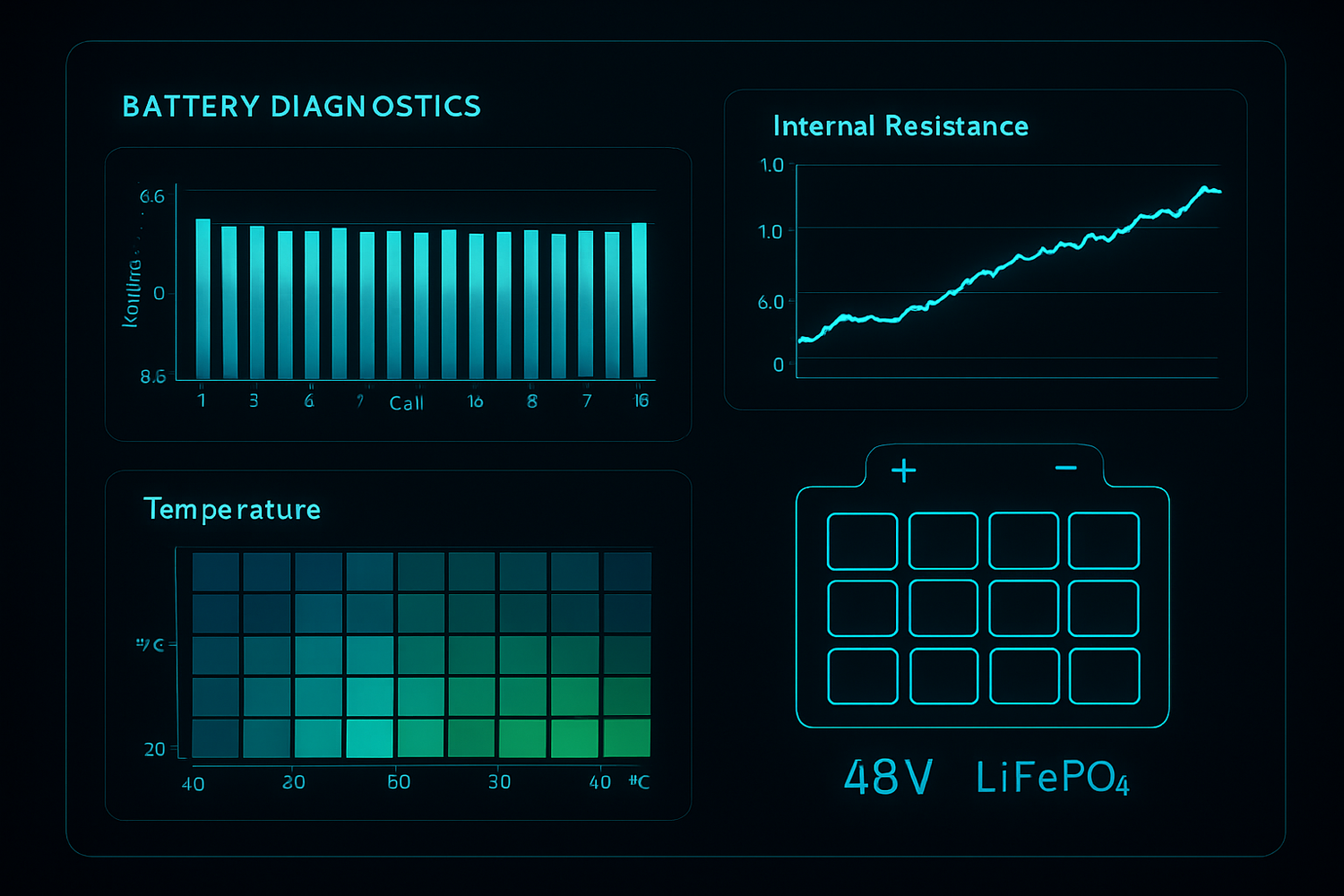

Your 48V LiFePO4 battery is the heart of your energy storage solution, a key component in achieving energy independence. While standard monitoring provides a basic overview, advanced diagnostics offer a much deeper understanding of your battery's health and performance. Moving beyond simple charge levels allows you to identify potential issues early, optimize efficiency, and significantly extend the lifespan of your investment. This is about proactive care for your hybrid system's core.

Beyond the Basics: Why Standard Metrics Are Not Enough

Many system owners are familiar with top-level indicators. Yet, these metrics only scratch the surface of battery health. Relying on them exclusively can lead to unforeseen performance degradation.

The Limitations of SoC and SoH

State of Charge (SoC) is simply a snapshot of the current energy level, much like a fuel gauge in a car. It tells you how much energy is available right now but reveals nothing about the battery's underlying condition. State of Health (SoH), while more indicative, is often a calculated estimate based on past performance. It's a lagging indicator that may not alert you to developing problems until they have already begun to impact capacity.

Uncovering Hidden Issues: The Need for Deeper Analysis

Beneath the surface, subtle issues can be developing. Problems like an imbalance between individual cells or a gradual increase in internal resistance can silently reduce your battery's effective capacity and shorten its operational life. These conditions often won't trigger a significant drop in the overall SoH value until the degradation is well underway. Advanced diagnostics are designed to detect these very issues.

