive than necessary. A validated model allows for design optimization, where material is used more efficiently without compromising safety. This leads to more cost-effective racking solutions. A well-built structure is the foundation for a high-performing energy system. Ensuring the array's integrity protects the entire investment, including the panels, inverters, and any connected energy storage. You can learn more about optimizing system output in the Ultimate Reference for Solar & Storage Performance.

A Data-Driven Approach to Structural Integrity

Ultimately, Finite Element Analysis is an incredibly powerful engineering tool, but its true value is unlocked when its predictions are confirmed by real-world evidence. The practice of validating FEA snow load cases with field data represents a mature, data-driven approach to solar engineering. This methodology ensures that solar installations are not only designed to code but are proven to withstand the specific environmental challenges they will face. As solar energy deployment expands into more diverse and demanding climates, a point emphasized by the U.S. Energy Information Administration, this level of engineering diligence will become the standard for building a resilient and reliable energy future.

Frequently Asked Questions

How often should field data be collected for snow load validation?

For effective validation, data should be collected continuously throughout the winter season. It is especially important to capture data during and after major snowfall events, freeze-thaw cycles, and high wind conditions, as these situations typically produce the highest loads on the structure.

Is FEA validation only for large-scale solar farms?

No, the principles of validation apply to projects of all sizes. While large utility-scale farms may employ more extensive sensor networks, the methodology of comparing simulation to real-world performance is just as valuable for commercial rooftop and even residential ground-mount systems in high-snow areas.

What are the main challenges in correlating FEA with field data?

Key challenges include ensuring the accuracy and proper calibration of sensors, correctly modeling the stiffness of bolted and clamped connections in the FEA software, and accounting for the non-uniform and often unpredictable nature of snow drifting and ice formation.

Can this process account for unusual snow events like ice damming?

Yes. A primary benefit of field data collection is its ability to capture unexpected loading conditions like ice damming or unbalanced loads from sliding snow. When these events are recorded, the data can be used to update and refine the FEA model, making it more robust for predicting behavior under these specific and often highly localized stress conditions.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.