Core Advanced Diagnostic Techniques for LiFePO4 Batteries

To truly understand your battery's condition, you need to look at more granular data. Advanced Battery Management Systems (BMS) provide access to these critical diagnostic points, transforming how you manage your hybrid system performance monitoring.

Internal Resistance (IR) Measurement

Internal resistance is a fundamental indicator of a battery's health. It represents the opposition to current flow within the battery. As a battery ages and degrades, its IR naturally increases. A higher IR means more energy is lost as heat during charging and discharging, reducing overall efficiency. It also limits the battery's ability to deliver high power. Monitoring the trend of IR over time is a powerful predictive maintenance tool; a sudden or steady increase is a clear sign of internal degradation.

Cell Voltage Balancing and Monitoring

A 48V LiFePO4 battery pack is composed of numerous individual cells connected in series. For optimal performance, all cells must maintain a nearly identical voltage. Cell balancing is the process of equalizing these voltages. If one cell becomes weaker than the others, its voltage will drop faster during discharge and rise faster during charging. This single cell can then limit the entire pack's capacity, causing the BMS to shut the system down prematurely, even if other cells are still well within their operating range. Monitoring individual cell voltages helps spot these imbalances early.

Coulomb Counting and Efficiency Tracking

Coulomb counting is a method used by a BMS to track the amount of energy flowing into and out of the battery. This provides a more accurate SoC calculation than voltage-based estimates alone. By comparing the energy put in during charging to the energy delivered during discharging, you can calculate the Round-Trip Efficiency (RTE). A declining RTE is a direct symptom of increasing internal losses, often tied to rising internal resistance. For a detailed look at key performance indicators like RTE, the ultimate reference on solar storage performance provides valuable benchmarks for evaluating your system.

Interpreting Diagnostic Data for Proactive Maintenance

Collecting data is only the first step. The real value comes from interpreting this information to make informed decisions about your system's operation and maintenance.

Identifying Common Fault Patterns

By correlating different data points, you can diagnose specific issues. A proactive approach to LiFePO4 battery health involves recognizing these patterns before they lead to significant downtime or damage.

| Symptom | Potential Issue | Key Diagnostic Clue |

|---|---|---|

| Rapid voltage drop under heavy load | High Internal Resistance | IR measurement trending upwards over time |

| System shuts down before reaching 0% SoC | Cell Imbalance | One or more cells hitting the low-voltage cutoff prematurely |

| Battery fails to reach a full 100% charge | Cell Imbalance or Faulty Cell | One or more cells hitting the high-voltage cutoff before the others |

| Noticeable heat from the battery during operation | High IR or a Poor Connection | Elevated readings from temperature sensors, especially localized hotspots |

The Role of Temperature in Battery Health

Temperature has a profound effect on battery chemistry and longevity. High temperatures accelerate the chemical degradation of battery components, while very low temperatures can reduce available capacity and efficiency. As the International Energy Agency's report on The Role of Critical Minerals in Clean Energy Transitions explains, managing battery performance across different conditions is crucial as storage deployment grows globally. Advanced diagnostics use temperature sensors to monitor for hotspots within the pack, which can indicate a failing cell or a high-resistance connection that requires immediate attention.

Challenges and Solutions in 48V Battery Monitoring

Implementing a robust diagnostic strategy involves more than just the battery itself; it requires seamless integration with your entire energy system.

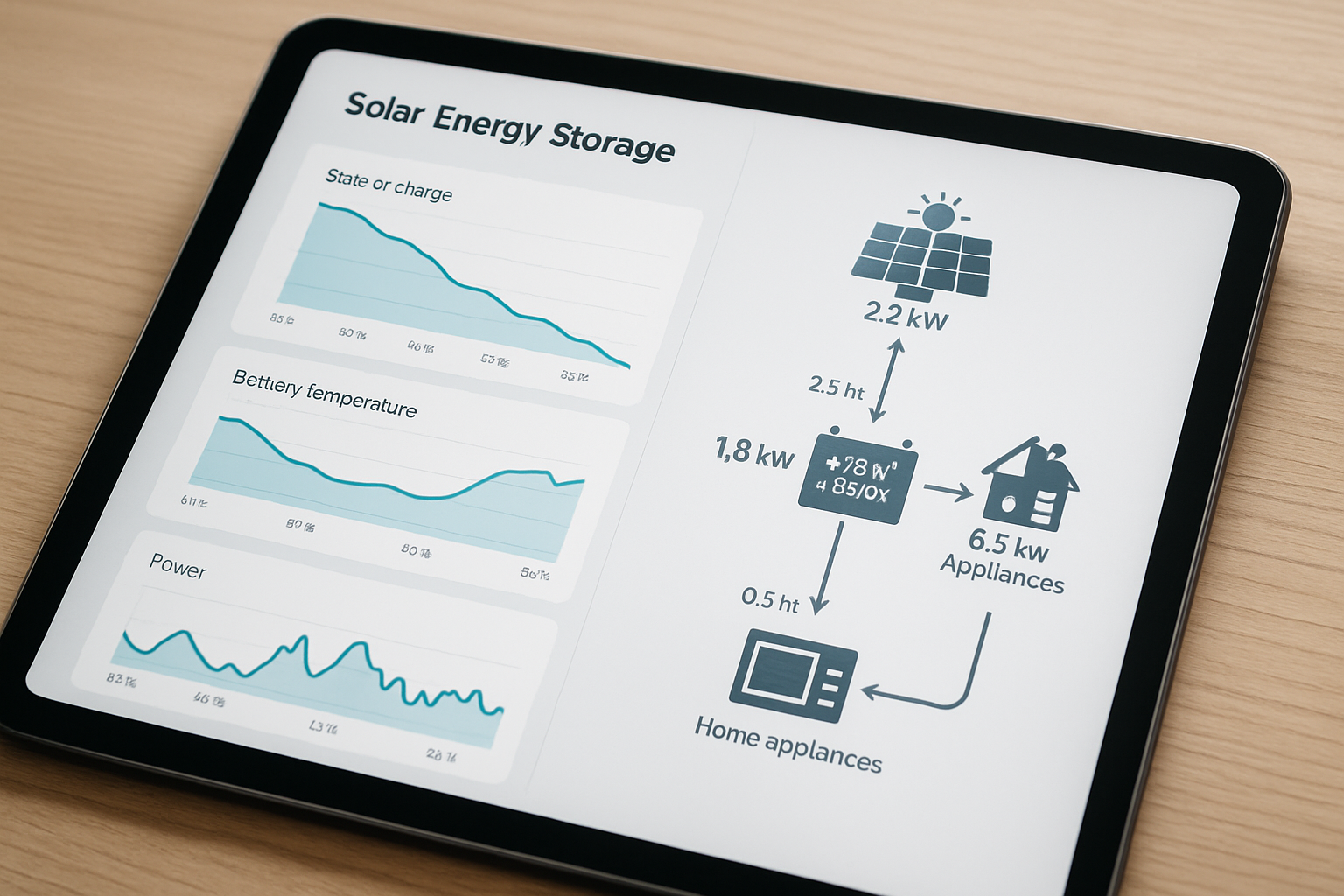

Integrating with Hybrid Inverters

Effective hybrid system performance monitoring depends on clear communication between the battery's BMS and the hybrid inverter. Using standard protocols like CAN or RS485, the BMS relays critical data that the inverter uses to optimize charging and discharging. A communication mismatch can lead to inaccurate reporting and inefficient operation, undermining the benefits of having an advanced system.

Data Logging and Trend Analysis

Real-time data is useful, but the most powerful insights come from analyzing trends over weeks and months. A gradual increase in the time it takes to balance cells or a slow rise in internal resistance are predictive indicators of future problems. As noted in IRENA's Innovation Outlook: Smart charging for electric vehicles, monitoring key parameters like battery health is essential for ensuring long-term reliability. This principle applies directly to stationary storage, where historical data empowers predictive maintenance.

Ensuring Data Accuracy

The reliability of your diagnostics is only as good as the data you collect. This makes the quality of the BMS paramount. High-quality systems use precisely calibrated sensors to ensure the voltage, current, and temperature readings are accurate. As the International Renewable Energy Agency points out in its Renewable Power Generation Costs in 2024 report, the economic viability of energy storage is directly tied to its performance and reliability, which are both underpinned by accurate monitoring and control systems.

A Clearer View of Your Energy Future

Transitioning from basic monitoring to advanced diagnostics provides a comprehensive view of your 48V LiFePO4 battery's health. By focusing on critical indicators like internal resistance, cell balance, and long-term data trends, you can move from a reactive to a proactive maintenance strategy. This approach not only helps maximize the lifespan and efficiency of your battery but also secures the reliability of your energy independence for years to come.

Frequently Asked Questions

How often should I perform advanced diagnostics on my 48V LiFePO4 battery?

While your BMS provides continuous monitoring, a thorough review of logged data and trends is recommended quarterly. You should also check for any system alerts or significant deviations from baseline performance on a monthly basis.

Can I measure internal resistance myself?

Measuring internal resistance accurately requires specialized equipment and knowledge. The most practical and safest approach for a system owner is to rely on the data provided by a high-quality Battery Management System (BMS) that includes this diagnostic capability.

What is the most critical advanced metric to monitor?

Individual cell voltage deviation is arguably the most critical real-time metric. A persistent imbalance between cells is often the earliest indicator of a developing problem that can compromise the entire battery pack's performance, safety, and longevity.

Does fast charging affect my battery's health diagnostics?

Yes, fast charging can temporarily increase internal resistance and cause minor, short-term cell imbalances due to the high currents involved. A healthy battery will see these metrics return to their normal baseline after it has rested. If they remain elevated, it could indicate underlying degradation.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.